Patents

Literature

36results about "Decalcomania" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

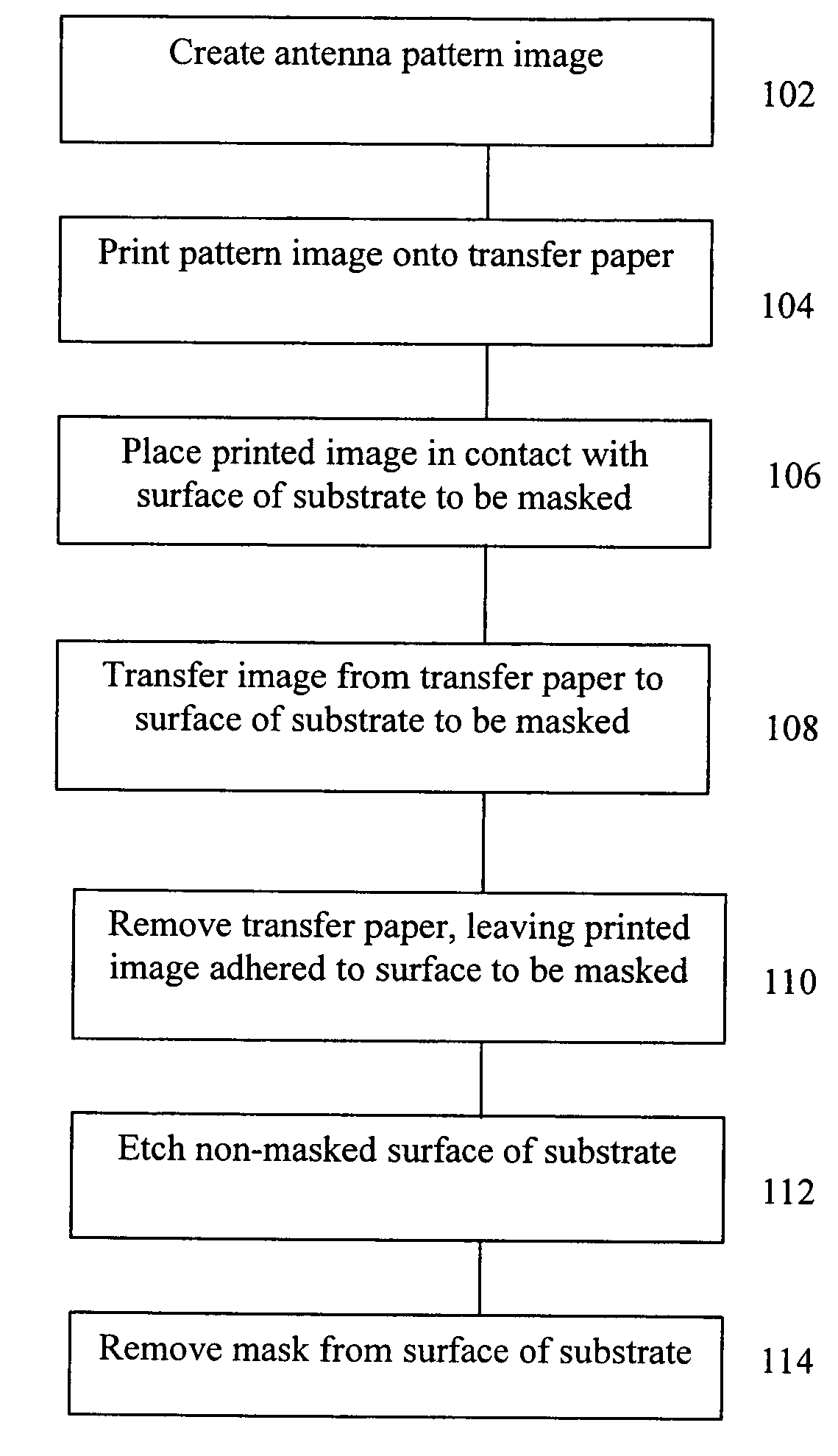

Low cost antenna array fabrication technology

ActiveUS20090169835A1Simple and cost-effective methodDecalcomaniaDecorative surface effectsEtchingImage transfer

