Telescopic cloth hanging trolley and cloth hanging control method

A cloth hanging trolley and telescopic technology, which is used in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problem of increasing the manufacturing cost of construction equipment, the poor versatility of the hanging cloth trolley, and the difficulty of changing the field of the hanging cloth trolley. and other problems, to achieve the effect of reducing the difficulty of transition, high construction efficiency and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

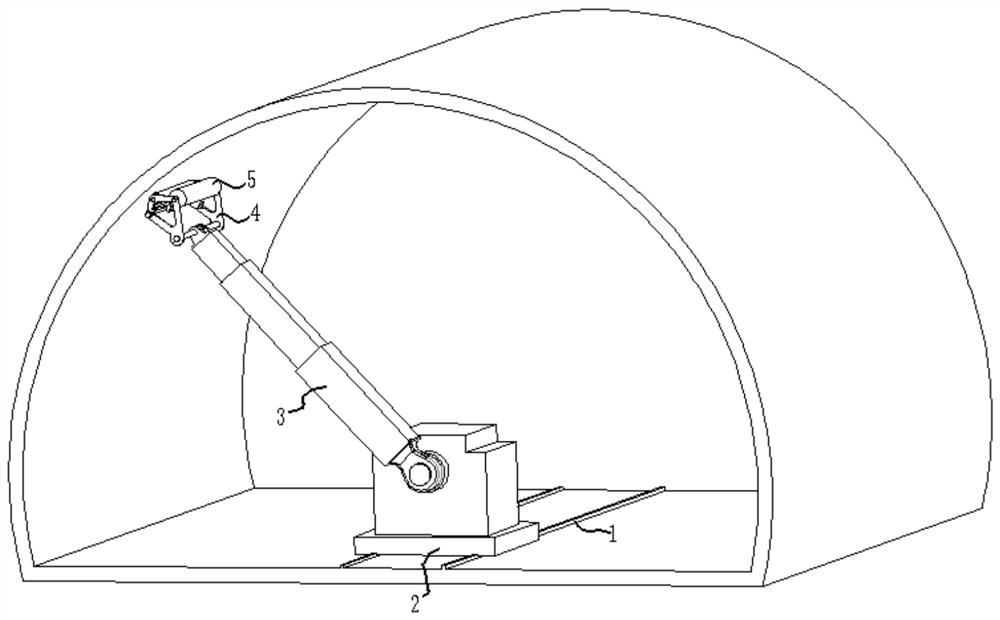

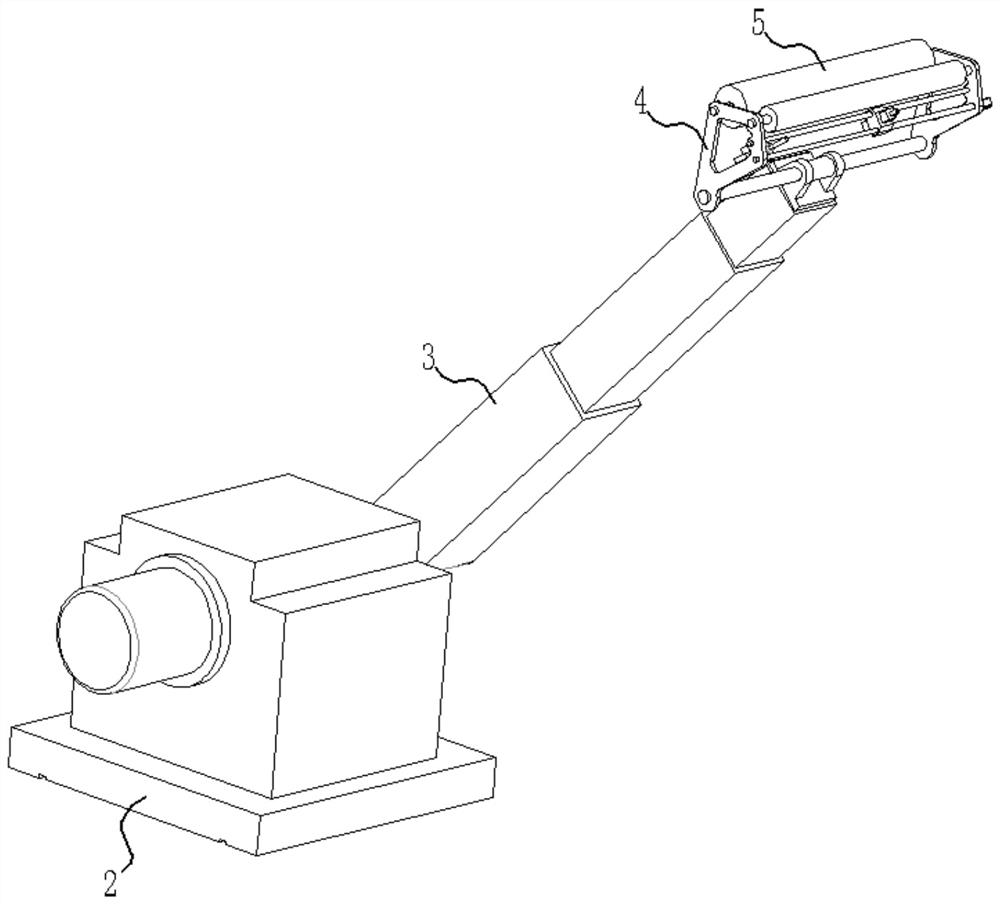

[0033] A telescopic type valance vehicle, such as figure 1 Shown, a foldable cloth hanging carriage, such as figure 1 It is shown, comprising a chassis 2 for traveling in a tunnel. Generally in the tunnel are laying rails 1, 2 is provided with the chassis thus is driven by the travel motor running wheels, running wheels can be run along the rail 1, by means of a moving track. So Puwan a tarpaulin, the chassis 2 is moved some distance, then the tunnel cloth hanging operation surface of the lower section of the arch. Base is articulated telescopic arm 3, the telescopic arm 3 is connected with a cloth hanging frame 4. Specifically, the chassis 2 is fixed with the arm motor, the boom after the motor gear reducer, controlled by the control system enables the telescopic arm 3 rotates in the cross-sectional surface of the tunnel arch.

[0034] Such as figure 2 , In the present embodiment, the telescopic arm 3 is three telescopic boom sections, three sections in telescopic boom equipped w...

Embodiment 2

[0043] The technical solution in Example 1 is suitable for use in a tunnel having a circular arc shape or near the arc shape, and the diaplashes of many tunnels are combined with a plurality of different curvatures, with arc arch There is also an elliptical arc arch and a parabolic zone. For the large-length zone, the feedback control cycle of the control system in Example 1 is increased, resulting in a decrease in construction efficiency.

