Steel structure beam column assembly type rigid joint

A prefabricated, steel structure technology, applied in building construction, construction, etc., can solve the problems of difficult installation quality, long cycle, large engineering volume, etc., and achieve the effect of convenient joint operation, reasonable structure and improved installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

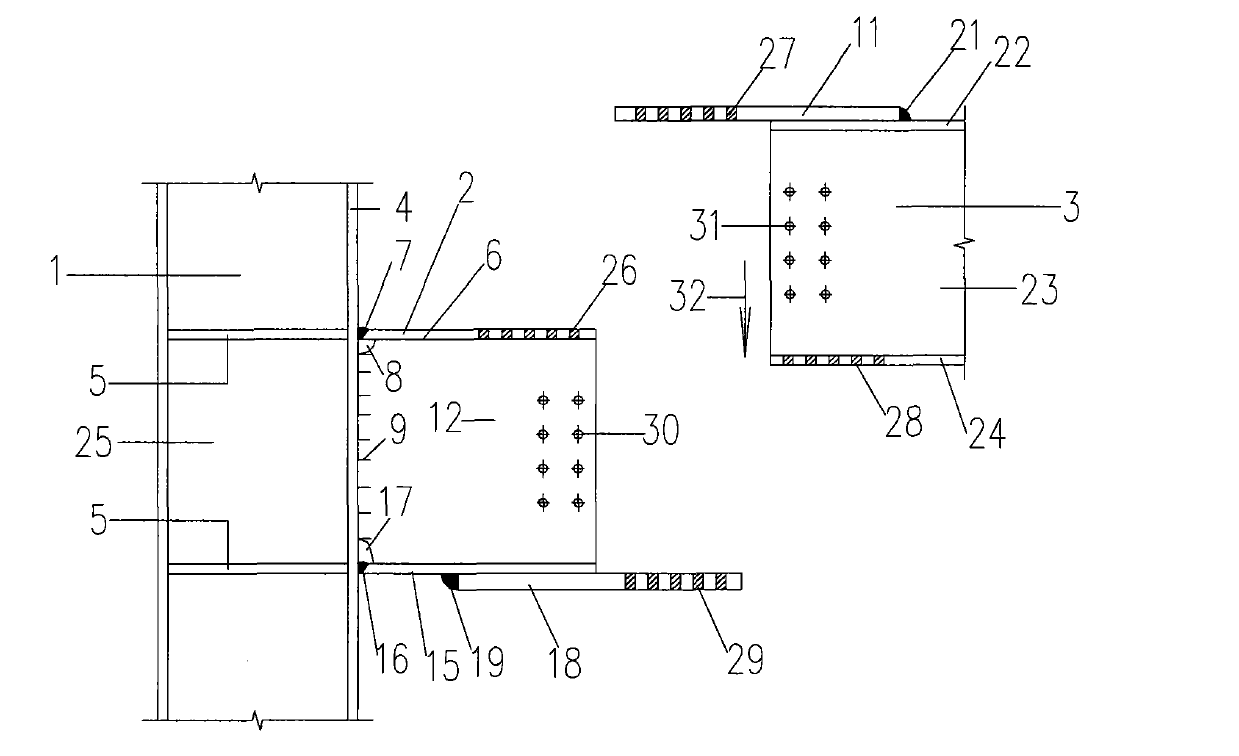

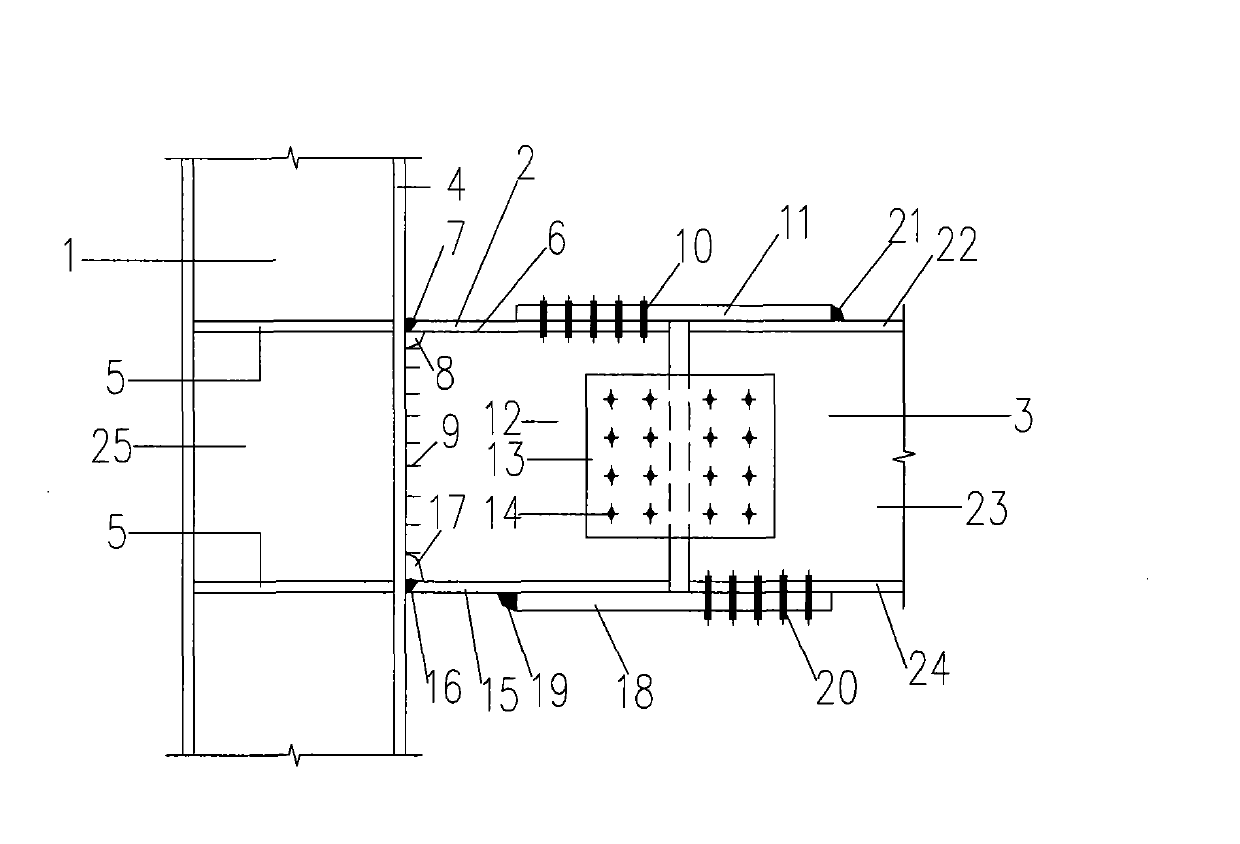

[0019] Such as Figures 1 to 2 As shown, a steel beam-column assembled rigid joint includes a steel column 1 , a cantilever beam 2 and a frame beam 3 . The upper flange 6 of the cantilever beam 2 is connected to the flange 4 of the steel column 1 by a butt weld 7, the web 12 of the cantilever beam 2 is connected to the flange 4 of the steel column 1 by a fillet weld 9, and the lower flange of the cantilever beam 2 The flange 15 and the flange 4 of the steel column 1 are connected by a butt weld 16, and the upper and lower ends of the web 12 of the cantilever beam 2 are respectively opened with weld passage holes 8 and 17, and the node domain 25 of the column contains ribs 4. The upper flange 6 of the cantilever beam 2 has a bolt hole 27, the lower flange 15 of the cantilever beam 2 is connected to one side of the splicing plate 18 through a fillet weld 19, and the other side of the splicing plate 18 is opened with a bolt hole 29 , There are bolt holes 30 on the web 12 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com