Automatic feeding and discharging vehicle for freeze-dried line

A freeze-drying line and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increased manufacturing and production costs, increased time costs, and reduced production efficiency, so as to prevent bending deformation and omit compensation for position deviation , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

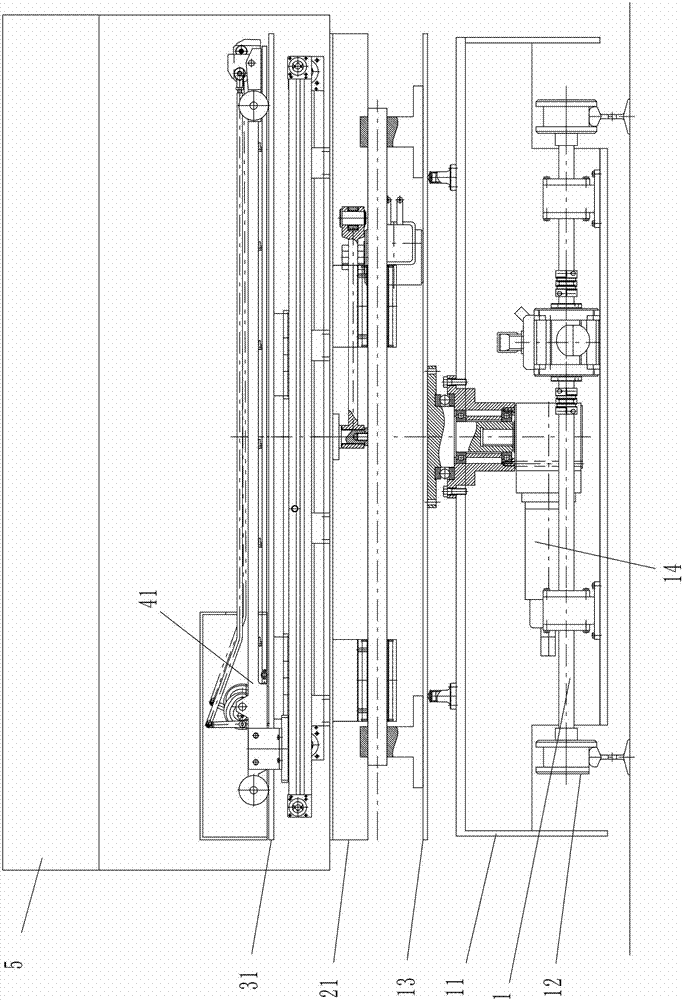

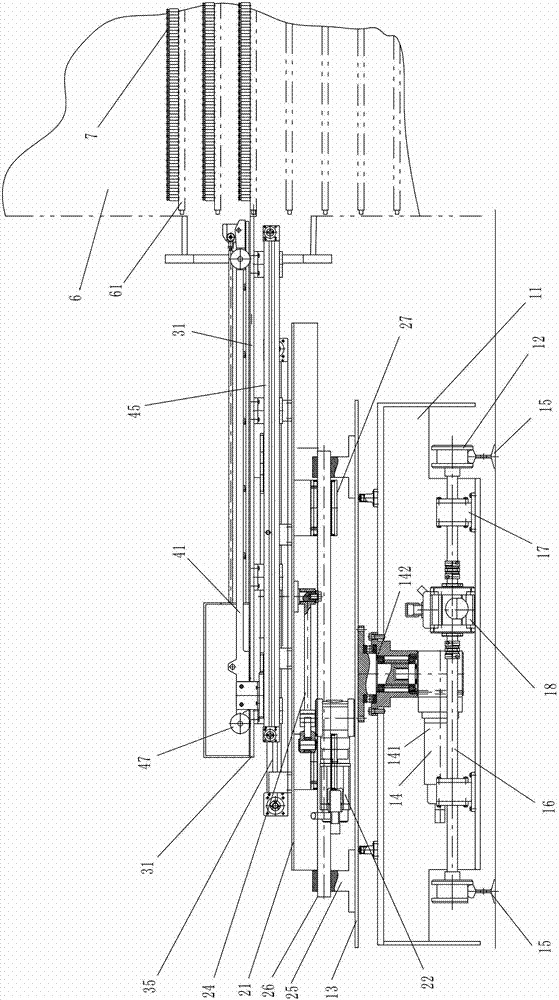

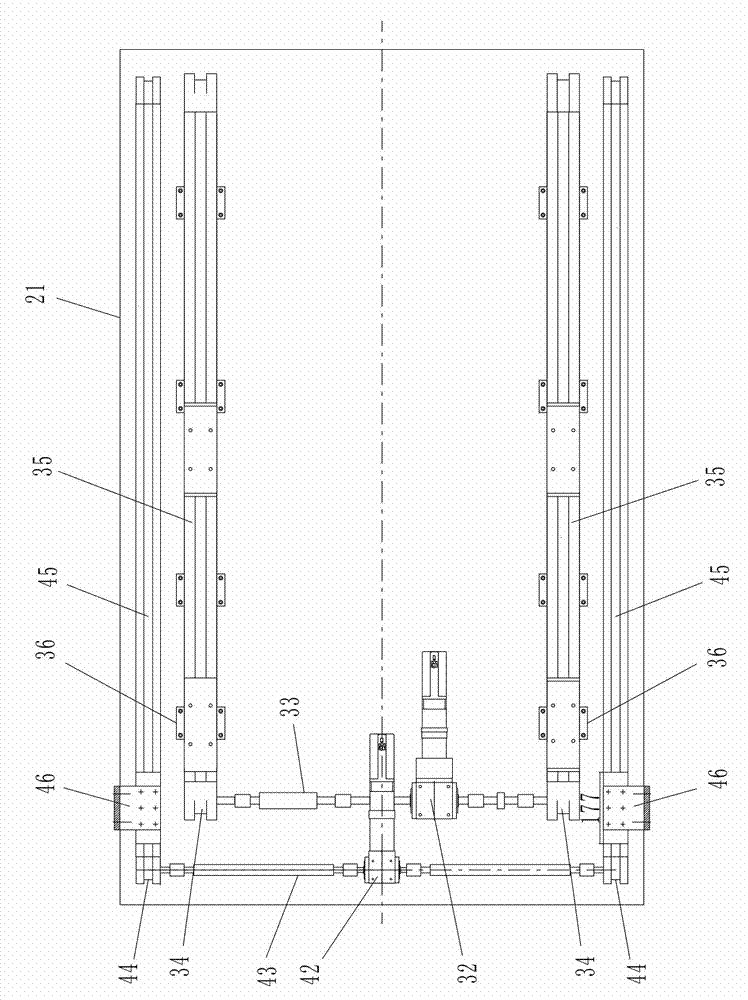

[0024] Such as figure 1 and figure 2 As shown, the automatic loading and unloading vehicle used on the freeze-drying line in this embodiment includes a walking assembly 1, a bottle collecting platform 31 and a lateral movement unit. To move, the bottle collecting platform 31 is connected to the transverse movement unit and can move linearly relative to the transverse movement unit along the moving direction of the transverse movement unit. Such as figure 2 As shown, when the bottle-collecting platen 31 is docked with the freeze-dryer plate 61, the horizontal movement unit can first move the bottle-collecting platen 31 laterally for a certain distance to get close to the freeze-dryer plate 61, and then move the set The bottle table 31 makes the bottle collection table 31 dock with the lyophilizer plate 61; in this way, the overhan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com