3mm coal sample milling and packaging integrated equipment and method thereof

A coal sample and equipment technology, which is applied in the field of 3mm coal sample pulverizing and packaging integrated equipment, can solve the problems of difficult collection of powder samples, large quality differences, easy dust drift, etc., and achieves improved technical level, reasonable structural design, and efficient pulverization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0036] Example.

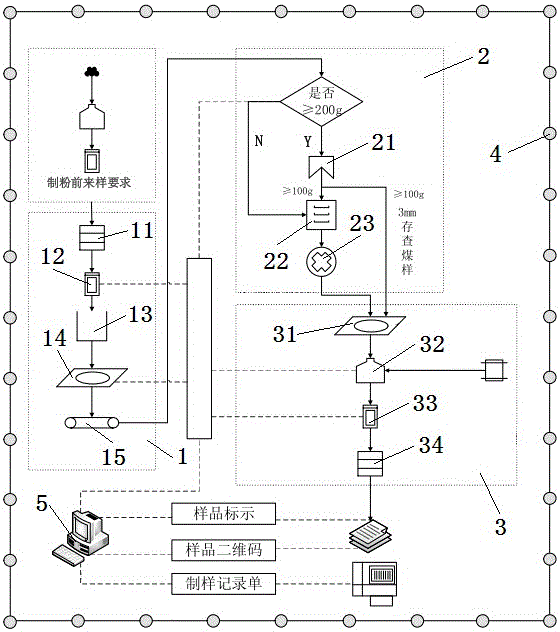

[0037] see figure 1 , the 3mm coal sample pulverizing and packaging integrated equipment in this embodiment includes a bottle unpacking and sampling system 1, a coal sample pulverizing system 2, a packaging coding system 3 and a dust removal system 4, a bottle unpacking and sampling system 1 and a coal sample pulverizing system The system 2 is connected, the coal sample pulverization system 2 is connected with the packaging coding system 3, and the dedusting system 4 is set around the debottle sampling system 1, the coal sample pulverization system 2 and the packaging coding system 3.

[0038] The 3mm coal sample pulverizing and encapsulating integrated equipment in this embodiment may also includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com