A tire bolt tightening machine calibration auxiliary device

An auxiliary device and tightening machine technology, which is applied to measuring devices, measuring torque/torsion force during tightening, metal processing equipment, etc., can solve problems such as torque sensor strain current fluctuations, calibration personnel's operating safety risks, and calibration results. Problems such as instability , to achieve the effects of reducing swing and floating, eliminating quality risks, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

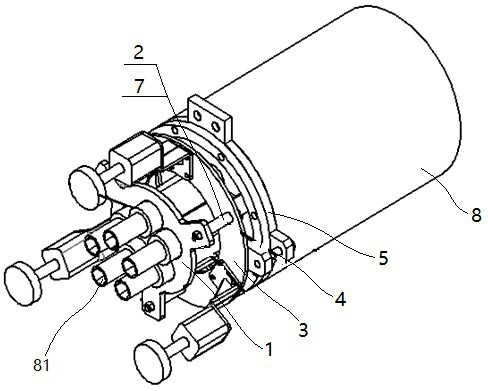

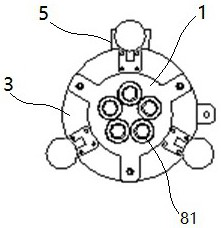

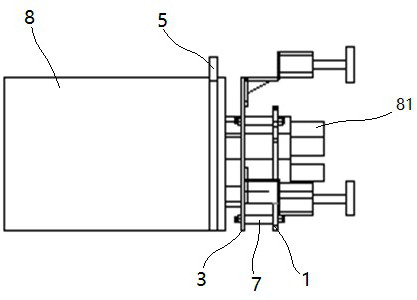

[0026] Figure 1 to Figure 4 The specific implementation of the tire bolt tightening machine calibration auxiliary device of the present invention is shown. Figure 1 to Figure 3 It is a structural schematic diagram of the tire bolt tightening machine calibration auxiliary device in this embodiment; Figure 4 It is a structural schematic diagram of the calibration board seat in this embodiment.

[0027] Such as Figure 1 to Figure 4 As shown, the tire bolt tightening machine calibration auxiliary device in this embodiment includes a calibration fixing seat 5, a tightening shaft clamping device and a calibration plate base 6, and the calibration fixing seat 5 is fixedly connected with the outer shell of the tire bolt tightening machine 8. , the tightening shaft clamping device is fixedly connected with the calibration fixed seat 5; the calibration plate base 6 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com