Double-core plug shell assembly and double-core plug

A plug housing and component technology, applied in the field of dual-core plug housing components and dual-core plugs, can solve the problems of error-prone, inconvenient polarity conversion of duplex connectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0049] The double-core plug of the present invention is used for inserting and matching with the adapter in the front and back direction, so as to realize the connection transmission of the optical fiber signal.

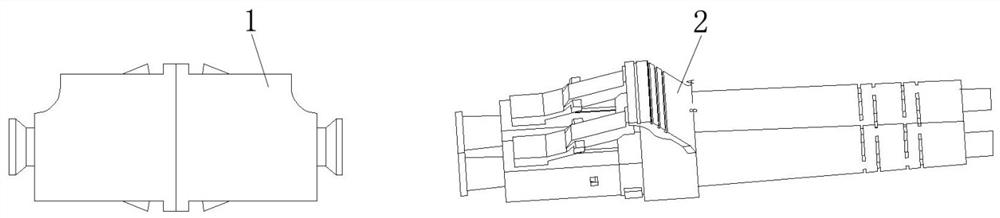

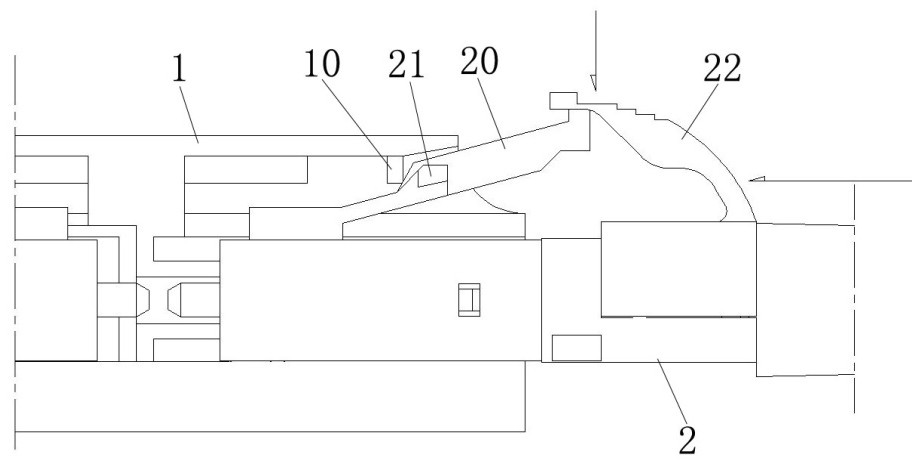

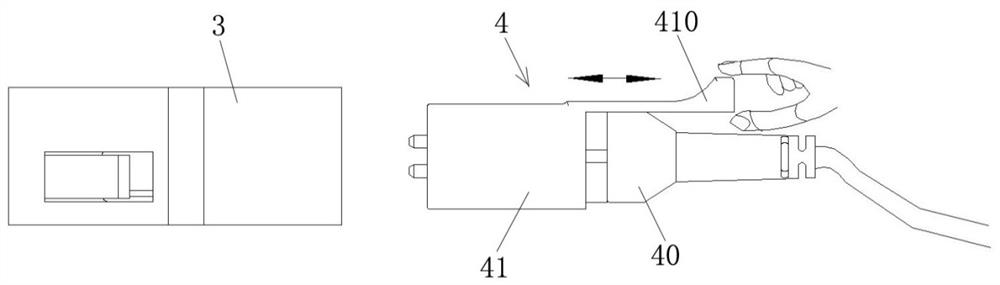

[0050] In this example, if image 3 , Figure 4 , Figure 7 , Figure 9 and Figure 10 As shown, the double-core plug includes a plug housing assembly 4 and an optical fiber extending into the plug housing assembly 4. The plug housing assembly 4 includes an inner housing 40 and an outer housing 41, and the inner housing 40 is fixed with a plug inner housing. There are two plug-in cores, and the optical fiber extends into the inner housing 40 from the rear end and is connected to the rear end of the corresponding plug-in inner core, so as to realize the connection between the optical fiber and the plug housing assembly 4 . The front end of the plug-in inner core is exposed from the front end of the inner housing 40 to form a plug-in end for plugging and mating wit...

specific Embodiment 2

[0069] The difference between it and the specific embodiment 1 is that there is only one plug-in position in the adapter housing adapted to the double-pin plug in this embodiment, that is, one adapter housing is mated with a double-pin plug, and the double-pin plug On the inner housing, the locking claw is arranged on the outer wall corresponding to the long side of the rectangular inner housing, and the corresponding hollow slot is arranged on the outer wall corresponding to the long side of the rectangular outer housing. The positions of the hollowed-out slots are corresponding.

specific Embodiment 3

[0071] The difference from the first embodiment is that only the upper side wall of the inner casing is provided with locking claws and elastic hooks, the lower side wall is not provided with locking claws and elastic hooks, and the locking elastics on the upper side wall The claws cooperate with the bayonet on the upper side of the adapter housing to realize the locking fit between the double-core plug and the adapter, and the resisting bosses and guiding protrusions on the adapter housing corresponding to the lower side wall of the inner housing are continuously arranged in the front and rear directions. That is, no bayonet is provided between the resisting boss on the lower side of the adapter housing and the guiding protrusion.

[0072] In other embodiments, only the locking claws and elastic hooks are provided on the lower side wall of the inner housing, and the upper side wall is not provided with locking claws and elastic hooks, which correspond to the upper side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com