Electric heating film cured precast beam integral mould

A technology of electrothermal film and prefabricated beams, which is applied in the direction of molds, manufacturing tools, mold fixtures, etc., can solve the problems of low mold turnover efficiency, low heat energy conversion rate, low construction work efficiency, etc., and achieve high maintenance efficiency and low electricity cost , The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, the purpose of providing these embodiments is to make the disclosure of the present invention more thorough and comprehensive.

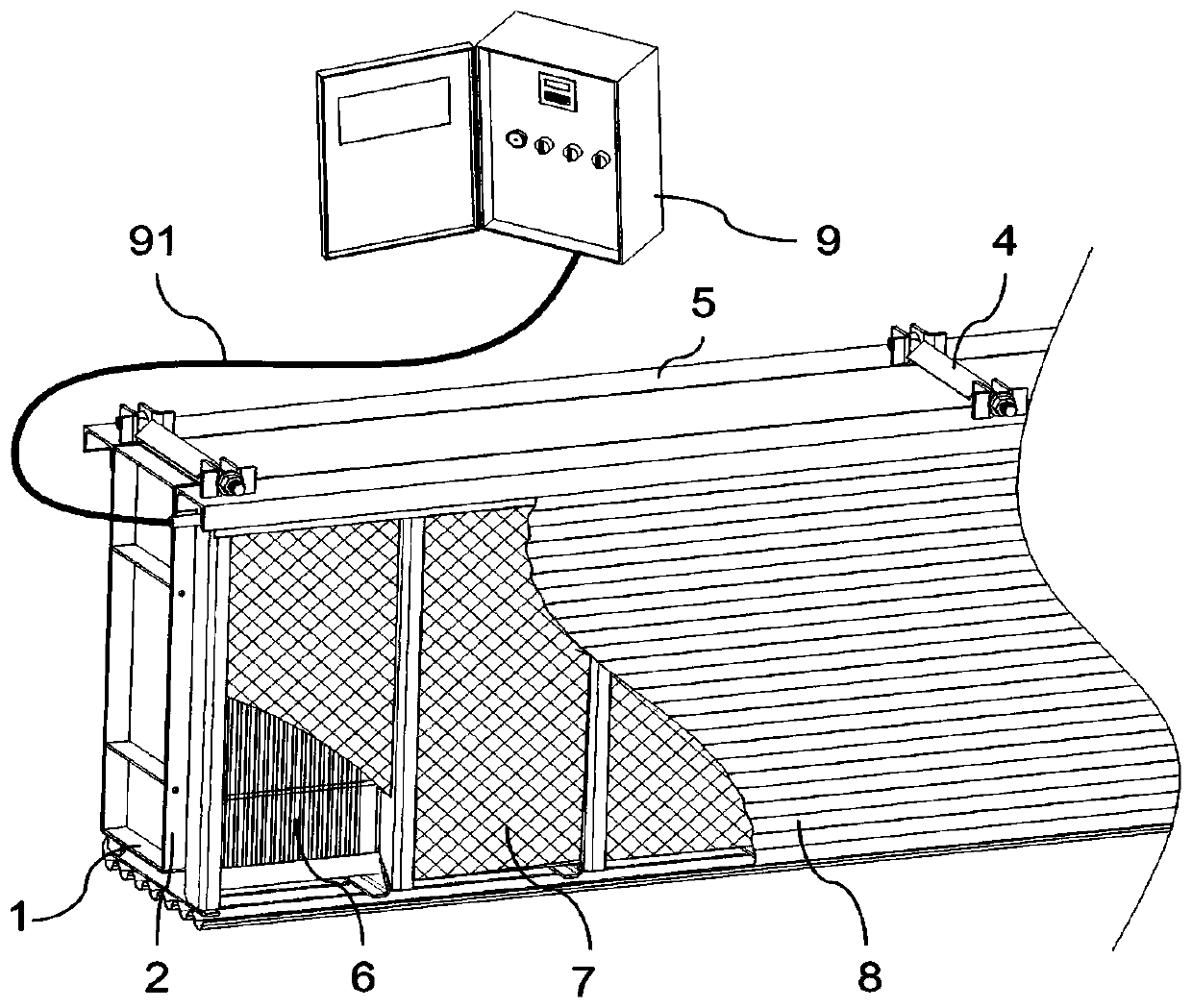