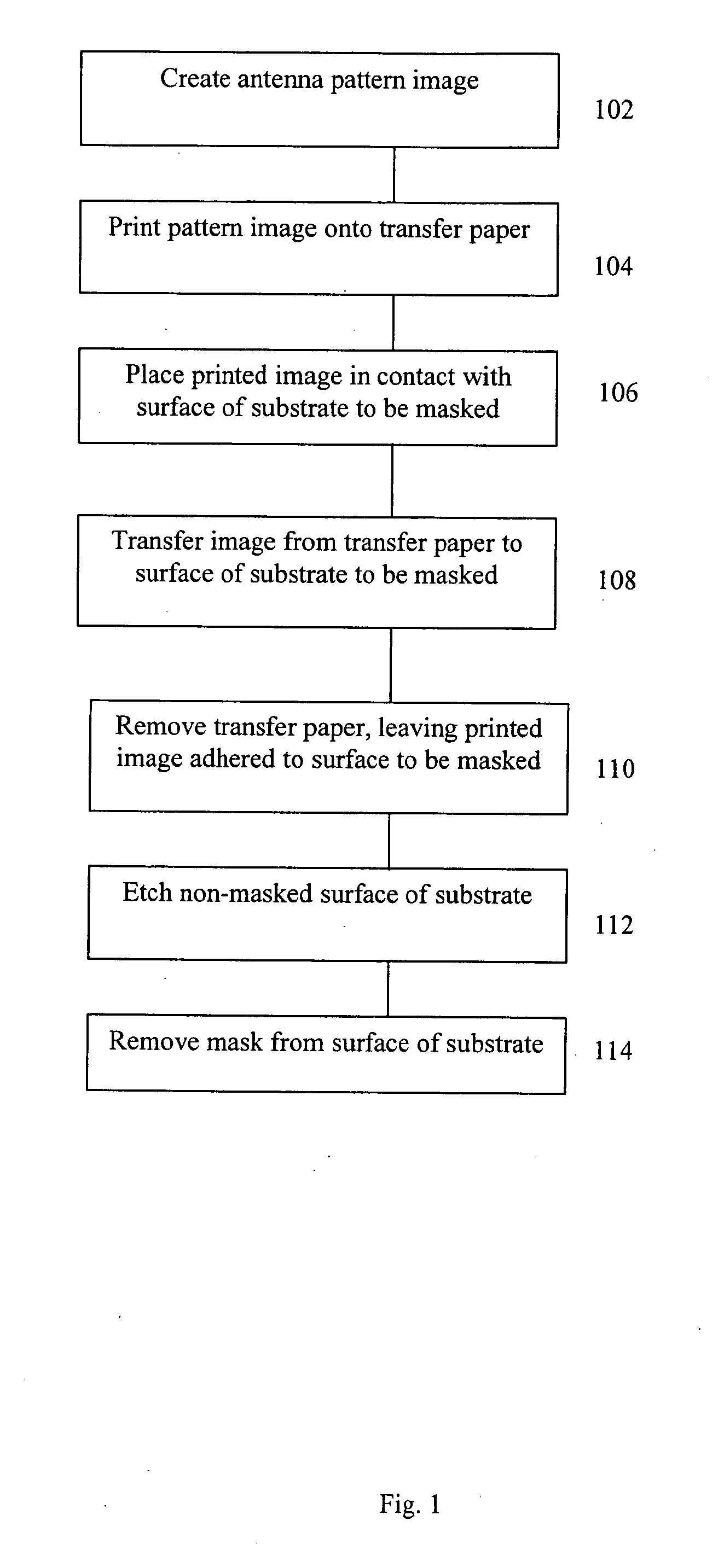

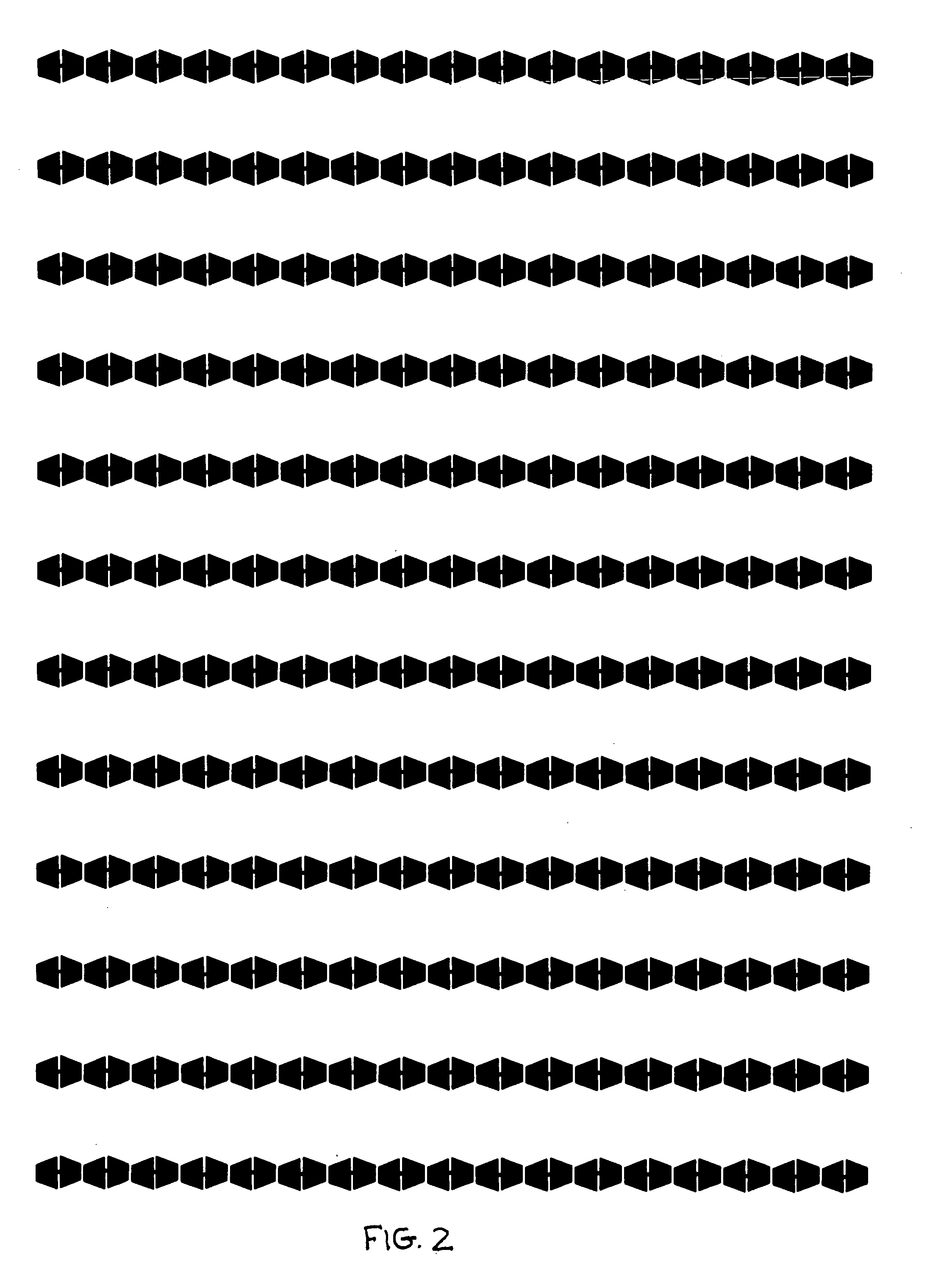

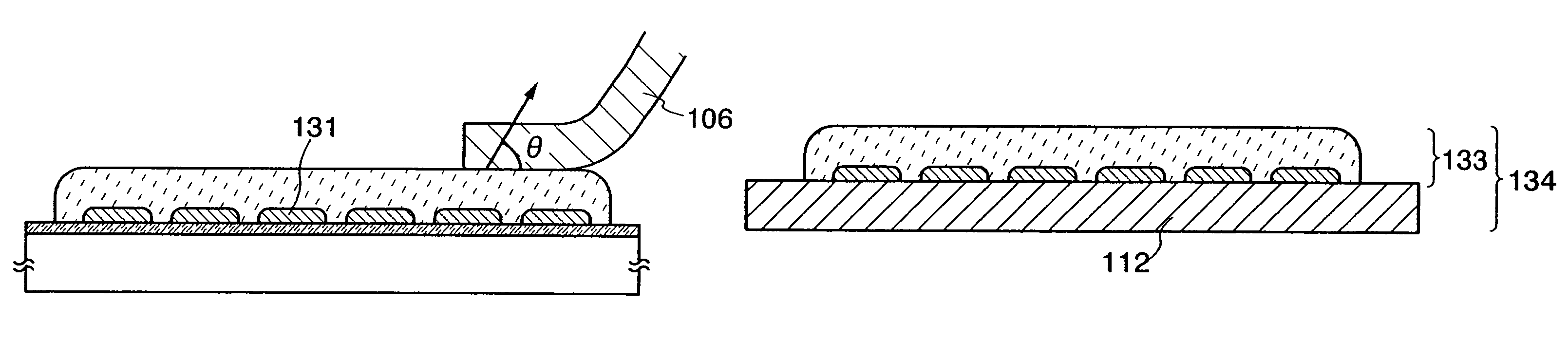

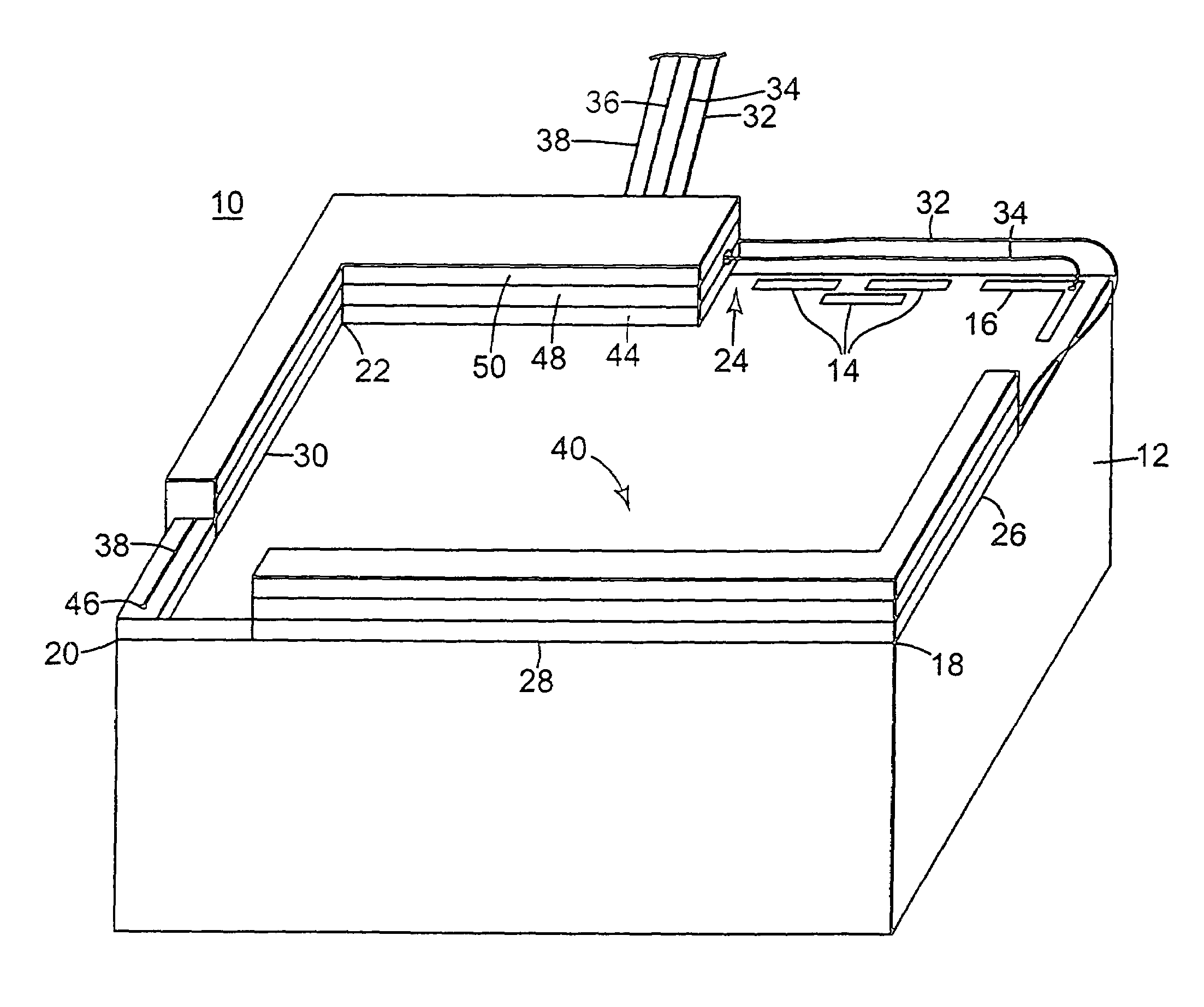

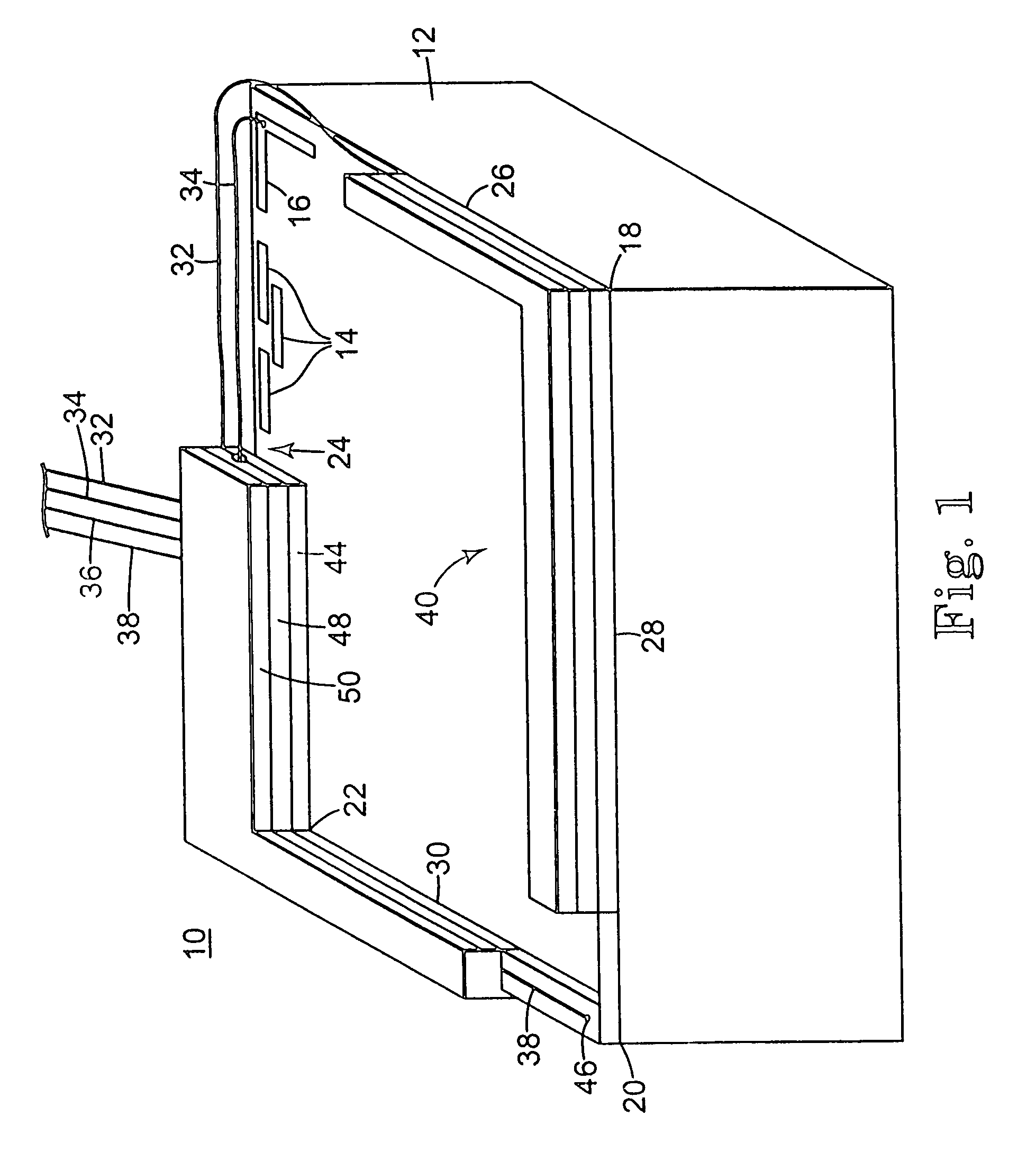

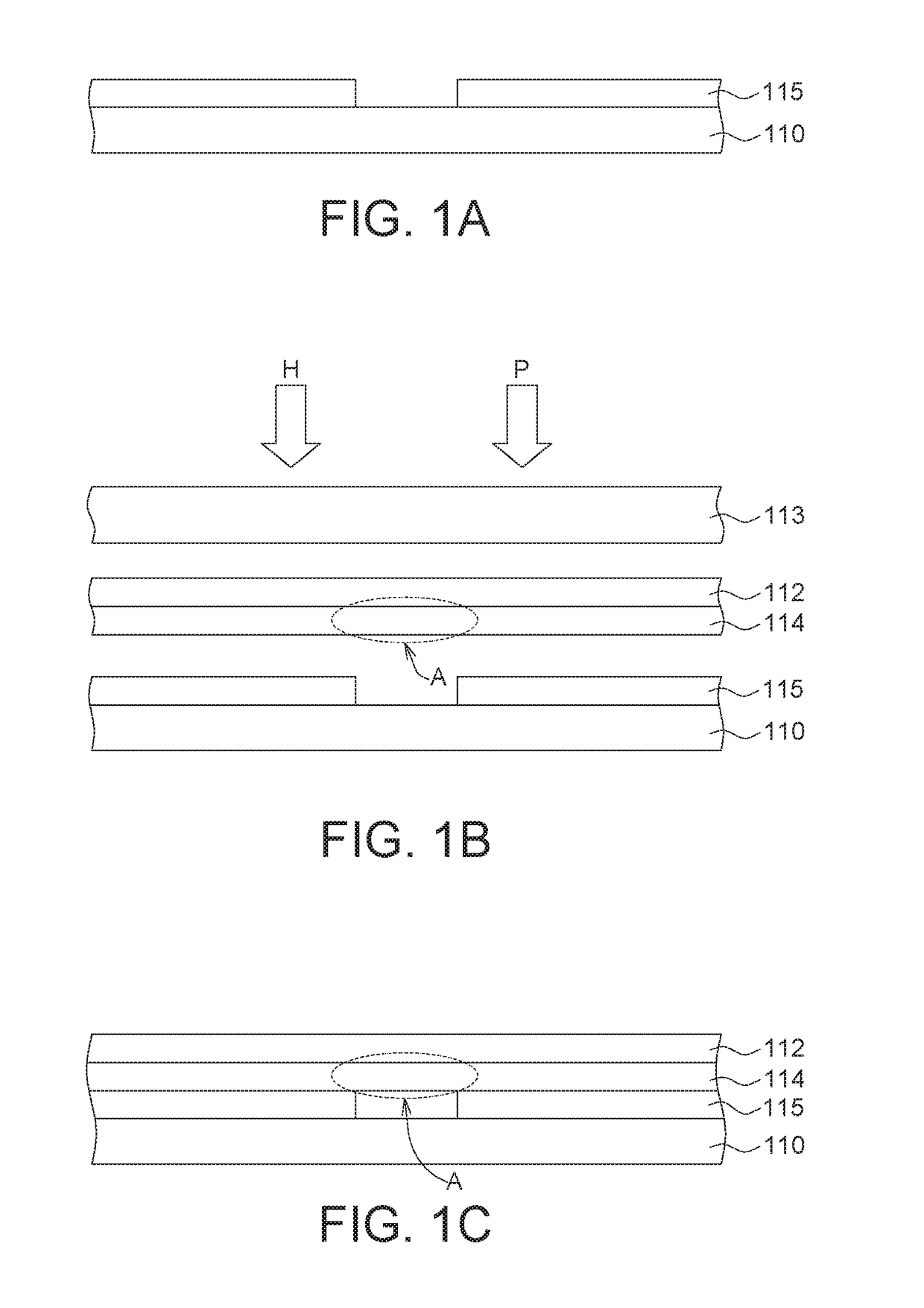

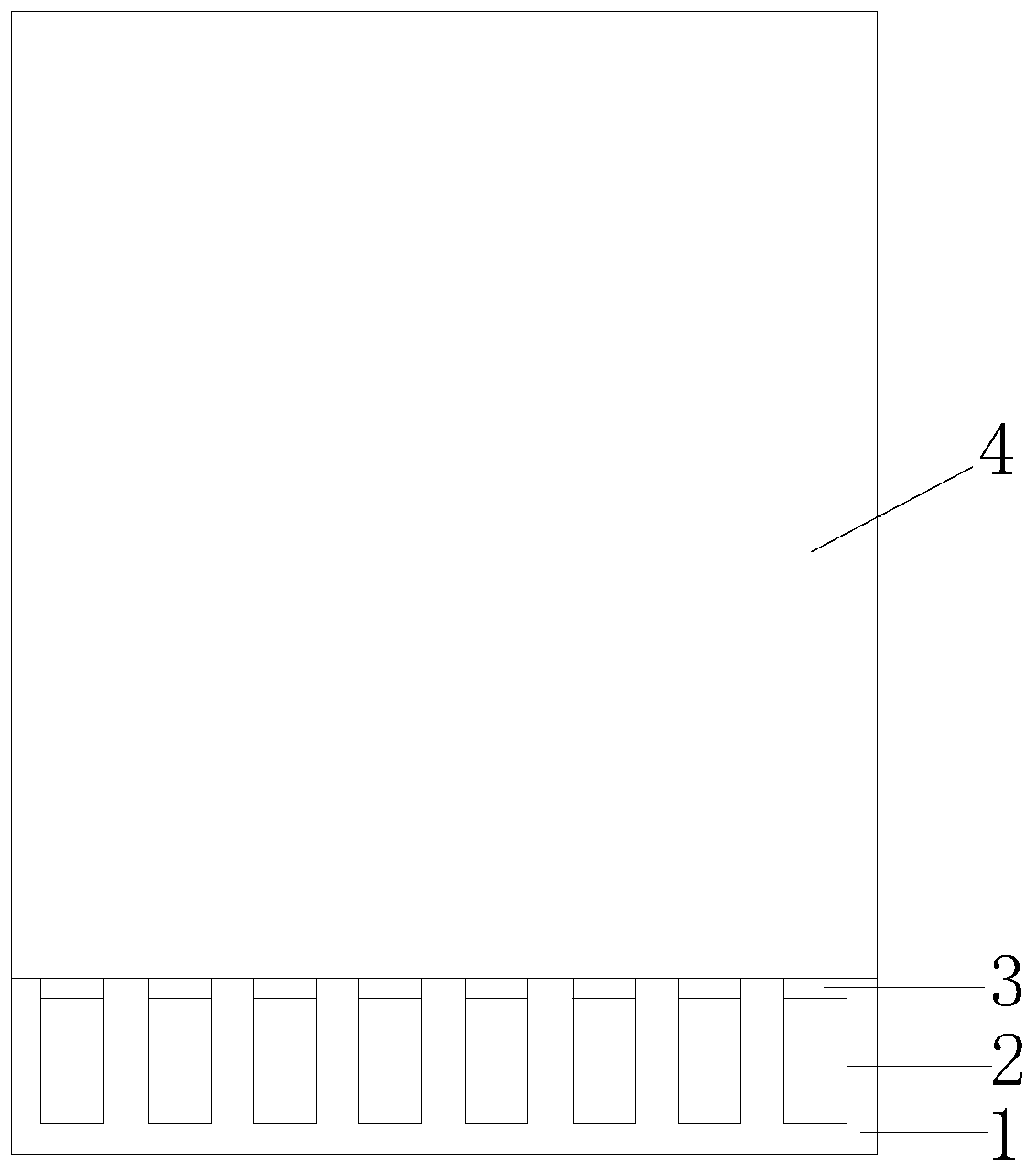

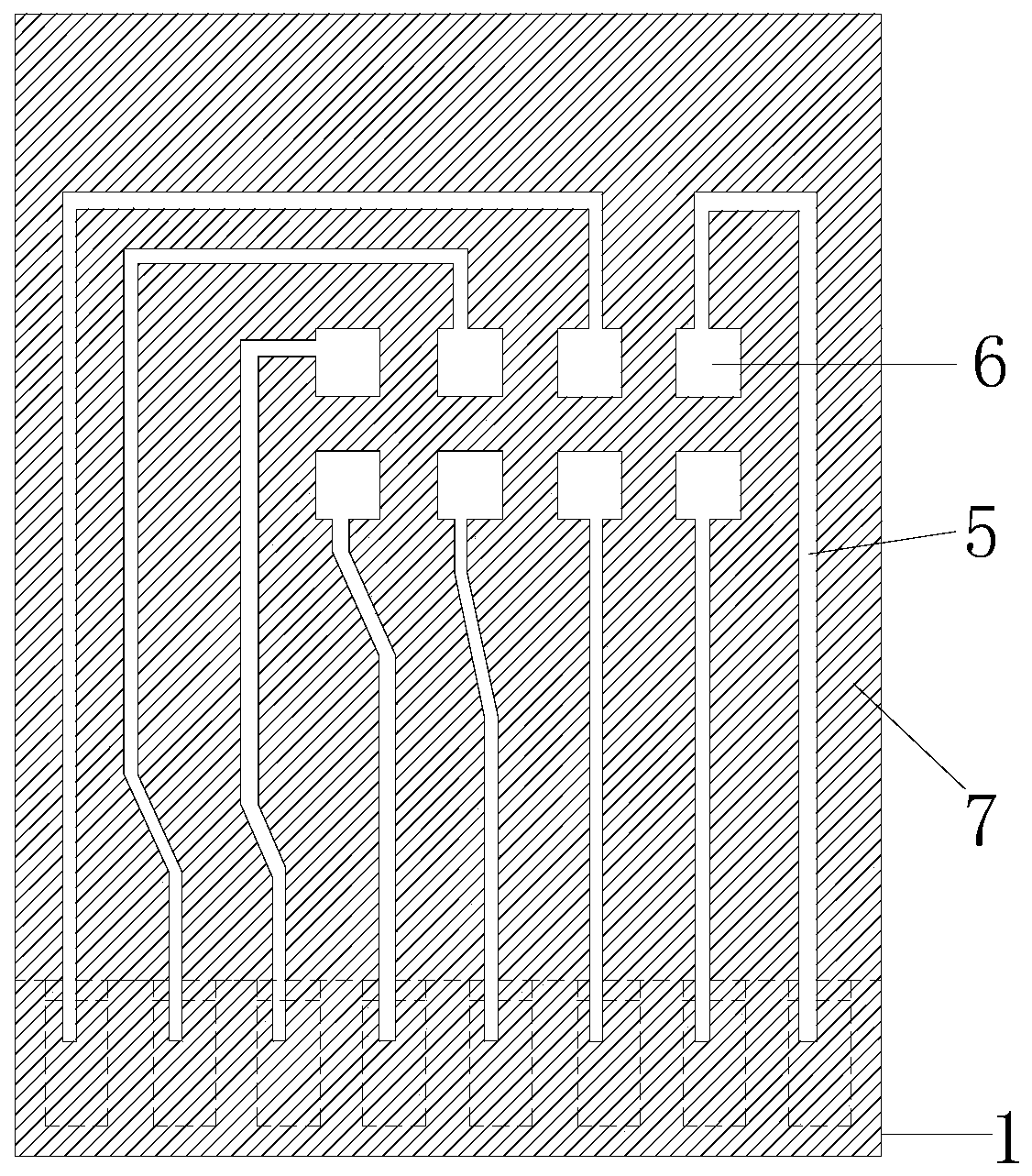

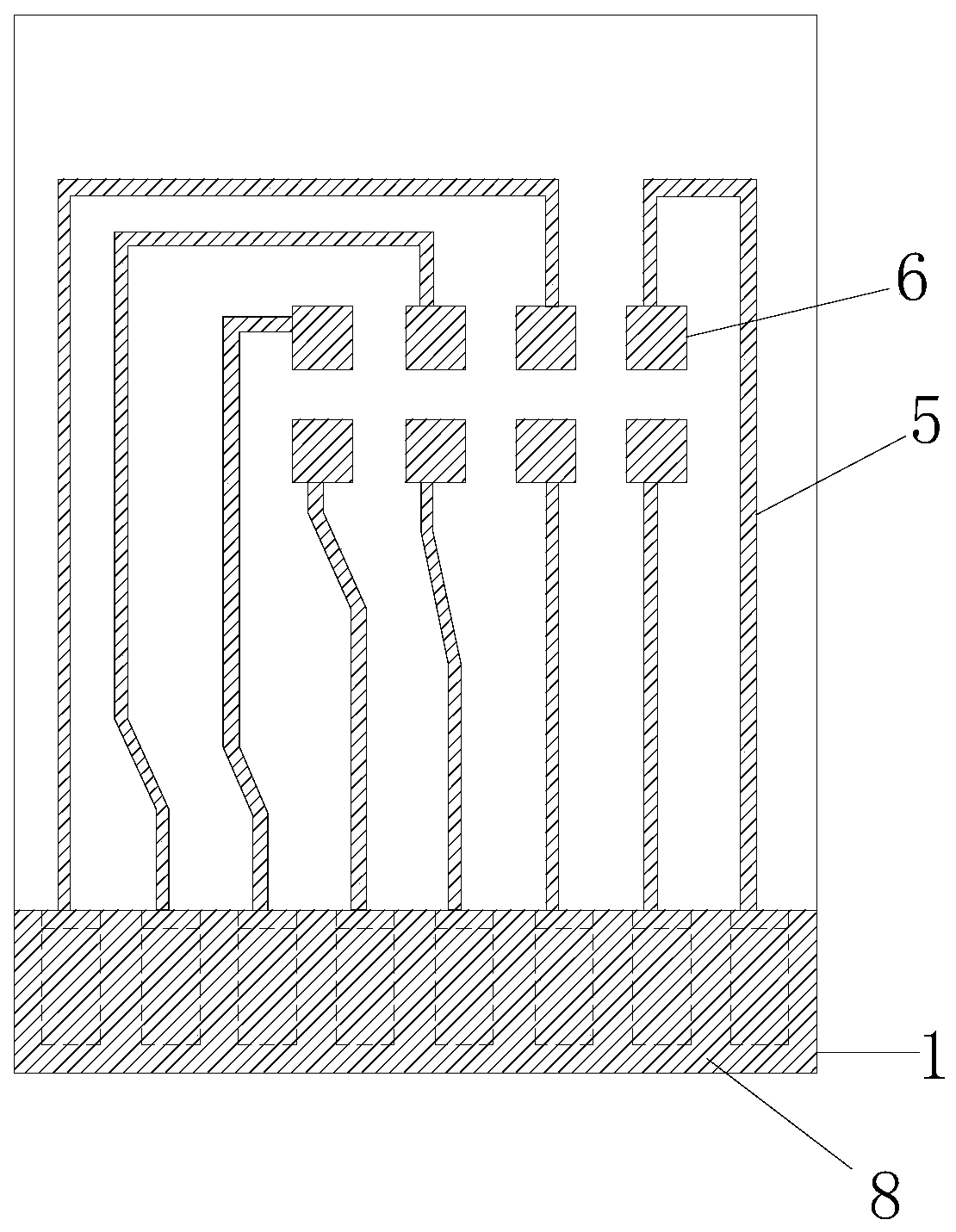

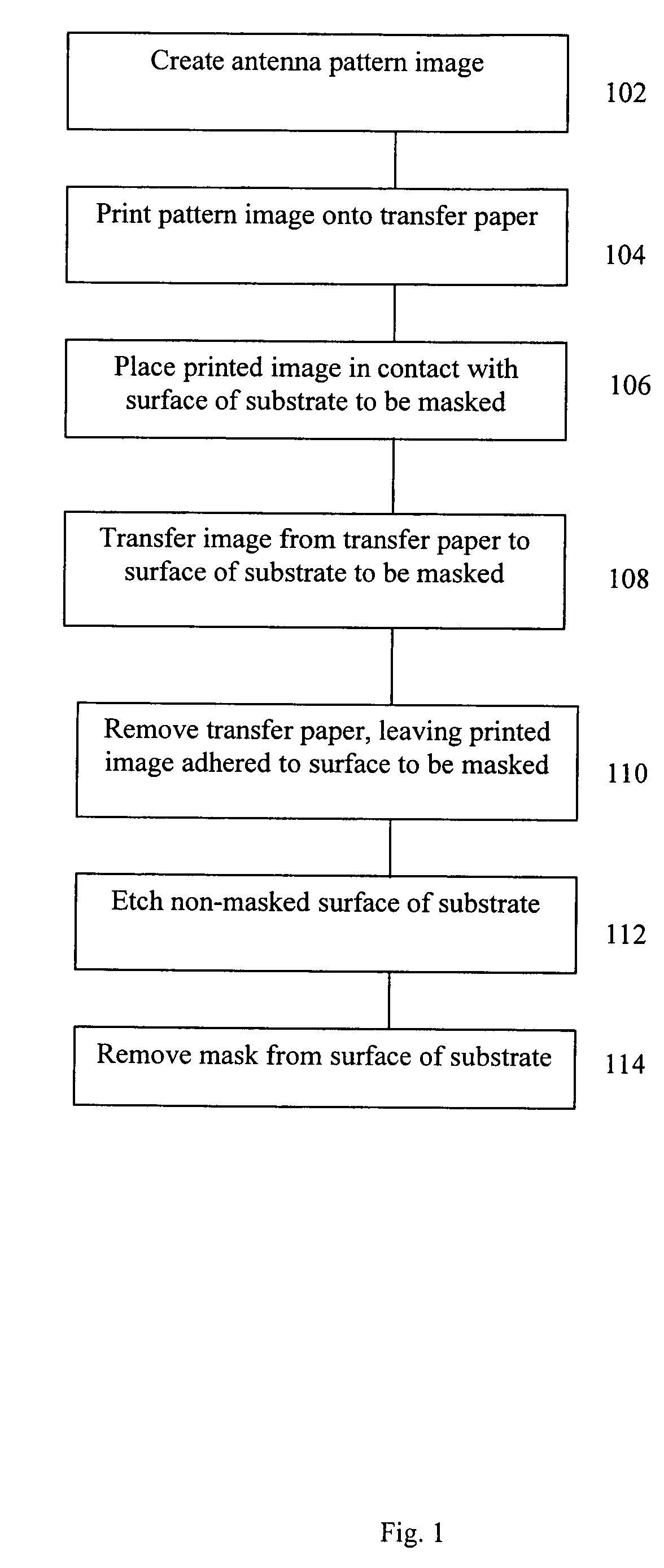

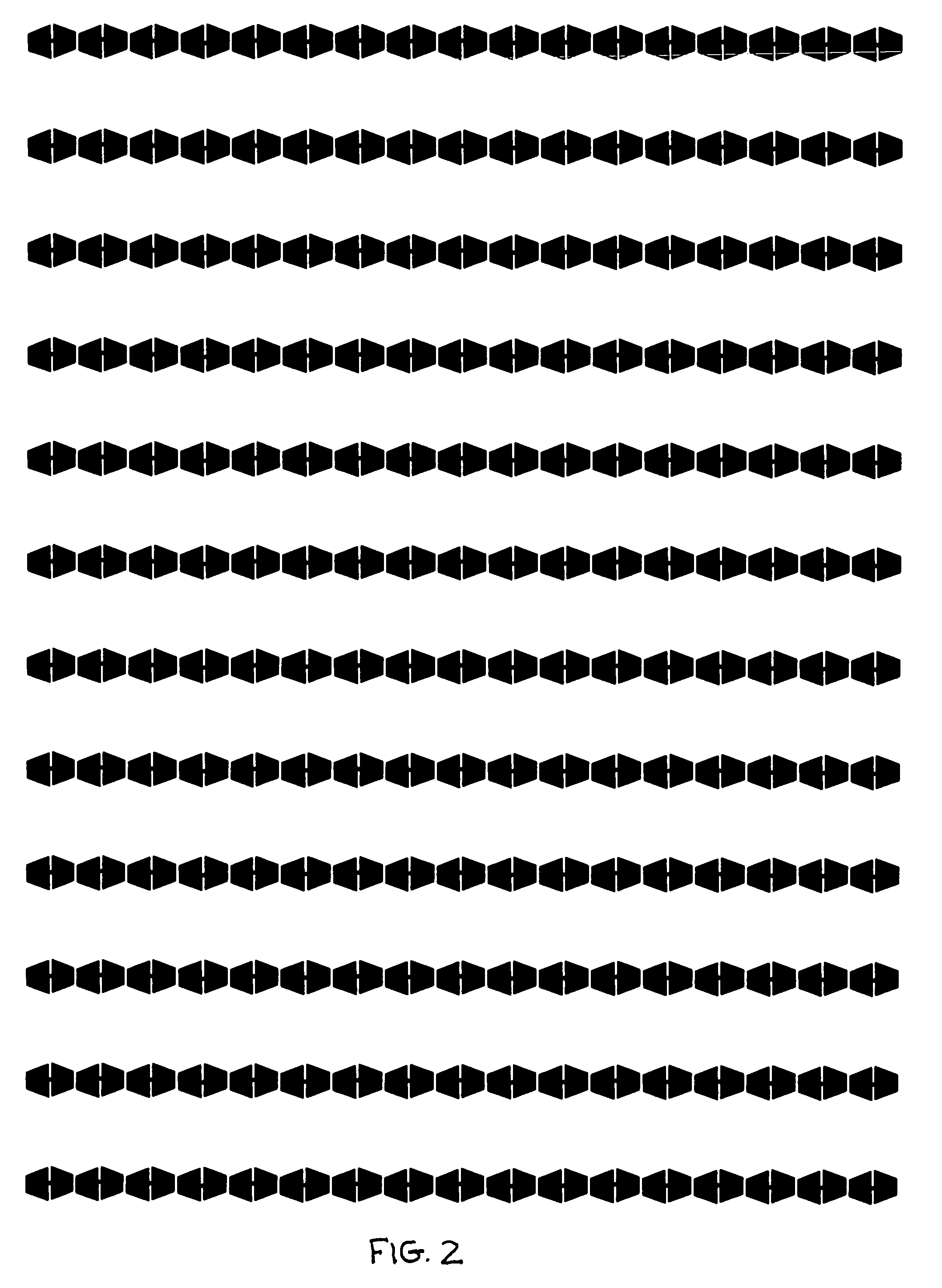

Methods are provided for producing large volumes of small antenna arrays. In one embodiment, the method comprises the steps of creating an antenna array pattern as a computer file, printing the created pattern onto the surface of a suitable transfer paper, placing the printed image surface in contact with the surface of a material to be etched, and transferring the printed image to the surface of the material to be etched. The transfer can be effected by any combination of chemicals, heat, and / or pressure. After transfer of the printed image, the transfer paper is removed. The step of removing the transfer paper optionally includes wetting the transfer paper in a manner that dissolves the transfer paper leaving the printed antenna pattern on the surface of the material to be etched. The method further includes the step of etching the non-printed portions of the material, preferably by chemical etching, and removing the printed pattern from the surface of the material to yield an antenna array comprising a non-etched portion of the substrate surface. Arrays, and substrates having an etch-resistant mask for making the arrays, are also provided.

