A brazing connection method of rhenium-carbon/carbon composite material and niobium

A carbon composite material and connection method technology, which is applied in the direction of welding/cutting media/materials, welding/welding/cutting items, welding equipment, etc., can solve the problem that solder cannot realize brazing connection of rhenium and niobium, is prone to cracking, and has low bonding strength Low-level problems, to achieve the effect of improving high-temperature mechanical properties, high miscibility, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

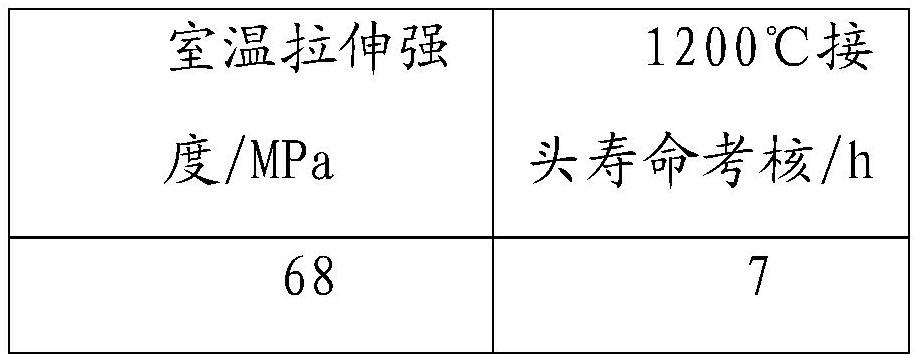

Embodiment 1

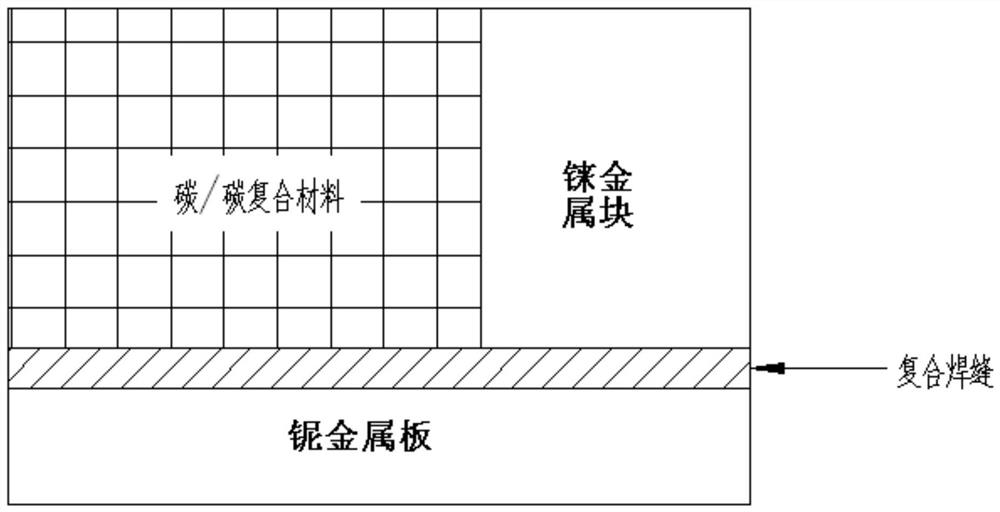

[0051] like figure 1 As shown, the embodiment of the present invention provides a brazing connection method of rhenium-carbon / carbon composite material and niobium, wherein the matrix is formed by pairing carbon / carbon composite material block and rhenium metal block, and the method specifically includes the following step:

[0052] 1. Brazing material configuration

[0053] Weigh the metal powder according to the following atomic mole fraction, and the particle size of the powder is 300 mesh:

[0054] Ti45%, Ni45%, Nb10%;

[0055] Pour the weighed powder into a ball mill jar equipped with agate balls, place the ball mill jar on a ball mill for ball milling for 2-3 hours; obtain the brazing filler metal for use;

[0056] 2. Brazing

[0057] Place the niobium metal plate horizontally, lay a layer of brazing material with a thickness of 0.3mm on its upper surface, and then place the carbon / carbon composite material block and the rhenium metal block on the brazing material ...

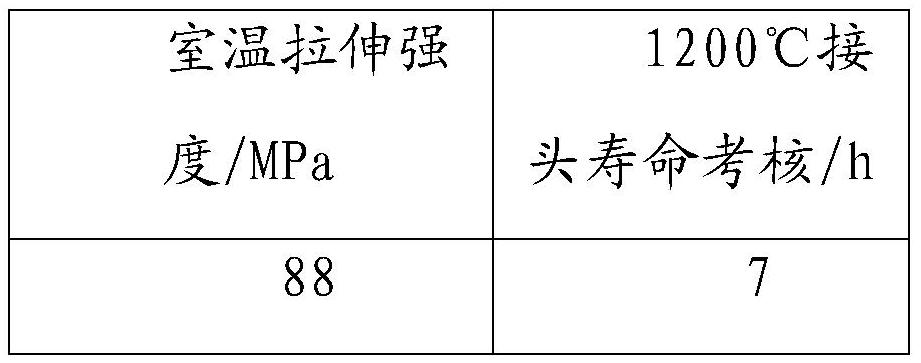

Embodiment 2

[0062] The embodiment of the present invention provides a brazing connection method of rhenium-carbon / carbon composite material and niobium, which specifically includes the following steps:

[0063] 1. Brazing material configuration

[0064] Polish the Ti foil, Ni foil and Nb foil with a thickness of 100 μm through 600-mesh sandpaper to remove the surface oxide film;

[0065] The metal foil after removing the surface oxide film is taken according to the following atomic mole fraction, and the initial thickness of the foil is 100 μm:

[0066] Ti 25%, Ni 45%, Nb 30%; finally take the Ti1 layer, Ni 2 layer, Nb2 layer, stack each foil in the order of Ti-Ni-Nb-Ni-Nb, and press it to 0.3 at 80°C mm thick, and then cut it to be consistent with the shape of the butt joint surface to obtain the brazing material to be laid;

[0067] 2. Brazing

[0068] placing the niobium metal plate horizontally, laying the solder to be laid on its upper surface, and then laying the carbon / carbon co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com