Closed-hole foamed aluminum component being easy to install and preparation method thereof

A closed-cell aluminum foam, easy-to-install technology, applied in the field of closed-cell aluminum foam components, can solve the problems of poor fixation of foamed aluminum, difficult to effectively fix foamed aluminum, and high density, and achieve mass production and easy mass production. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

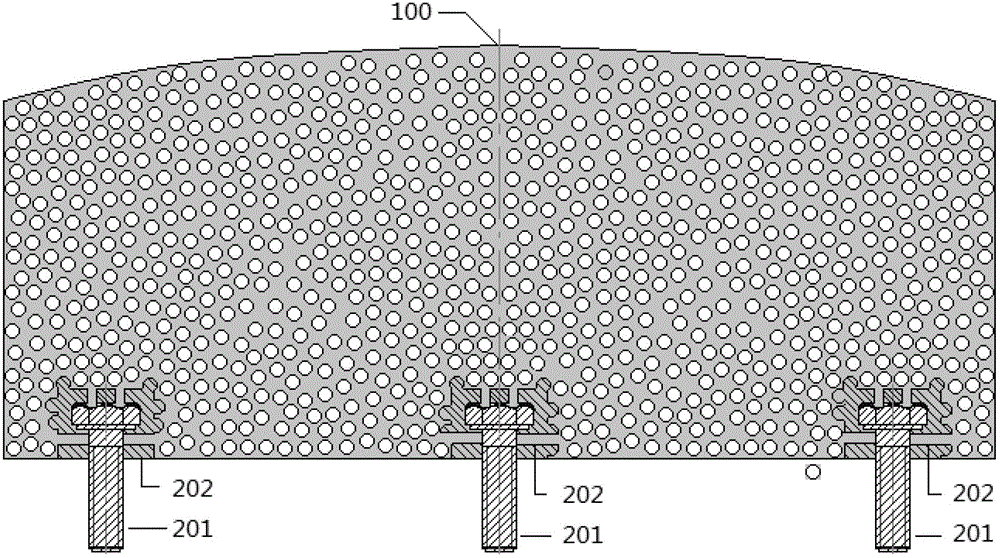

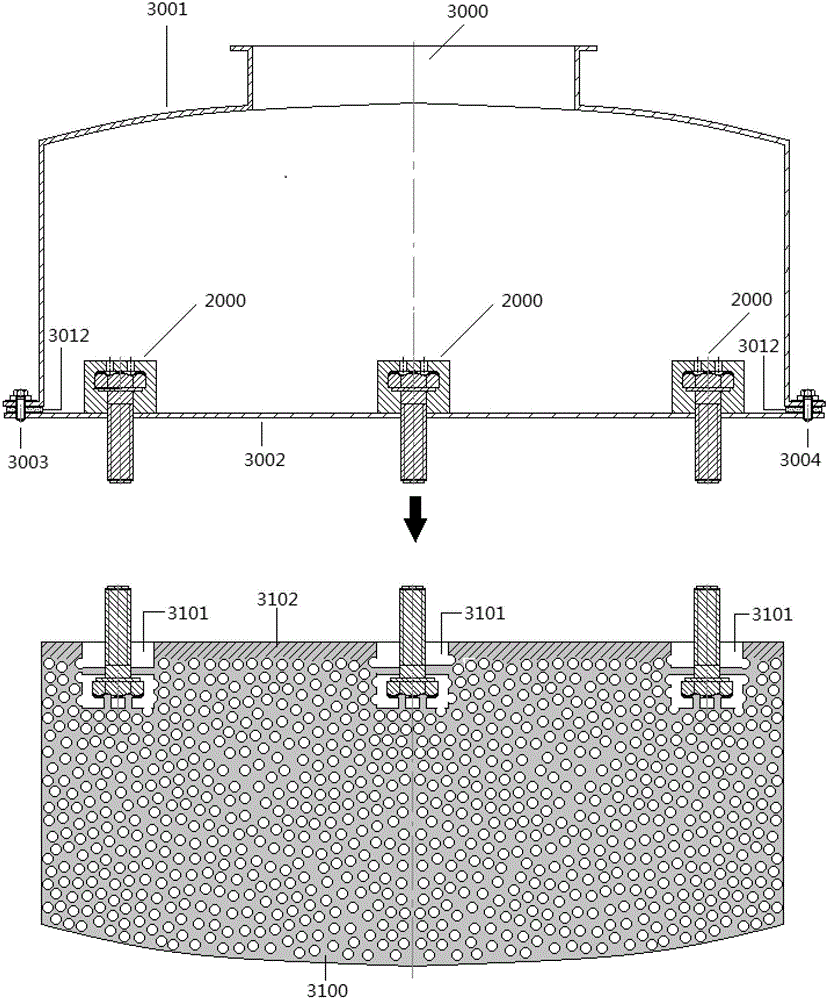

[0040] The process of preparing foamed aluminum components that are easy to install by directly pouring foamed aluminum melt into closed-cell foamed aluminum component molds

[0041] This embodiment adopts TiH 2 As a foaming agent, 102 alloy is used as the aluminum alloy raw material. Combine below figure 1 , figure 2 and image 3 Now, this embodiment will be described.