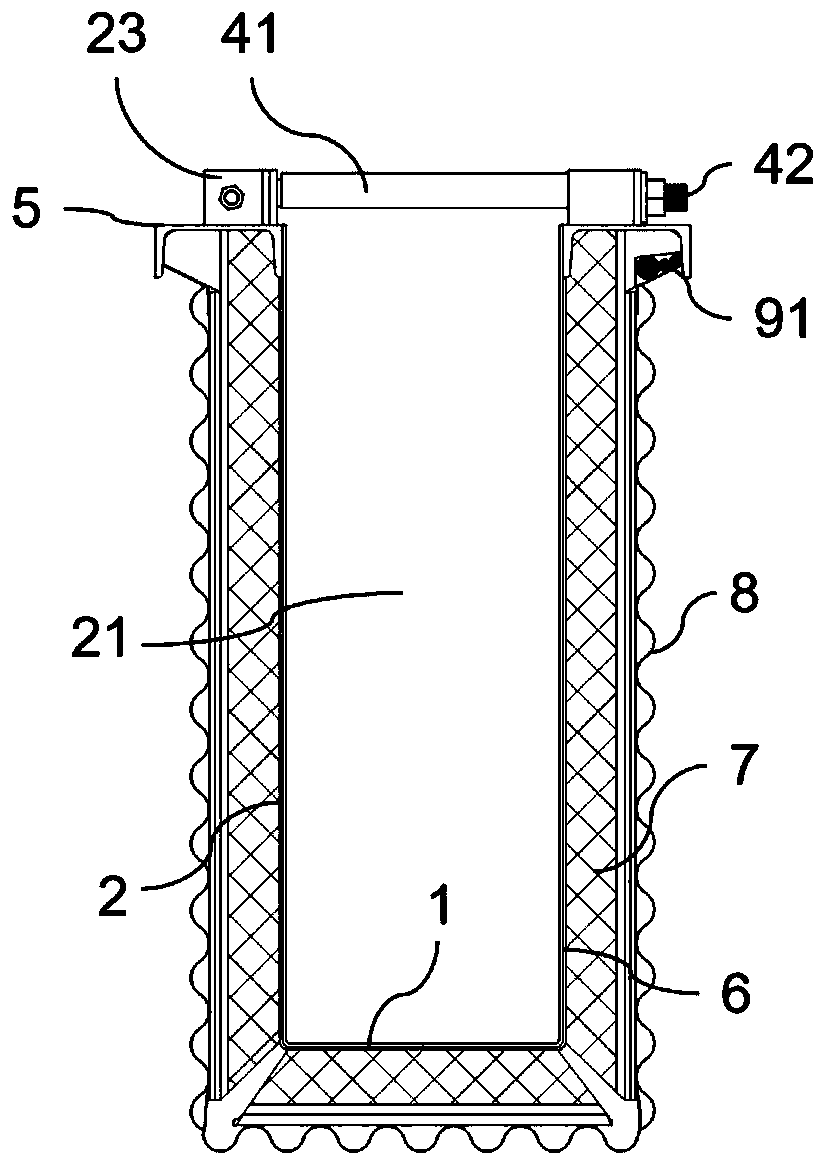

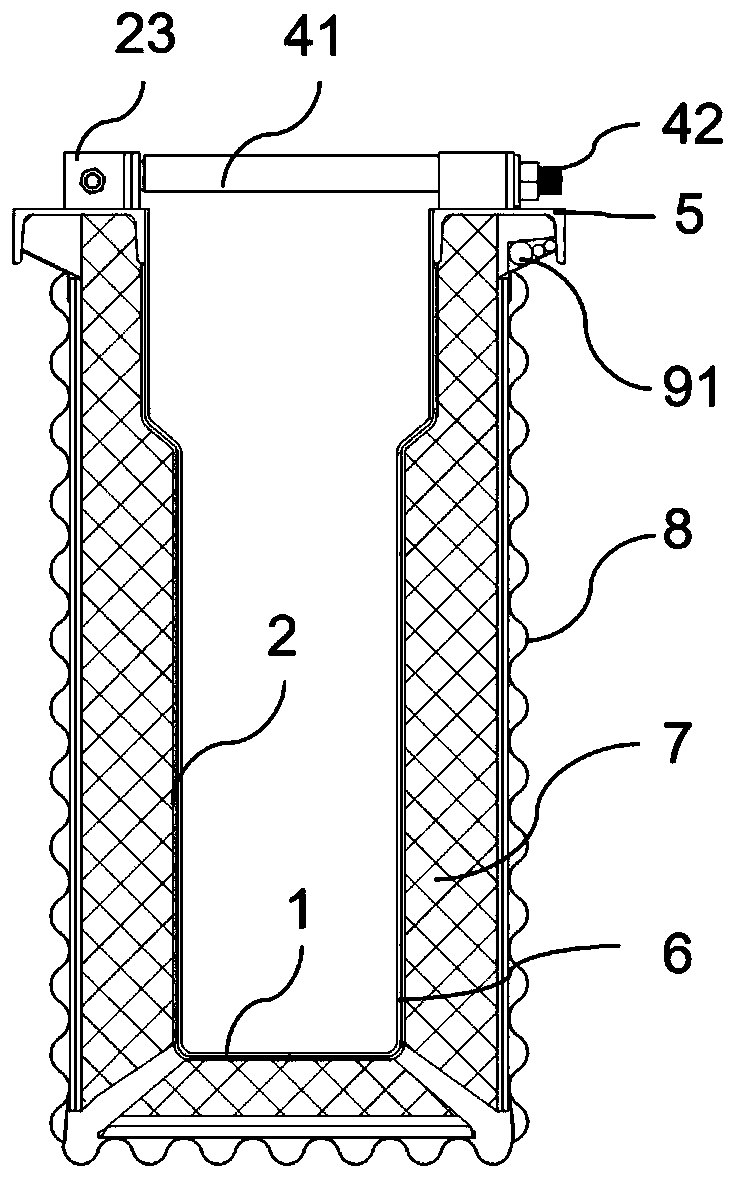

[0026] see Figure 1 to Figure 5 , in the embodiment of an integral mold for electrothermal film maintenance of prefabricated beams given in the present invention, it includes bottom plate 1, side plate 2, flexible corner 3, tie rod 4, horizontal beam 5, electrothermal film 6, heat preservation plate 7 and protection plate 8. The base plate 1 and the side plate 2 form a cavity 21 with an upper opening, the flexible corner 3 is provided at the intersection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com