Abnormal shape steel case and orthotropic plate bottom formwork combined type moving die carrier framework and construction method thereof

An orthotropic plate and mobile formwork technology, applied in the erection/assembly of bridges, bridge materials, bridges, etc., can solve problems such as the inability of formwork via technology to adapt, and achieve good appearance quality, light weight and high cost performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

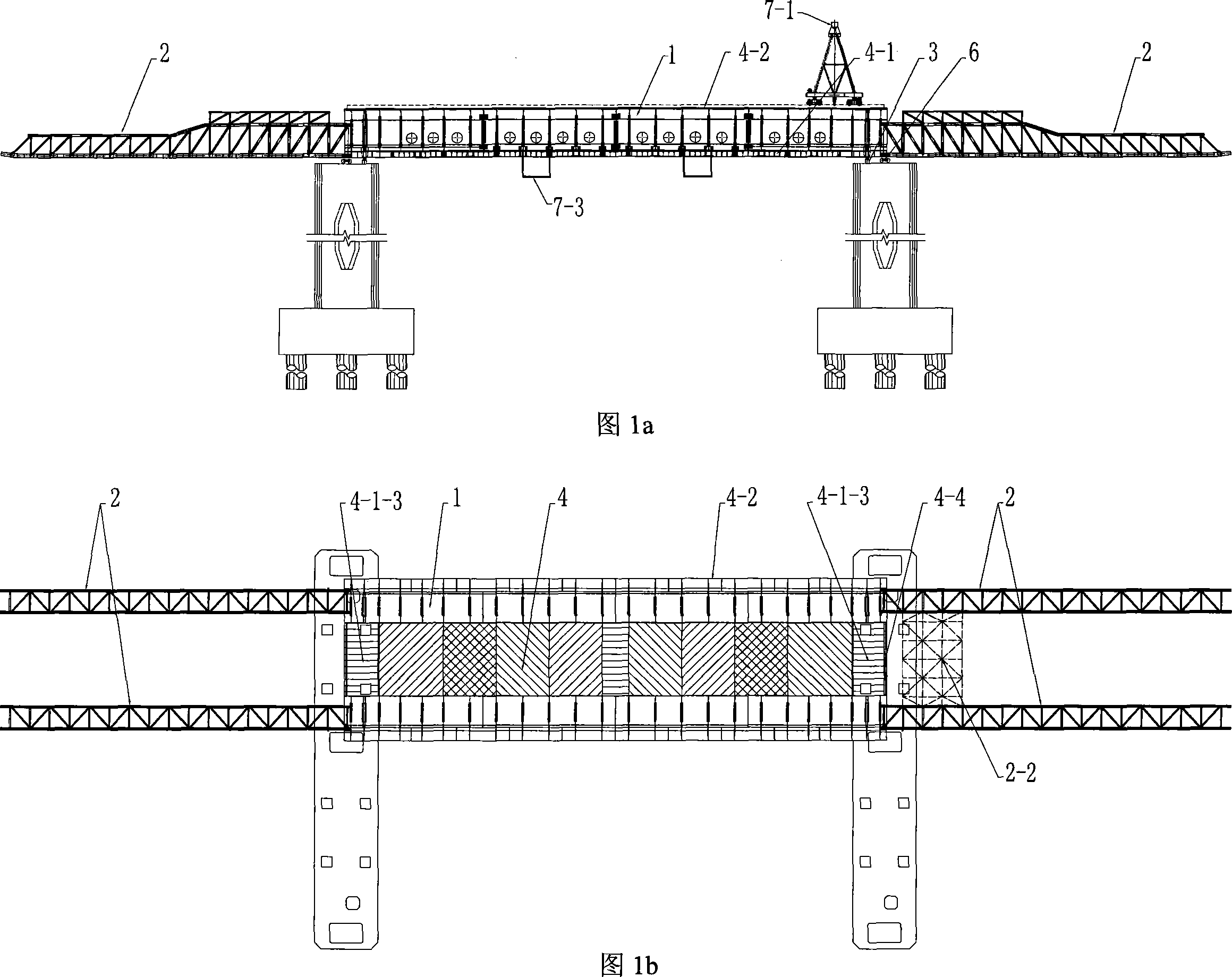

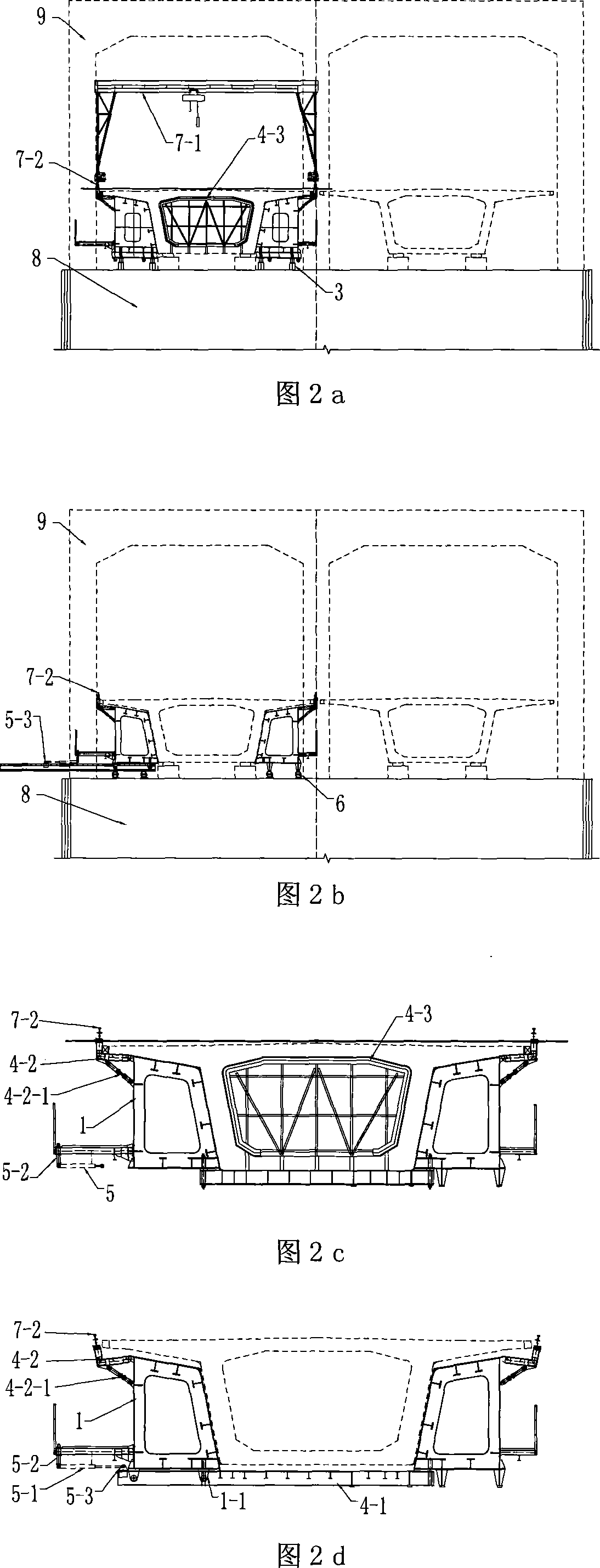

[0056] The combined mobile formwork of special-shaped steel box and orthotropic plate bottom formwork is mainly composed of load-bearing main girder (1), guide beam (2), supporting device (3), formwork system (4), and bottom formwork opening and closing system (5). , Longitudinal mold shifting system (6) and auxiliary structure.

