Node of steel tube concrete pole and steel reinforced concrete beam and processing method thereof

A technology for reinforced concrete beams and CFST columns, which is applied to the joint structure of CFST columns and reinforced concrete beams and their construction fields, can solve problems such as the inability to adopt the joint form with ring beams, reduce welding workload, and ensure welding The effect of seam quality and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

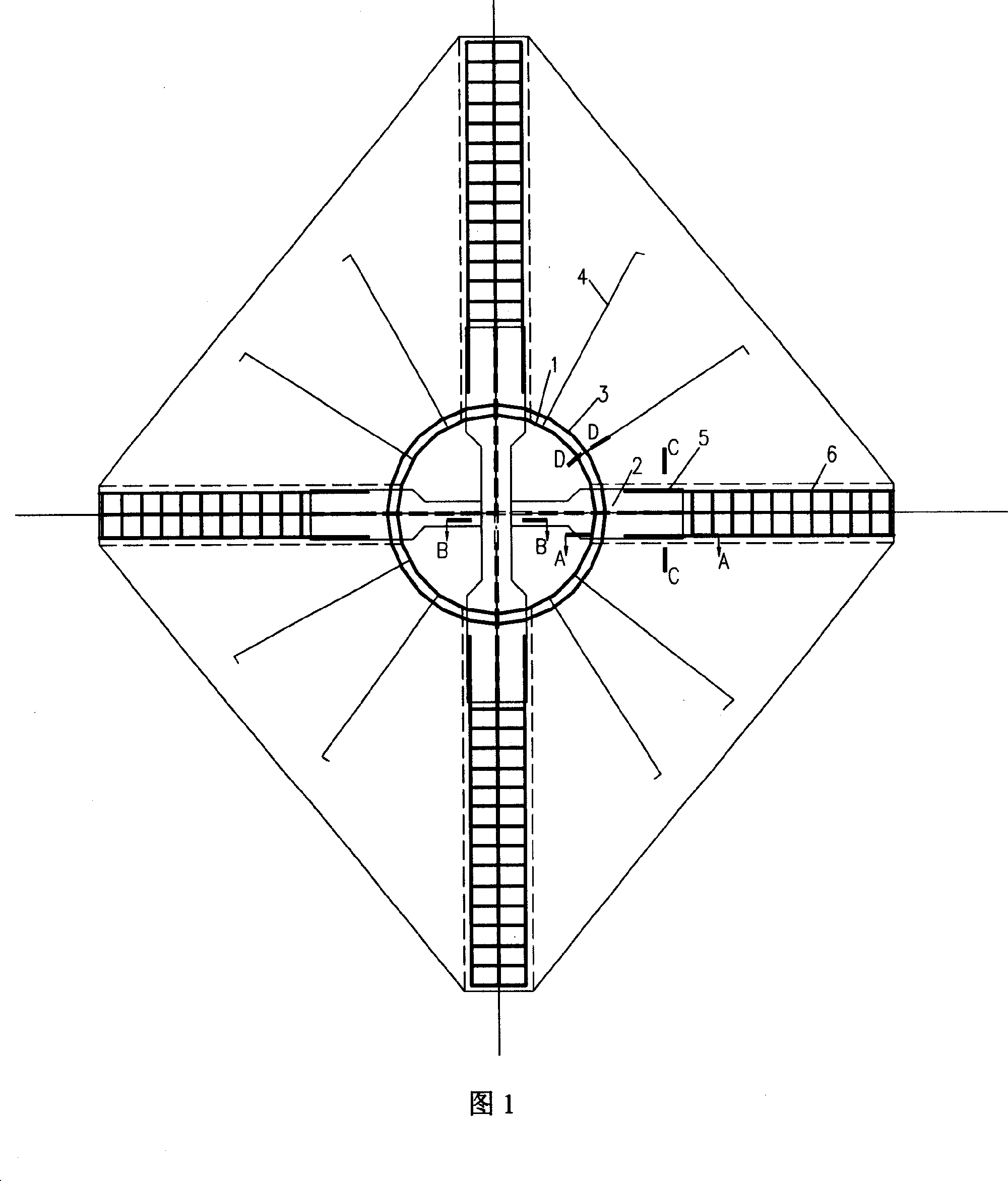

[0025] Fig. 1 is the specific structural diagram of the joint structure of the concrete-filled steel pipe column and the reinforced concrete beam. 4. Beam main reinforcement thread sleeve 5, beam main reinforcement 6. 4 I-shaped dark piercing steel corbels 2 pass through the steel pipe 1 and intersect and weld in the pipe, the ring reinforcement 3 is welded on the upper flange of the steel corbel 2, and 7 plates The surface radial ribs 4 are evenly distributed between the beams and extend to the bottom of the floor slab; the double-sided fillet welds of the threaded sleeve 5 are welded to the flange at the upper end of the steel corbel, and are on a straight line with the main ribs 6 of the beam.

