Aluminum-replacing trough cart

A launder car and launder technology, which is applied in the field of refined aluminum trough aluminum exchange device, can solve the problems of low work efficiency, high labor intensity, and heatstroke of molten aluminum in refined aluminum trough, so as to eliminate quality risks and reduce labor intensity , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0020] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

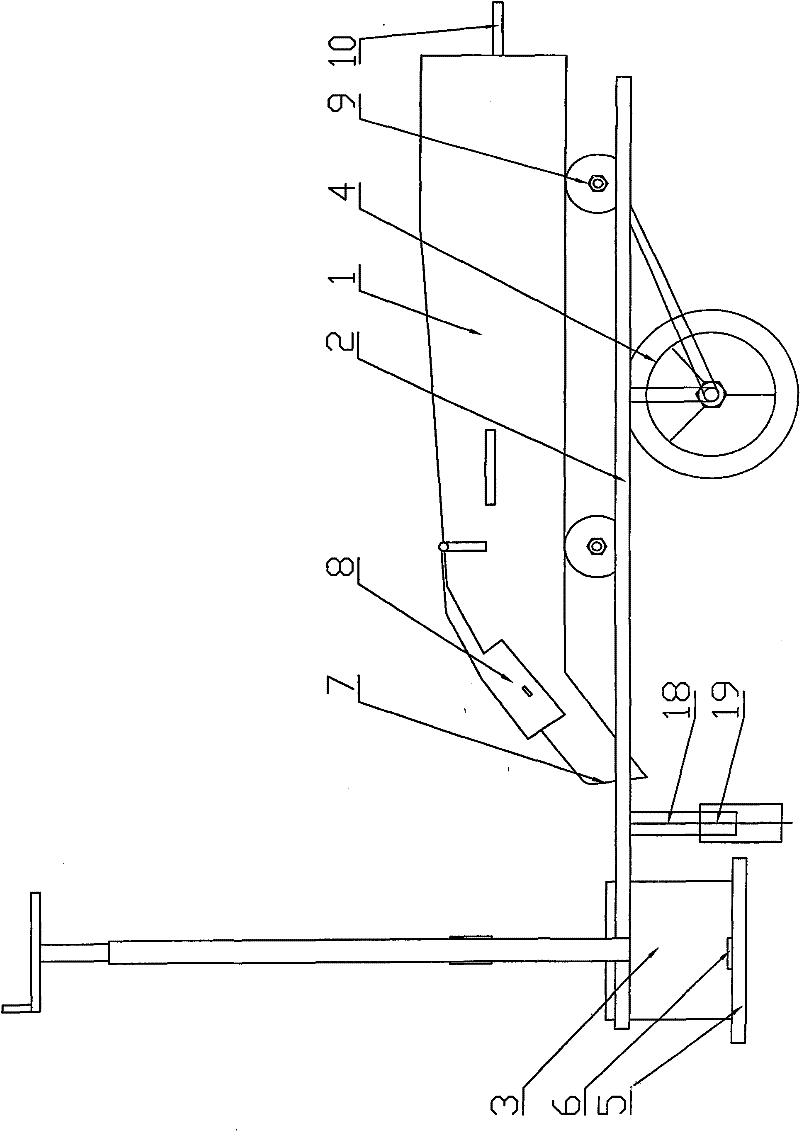

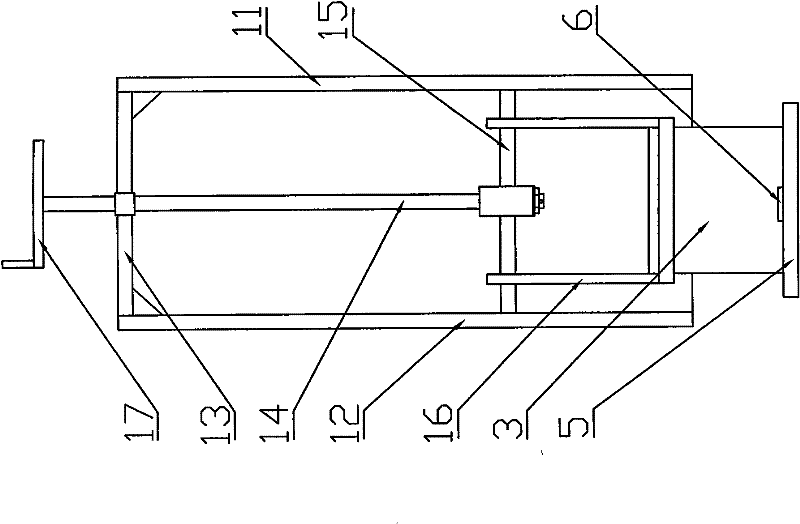

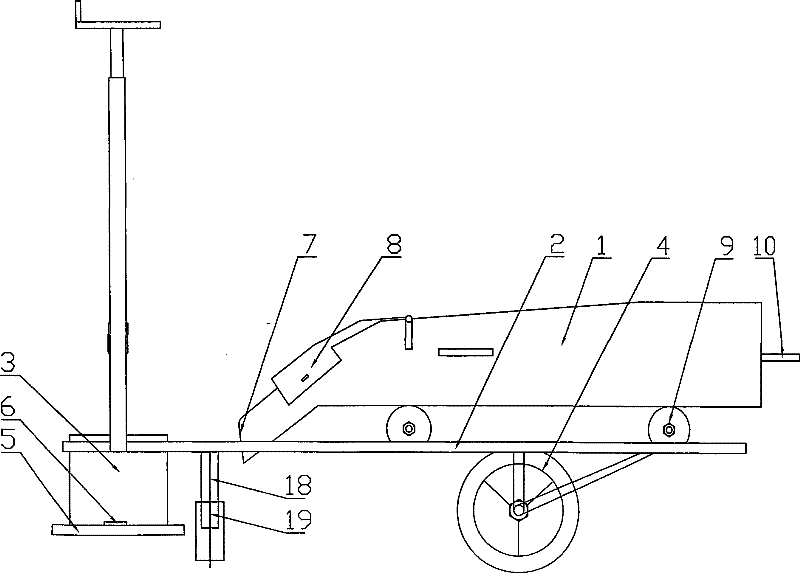

[0021] as attached figure 1 , 2 As shown, the laundering car for aluminum replacement includes an aluminum launder 1, a vehicle frame 2 and a buffer tank 3; wheels 4 are installed at the bottom of the vehicle frame 2, and the upper end of the buffer tank 3 is installed on the left part of the vehicle frame 2. The bottom of the buffer tank 3 is equipped with a buffer diverter plate 5, and at the lower end of the buffer tank 3, there is no less than one aluminum outlet hole 6 corresponding to the buffer diverter plate 5. The aluminum launder 1 is placed on the frame 2, and the The left part of the aluminum launder 1 has an aluminum outlet 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com