Tool for machining oil injection ring and method for machining oil injection ring through tool

A technology of oil injection ring and tooling, which is applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc. It can solve the problems of low processing efficiency and inability to guarantee the dimensional accuracy of processing parts, so as to improve product quality, speed up production progress, Effect of Optimizing Cutting Parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

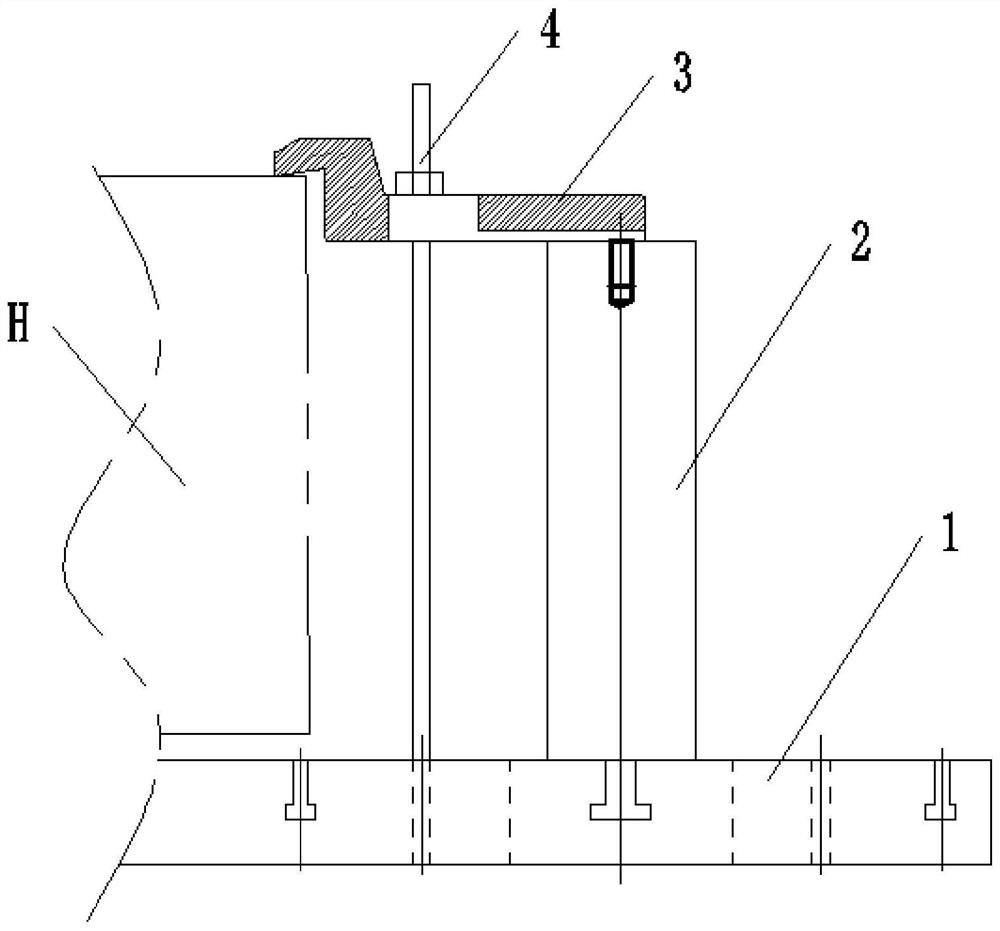

[0022] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a tooling for a gas turbine fuel injection ring in this embodiment, which includes a base 1, a plurality of stepped support columns 2, a plurality of movable bending plates 3 and a plurality of connecting assemblies 4,

