Sloping wedge clamp of building moulding board and mounting, unloading tool thereof

A technology for building formwork and loading and unloading tools, which is applied in the on-site preparation of building components, construction, connection of formwork/formwork/work frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

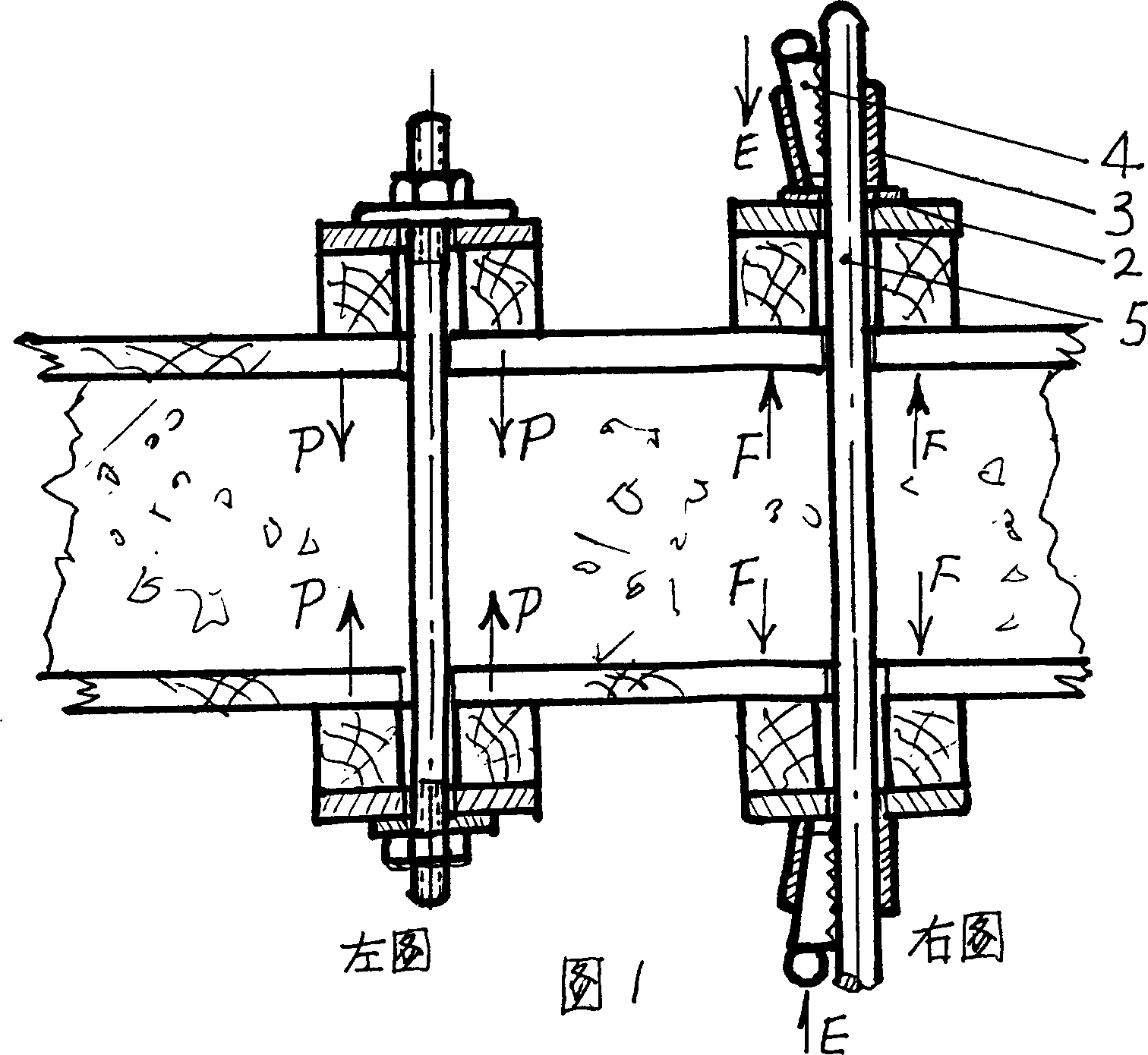

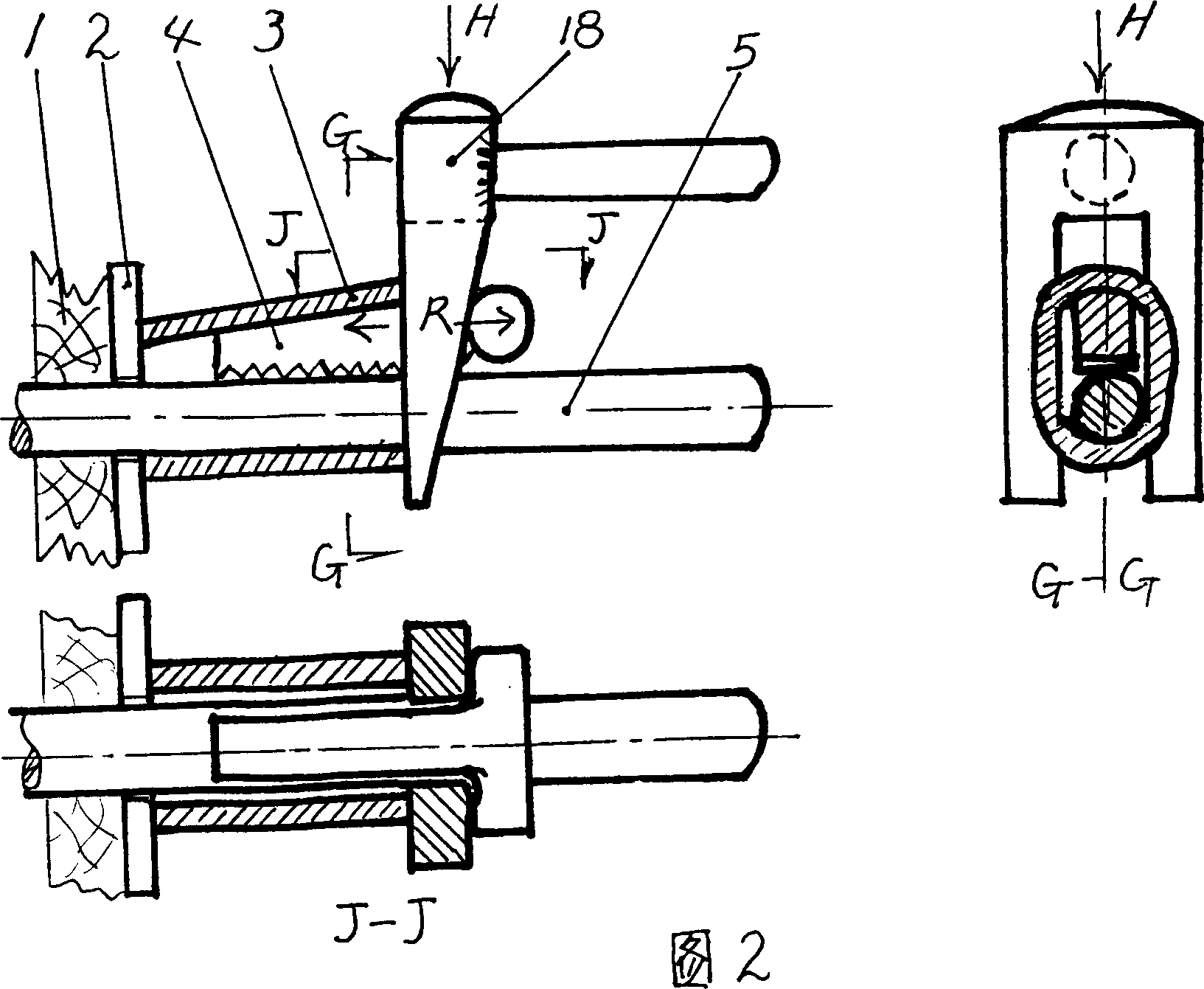

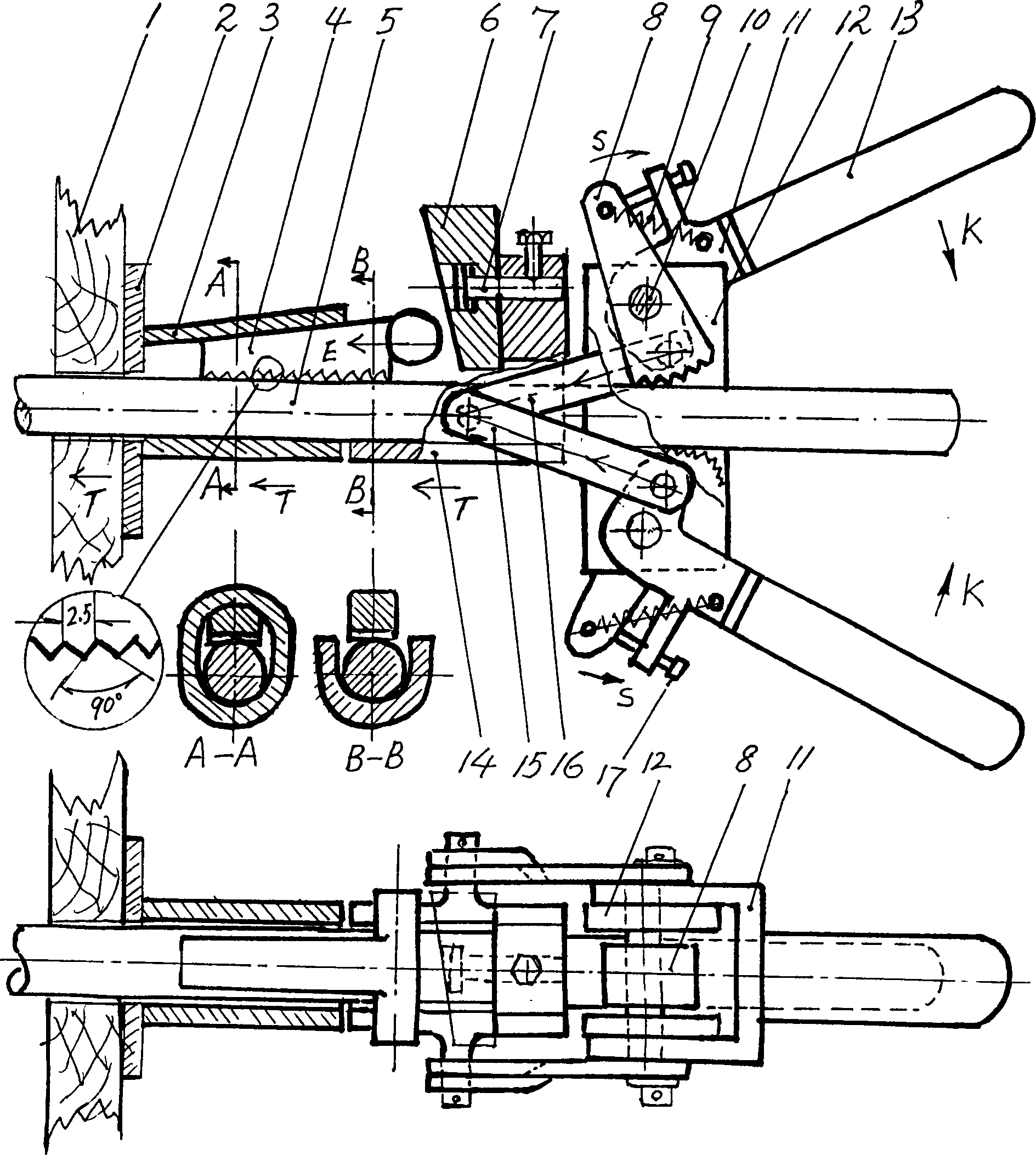

[0018] Below according to the accompanying drawings 1, 2, 3, the specific implementation method of the present invention is exemplified for further details.

[0019] According to Figure 1, the picture on the right is the general construction formwork clamping method. First put on the polished rod 5, install the inclined sleeve 3 and the inclined wedge 4 on both ends, and first use a hammer to knock the inclined wedge 4 on one end into the inclined sleeve according to the E direction. 3, press the other end image 3 As shown in the installation tool pliers, when the two handles 13 are forced in the K direction, the stop ratchet 8 bites into the polished rod 5 and withstands the body of the pliers 12 without sliding back, and the inclined sleeve 3 is pushed forward, because the polished rod 5 The other end has been clamped into a set of fixtures to withstand the other template, so it cannot retreat. The inclined sleeve 3 can only be pushed in the direction of T, and the inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com