[0044] The arch faces of each tunnel have a rule of the arch curve, and the arch curve can be expressed in the form of a polar coordinate. Therefore, in the present embodiment, it is different from that of the first embodiment: the arm motor is a servo motor, and the servo motor can rotate the arrow angle of the three telescopic arms under the control of the control system. The two cylinders in the three telescopic arms are servo cylinders, and the servo cylinders drive three telescopic arms lower telescopic under the control of the control sy...

Embodiment 3

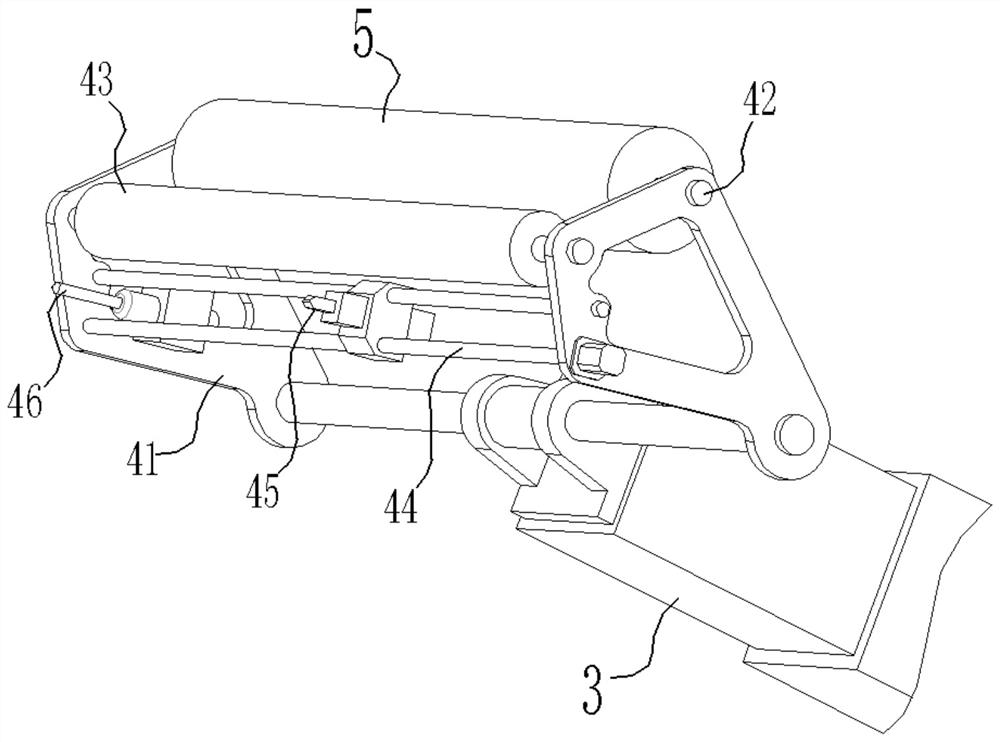

[0050] Unlike Example 2, in the present embodiment, the arm motor is a normal motor, and the two cylinders in the three telescopic arms are also ordinary cylinders. Since there is no servo system, this adjustment can reduce the procurement cost of the motor, cylinder, and control system. In addition, if Image 6 As shown, the hanging arrangement 4 is hinged to the telescopic arm 3, and the electric telescopic rod 6 is hinged between the hanging arrangement frame 4 and the telescopic arm 3, and the telescoping of the electric telescopic rod 6 is controlled by the control system. The hanging arrangement 4 is hinged to the telescopic arm 3, which increases a rotational degree of freedom to the hanging arrangement 4, and the distance between the pressure roller 43 and the inner wall of the tunnel, and the pressure of the pressure roller 43 on the inner wall of the tunnel can pass the electric telescopic rod. 6 is adjusted.

[0051] Specifically, when there is a pit in the tunnel arch s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com