Ethylene glycol water solution sealing liquid for hydraulic pressure safety valve of oil storing tank

A technology of sealing liquid and ethylene glycol, which is applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve problems such as difficulty in timely grasping the height of sealing liquid, blocking the gas channel of the oil storage tank, and loss of safe operation of the oil storage tank, etc., to achieve It is beneficial to the maintenance of industrial hygiene, reduces labor intensity, and is easy to wipe clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

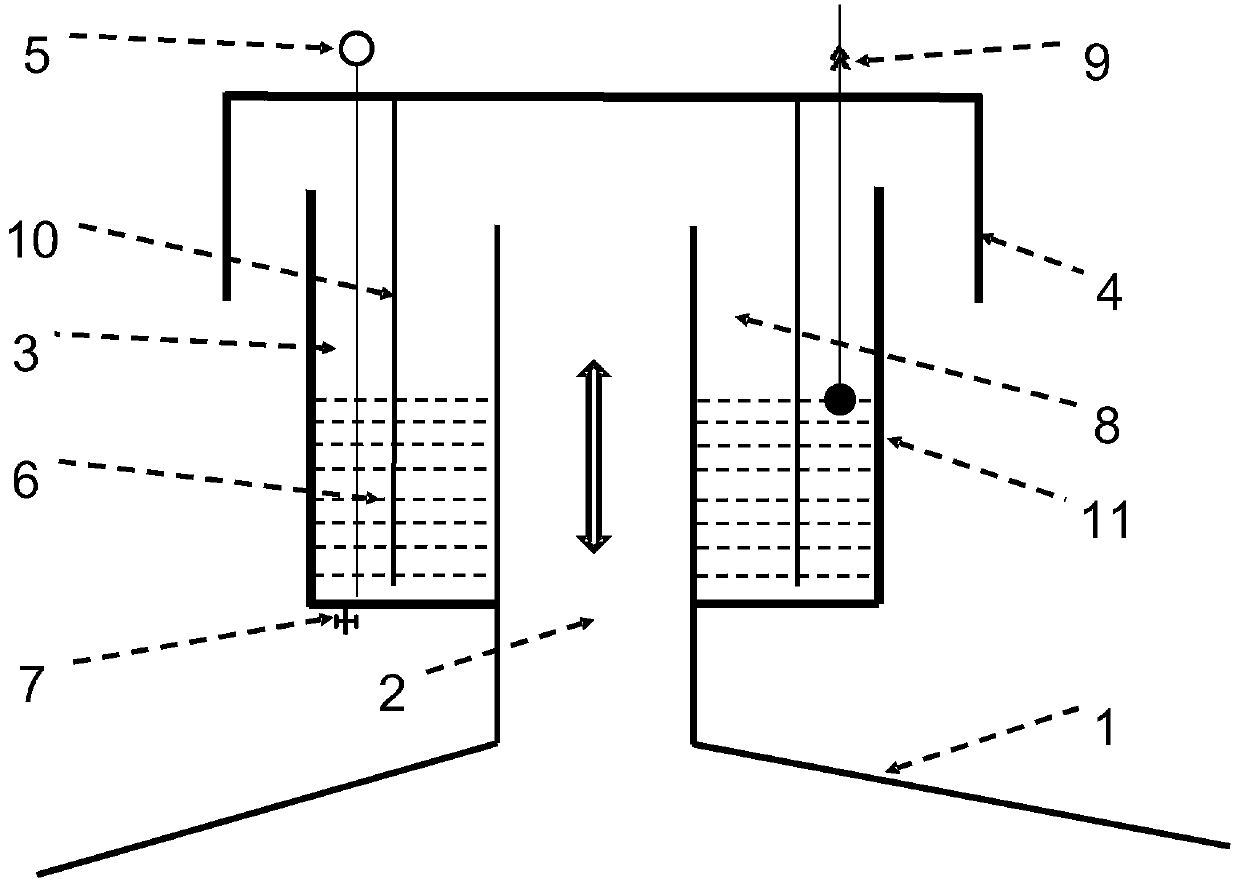

[0026] In conjunction with the accompanying drawings, the use method and principle of the present invention are described