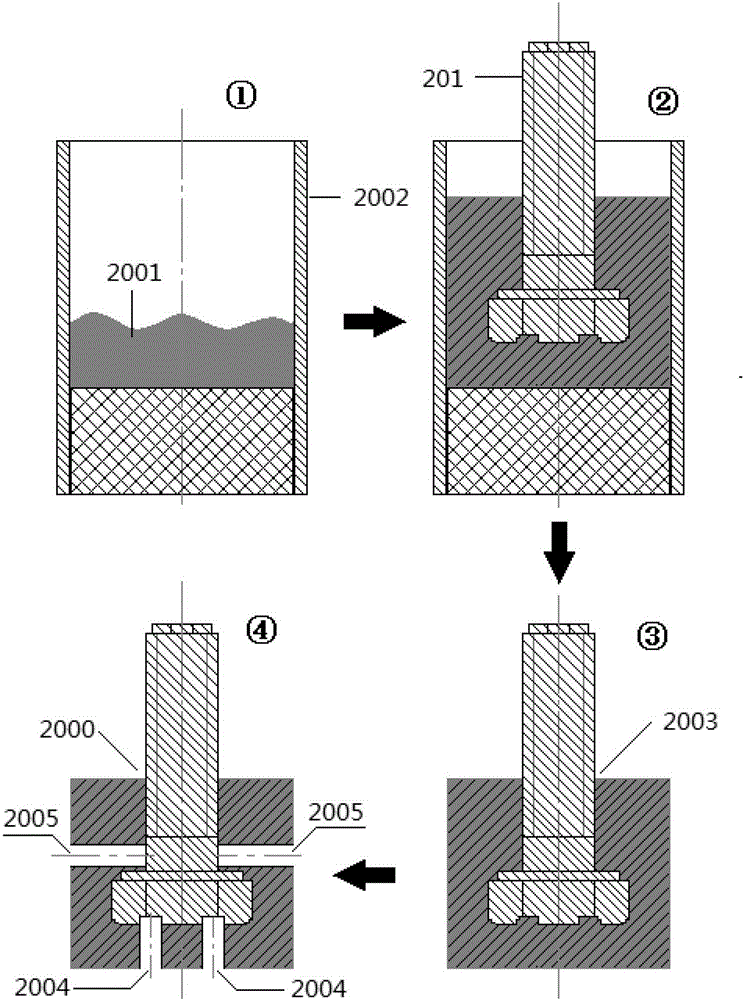

[0042] The first step is the preparation of dissolvable prefabricated parts containing bolts. For the specific process, see figure 2 :

[0043] ① Prepare the mixed powder material for the preparation of soluble preforms, according to TiB 2 40wt%, FeO20wt%, CaSO 4 0.5H 2 O20wt% and MgSO 4 Weigh the raw material powder at 20 wt%, and then mix these powders in a three-dimensional mixer for 2 hours, and finally, while stirring the powder, spray 5% water of the powder mass into the mixed powder to obtain the mixed powder material 2001;

[0044] ② Put part of the mixed powder material 2001 in the pressu...

Embodiment 2

[0062] The process of preparing closed-cell foamed aluminum components by pouring aluminum melt into the inner mold → adding foaming agent → lifting out the inner mold

[0063] This embodiment adopts TiH 2 As the foaming agent, 6063 alloy is used as the aluminum alloy raw material. Combine below figure 1 , figure 2 and Figure 4 Now, this embodiment will be described.

[0064] The first step is the preparation of dissolvable prefabricated parts containing bolts. For the specific process, see figure 2 .

[0065] ① Prepare the mixed powder material for the preparation of soluble preforms. According to 50wt%TiB 2 , 20wt%Fe 2 o 3 , 5wt%CaSO 4 0.5H 2 O with 25wt%K 2 SO 4 Weigh the raw material powders, and then mix these powders in a three-dimensional mixer for 4 hours, and finally, while stirring the powders, spray 5% water of the powder mass into the mixed powders to obtain the mixed powder material 2001.

[0066] ② Put part of the mixed powder material 2001 in th...

Embodiment 3

[0084] The process of preparing closed-cell foamed aluminum components by pouring aluminum melt into the inner mold → adding foaming agent → lifting out the inner mold

[0085] This embodiment adopts TiH 2 As the foaming agent, 6063 alloy is used as the aluminum alloy raw material. Combine below figure 1 , figure 2 and Figure 4 Now, this embodiment will be described.

[0086] The first step is the preparation of dissolvable prefabricated parts containing bolts. For the specific process, see figure 2 .

[0087] ① Prepare the mixed powder material for the preparation of soluble preforms, according to TiB 2 45wt%, FeO20wt%, CaSO 4 0.5H 2 O20wt% and MgSO 4 Weigh the raw material powder at 15wt%, then mix these powders in a three-dimensional mixer for 2 hours, and finally, while stirring the powder, spray 5% of the powder mass into the mixed powder to obtain the mixed powder material 2001;

[0088] ② Put part of the mixed powder material 2001 in the pressure mold 2002,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com