Assembled framework beam-column joint adopting transverse connection and construction method thereof

A beam-column joint, prefabricated technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficult to meet the structural crack resistance and integrity, seismic performance, poor reliability, etc., to achieve simple structure, high strength Reliable and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

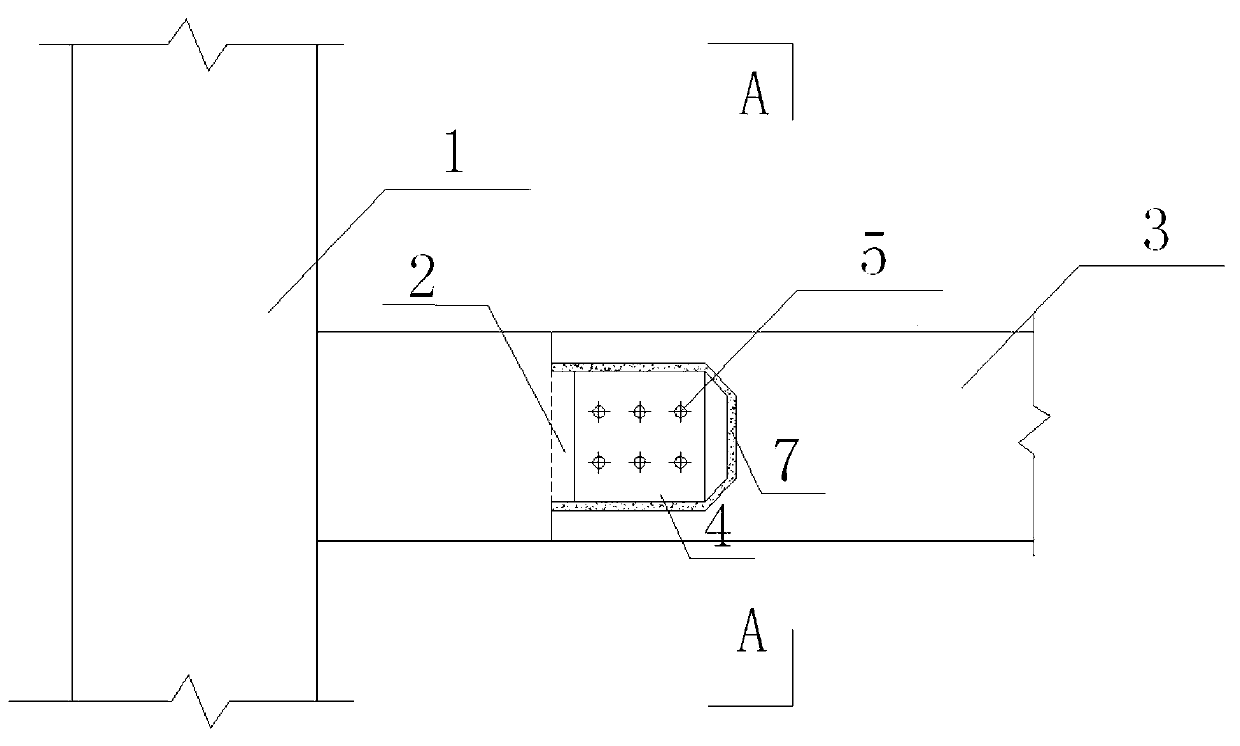

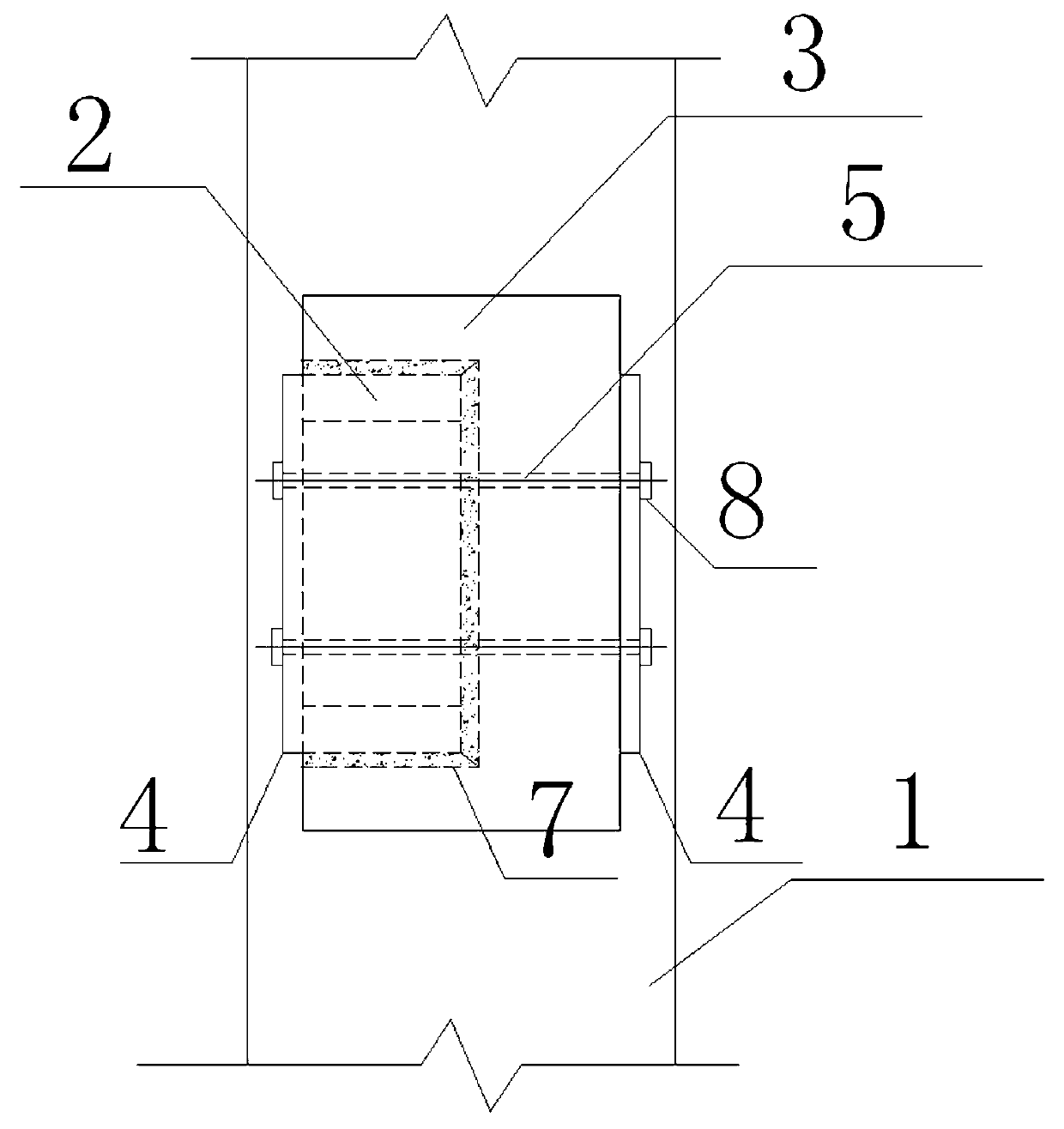

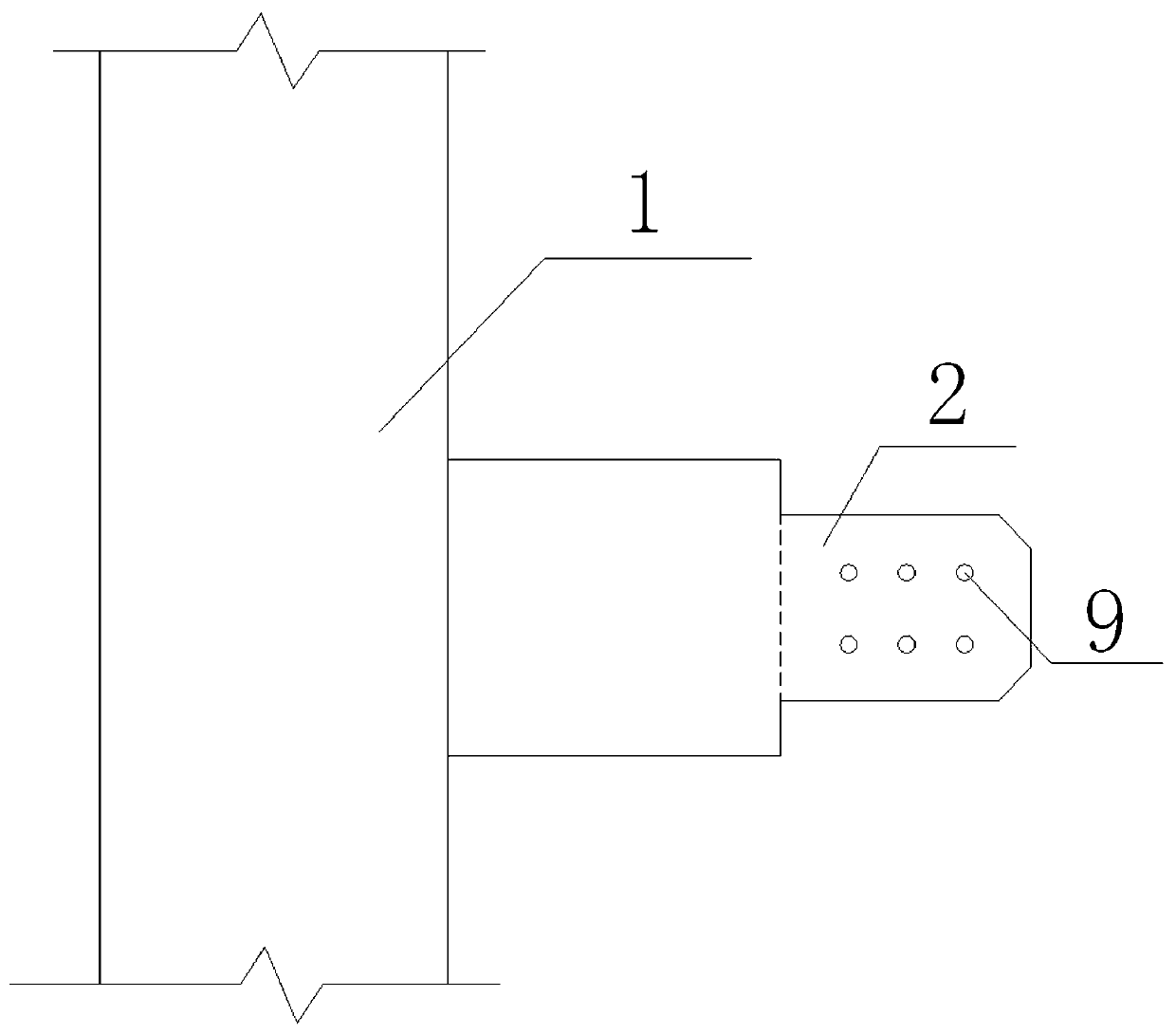

[0027] Example: such as Figure 1-6 As shown, a prefabricated reinforced concrete frame beam-column joint connected by transverse bolts includes a hidden corbel 2 set on the beam of the prefabricated column 1. The cross section of the dark corbel 2 is rectangular or trapezoidal, and the upper Bolt holes 9 for concealed corbels are reserved in the horizontal direction; notch grooves 6 matching with concealed corbels 2 are provided on the front / rear sides of the joints at the ends of the prefabricated beams 3, and the notches 6 start from the vertical axis of the prefabricated beams 3 Dig a gap to one side, the gap has the same cross-sectional shape as the hidden corbel 2, and the size of the gap is slightly larger than the hidden corbel 2, so as to facilitate the embedding of the two, reserve prefabricated beam bolts at the corresponding position at the bottom of the notch groove 6 along the transverse direction Holes 10; the width of the concealed corbel 2 along the transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com