Construction method for 45-DEG-inclined long-overhanging reinforced concrete structure project

A technology of reinforced concrete and construction method, which is applied in building structure, construction, construction material processing and other directions, can solve the difficulty of manual straight thread connection operation, the construction method has not been disclosed, the stability and anti-overturning resistance of ordinary steel pipe truss support system The check calculation cannot meet and ensure the construction quality and safety and other problems, so as to achieve the effect of shortened construction period, reasonable stress and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

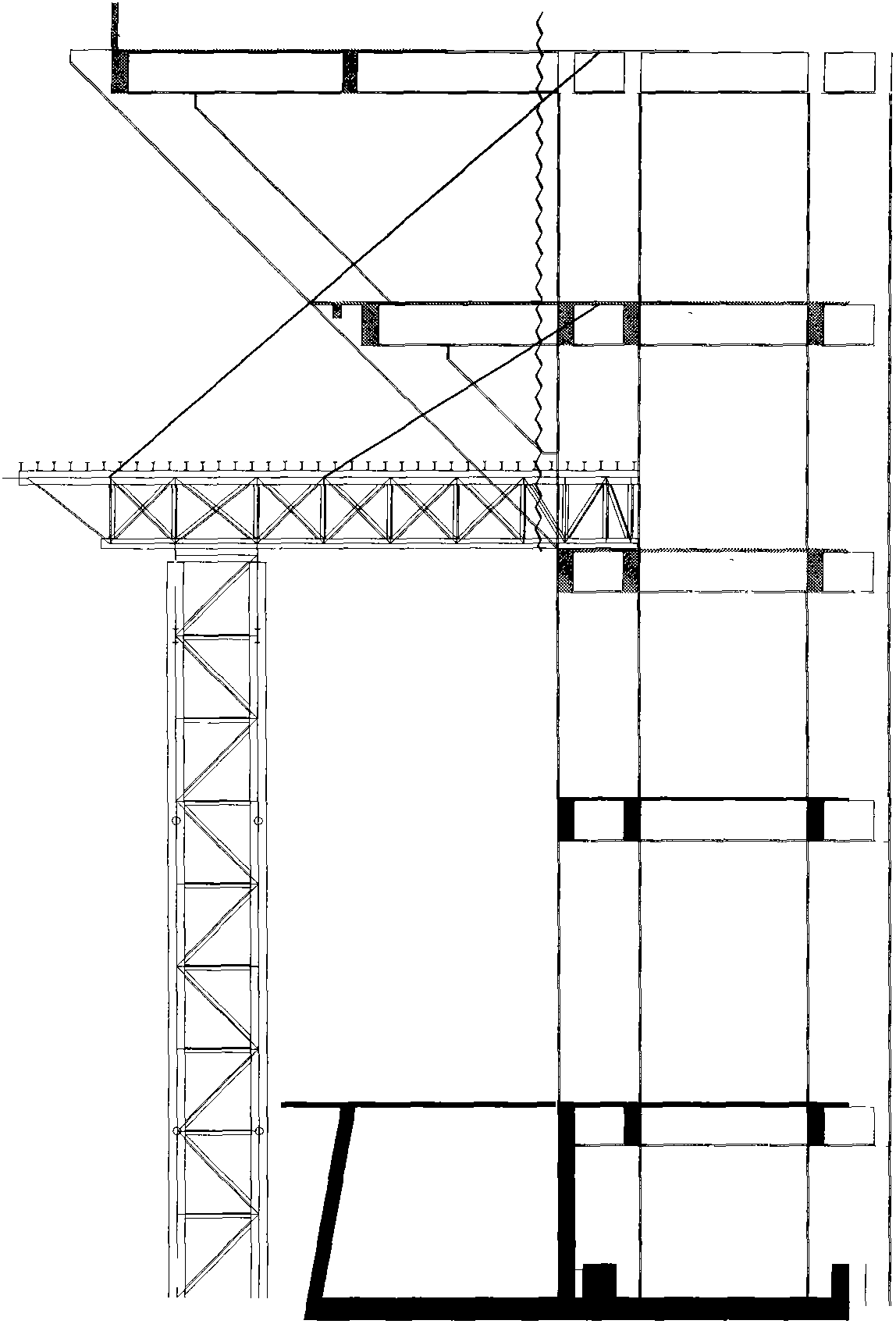

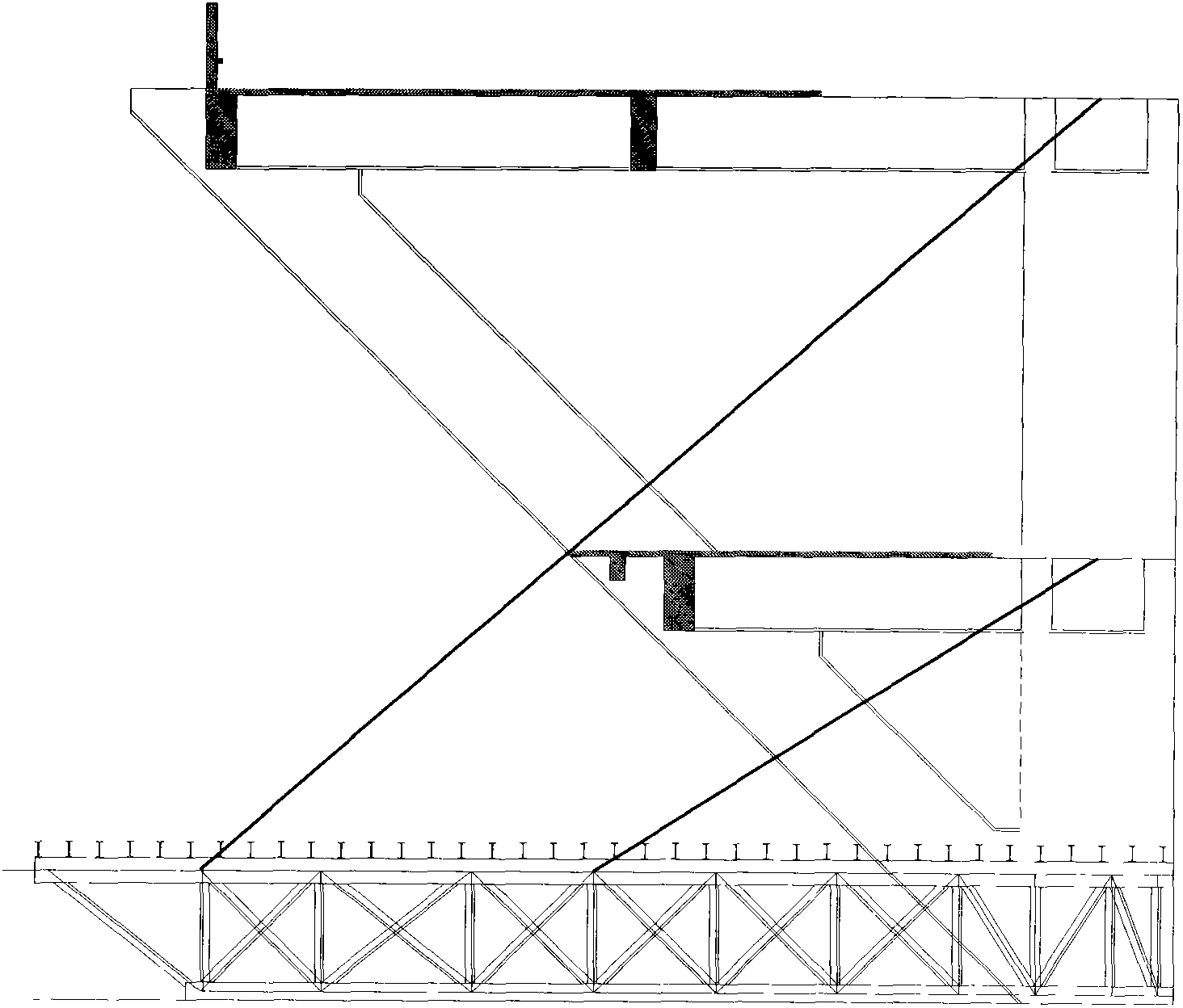

[0013] The invention includes the combination of a cable-stayed steel pipe tower frame and a scaffold during construction.

