New dipping former for producing elastic articles

A product and dipping technology, which is applied in the production process of elastomer material dipping products, can solve problems such as waste, achieve the effects of reducing amortized costs, reducing capital investment, and saving total energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

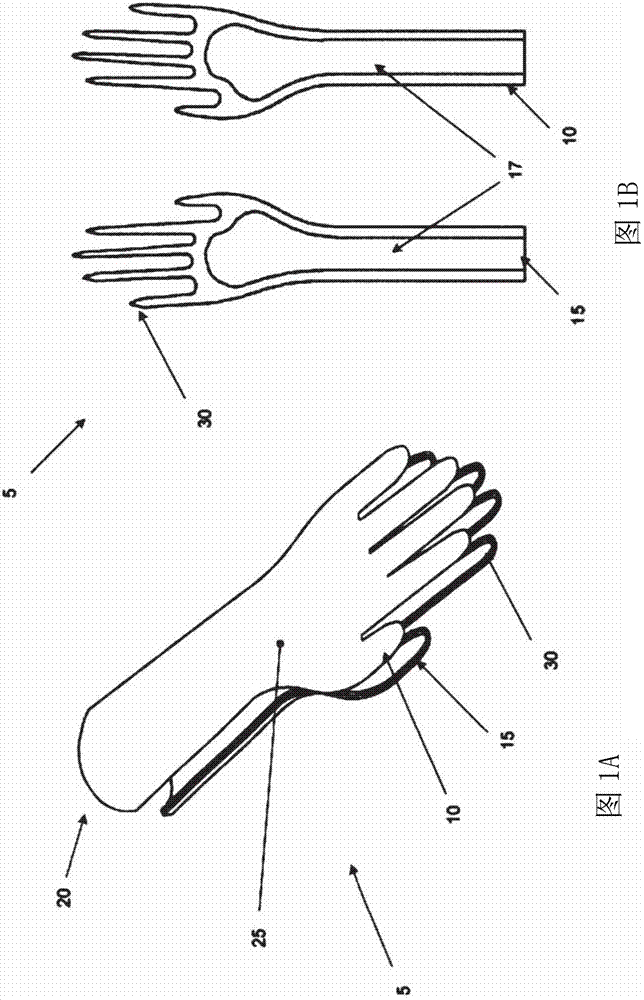

[0032] For ease of illustration, the following description refers to the application of the present invention to the manufacture of gloves. It should be understood that the present invention is applicable to any dipped product, including condoms, probe sheaths, and other objects formed by dipping a mold into a bath of elastomer. Accordingly, reference to glove manufacture should not be viewed as limiting the application of the invention.

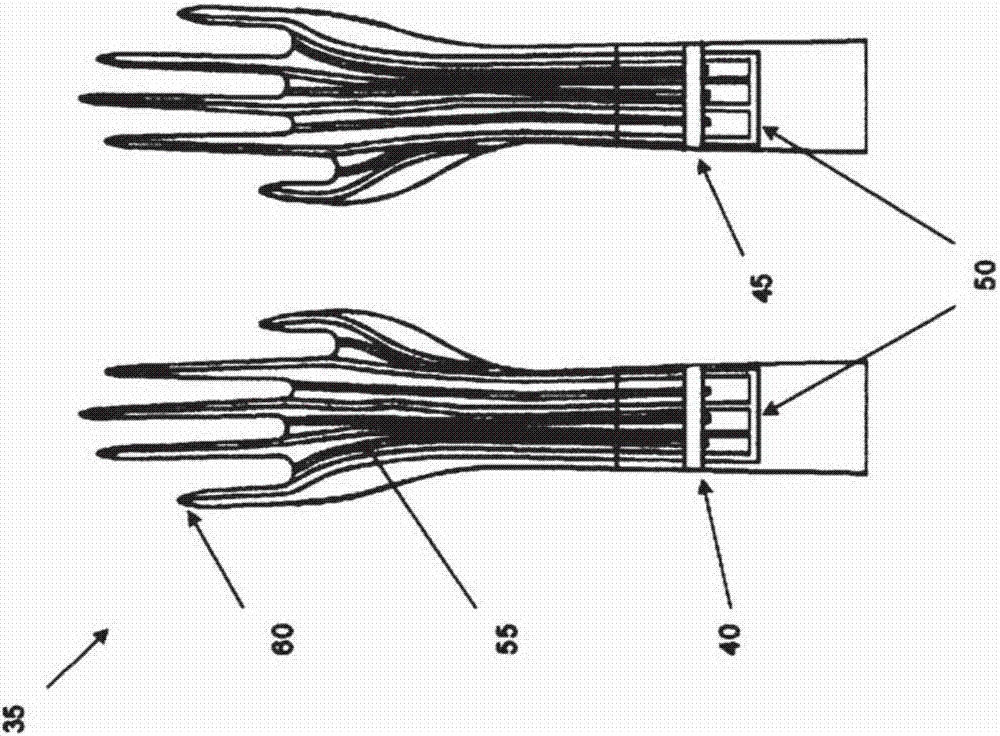

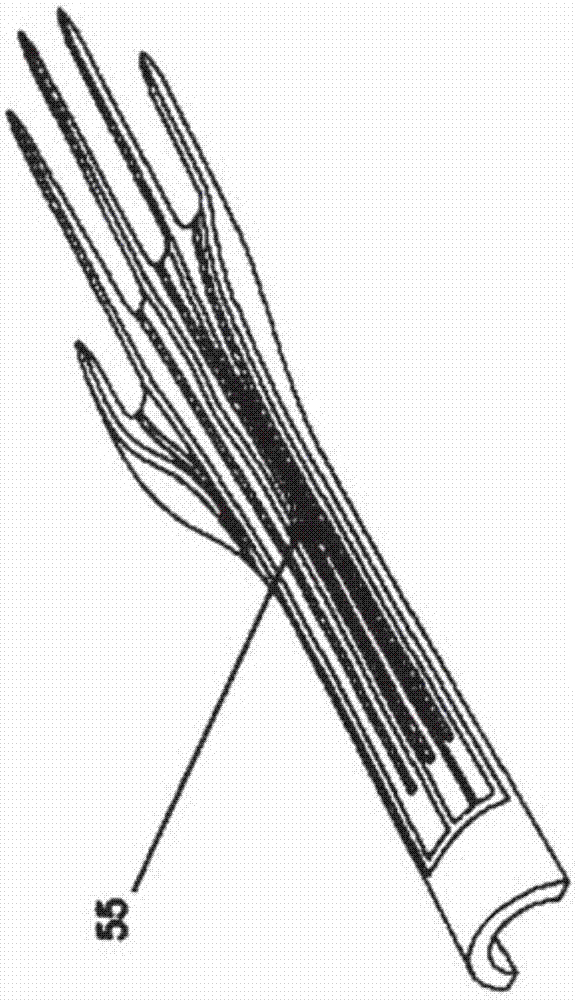

[0033] The present invention involves providing a heating medium within a glove module to transfer heat from the heating medium within the assembly to an elastomer which may be formed on the outer layer of the mold shell to dry and cure the glove. In contrast, passing the glove mold assembly through an oven heated to a temperature not only cures the elastomeric glove film, but also maintains the heat in the oven above the temperature required for the resin to cure.

[0034] One embodiment in practicing the invention may include applying a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com