Fabricated steel structure type reinforced ring plate type flange beam column joint and using method thereof

A technology to strengthen the ring plate and steel structure, applied in the direction of building structure, construction, etc., can solve the problems of poor integrity, complex assembly, insufficient bearing capacity and energy dissipation capacity, etc., to achieve clear force transmission, convenient construction, and effective Conducive to the effect of safety and earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

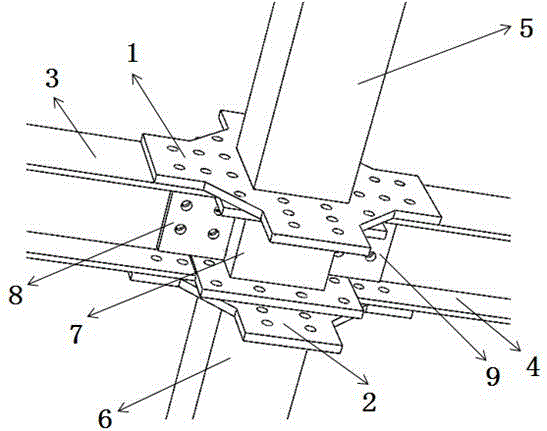

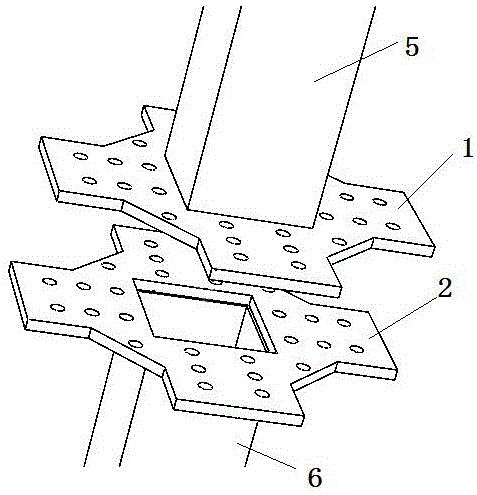

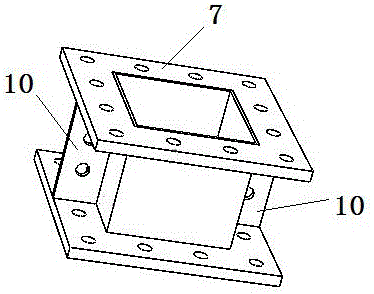

[0029] Embodiment 1: as figure 1 As shown, an assembled steel structure like reinforced ring-plate flange beam-column node and its use method, in this embodiment, the position of the node needs to be provided with a cross-shaped beam-column, including a reinforced ring plate, a column base 7, a pasting plate , Lap board 10; Described column comprises upper column 5, lower column 6; Strengthening ring plate comprises upper ring plate 1, lower ring plate 2; Beam comprises left beam 3, right beam 4; Sticker plate 9; the upper column 5 and the lower column 6 are respectively connected by the upper ring plate 1, the lower ring plate 2 with prefabricated bolt holes at the column end, and the flange plate high-strength bolts at the upper and lower ends of the column base 7; the upper column 5. The lower column 6 and the beam flange are respectively connected through the prefabricated bolt holes on the upper ring plate 1 and the lower ring plate 2 and the high-strength bolt holes on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com