Large-span truss subsection hoisting high-altitude closure measure device and construction method

A segmented hoisting and large-span technology, which is applied in construction, building structure, and building material processing, can solve the problems of low butt joint accuracy of large-span truss main pipes, unsafe unloading process, and complicated installation, and achieve light weight, The effect of low amortization cost and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

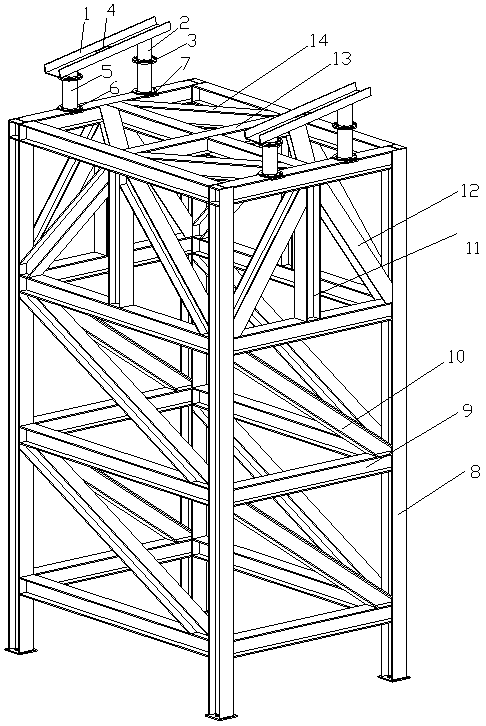

[0032] see figure 1 , the large-span truss segmented hoisting high-altitude closing measures device, including a number of bracket units and support platforms.

[0033] Each bracket unit is composed of a U-shaped groove 1, two pillars 2 and two flanges I. The U-shaped groove 1 is composed of a bottom plate and two baffles. The width of the bottom surface of the U-shaped groove 1 is slightly larger than that to be placed. the width of the main truss main pipe, and ensure that the two baffles of the U-shaped groove play a fixed and clamping role on the main truss main pipe placed in the groove; the bending arc or slope of the U-shaped groove 1 in the length direction is the same as The upper corresponding part of the truss main pipe corresponds to the truss main pipe, so that the truss main pipe is placed in the corresponding U-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com