Node assembly of U-shaped steel-concrete composite beam and rectangular steel tube concrete column

A technology of rectangular steel pipes and concrete columns, which is applied in the direction of construction and building construction, can solve the problems of insufficient ductility and energy dissipation capacity in the core area of nodes, unreasonable connection methods of nodes, and low bearing capacity of nodes, so as to achieve easy building decoration, The effect of reasonable force and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

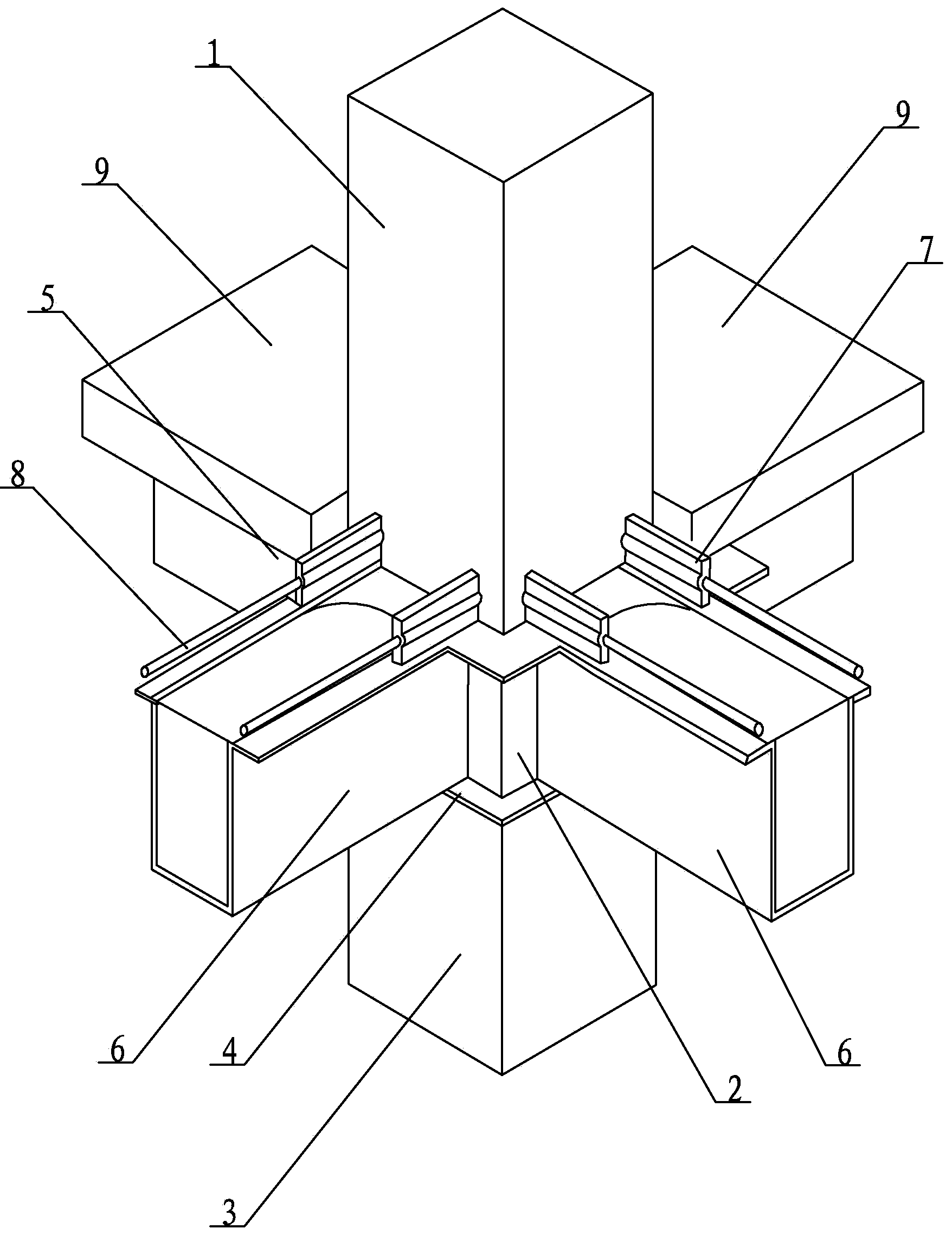

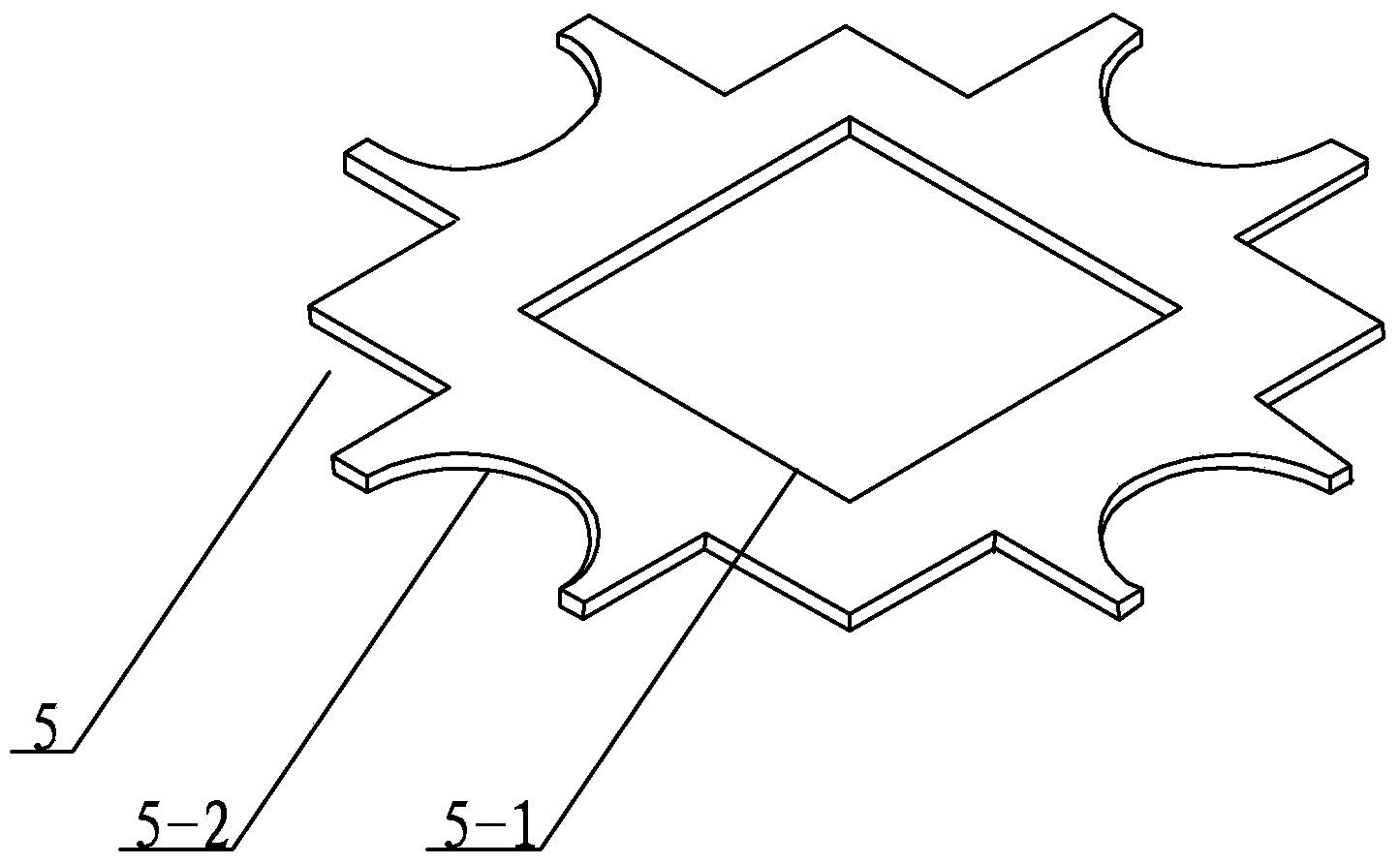

[0013] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the joint assembly of U-shaped steel-concrete composite beam and rectangular steel pipe concrete column in this embodiment, it includes the first rectangular steel pipe 1, the second rectangular steel pipe 2, the third rectangular steel pipe 3, and the partition plate 4 in the joint area , reinforcement ring 5 in the joint area, four U-shaped steel beams 6, multiple concrete slabs 9, multiple inserting plates 7 in the joint area and multiple steel bars 8 with the same number as the inserting plates 7, the first rectangular steel pipe 1, the second rectangular The steel pipe 2 and the third rectangular steel pipe 3 are arranged sequentially from top to bottom, the partition plate 4 in the node area is fixedly arranged between the second rectangular steel pipe 2 and the third rectangular steel pipe 3, and the reinforcing ring 5 in the node area is fixedly arranged on the first rectangula...

