T-shaped component manufacturing die

A technology for manufacturing molds and components, which is applied in the field of building prefabricated components, can solve the problems of high mold cost, complex formwork structure, and low production capacity, and achieve the effects of high pedestal utilization, small pedestal area, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

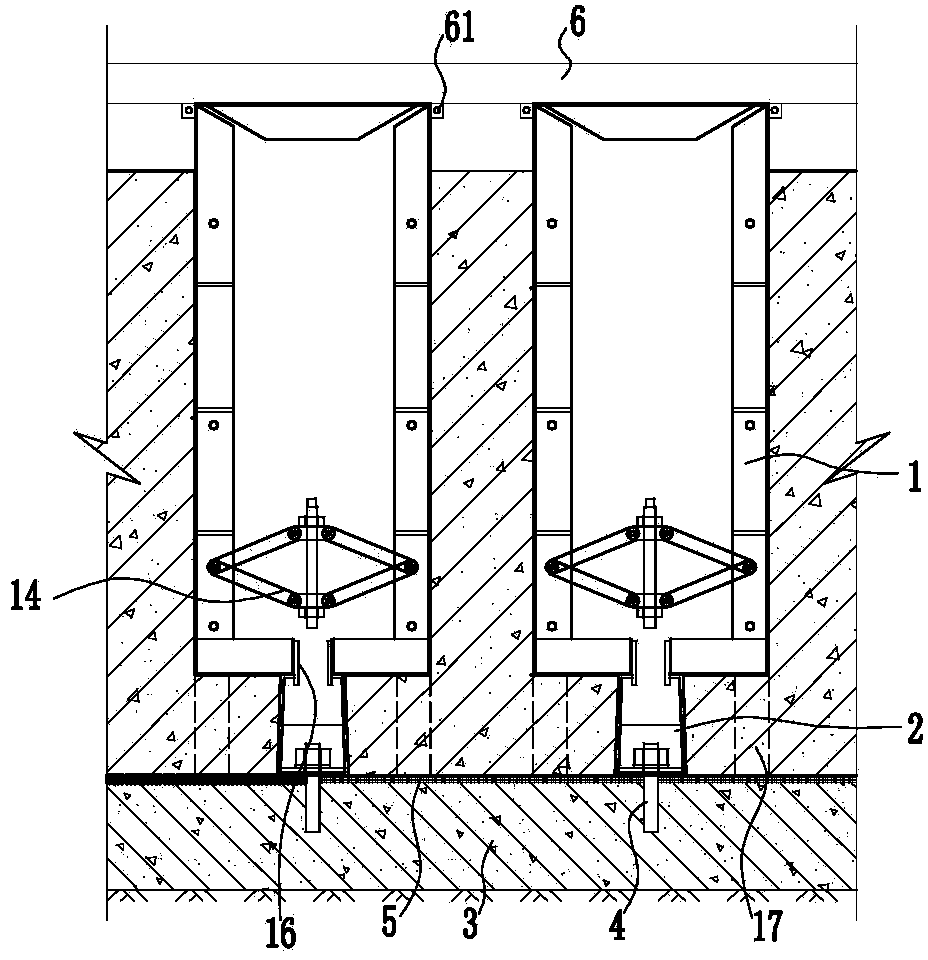

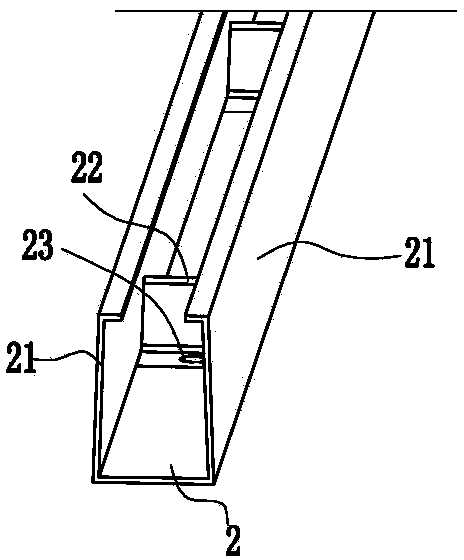

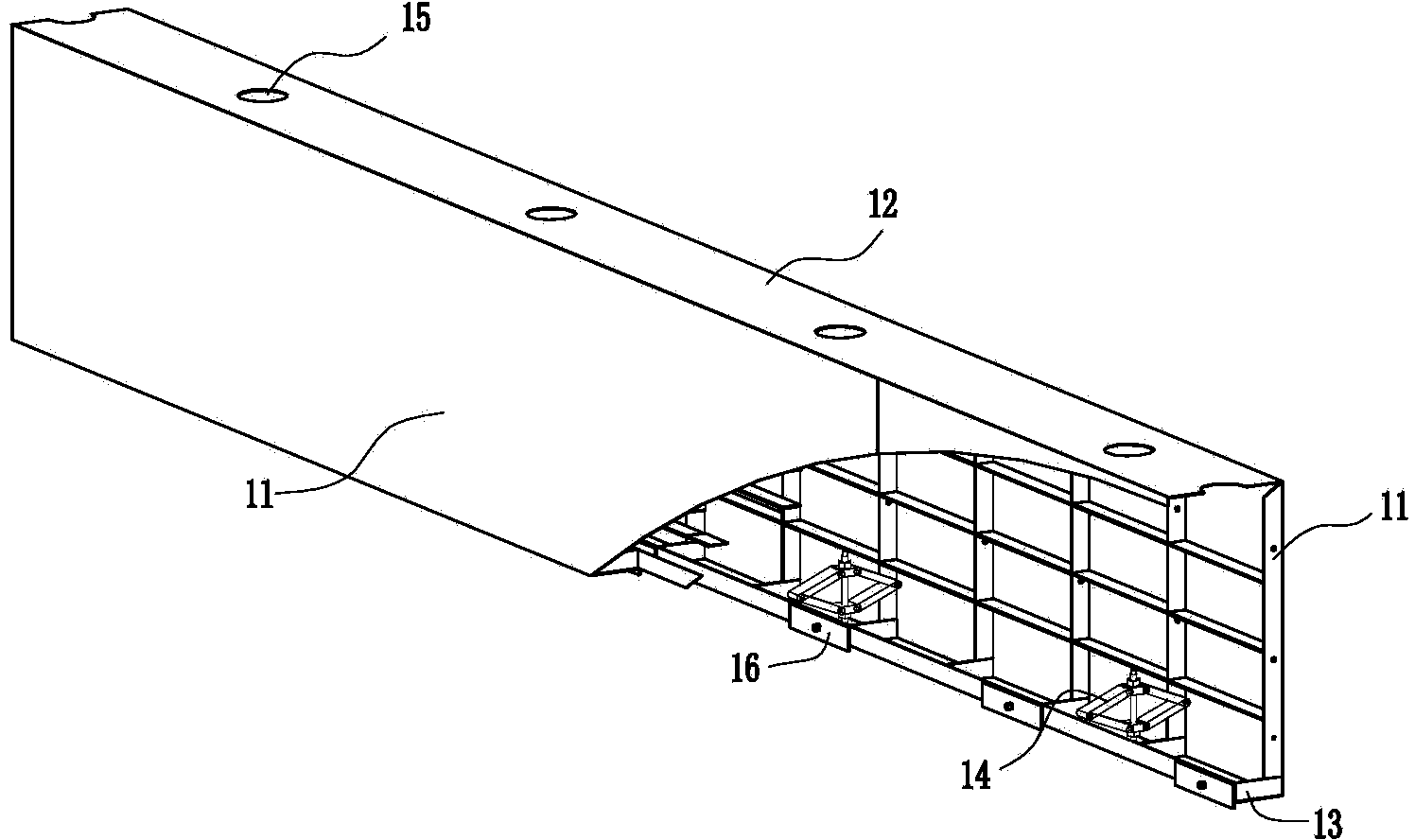

[0018] see Figure 1 to Figure 3 , a T-shaped component manufacturing mold provided in the present invention includes a web side form 1, a flange side form 2 and a pedestal floor 3. The web side form 1 includes two vertical plates 11 and a top plate 12, the lower ends of the two vertical plates 11 are connected with L-shaped horizontal beams 13, and the lower ends of the two vertical plates 11 are connected with a diamond-shaped retractable mechanism 14 along the longitudinal interval. The flange sideform 2 includes two side plates 21, and the flange sideform 2 is connected with the platform floor 3 by bolts 4; the width of the upper opening of the flange sideform 2 is smaller than that of the lower opening. The web side formwork 1 and the two vertical plates 11 are used as the side formwork of the adjacent T-shaped member to undertake the side pressure of the concrete and transmit the side pressure to the upper top plate 12 and the lower L-shaped horizontal beam 13. The oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com