Open presser workbench surface processing special machine tool

A technology of open presses and special machine tools, which is applied to metal processing machinery parts, metal processing equipment, milling machine equipment, etc. It can solve the problems of easily damaged milling tools and even floor boring machines, high cost of use, and low work efficiency. Mass production, reduce processing costs, improve work efficiency and the best effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

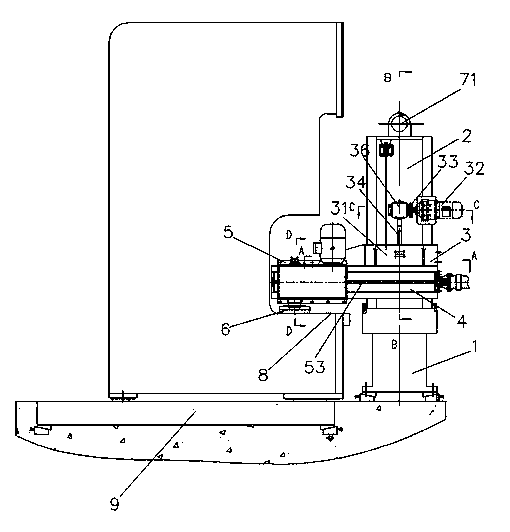

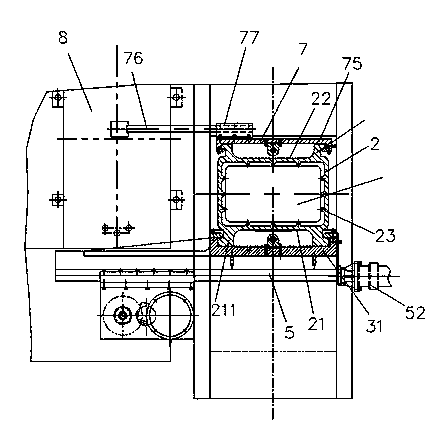

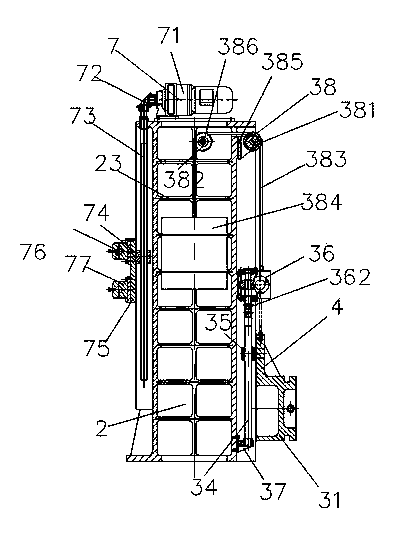

[0021] Figure 1~ Figure 5 As shown, this embodiment includes a power slide table 1, a column 2, a vertical carriage moving device 3, a beam 4, a horizontal carriage feeding device 5, a milling power head 6, and a press table leveling measuring device 7. The sliding table 1 is arranged in parallel on the front side of the press table 8, and its length is longer than that of the press table 8. The lower end of the column 2 is fixed on the power sliding table 1, so that the column 2 can move longitudinally along the power sliding table 1, and the processing press The worktop of Workbench 8. The vertical carriage moving device 3 is vertically slidingly connected to the first side 21 of the column, and one end of the beam 4 is fixed on the vertical carriage moving device 3 . The horizontal carriage feeder 5 is horizontally connected to the crossbeam 4 , the milling power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com