Engine piston pin snap ring press fitting tool

A technology for press-fitting tooling and piston pins, which is applied in the manufacture of tools, hand-held tools, etc., can solve problems such as insufficient accuracy of detection methods, and achieve the effects of eliminating quality risks, improving quality control levels, and good error-proofing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

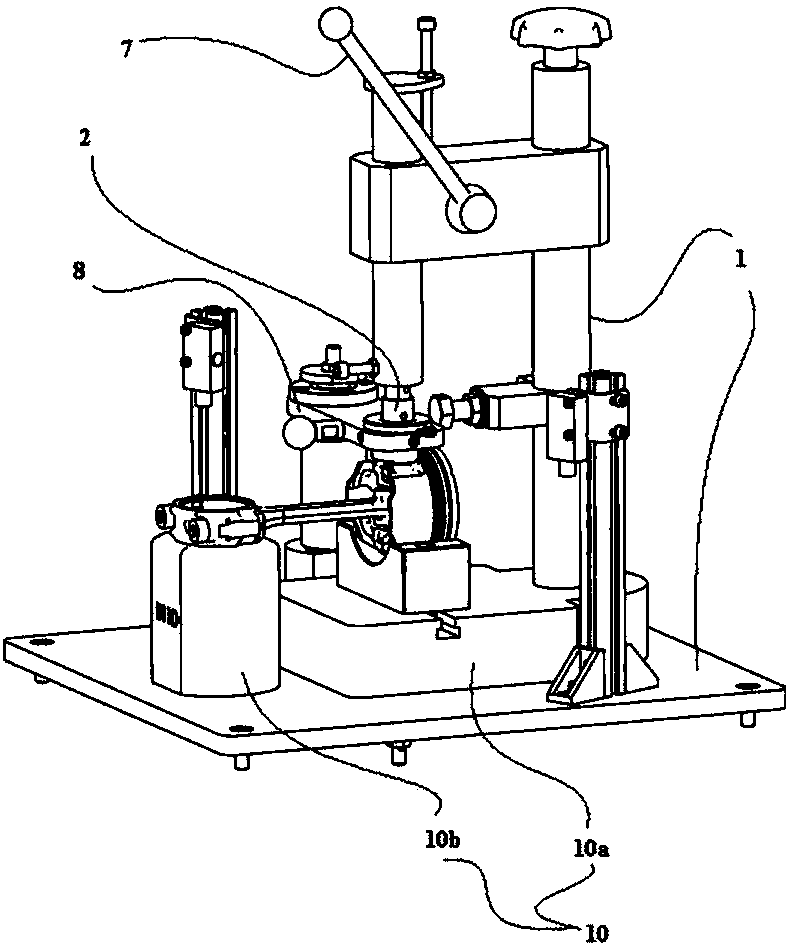

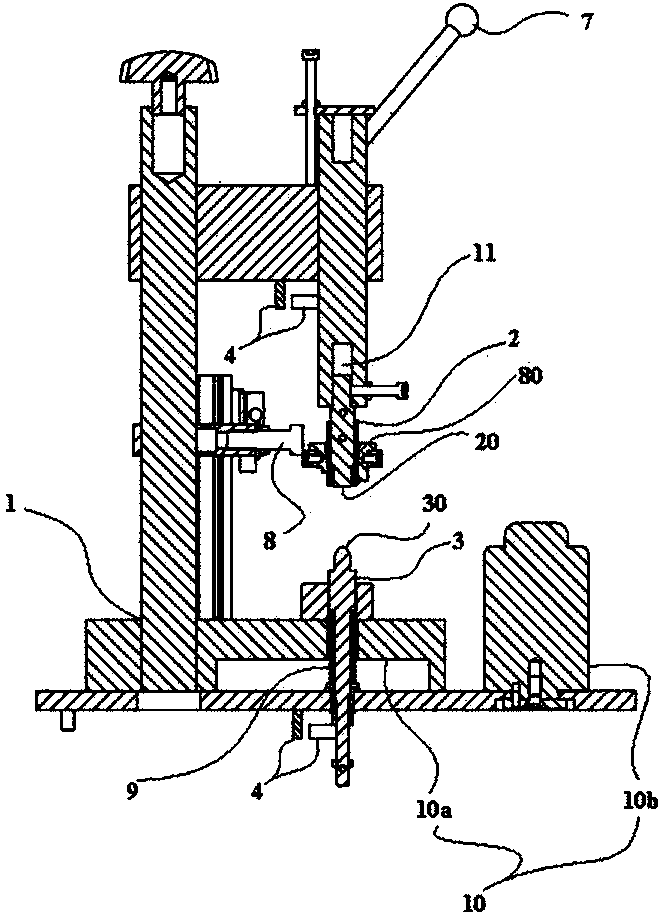

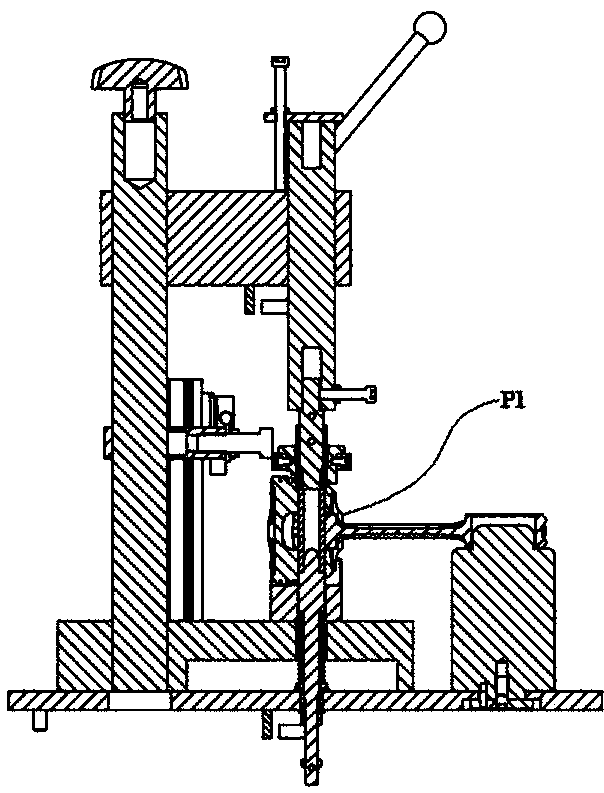

[0037] like figure 1 , Image 6 As shown, the engine piston pin snap ring press-fitting tooling of the embodiment of the present invention includes a bracket 1 and a pressure rod 2 fixed on the bracket 1 and capable of being controlled to expand and contract; the bracket 1 includes a support seat 10 for supporting the engine piston. The rod assembly P1 has a positioning device on the support seat 10; the front part of the pressure rod 2 is the pressure head 20, and the middle part is provided with a boss, named as the upper boss 21, and the snap ring can be placed on the pressure head 20 of the pressure rod 2 And it is conflicted by the upper boss 21 table; the position of the pressure rod 2 corresponds to the position of the support seat 10. Preferably, the indenter 20 is made of 65Mn material, the hardness is HRC 45-50 after heat treatment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com