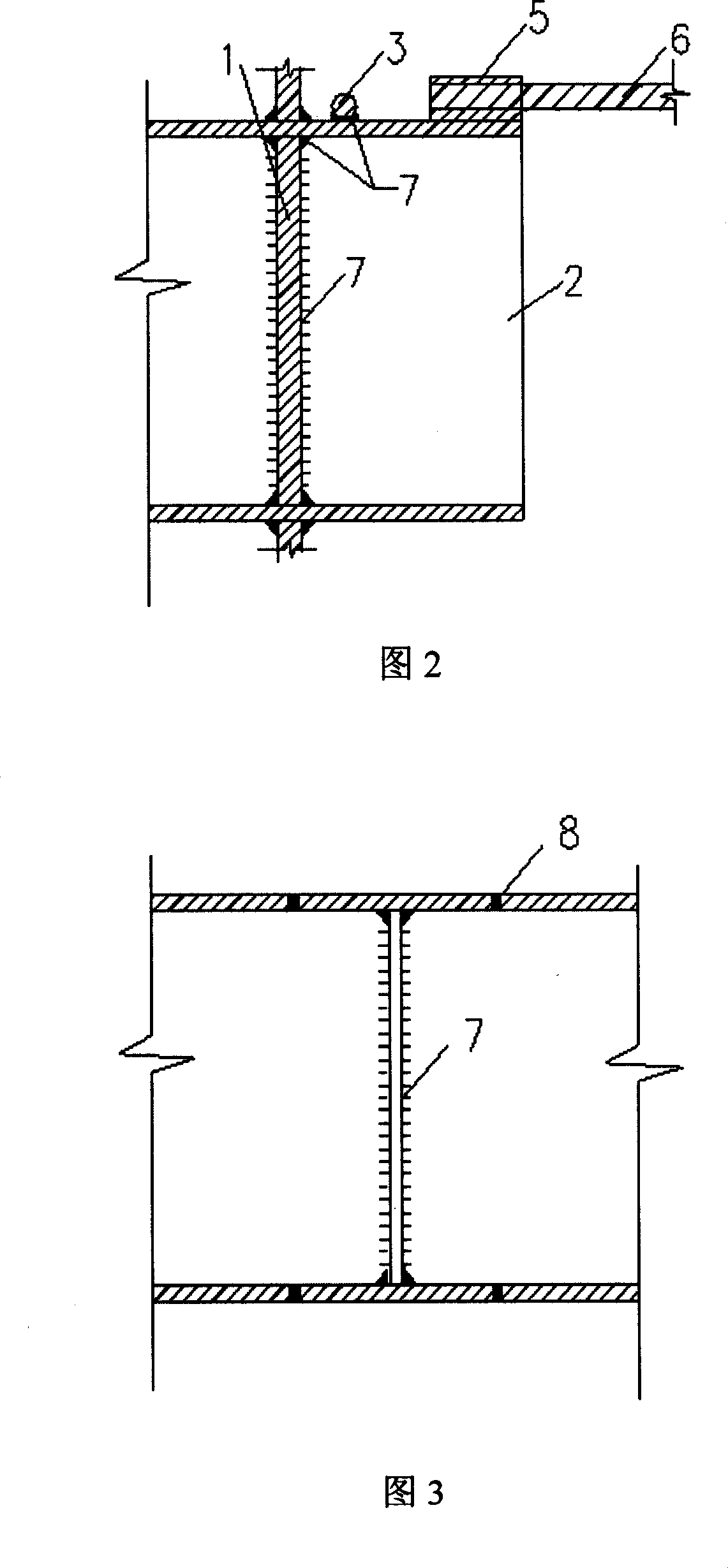

[0026] Fig. 2 is a cross-sectional view of the connection relationship between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com