Fast positioning and correction-free fixture

A fast and fixture technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of low accuracy of product center alignment, large casting blank tolerance margin, and high frequency of repeated correction of fixtures, achieving simple design, The effect of improving production efficiency and quality assurance, eliminating quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

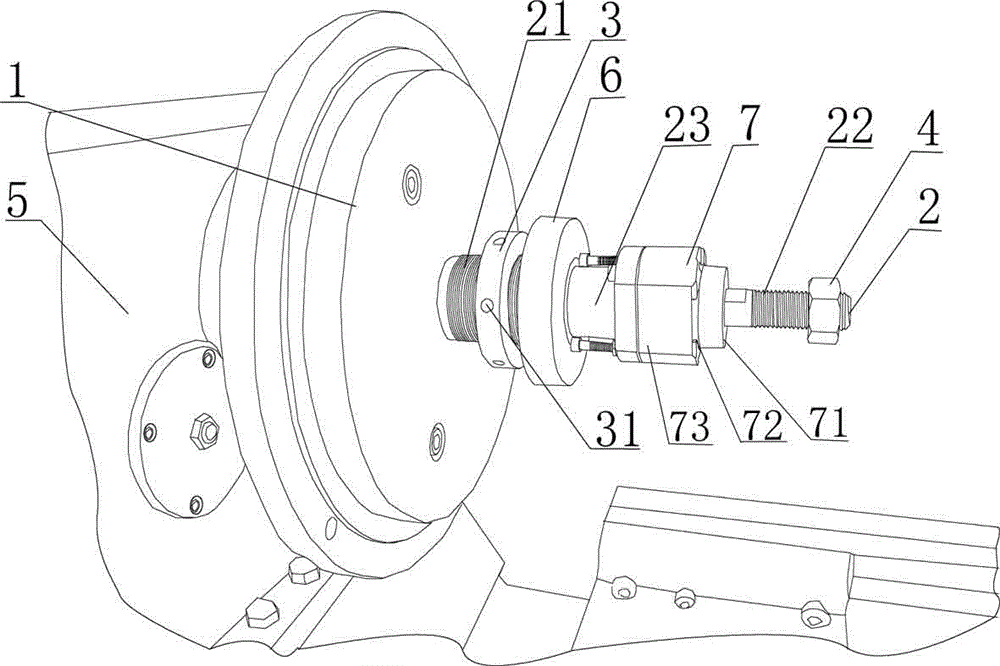

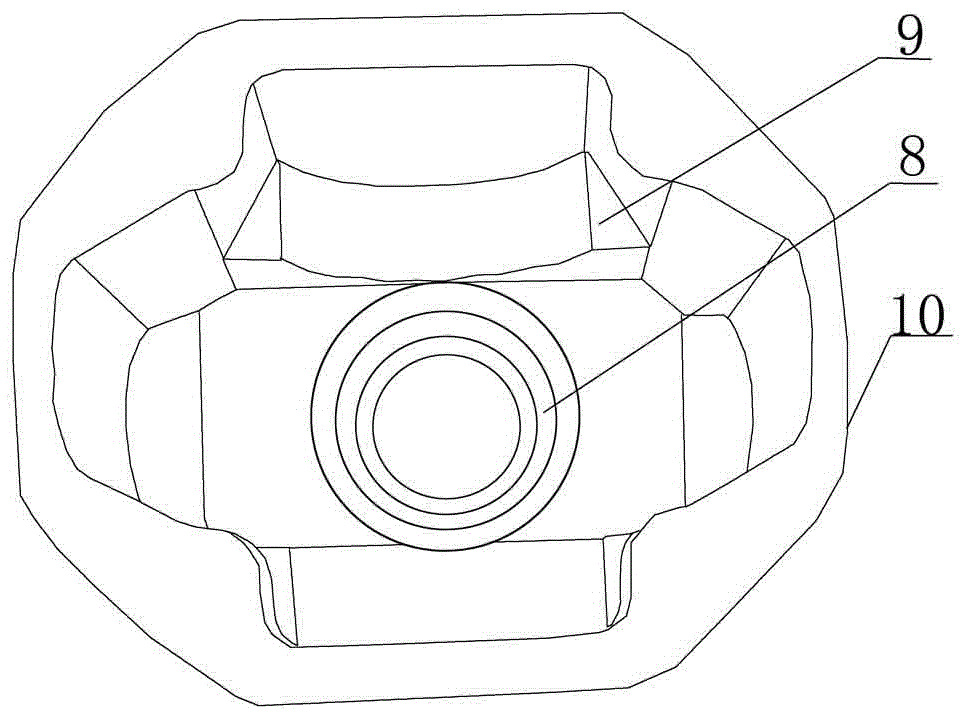

[0023] Refer to attached figure 1 , a fast positioning and correction-free fixture, which includes a rotating wheel 1, a rotating shaft 2, a locking rotating disk 3, a positioning orienting block and a pressing disk 4. In the front center of wheel 1, the rotating shaft 2 is divided into three sections. The one close to the rotating wheel is the large cylindrical rotating shaft 21, the one far away is the small cylindrical rotating shaft 22, the middle is the middle cylindrical rotating shaft 23, and the large cylindrical rotating shaft 21 has threads to lock the rotating disk. 3 is screwed on the threaded position on the large cylinder rotating shaft 21, and the positioning orienting block includes a rear center positioning block 6 and a front center positioning block 7. Positioning block 7 is contained in the middle cylinder rotating shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com