Efficient milling process method of split type receiver

A process method and milling technology, which are applied in the field of high-efficiency milling processing of split casings, can solve the problems of low cutting speed and feed, large cutting depth, large processing deformation, etc., so as to reduce tool cost and improve processing. Efficient, efficient milling results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

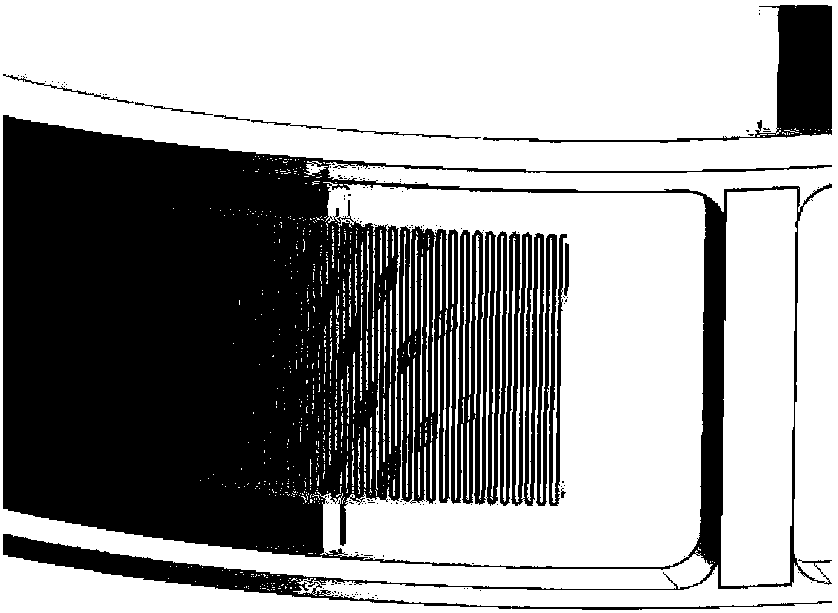

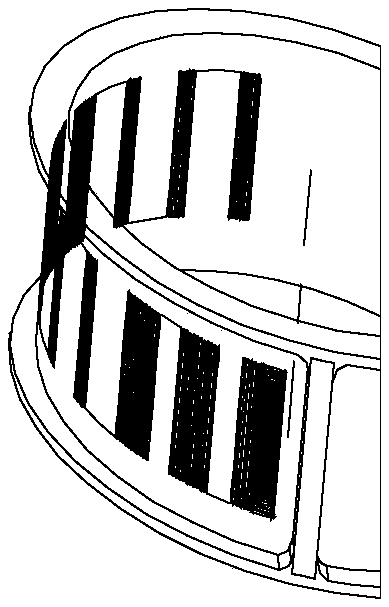

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0024] The present invention is a high-efficiency milling process method for a split casing, which adopts the cycloidal milling tool path, and the steps are as follows:

[0025] Efficient milling tool path planning;

[0026] Cutting parameters are optimized by adopting large cutting depth, small cutting width and fast feed speed.

[0027] Efficient milling toolpath planning includes:

[0028] Select the tool path of helical feed and cycloid opening pre-processing groove;

[0029] Select the cycloid reciprocating tool path;

[0030] Arc transitions are used between cycloids to avoid right-angle turns.

[0031] Optimize cutting parameters to include:

[0032] Linear speed, 100~120m / min;

[0033] Cutting depth, 25~30mm;

[0034] Cutting width, 0.3~0.5mm;

[0035] Feed rate, 500~800mm / min.

[0036] In this embodiment, the trochoidal milling too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com