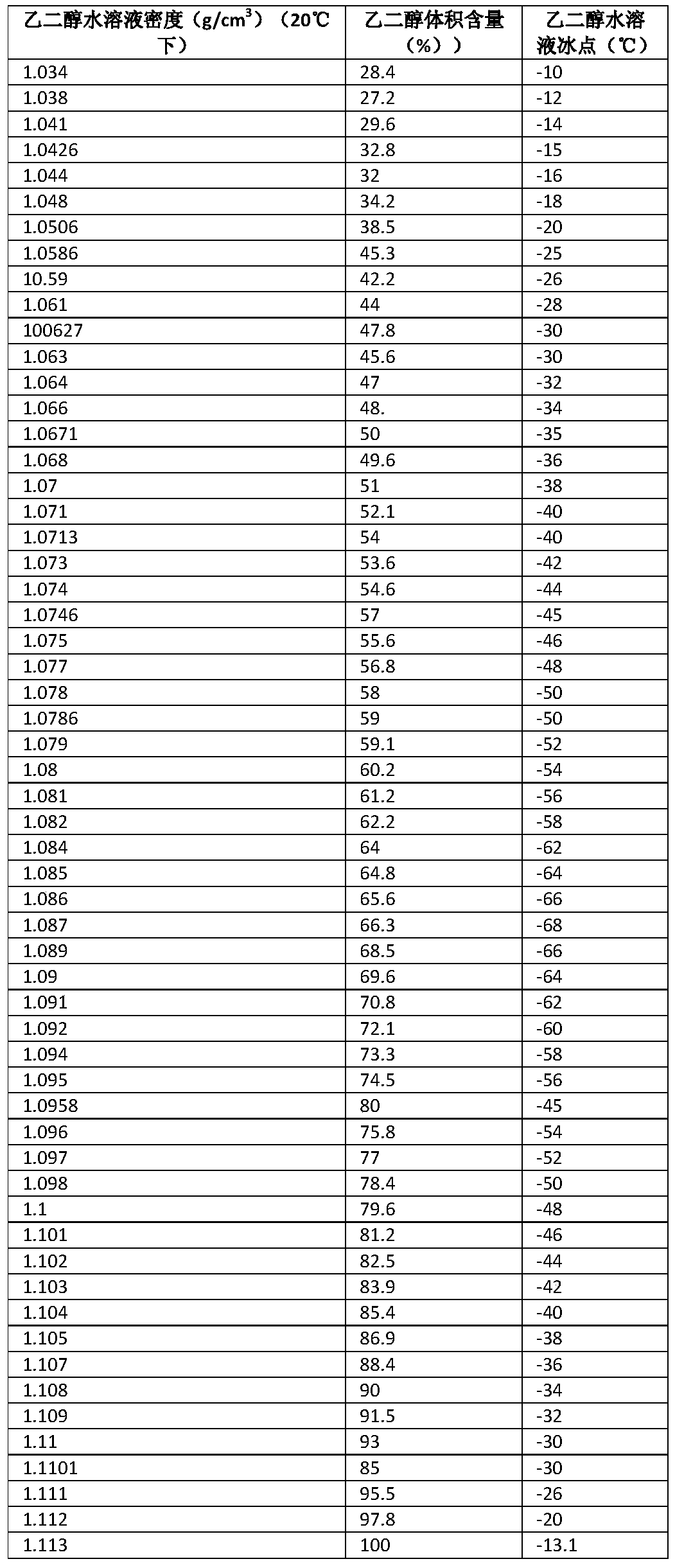

[0027] For example, the lowest temperature in winter in a certain place is -25°C, and the freezing point of the sealing fluid should be set at about -35°C. By checking the freezing point comparison table of aqueous solutions of different concentrations of ethylene glycol, the volume concentration of ethylene glycol is 50% at -35°C. From this, it can be easily obtained that the ratio of ethylene glycol and clear water in the sealing liquid is 50%:50%. (Due to different laboratory conditions, there are slight differences in the correspondence between the concentration of ethylene glycol aqueous solution and the freezing point, but it does not affect the use. When using it, the lowest freezing point of the ethylene glycol aqueous solution can be lowered to -1°C according to the local actual situation)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com