End plate type steel pipe concrete column-steel beam connection node

A technology for CFST column and CFST, which is applied in construction, building structure, etc., can solve the problems of unsuitable construction of high-strength bolts, and achieve the effect of solving unsuitable construction, easy disassembly and replacement, and clear force transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

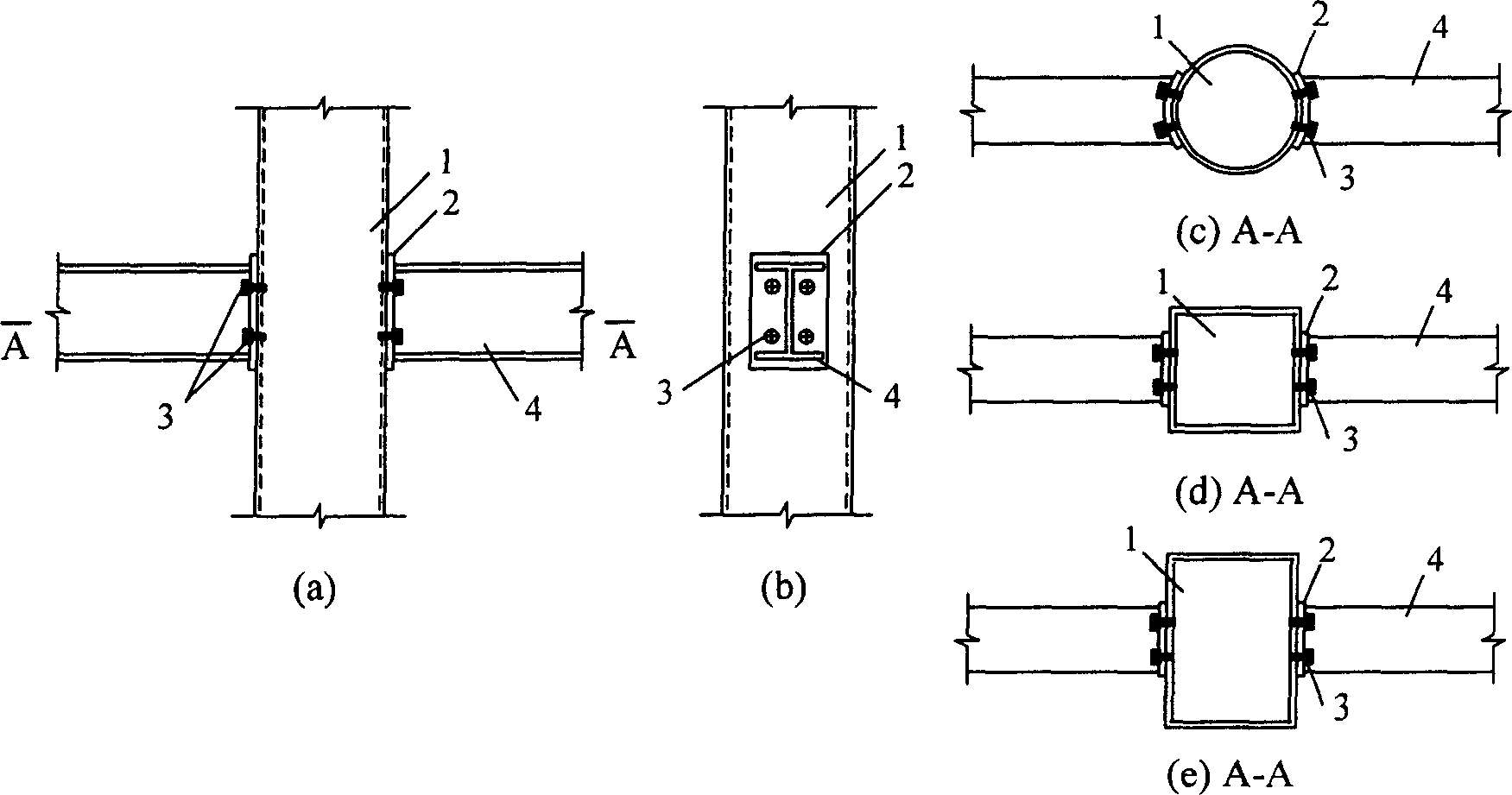

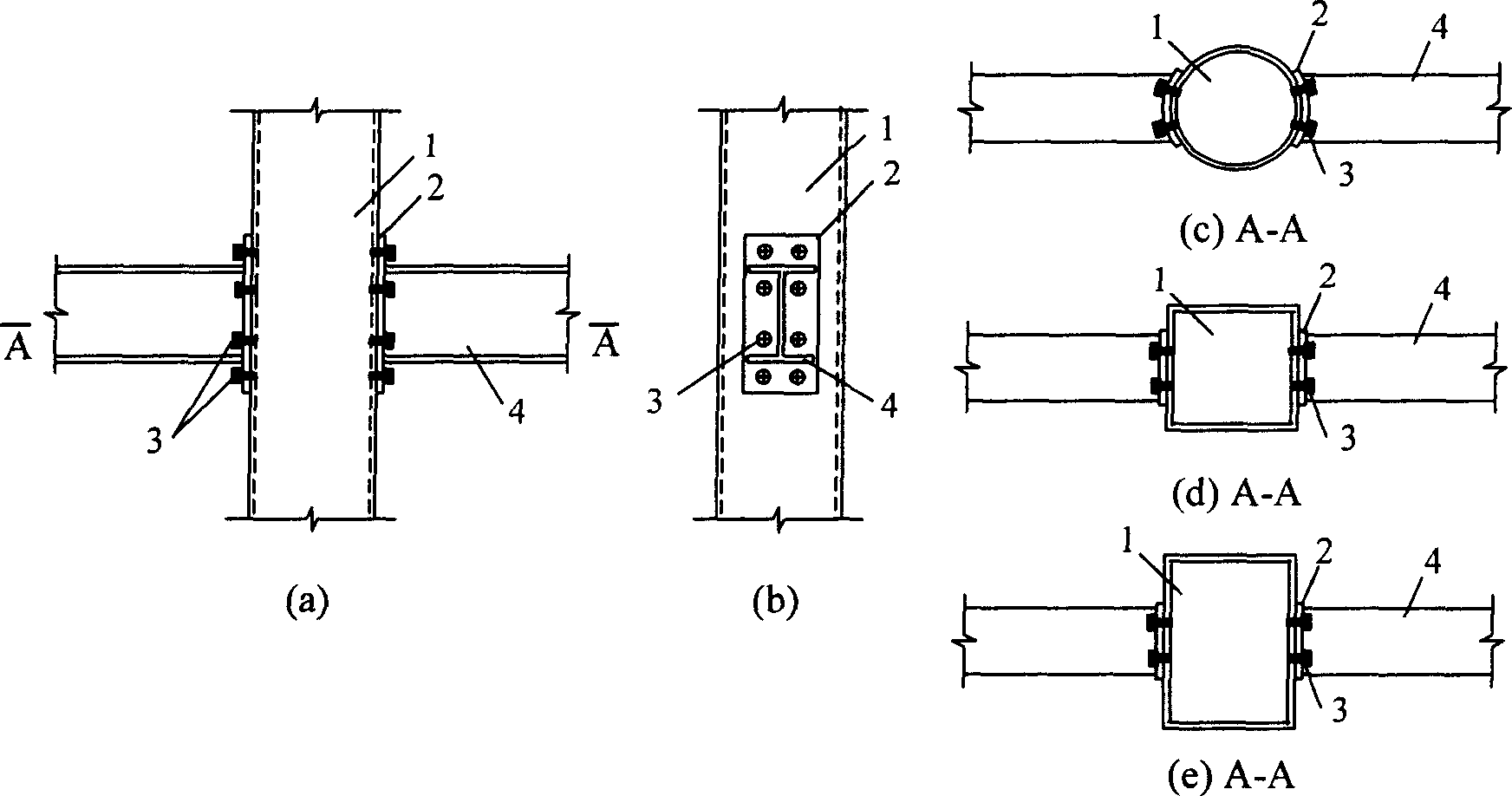

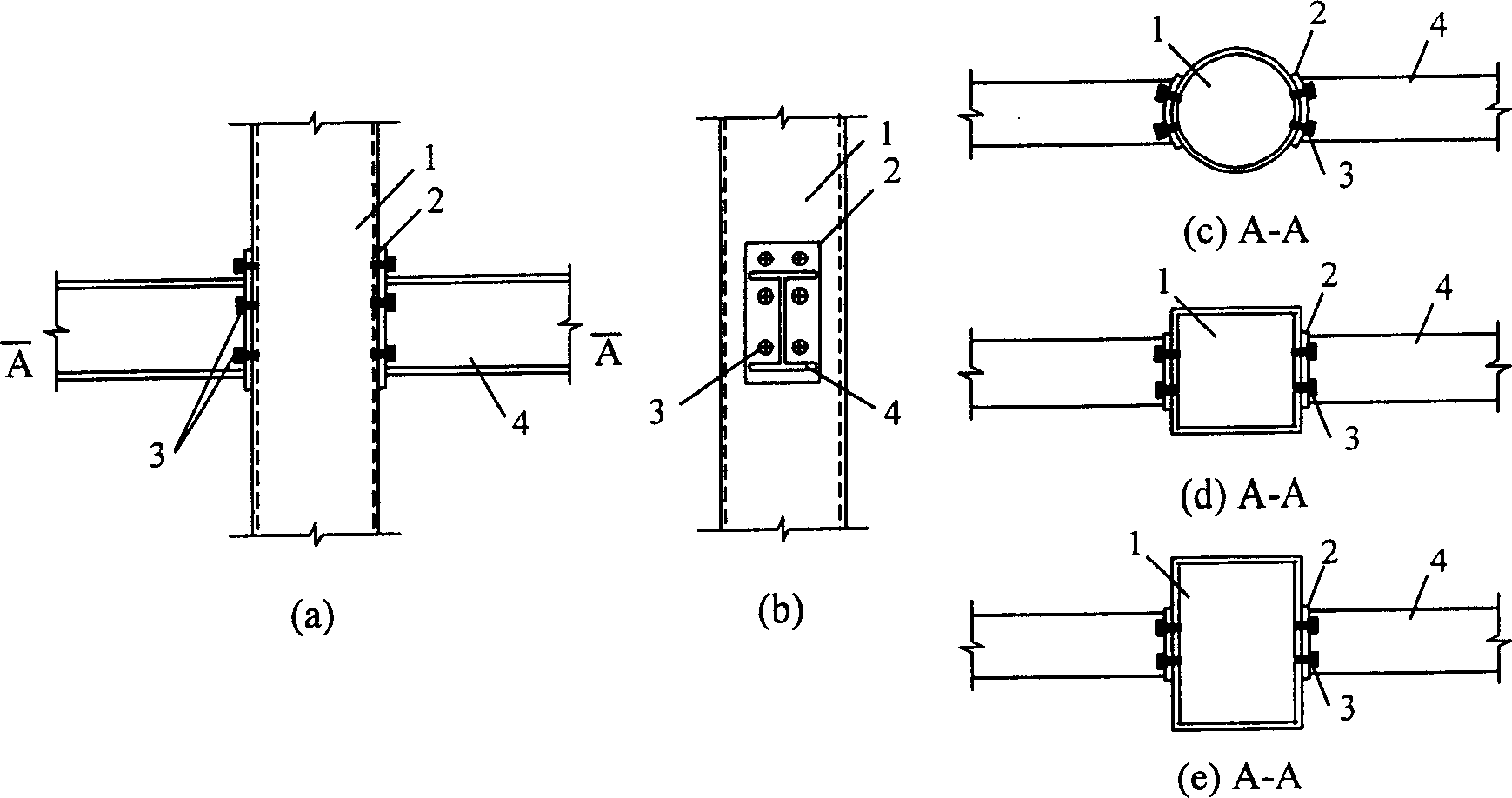

[0015] In this embodiment, Type HB-Hollo-Bolt one-way self-tightening bolts produced by the British Lindapter Company are used. First, position and install the steel pipe of the CFST column; then directly insert a new type of one-way self-tightening bolt into the connection hole between the steel pipe column wall and the end plate (the end of the steel beam is fixed on the end plate), and the bolt head is on the inside of the steel pipe The riveting head is automatically formed, the joint is fastened and there is no need to reach into the inner side of the steel pipe for operation; finally, concrete is poured into the steel pipe column to form a steel pipe concrete column-steel beam connection node structure.

[0016] The technology of the present invention can be applied to the connection of frame columns with circular, square and rectangular cross-section concrete-filled steel pipe columns (processing technology is casting, rolling, cold bending and welding) and steel beams (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com