A simple-supported prefabricated monolithic composite bridge and its construction method

A construction method and technology of prefabricated beams, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of poor connection integrity of prefabricated bridges, slow manufacturing and installation speed, high formwork amortization cost, etc. Crack problem, good performance of beam synergy, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

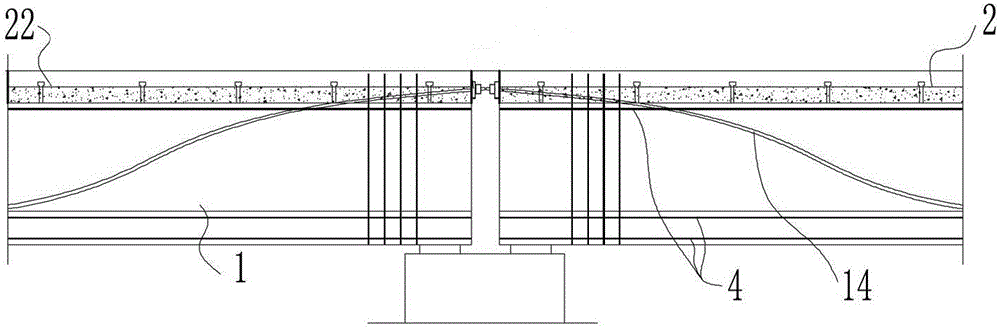

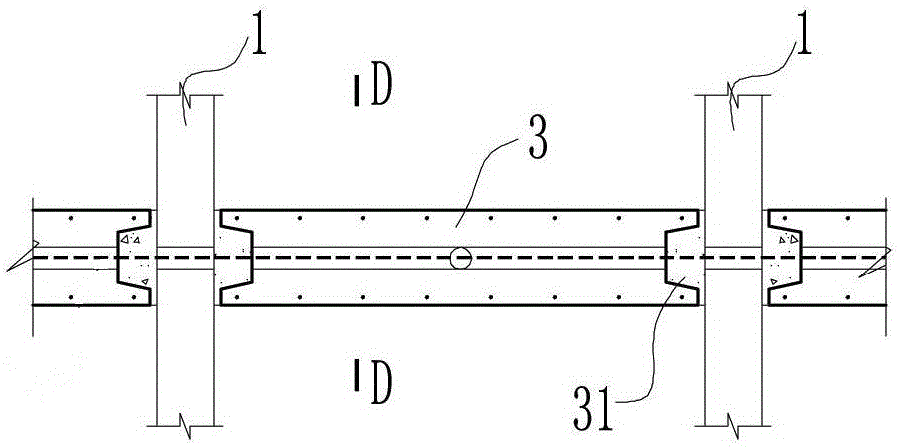

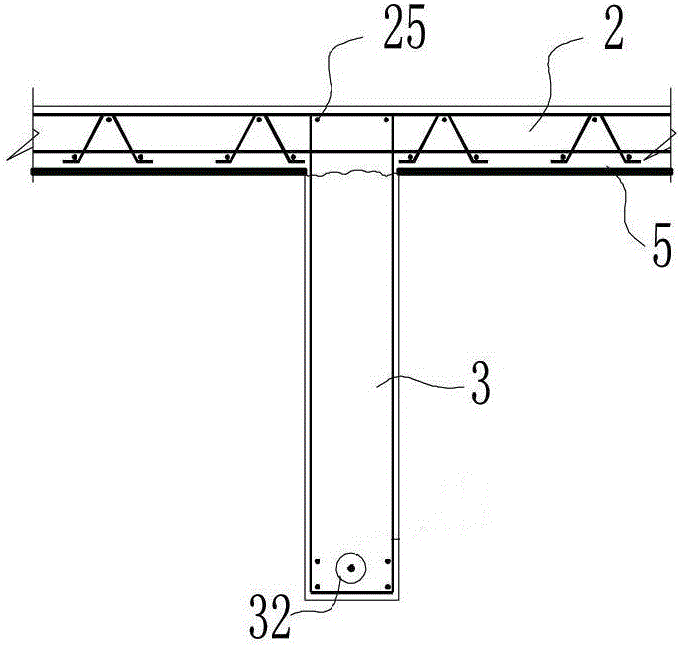

[0040] see Figure 1 to Figure 10 , an embodiment of a simple-supported prefabricated monolithic composite bridge provided in the present invention includes an inverted T-shaped prestressed prefabricated beam part 1, a cast-in-place part 2 and a diaphragm 3, and the cast-in-place part 2 includes The cast-in-place slab 21 and the superimposed part 22 of the upper part of the beam, the lower flange 11 of the inverted T-shaped prestressed prefabricated beam 1 and the upper part of the web 12 are all embedded with pre-tensioned prestressed steel strands 4, and the transverse diaphragm 3 It is a prefabricated slab, and the transverse diaphragm 3 is arranged between the webs 12 of adjacent prefabricated beams at a certain distance along the longitudinal direction, and is located above the lower flange 11 of the inverted T-shaped prestressed prefabricated beam 1 . The present invention forms a superimposed bridge through the inverted T-shaped prestressed prefabricated beam 1, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com