Sliding construction device and method for large-span arc-shaped roof

An arc-shaped, long-span technology, applied in the direction of construction, building structure, and building materials, can solve the problems of inconvenient construction methods and low safety factors, achieve ideal sliding speed, improve construction efficiency, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

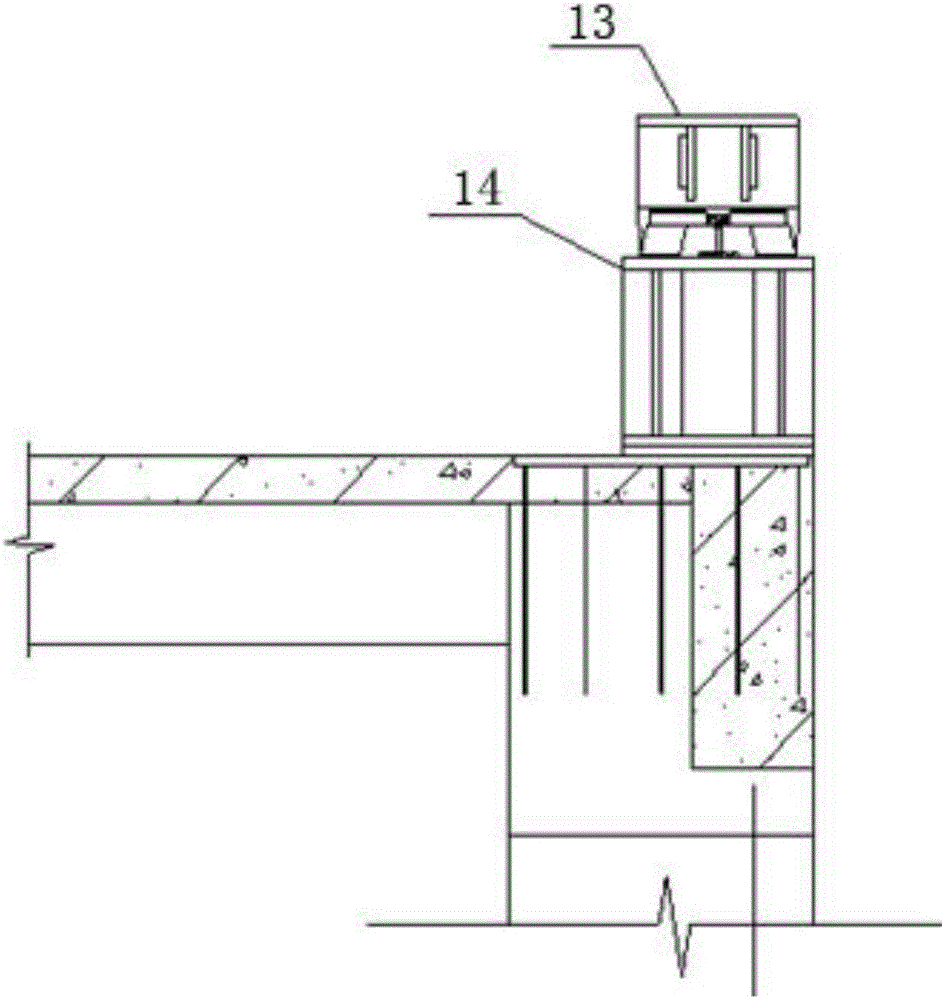

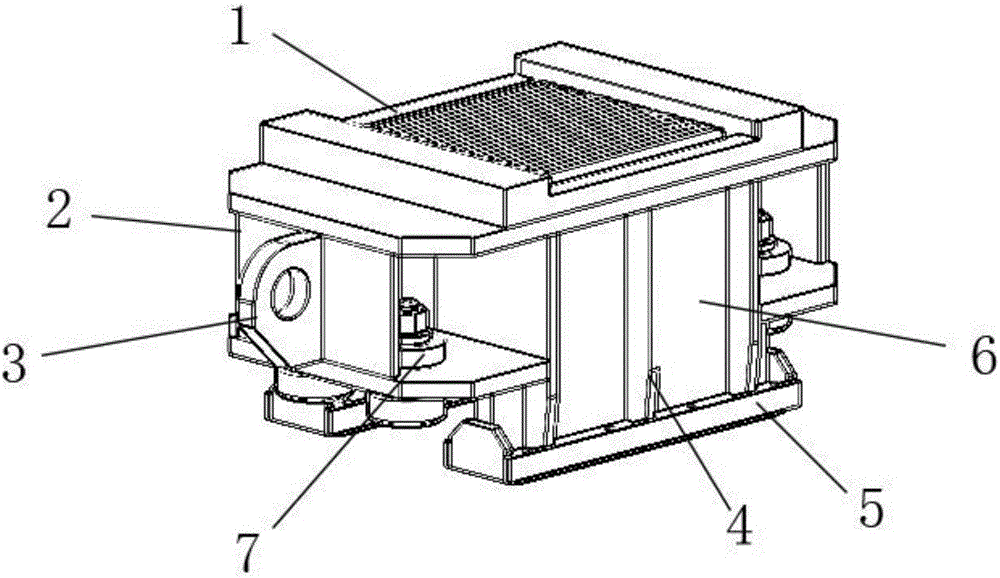

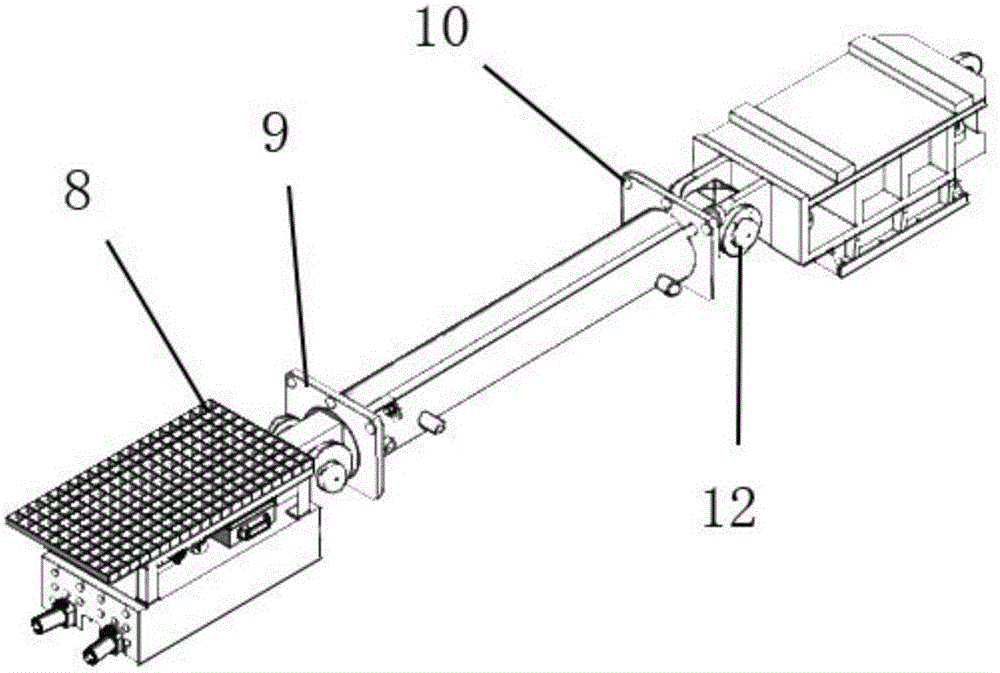

[0025] The present invention uses finite element structure analysis software to analyze the stress change of each member according to the actual working conditions of each stage of installation, and compares it with the stress limit requirement of the design state to ensure the structural safety of the construction stage without causing adverse additional stress. According to the reaction force of each support, the reaction force at the supporting tire frame, and the force limit of the column and beam of the reinforced concrete structure analyzed by the software, design the temporary supporting tire frame, sliding shoe, arc-shaped sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com