Inserting type steel plate connection structure of prefabricated shearing walls and construction method thereof

A prefabricated shear force and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of uncontrollable construction quality, cumbersome operation, exposed steel bars, etc., achieve controllable construction quality, increase connection stiffness and Strong, easy-to-position effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

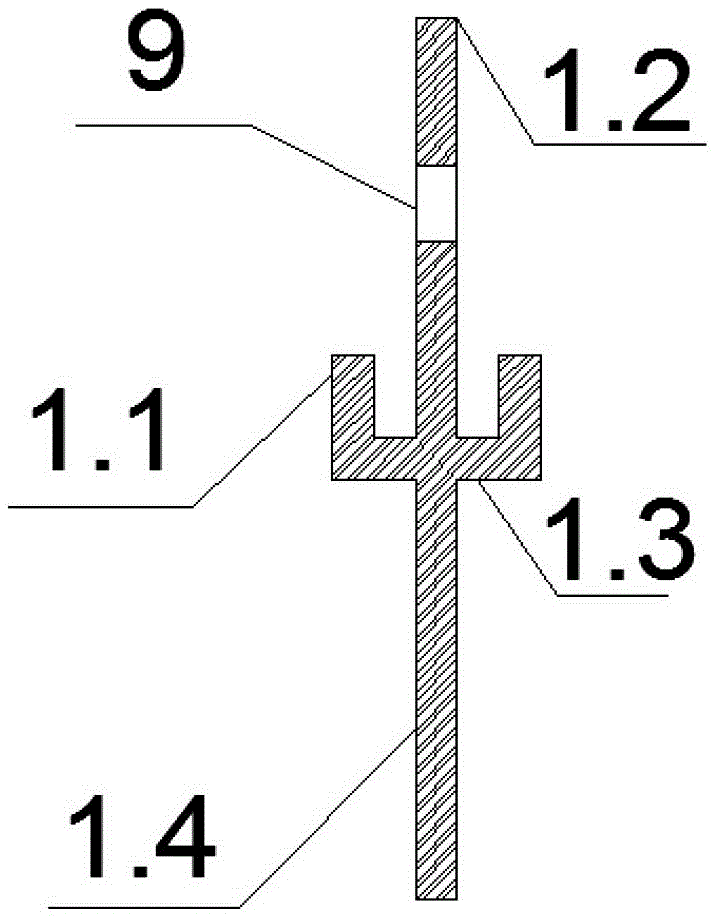

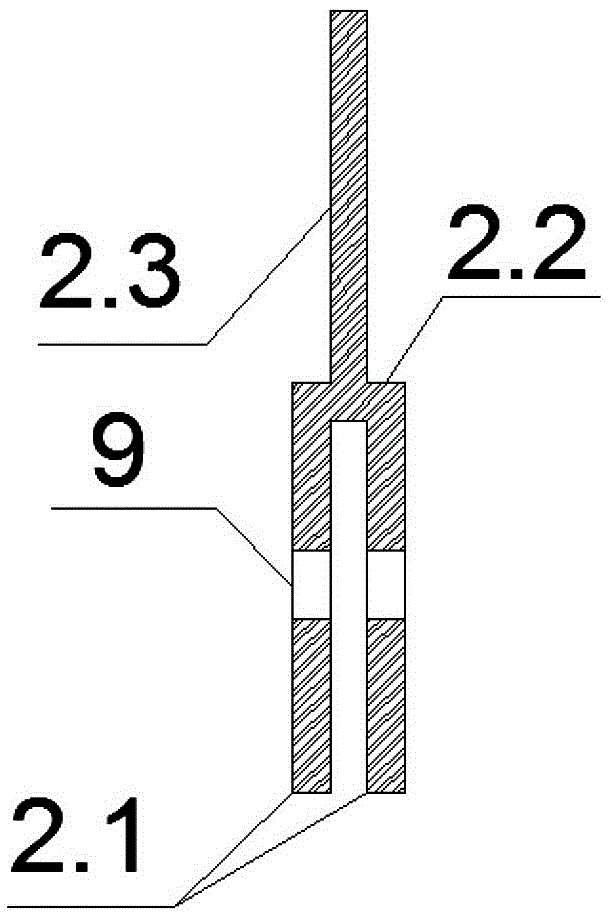

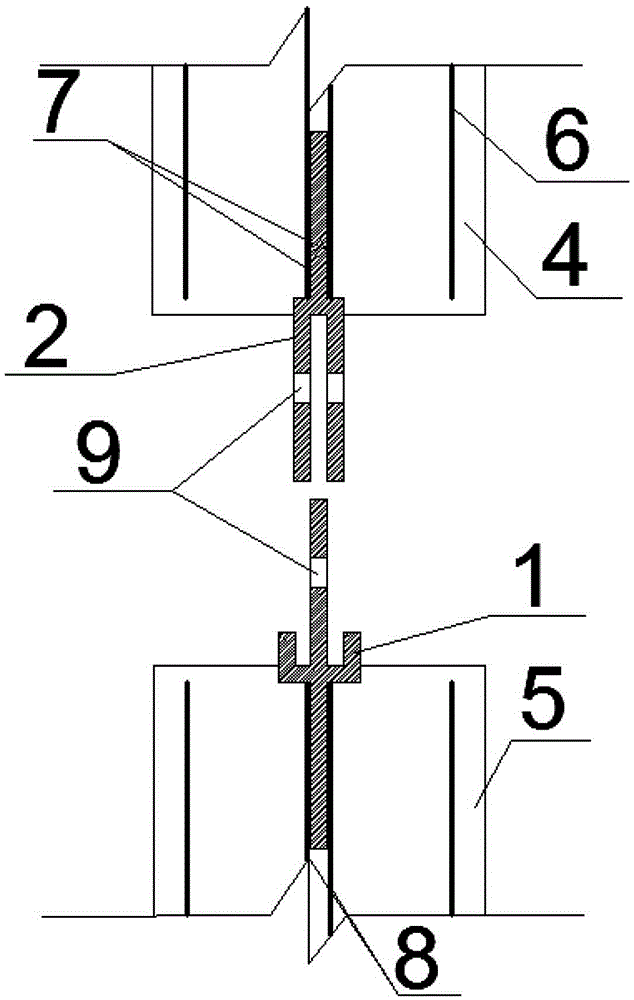

[0041] Examples see Figure 5 As shown in this prefabricated shear wall plug-in steel plate connection structure, the upper prefabricated shear wall panel 4 and the lower prefabricated shear wall panel 5 are assembled and connected by connecting components, and concrete is poured after the joints of the two components. It includes a mountain-shaped steel plate 1 and a Y-shaped steel plate 2 that are arranged in pairs. The two are engaged and connected and fastened by a fastener 3. The fastener 3 is a high-strength bolt. The strength of the concrete poured at the joint is The grade is one level higher than the strength grade of the prefabricated shear wall panel; the prefabricated shear wall panel includes a concrete body and a steel skeleton poured in the concrete body, and the steel skeleton includes vertical steel bars 6, transverse steel bars, stirrups and Anchor bars 8.

[0042] see Figure 4 As shown, the Y-shaped steel plate part 2 is pre-embedded at the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com