Stable collet chuck structure and machine tool applying same

A stable, collet technology, used in clamping, positioning devices, metal processing machinery parts, etc., can solve the problems of easy tool vibration and reduced machining accuracy, reduce overhang length, improve stability, and improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

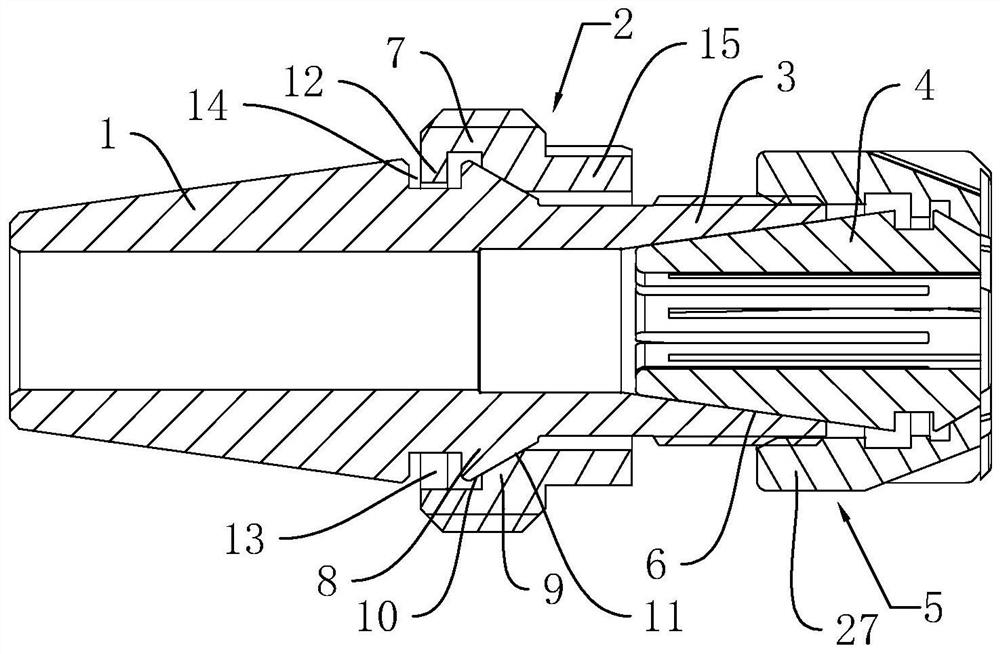

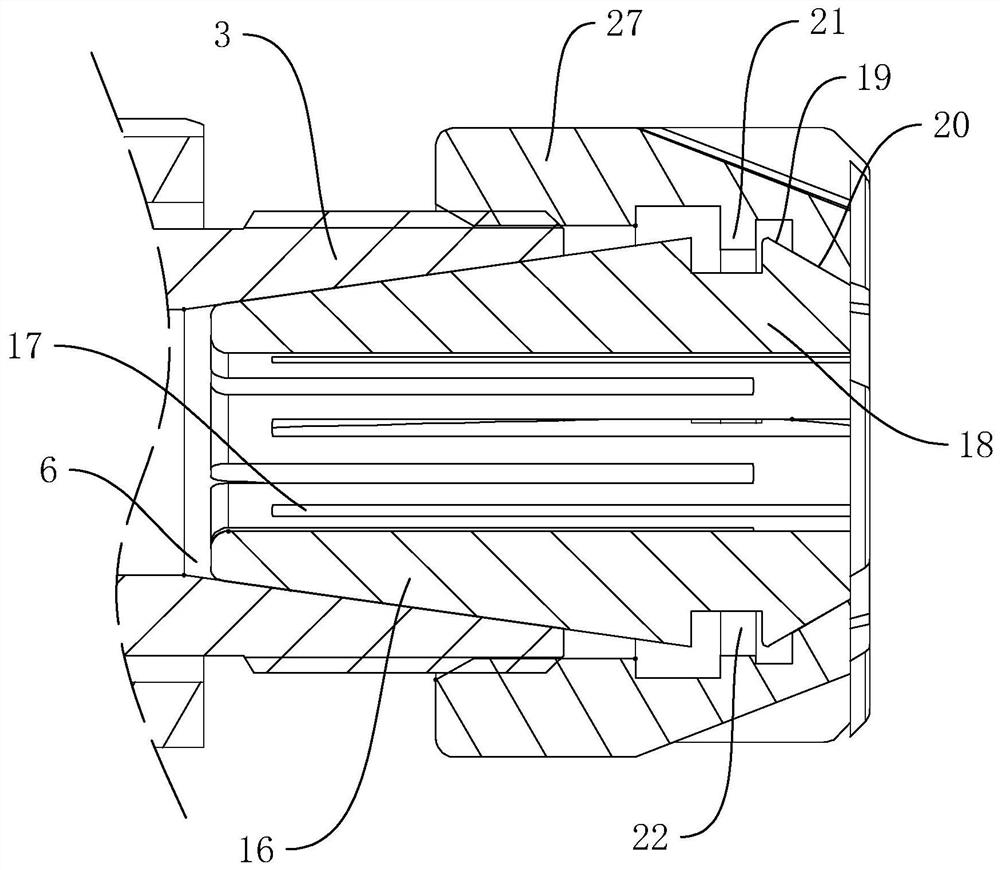

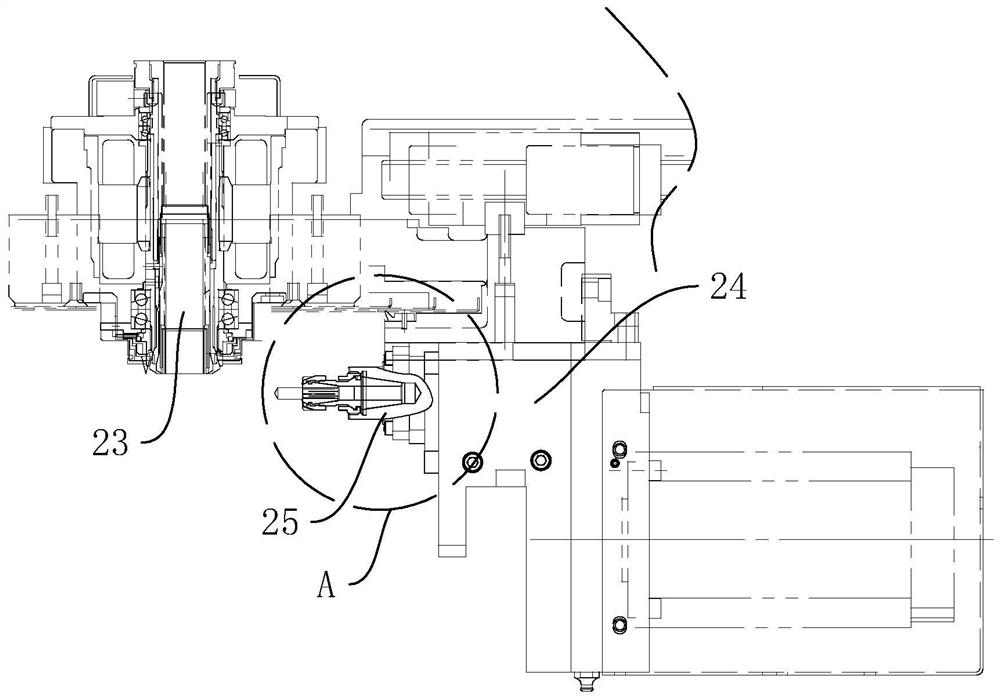

[0035] The following is attached Figure 1-4 The application is described in further detail.

[0036] The embodiment of the present application discloses a stable collet structure. refer to figure 1 and figure 2 , the structure includes a conical taper shank 1, a connecting rod 3 integrally connected to the large-diameter end of the taper shank 1, a collet 4 pierced in the connecting rod 3, wherein the connecting rod 3 is cylindrical, and the taper shank 1, connecting The rod 3 and the collet 4 are coaxial, and a through channel is opened along the axis of the three, and the tool is passed through the channel. The structure also includes a connecting piece 2 connected to the large-diameter end of the taper shank 1 and a locking piece 5 connected to the end of the connecting rod 3. The connecting piece 2 is used to fix the taper shank 1 to the mounting part of the machine tool, and the locking piece 5 is used for To connect the collet 4 to the connecting rod 3.

[0037] r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com