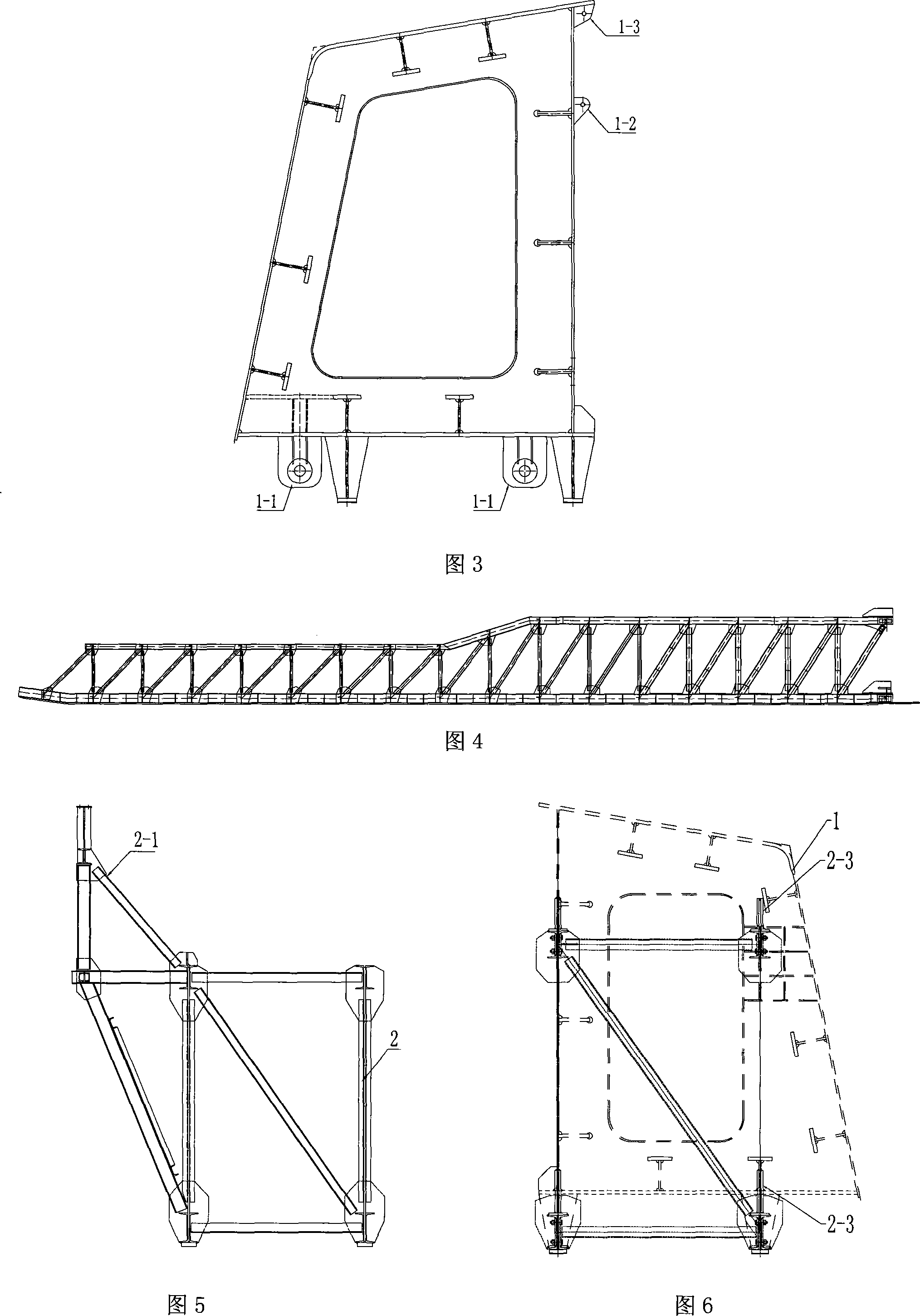

[0057] 1. Load-bearing main beam: the main beam adopts special-shaped steel box girder, and a set of mobile formwork includes 2 main beams. The single main beam is manufactured in sections, and the sections are connected with bolts.

[0058] (1) Beam body: The beam body is a steel box structure, its top plate and inner web are inclined (the size of the external mold of the cast-in-place box girder), the bottom plate is horizontal, and the outer web is vertical. Partition plates and longitudinal stiffeners, bottom formwork hanging hinges and walkways are set at the bottom of the beams. The typical section of special-shaped steel box is shown in Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com