Prefabricated wall concrete door and window frame and construction method

A prefabricated concrete and prefabricated wall technology, applied in the direction of walls, base frames, building components, etc., can solve the problems that the strength is difficult to meet the requirements of transportation and hoisting, the strength requirements of lattice steel bars are high, and the door and window mold schemes are complex. The quality of components is easy to ensure, the amortized cost of the template is saved, and the quality of the look and feel is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

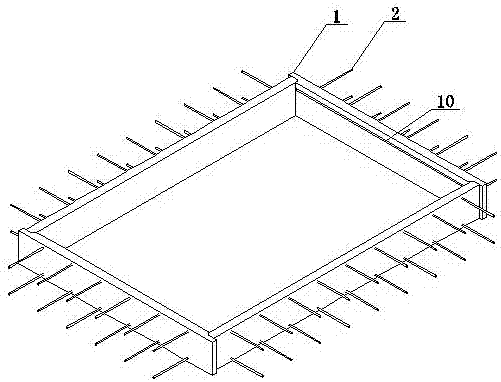

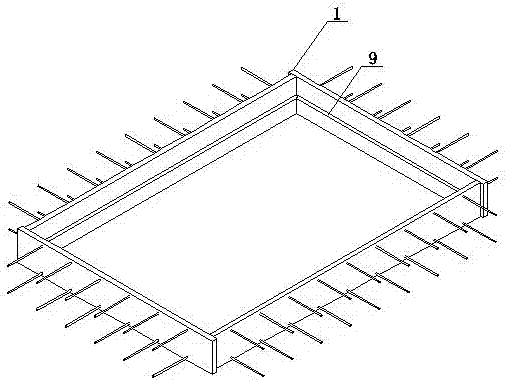

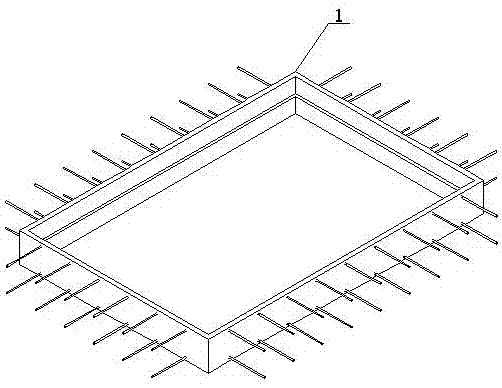

[0032] A prefabricated concrete door and window frame for walls, which consists of: a prefabricated concrete door and window frame 1, the prefabricated concrete door and window frame is assembled into a square frame shape or an integrated square frame shape by straight strips, and the outside of the straight strips or the The said integrated frame is equipped with outwardly stretched tie bars 2 all around, and said outwardly stretched tie bars stretch into the walls 3 on each side of the door window.

Embodiment 2

[0034] According to the prefabricated concrete door and window frame of the wall body described in Example 1, the outer surface of the wall is respectively equipped with an insulation layer 5 and a decorative surface layer 6, and the doors and windows of the prefabricated concrete door and window frame are integrally formed along the thickness direction of the wall body. The disconnected part is connected as a whole through the thermal insulation connector 7, and the disconnected part of the prefabricated concrete door and window frame is filled with foam glue 11.

Embodiment 3

[0036] According to the prefabricated wall concrete door and window frame described in embodiment 1, the upper part of the precast concrete door and window frame is provided with a door and window embedded part 8, and the concrete door and window frame is provided with a waterproof platform structure 9 in the thickness direction of the wall. The top edge of the concrete door and window frame window is provided with a drip line structure 10 or an olecranon structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com