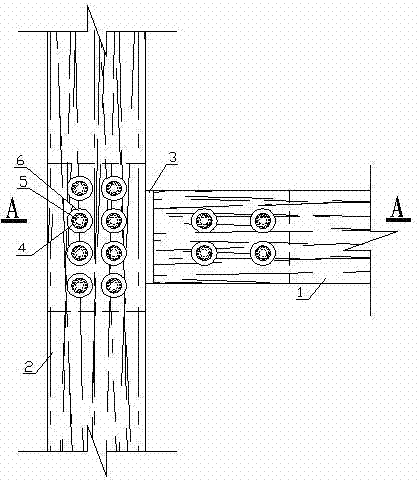

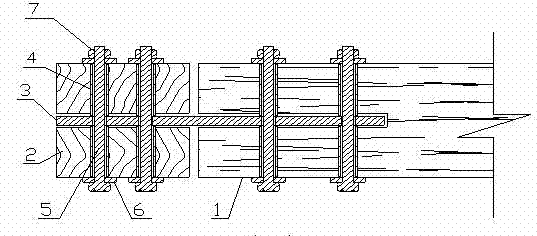

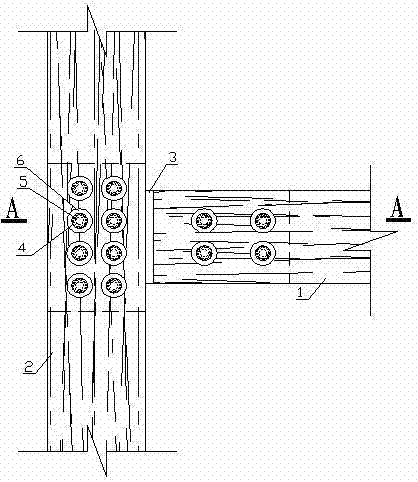

Bolted steel filling plate-sleeve connection node for beam-post wood structure

A technology for connecting nodes and beam-column connections, applied in building structures, buildings, etc., can solve the problems of limited rigidity, reduce the bending rigidity of connections, and reduce the seismic performance, so as to improve the compressive capacity and ductility, improve the resilience and The effect of improving energy dissipation and structural seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: as figure 1 — figure 2 As shown, the present invention is to embed a sleeve 4 in the bolt hole on the beam-column connection node connecting the wooden beam 1 and the wooden column 2, and after the bolt 5 is penetrated in the sleeve 4, the gasket 6 is compressed by the tension bolt 5 The casing 4, so that the casing 4 is pressed against the steel filler plate 3 to generate a relatively large pressure, and the friction generated by the pressure is used to resist shearing and the increase and decrease of the compressive stress are used to resist bending. During implementation, first insert the steel filler plate 3 into the wooden beam 1 and the wooden column 2, then insert the casing 4 in the bolt holes of the wooden beam 1 and the wooden column 2, insert the bolt 5 into the casing 4, and finally tension the bolt 5 and tighten the nut 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com