A method and device for adjusting the position of the center of gravity of a wind turbine blade

A technology of wind turbine and center of gravity position, which is applied in the assembly of wind turbines, wind power generation, transportation and packaging, etc., which can solve the problems of increasing unit development costs and hoisting costs, poor versatility of single-blade spreaders, and reduced use of single-blade spreaders Efficiency and other issues to achieve the effect of speeding up development progress, improving use efficiency, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

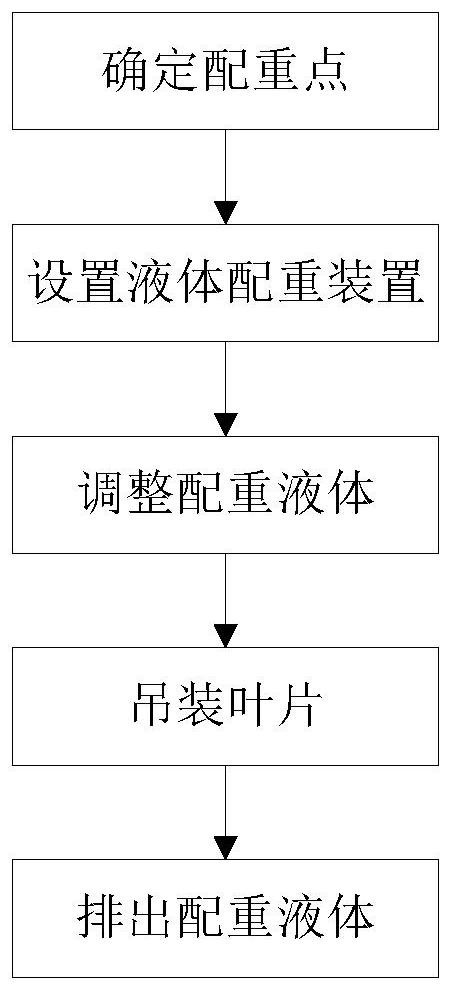

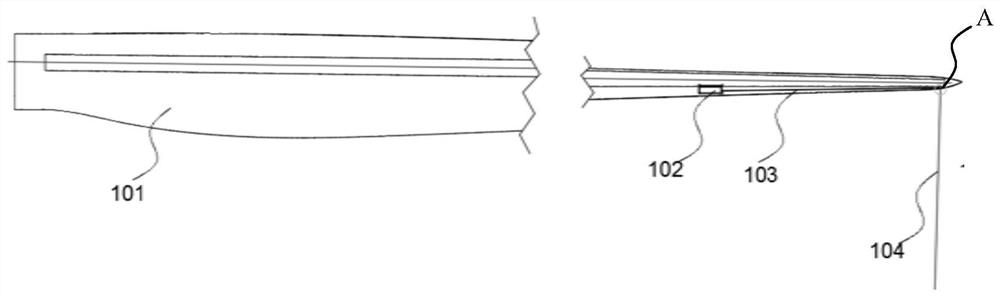

[0028] Taking the position of the center of gravity of the blade of the wind turbine to be hoisted closer to the blade root than the position of the center of gravity required by the single-blade spreader as an example, adjust the position of the center of gravity of the blade of the wind turbine to be hoisted, such as figure 2 and image 3 As shown, the adjustment method includes the following steps:

[0029] Step 1, designing and selecting the emphasis point of the blade tip position of the blade 101;

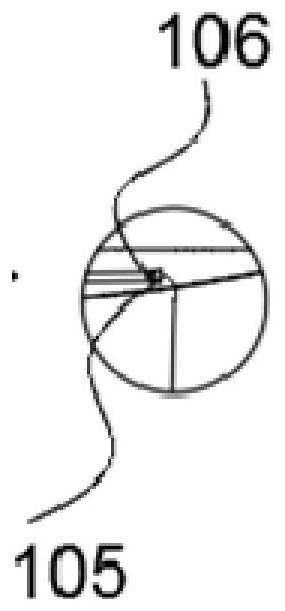

[0030] Step 2, before the shell of the blade 101 is solidified, prefabricate the drainage hole 106 on the blade shell;

[0031] Step 3, preparing a hollow cavity 102 conforming to the inner surface of the blade shell, fixing the hollow cavity 102 on the inner surface of the blade 101 shell before the blade is molded, and sealing the hollow cavity 102 and the junction;

[0032] Step 4, connect the hollow cavity 102 with the pipeline 103, seal the connection, fix the pipelin...

no. 2 example

[0039] Taking the position of the center of gravity of the blade of the wind turbine to be hoisted closer to the blade root than the position of the center of gravity required by the single-blade spreader as an example, adjust the position of the center of gravity of the blade of the wind turbine to be hoisted, such as Figure 4 and Figure 5 As shown, the adjustment method includes the following steps:

[0040] Step 1. Design and select the counterweight of the blade tip position of the blade 201, weigh the blade 201, and calculate the weight required for the counterweight;

[0041] Step 2, preparing an annular rubber ring 202 with an inner cavity similar in appearance to the blade tip matching position;

[0042]Step 3. Put the rubber ring 202 on the balance point of the blade tip, inject water into the inner cavity of the rubber ring 202 through the opening on the rubber ring 202, so that the weight of the water and the weight of the rubber ring can reach the required count...

no. 3 example

[0046] Taking the position of the center of gravity of the blade of the wind turbine to be hoisted closer to the blade tip than the position of the center of gravity required by the single-blade spreader as an example, to adjust the position of the center of gravity of the blade of the wind turbine to be hoisted, the adjustment method includes the following steps:

[0047] Step 1. The weight of the blade root is selected at the baffle of the blade root, weigh the blade, and calculate the weight required for the weight;

[0048] Step 2. Arrange a buckle or fixing point on the blade root side where the blade root baffle and the blade shell are combined.

[0049] Step 3. Fix the rubber flexible container at the buckle or fixed point, inject water into the inner cavity of the rubber container, so that the weight of the water and the weight of the rubber container reach the required counterweight weight,

[0050] Step 4. Use the single-blade spreader to lift the blade into the impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com