An Optimum Method for Up-and-Up Milling of Carbon Fiber Composite Materials

A composite material and carbon fiber technology, applied in metal processing equipment, cutting tools for milling machines, workpieces, etc., can solve the problem of low surface roughness and delamination damage, without in-depth analysis of the essential influence of milling methods on processing quality, and has not yet formed an optimal solution Principles and methods, etc., to achieve high-precision milling, good engineering application prospects, and simple calculation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

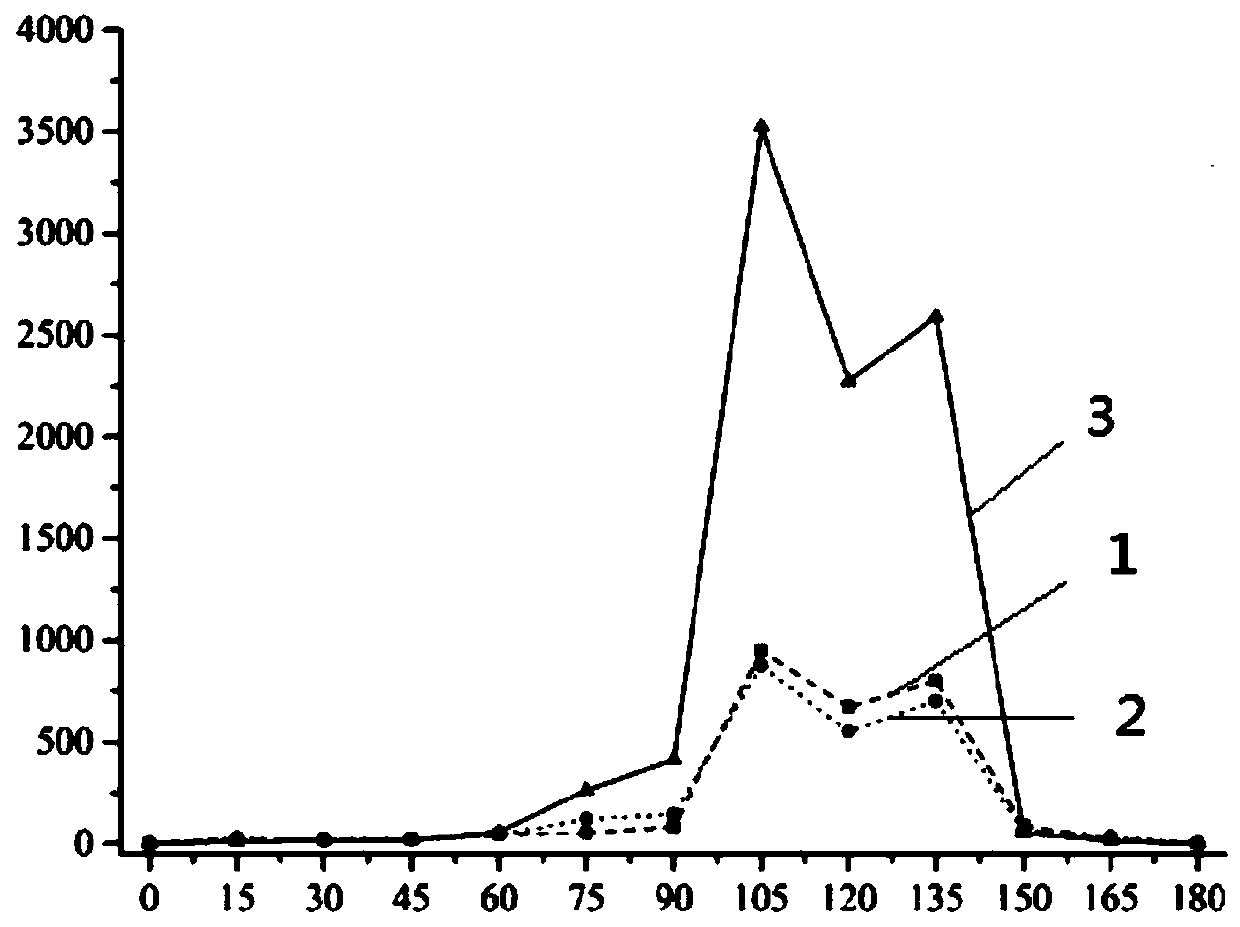

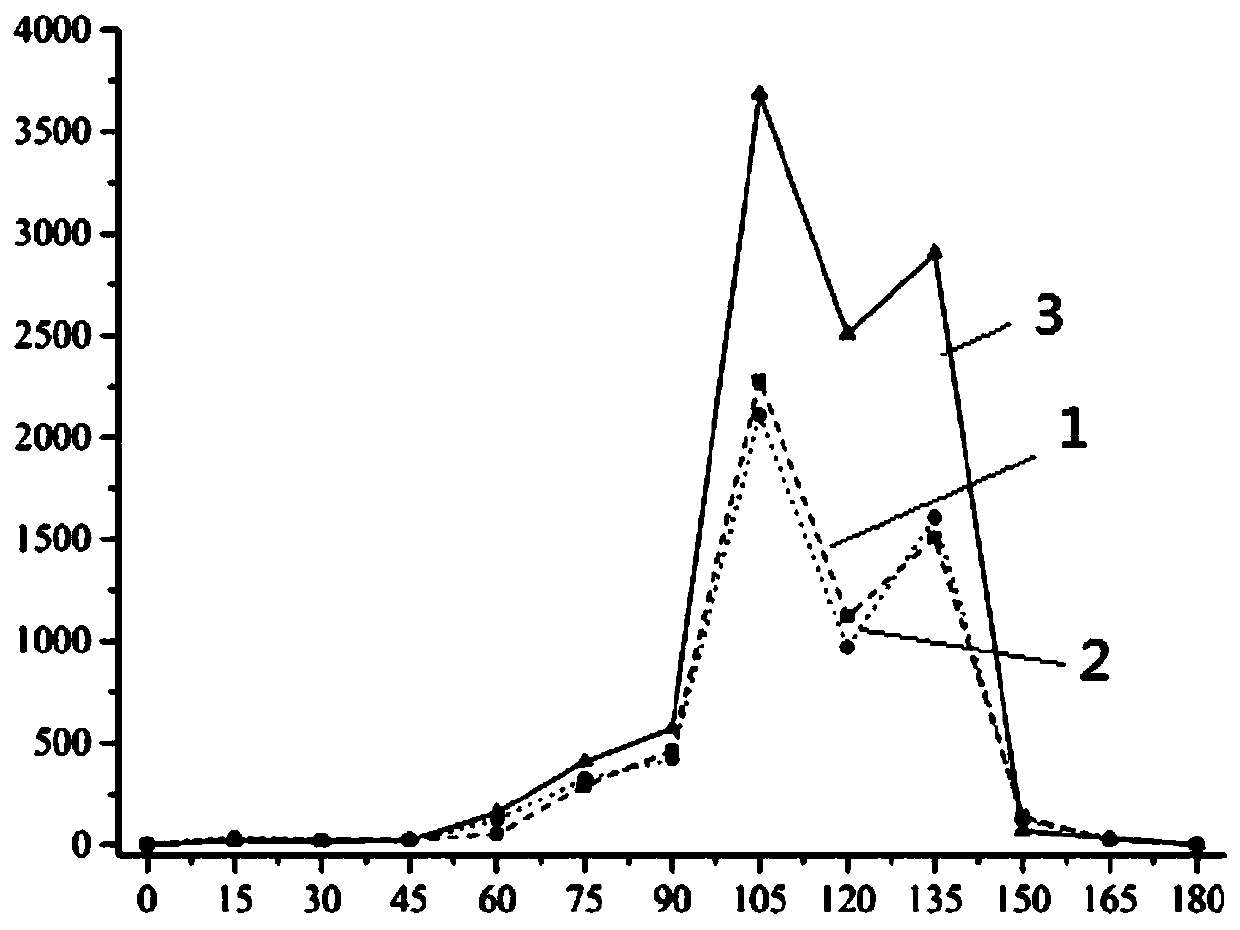

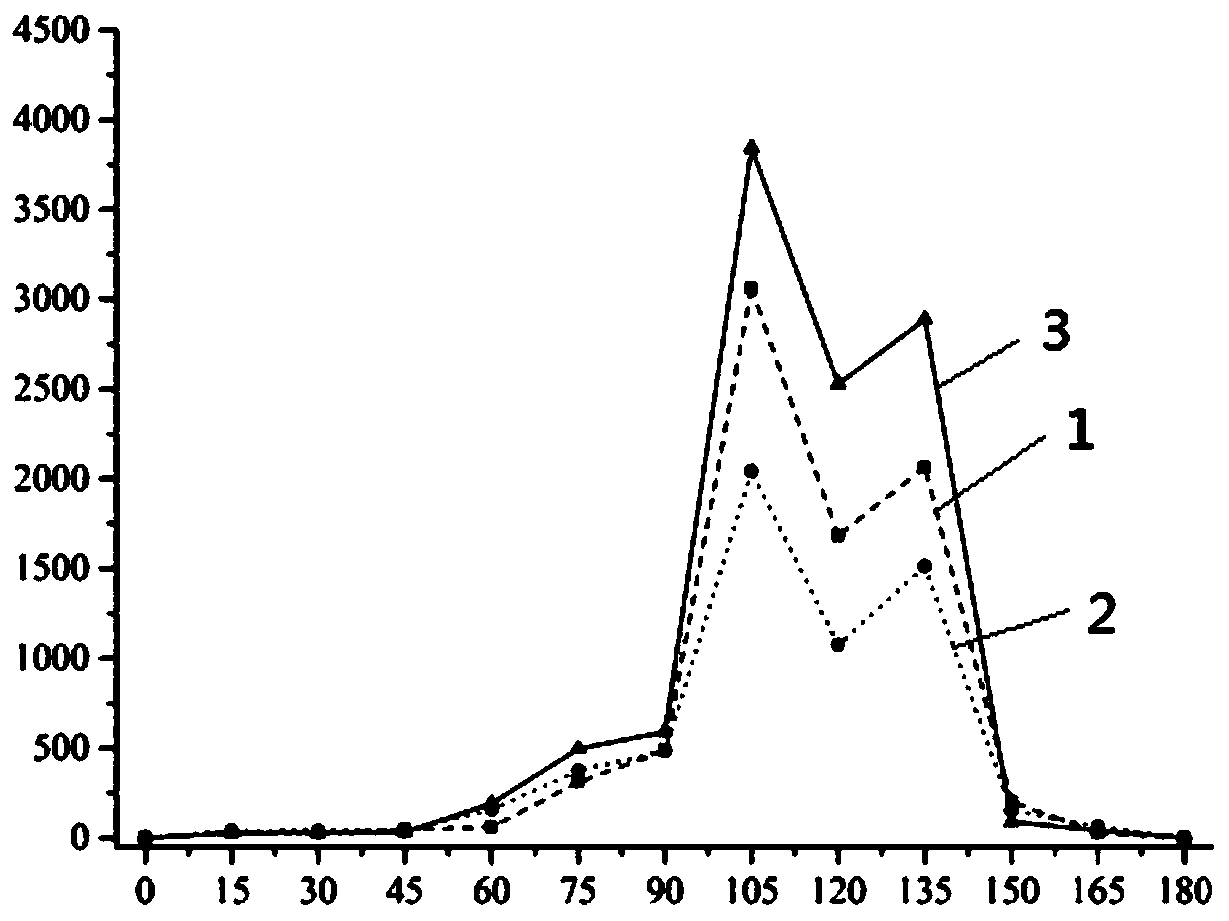

[0028] The specific implementation of the present invention will be described in detail below in conjunction with the drawings and technical solutions.

[0029] In this embodiment, a cemented carbide double straight-edged milling cutter with a rake angle of 5°, a back angle of 10°, and a blunt radius of 15 μm is used to mill a T800 grade carbon fiber composite unidirectional plate with a fiber angle of 150° Preferably, the processing parameters are shown in Table 1:

[0030] Table 1 Milling processing parameters

[0031]

[0032] The first step: Solve the actual range of fiber cutting angle during the up and down milling process respectively

[0033] From the processing parameters in Table 1, we get:

[0034]

[0035] Satisfy: The actual range of fiber cutting angle in up-milling processing is:

[0036]

[0037] The corresponding range of fiber cutting angle in down milling is:

[0038] ψ D =180°-ψ U ∈[30°,66.87°]

[0039] Step 2: Determine the optimal range of fiber cutting angle accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com