3d printing process and concrete combined building structure and construction method

A technology of concrete combination and 3D printing, which is applied in building structure, building components, construction, etc., can solve the problems of difficult construction, uneven force, troublesome construction, etc., so as to save construction time and cost, improve distribution and Strength needs, effect of steps to save formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

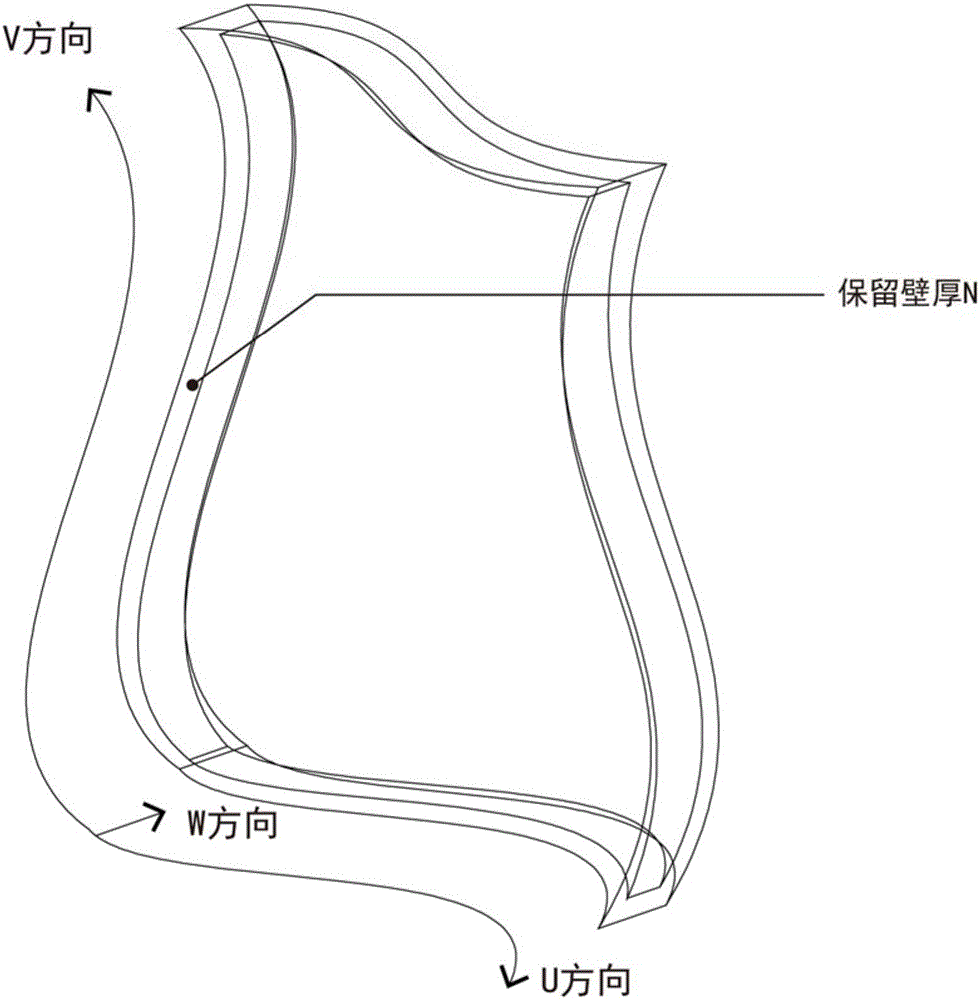

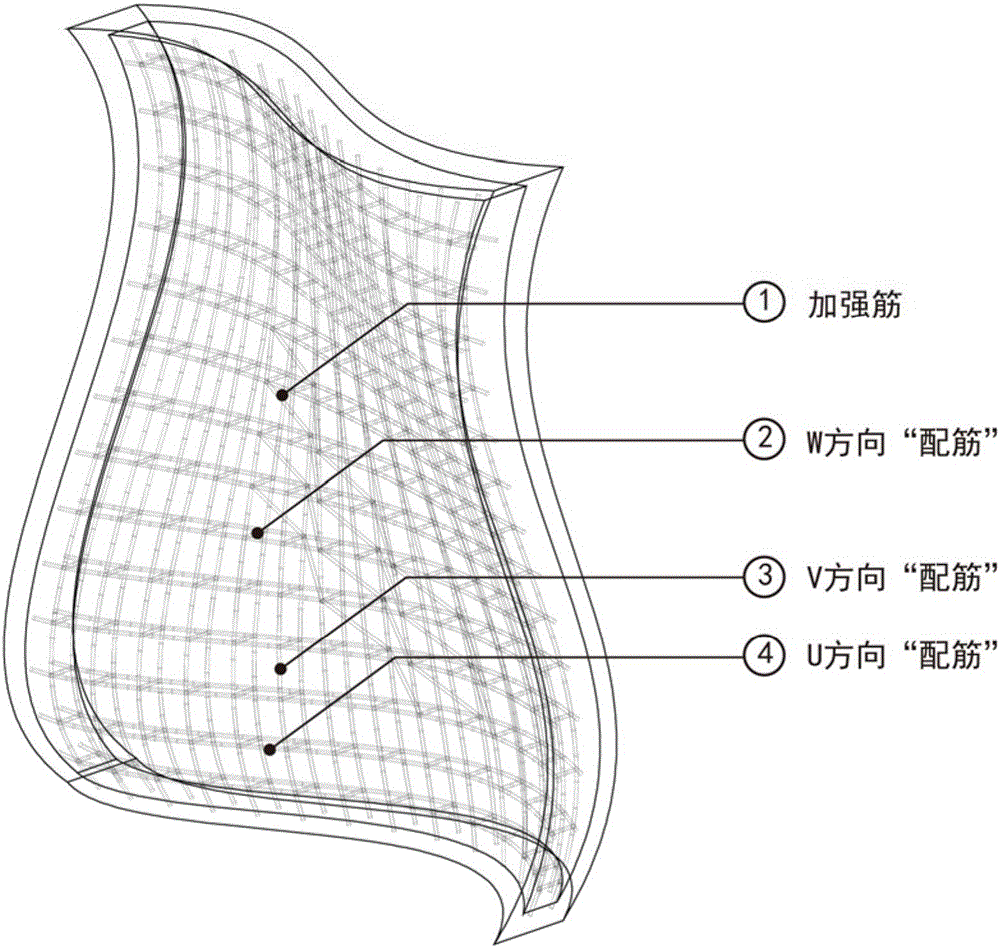

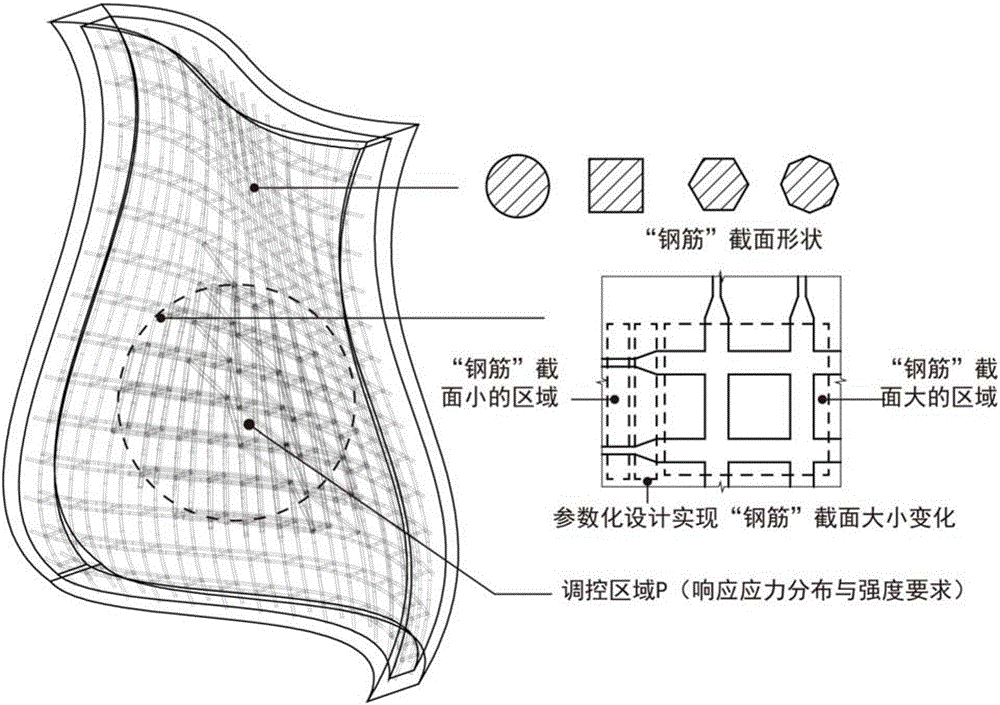

[0032] The building structure and construction method combined with 3D printing technology and concrete described in the present invention are suitable for building components of any shape, specifically, using 3D printing technology to make a "template" shell and "reinforcement" internal structure integrated integral hollow components, and then The construction and construction of building components by pouring concrete can effectively solve the difficult problem of making steel bars in the construction of special-shaped curved reinforced concrete. The force transmission is clear, and the construction components are reduced, the construction procedure is simplified, and the construction cost is saved.

[0033] Below we take the complex hyperboloid component as an example to illustrate the building structure and construction method of the present invention. The node structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com