Owner:GENERAL ELECTRIC CO

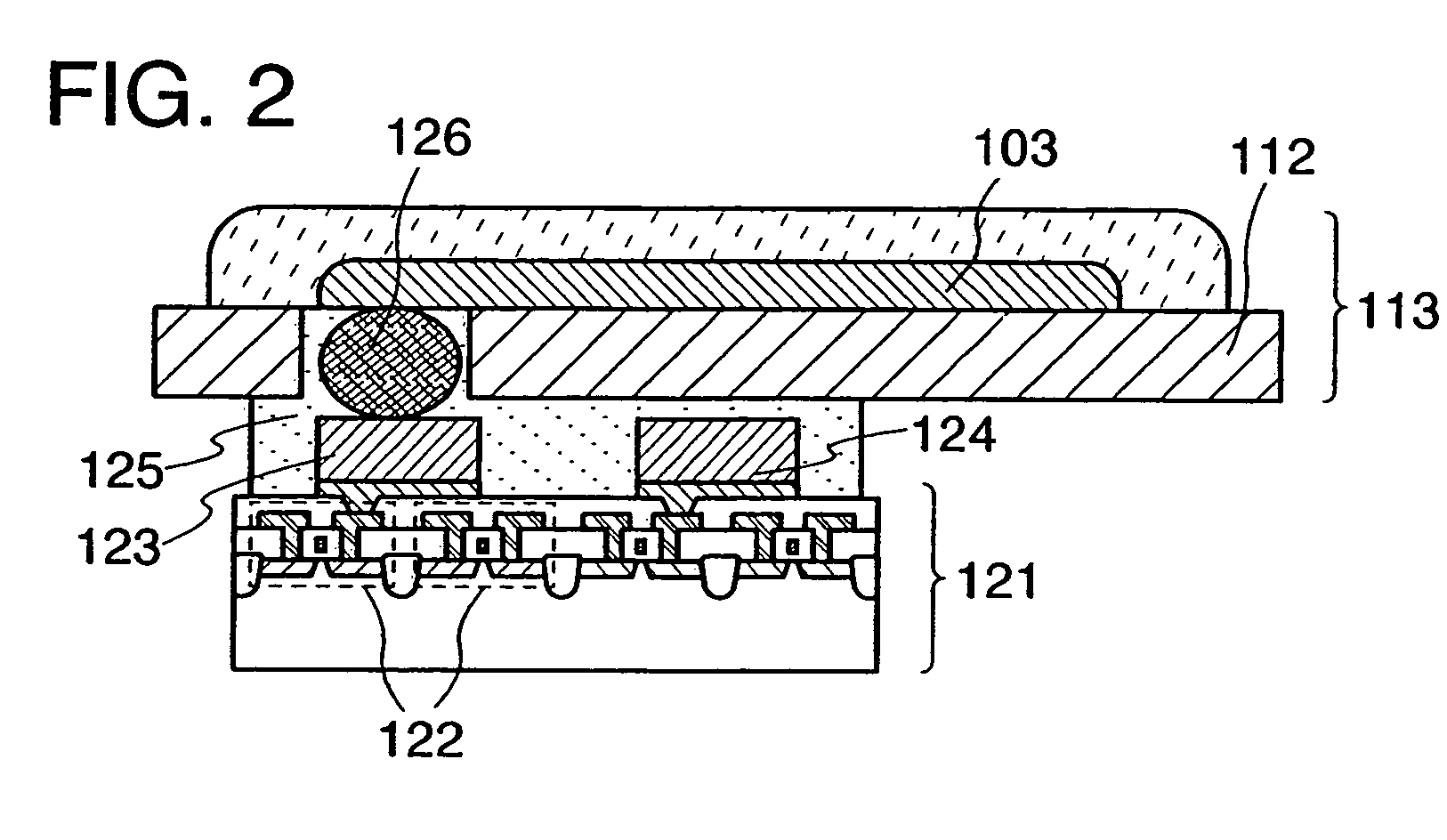

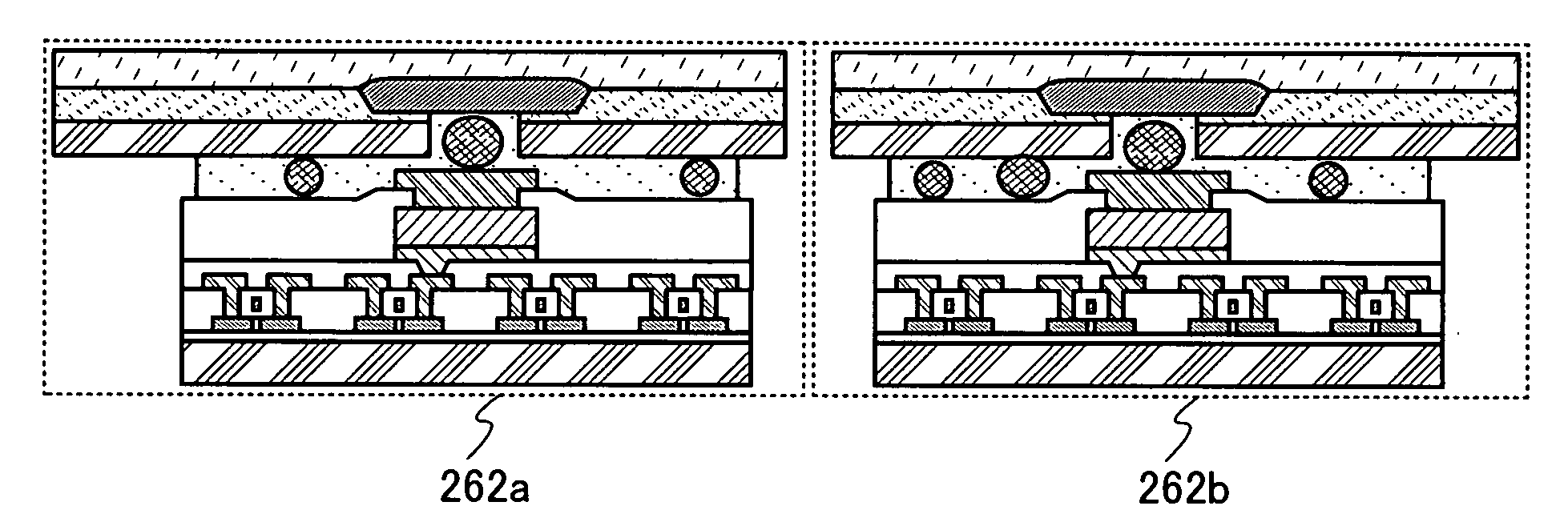

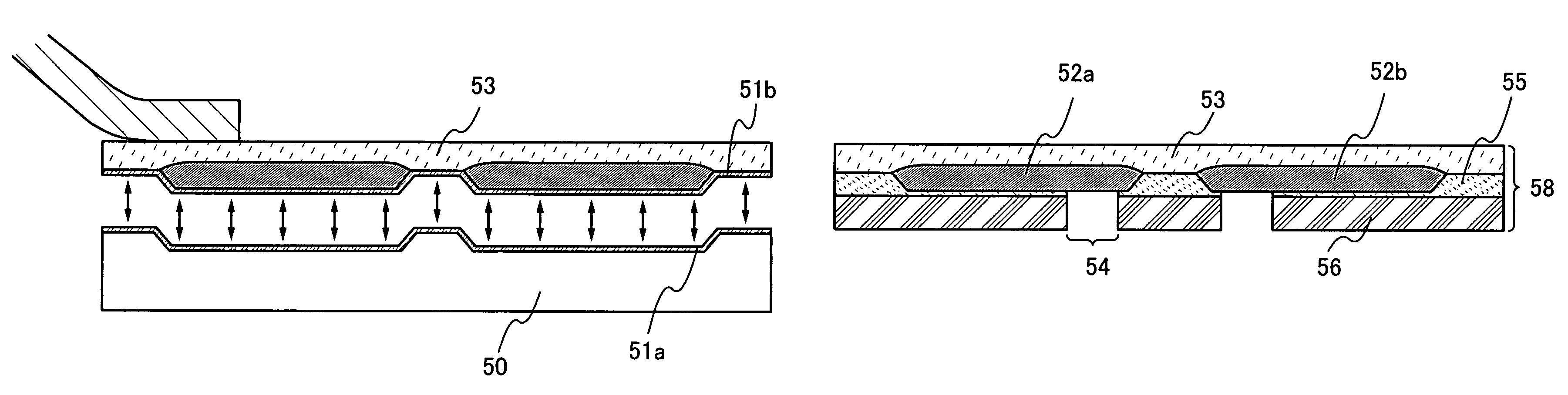

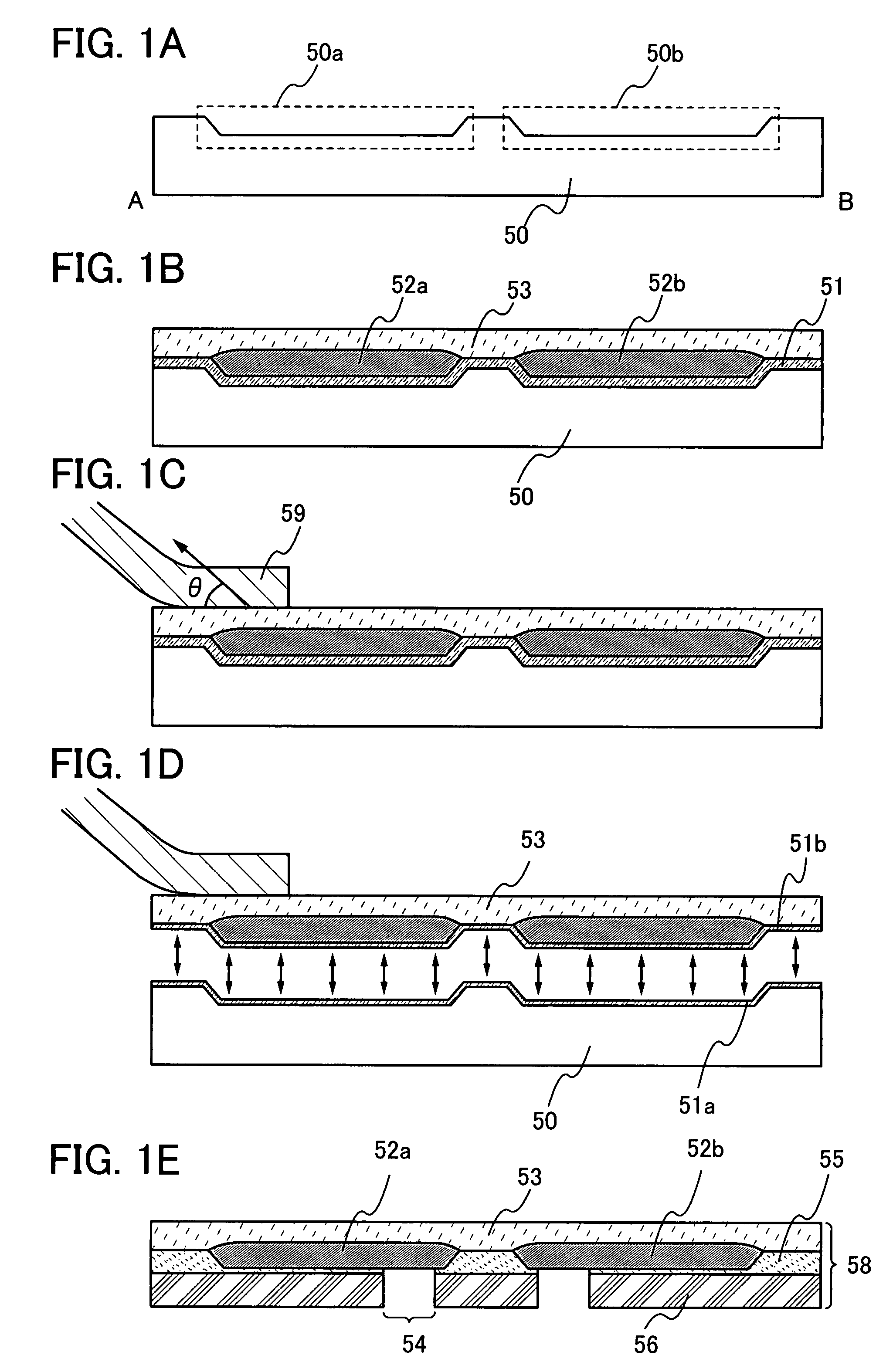

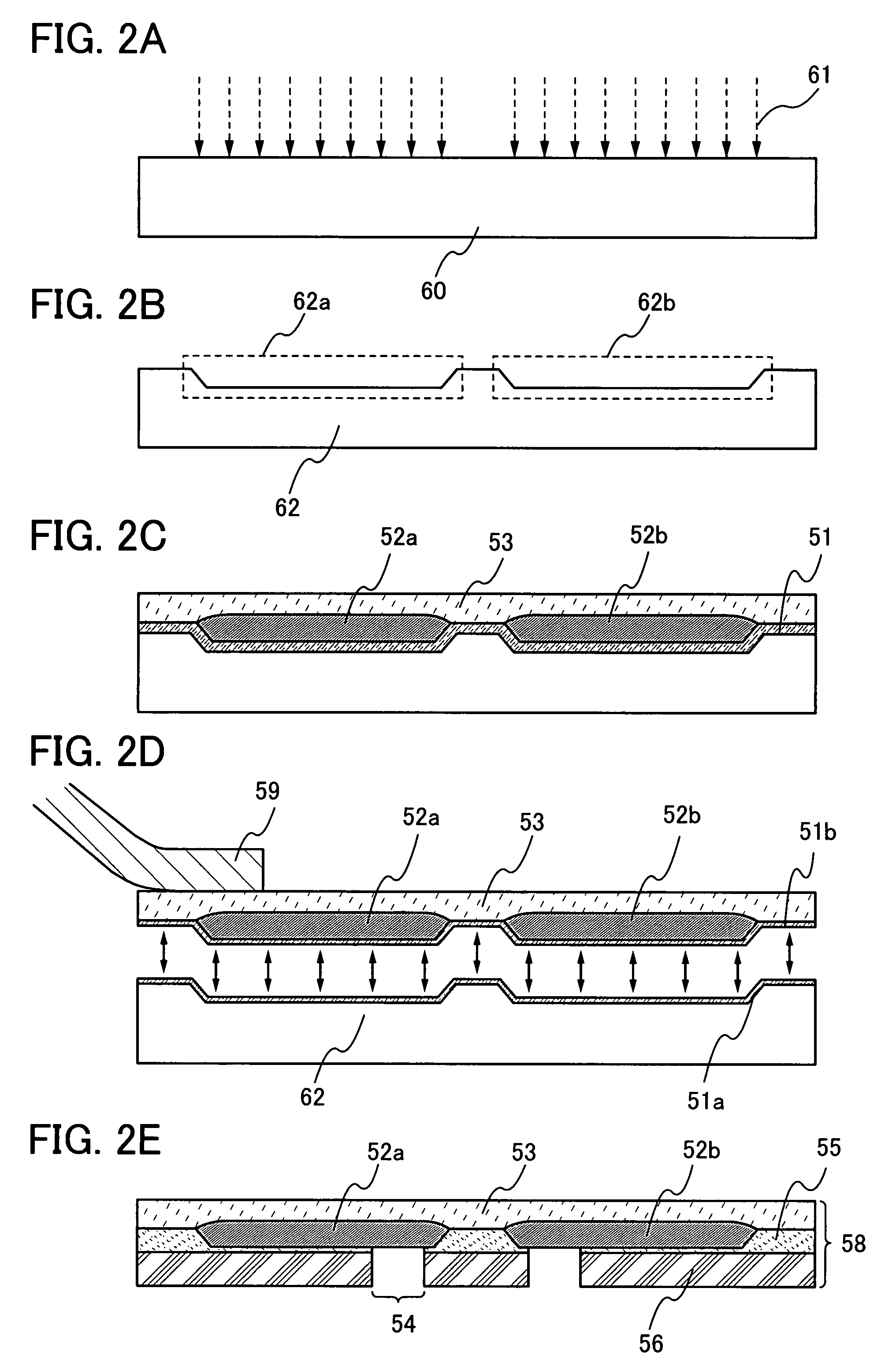

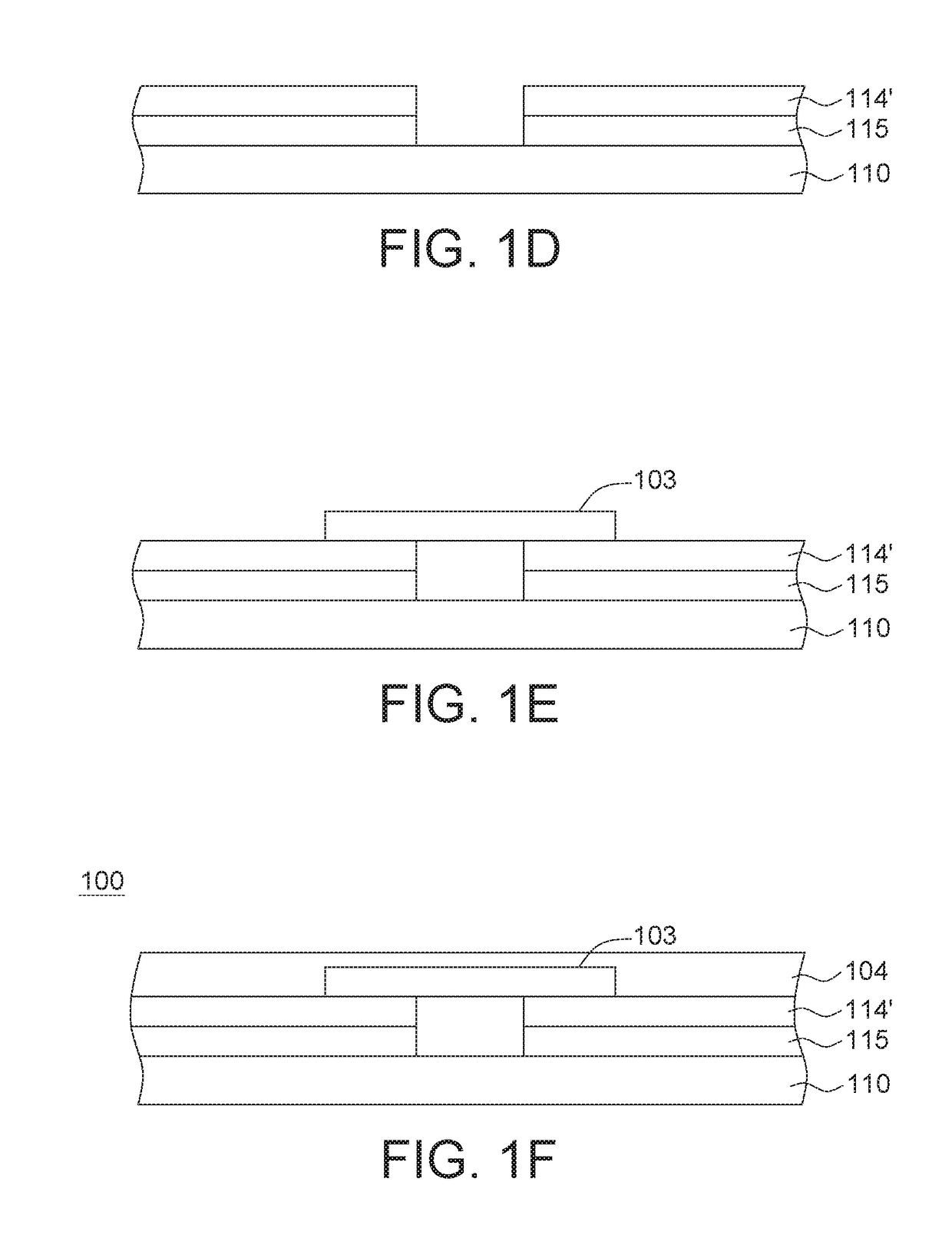

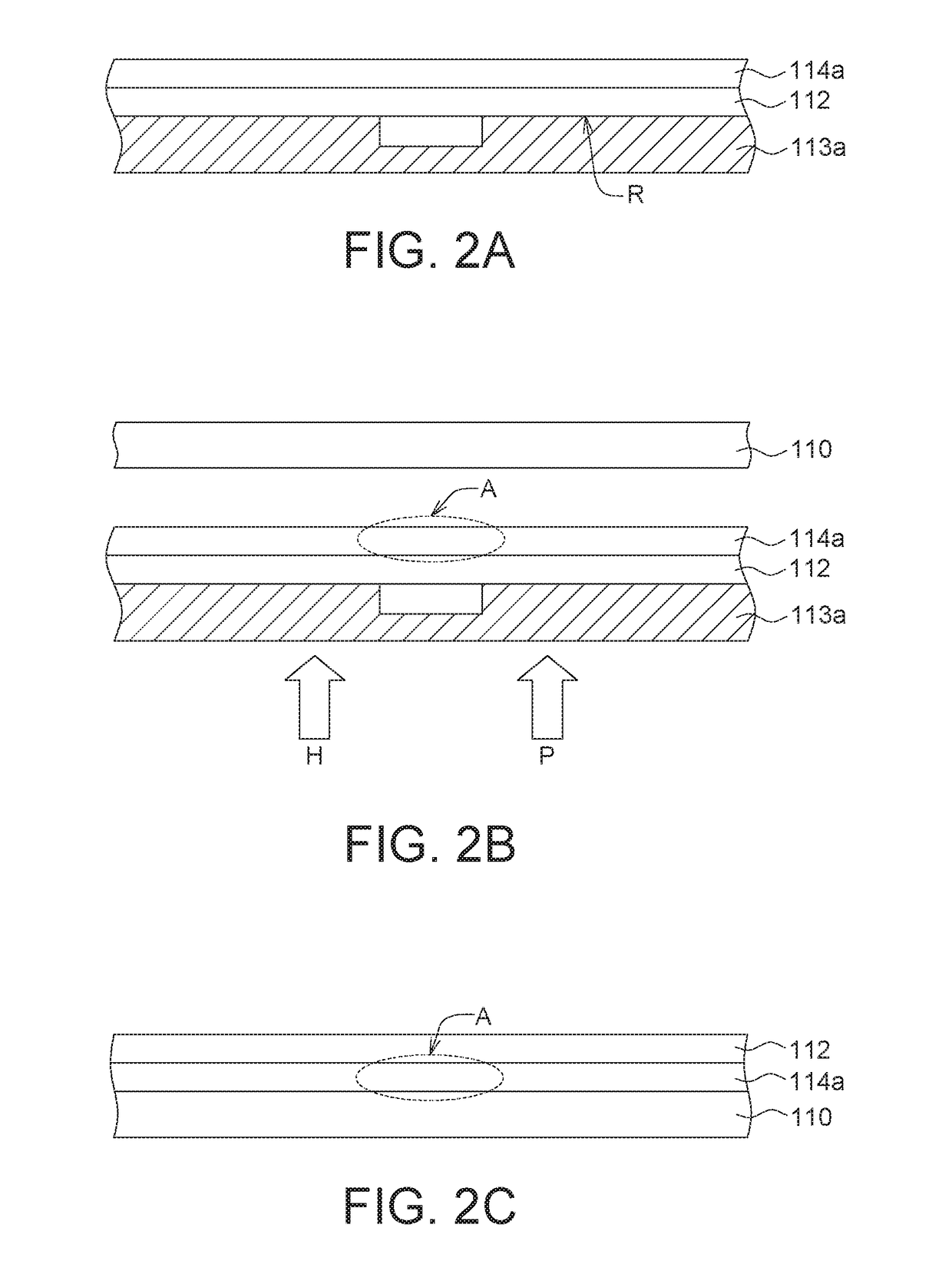

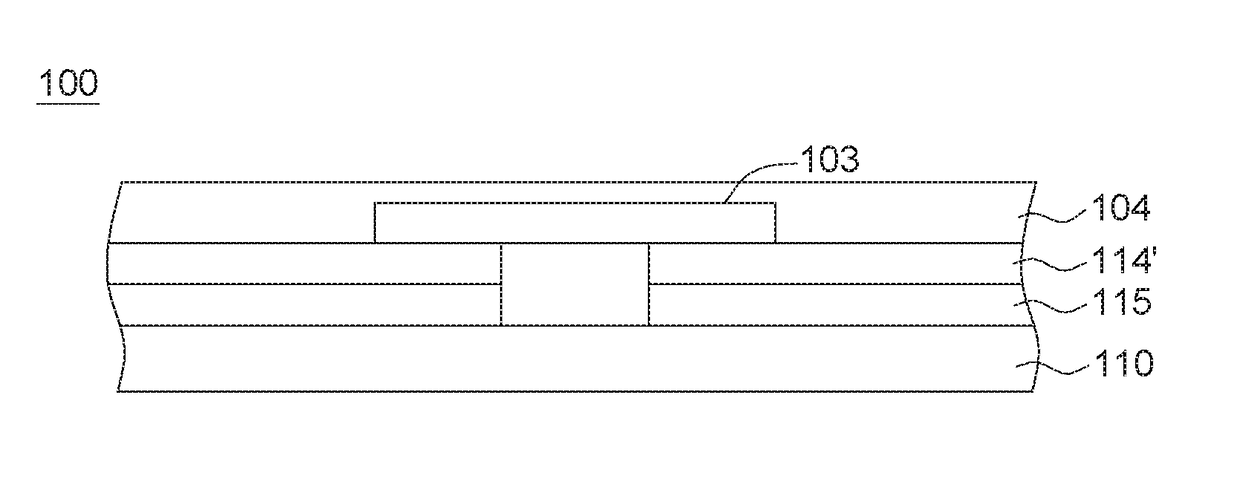

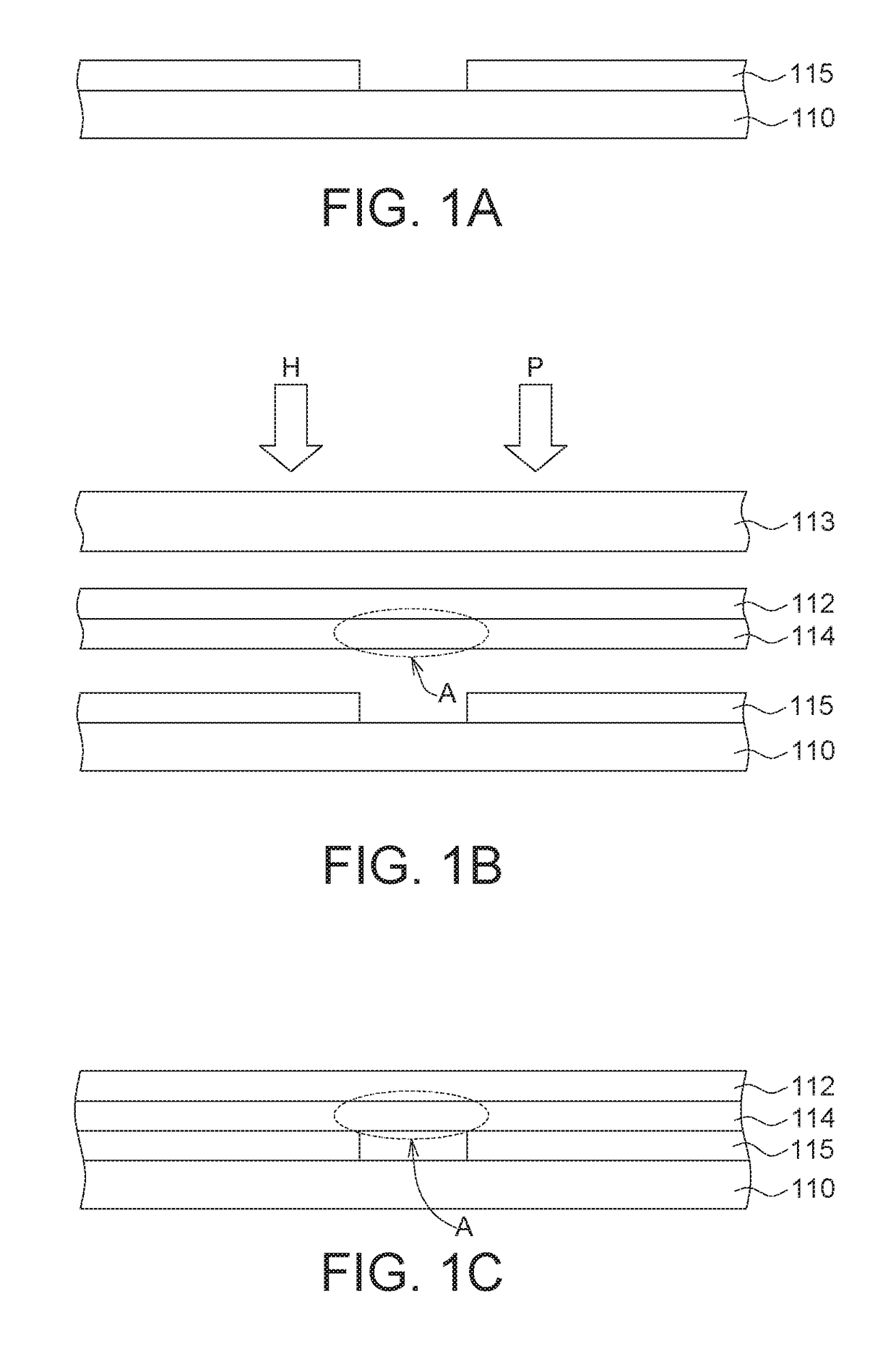