specific Embodiment approach 2

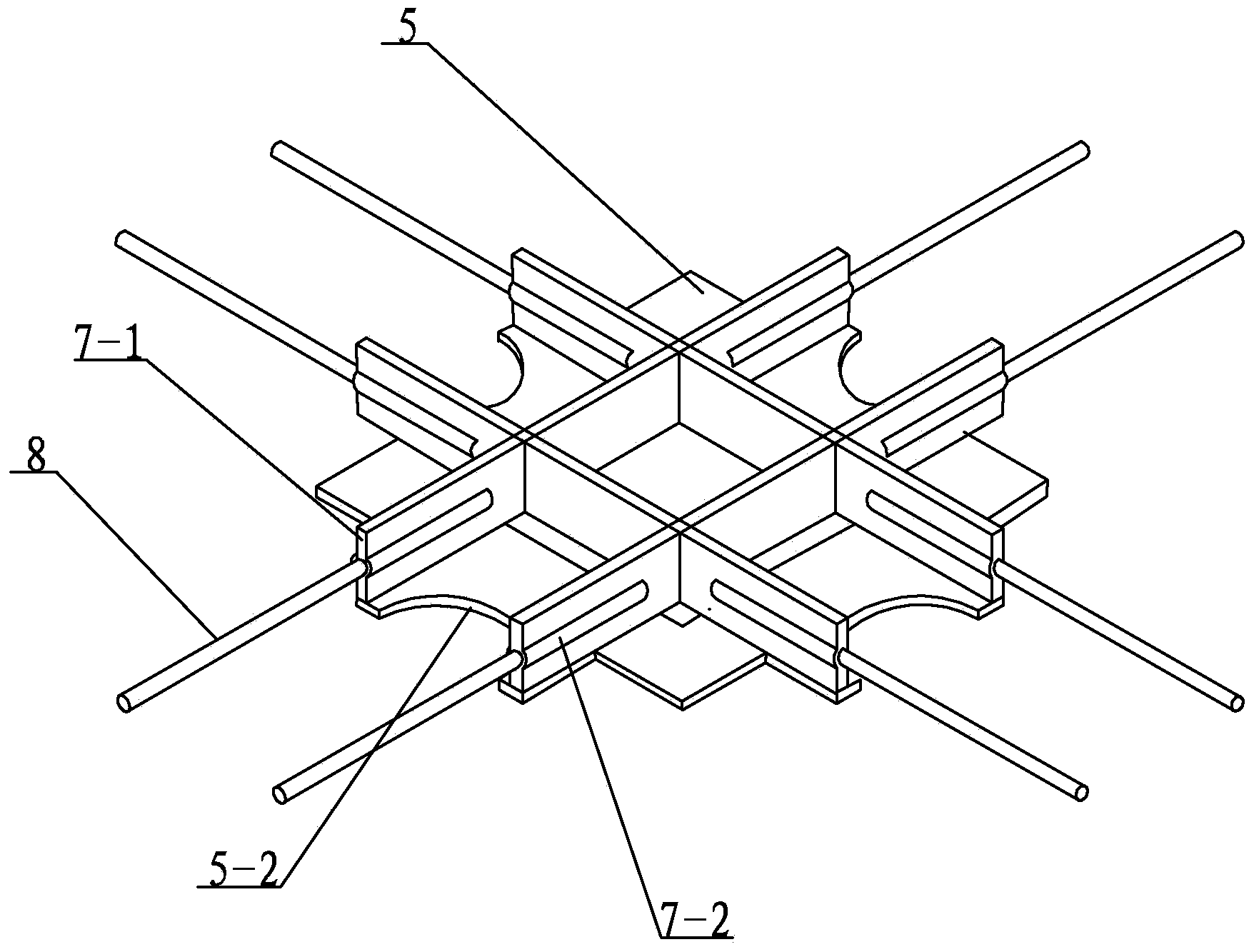

[0020] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, each node area inserting plate 7 in this embodiment includes a plate body 7-1 and two threaded circular sleeves 7-2, and two ends of the plate body 7-1 are respectively provided with a belt There is a threaded circular sleeve 7-2, and the threaded circular sleeve 7-2 is arranged along the length direction of the plate body 7-1. Such setting facilitates the connection between the threaded circular sleeve 7-2 and the steel bar 8, facilitates the connection at the construction site, and speeds up the construction. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, each node area inserting plate 7 of this embodiment is connected to a steel bar 8 through threads. So set, easy to install and disassemble. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com