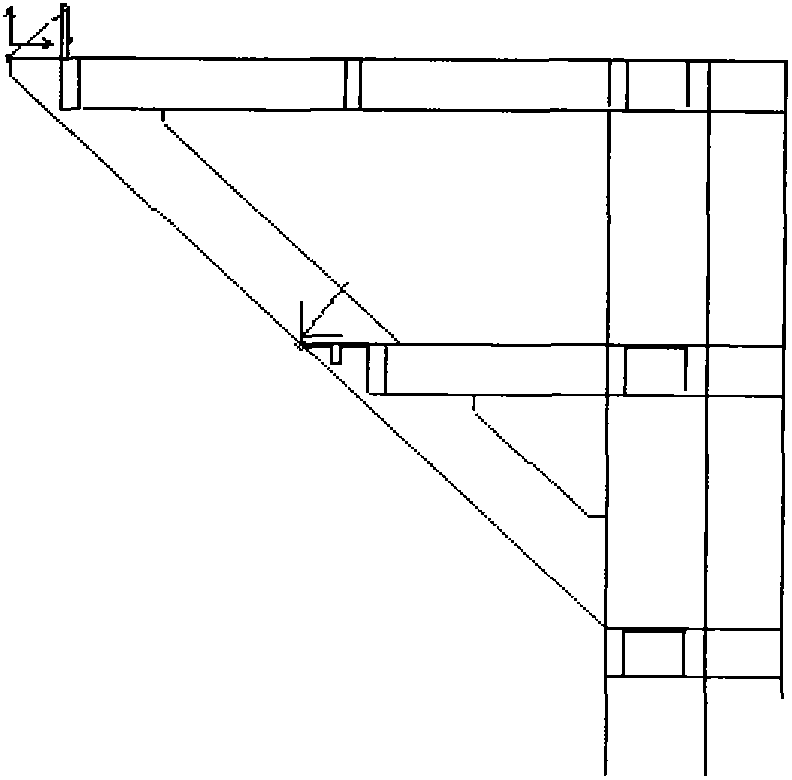

[0014] Before construction, the complex block finite element assembly analysis technology and the integrated technology of design and construction of inclined structure frame are used for design.

[0015] Construction design using complex block finite element assembly analysis technology: namely

[0016] The 45° inclined molding project all adopts the cast-in-place reinforced concrete structure system. During the construction process, a mechanical model for the finite element construction analysis of the complex block is established to analyze the development and change process of its internal force and deformation during the construction process, and to determine the mechanics of various simulations. Shape and control parameters, put forward the warning parameters and motion state during the construction process, and finally establish the combination mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com