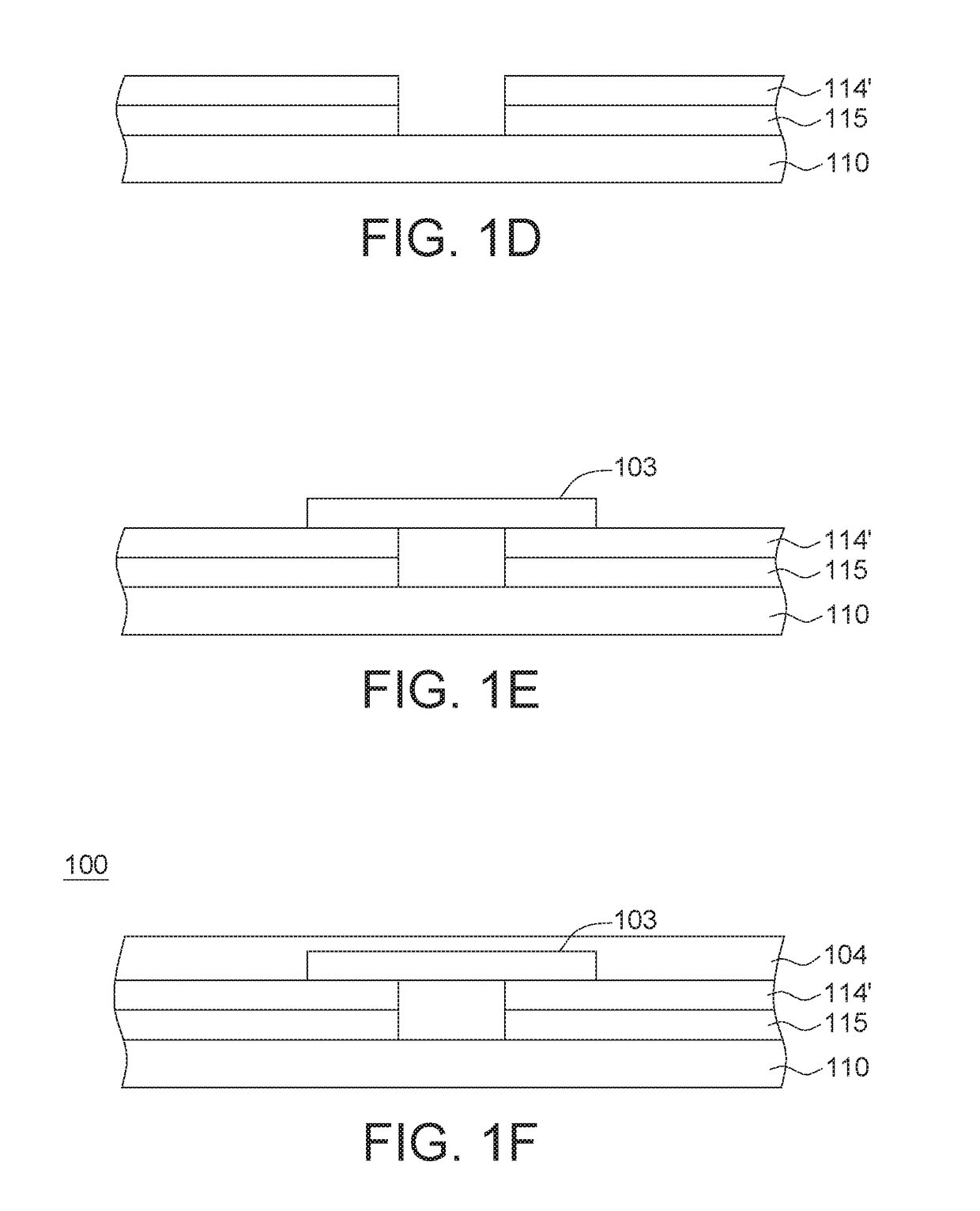

Layer having functionality, method for forming flexible substrate having the same, and method for manufacturing semiconductor device

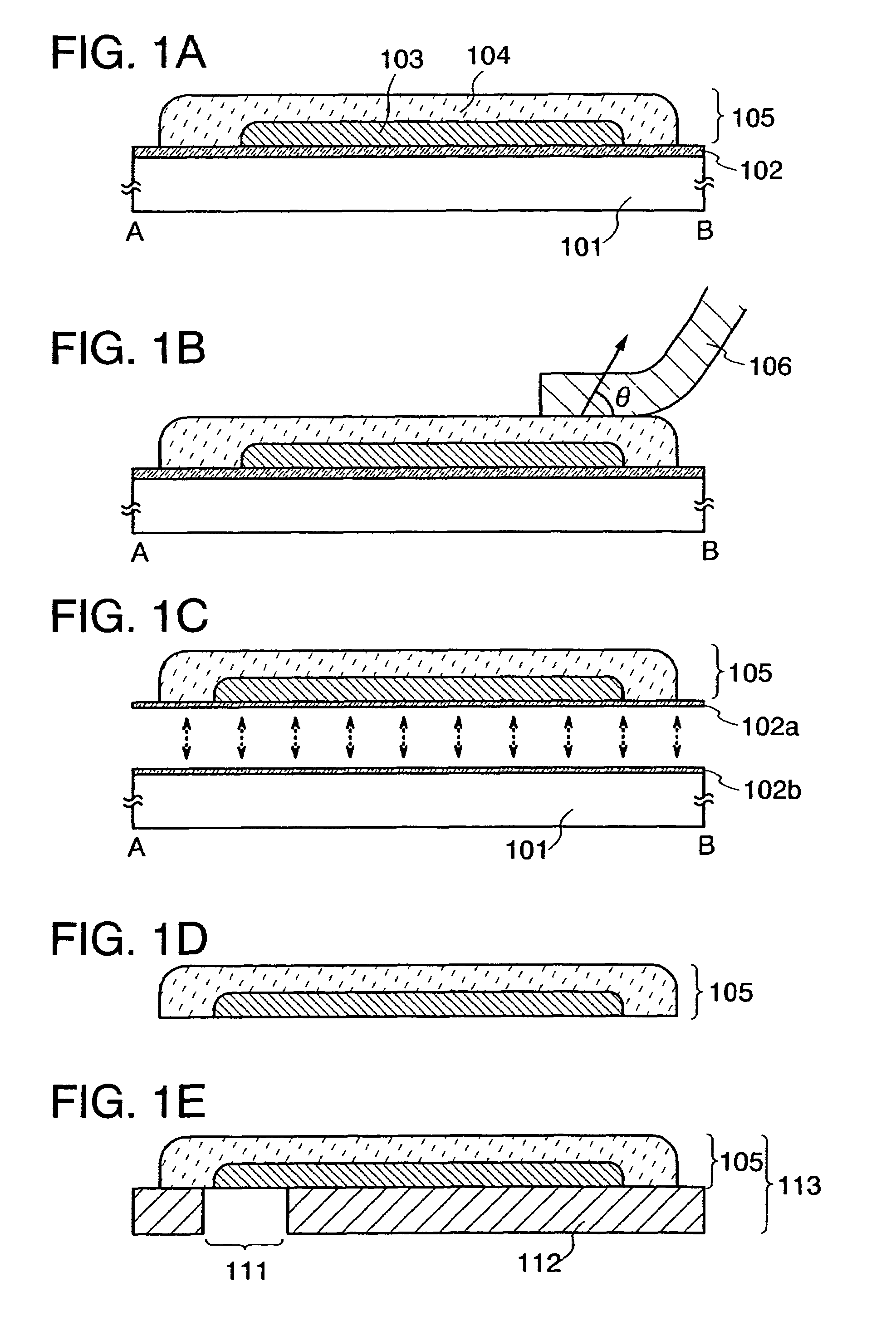

It is an object of the present invention to provide a method for forming a layer having functionality including a conductive layer and a colored layer and a flexible substrate having a layer having functionality