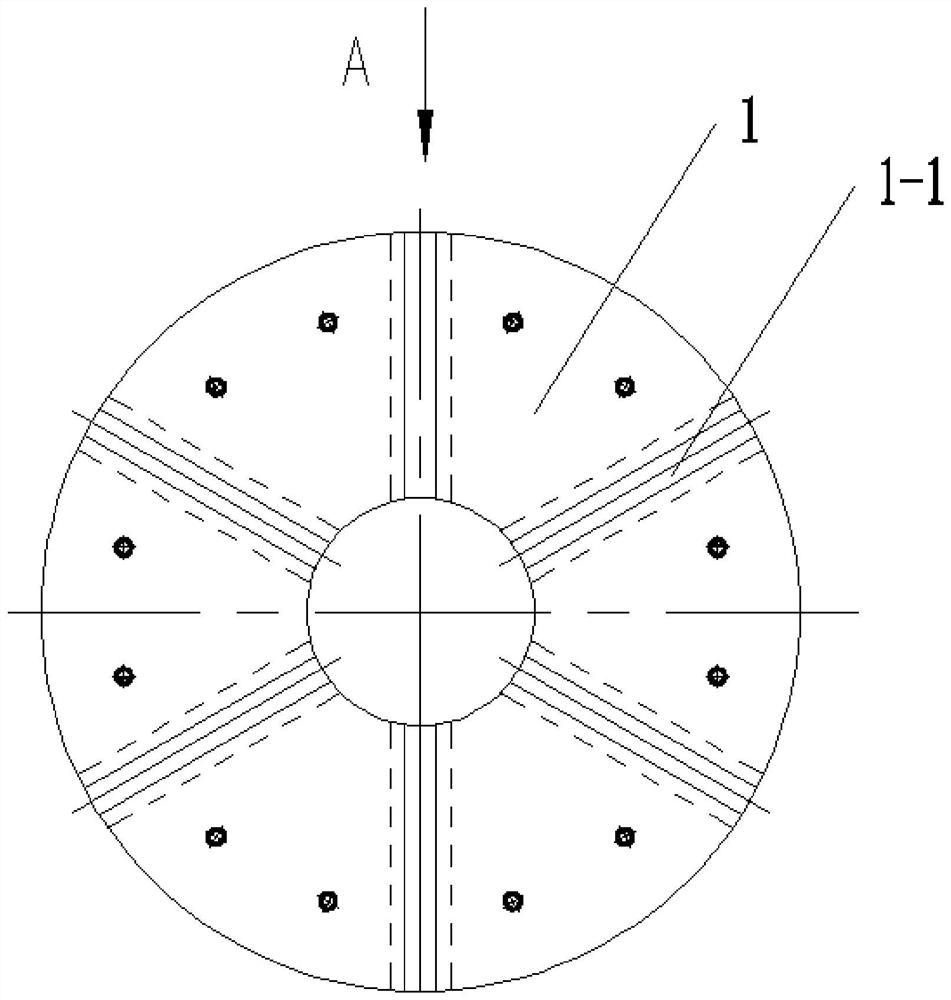

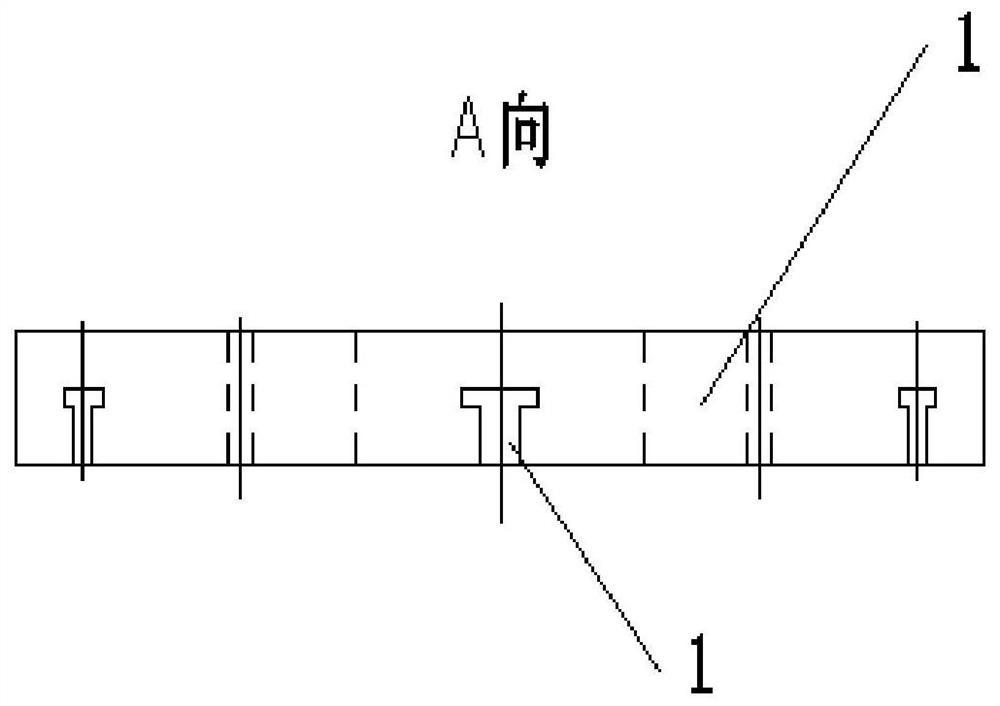

[0023] The base 1 is a disc-shaped seat, and a plurality of inverted T-shaped grooves 1-1 are provided in the form of a circular array on the base 1, and a stepped support column 2 is slidably installed in each inverted T-shaped groove 1-1. The oil ring H is coaxially installed on the base 1, and a plurality of movable bending plates 3 are press-fitted on the upper end surface of the oil injection ring H and the upper end surface of the stepped support column 2, and the movable bending plate 3 and the base 1 are connected by Component 4 is detachably connected.

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 with Figure 4 This embodiment will be described. The number of inverted T-shaped grooves 1-1 in this embodiment is six. Such setting facilitates clamping according to the actual size of the fuel injection ring. In addition, the use of six inverted T-shaped grooves 1-1 can satisfy the symmetry and precision of clamping. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 with Figure 5 To illustrate this embodiment, the mobile bending plate 3 of this embodiment includes a main clamping section 3-1 and an auxiliary clamping section 3-2, and the auxiliary clamping section 3-2 is fixedly installed on the left end of the main clamping section 3-1. And the clamping surface of the main clamping section 3-1 is lower than the clamping surface of the auxiliary clamping section 3-2. Such arrangement facilitates the firmness of the clamping. Other compositions and connections are the same as those in Embodiment 1

[0026] The function of the bottom plate with grooves in this embodiment: the base plays the role of a bond connecting the stepped support column with the workbench. The design of the dovetail groove of the base is mainly to fix the supporting column and the bolt with groove, and increase the stability of the supporting column and the bolt.

[0027] The function of tooling: thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com