Bridge steel box girder aerial work operation platform and construction method thereof

A technology for operating platforms and high-altitude operations, applied in bridge construction, bridge erection/assembly bridges, etc., can solve problems affecting vehicle traffic and high costs, achieve obvious economic benefits, high utilization rate, and avoid application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

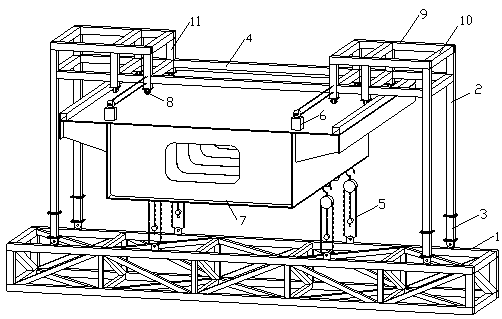

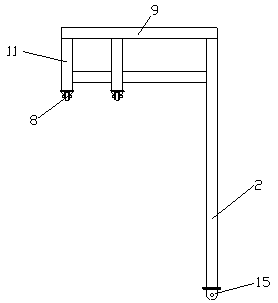

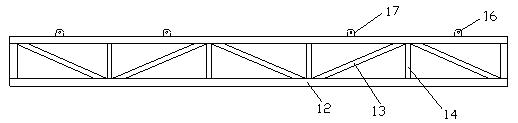

[0028] see figure 1 , figure 2 and image 3 , bridge steel box girder aerial work operation platform, including steel pipe truss 1, two mobile pylons, two hoists 6, four chains 5 and eight rollers 8, the steel pipe truss 1 is a cuboid structure, composed of a supervisor 12 and several The branch pipe is formed, wherein the main pipe 12 includes two upper chord main pipes and two lower chord main pipes, which are used for the frame of the space cuboid, and the branch pipes are composed of straight pipes 14 and inclined pipes 13, which form a stable triangular structure with the main pipe, ensuring that the entire space cuboid Structural safety of the lattice frame. The length of the steel pipe truss is greater than the maximum width of the steel box girder 7 to be operated; in this embodiment, the steel pipe truss is welded by squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com