with a high yield. Further, it is an object of the present invention to provide a method for manufacturing a semiconductor device that is small-sized, thin, and lightweight. After coating a substrate having heat resistance with a silane coupling agent, a layer having functionality is formed. Then, after attaching an adhesive to the layer having functionality, the layer having functionality is peeled from the substrate. Further, after coating a substrate having heat resistance with a silane coupling agent, a layer having functionality is formed. Then, an adhesive is attached to the layer having functionality. Thereafter, the layer having functionality is peeled from the substrate, and a flexible substrate is attached to the layer having functionality.

Owner:SEMICON ENERGY LAB CO LTD

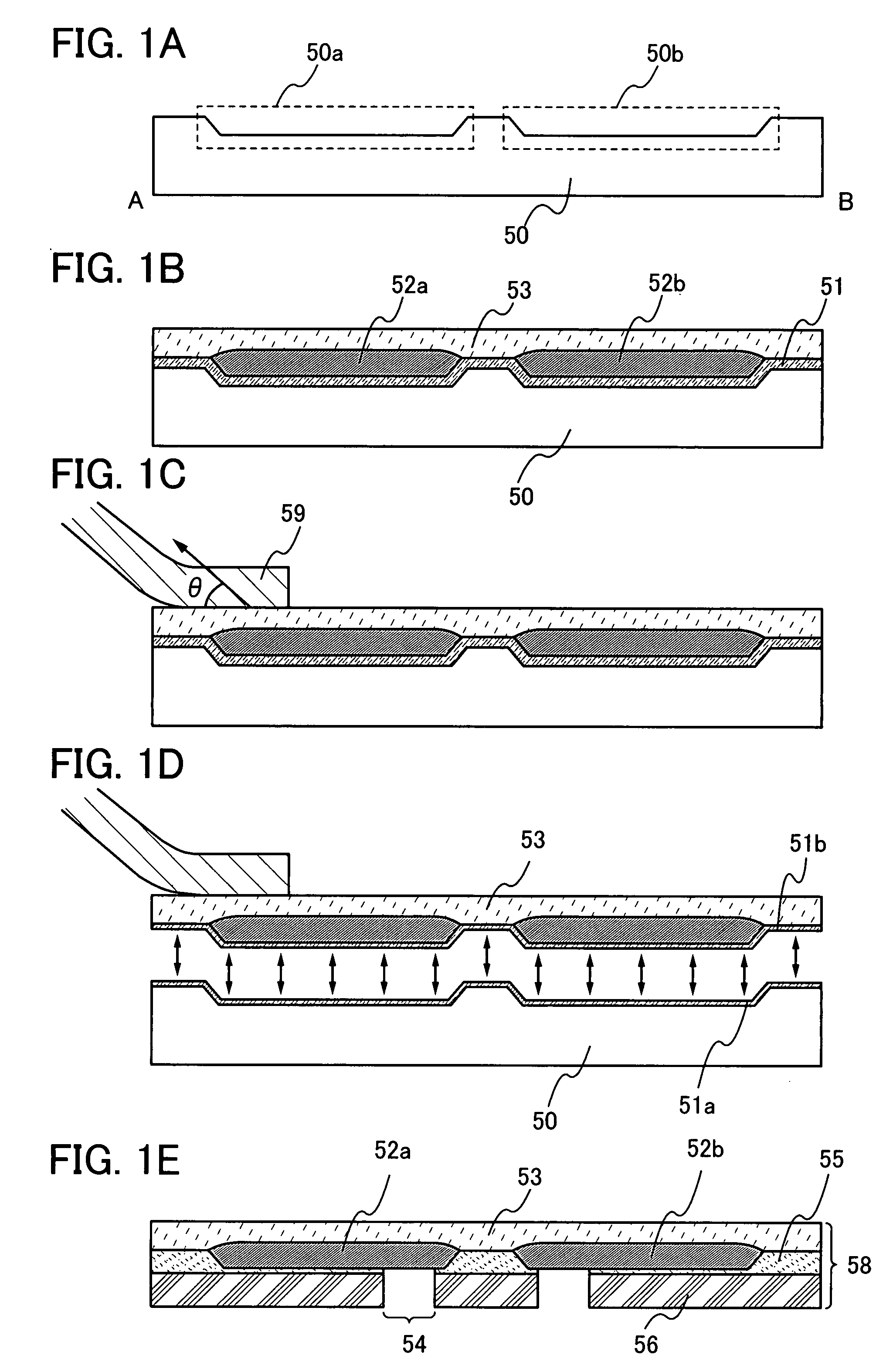

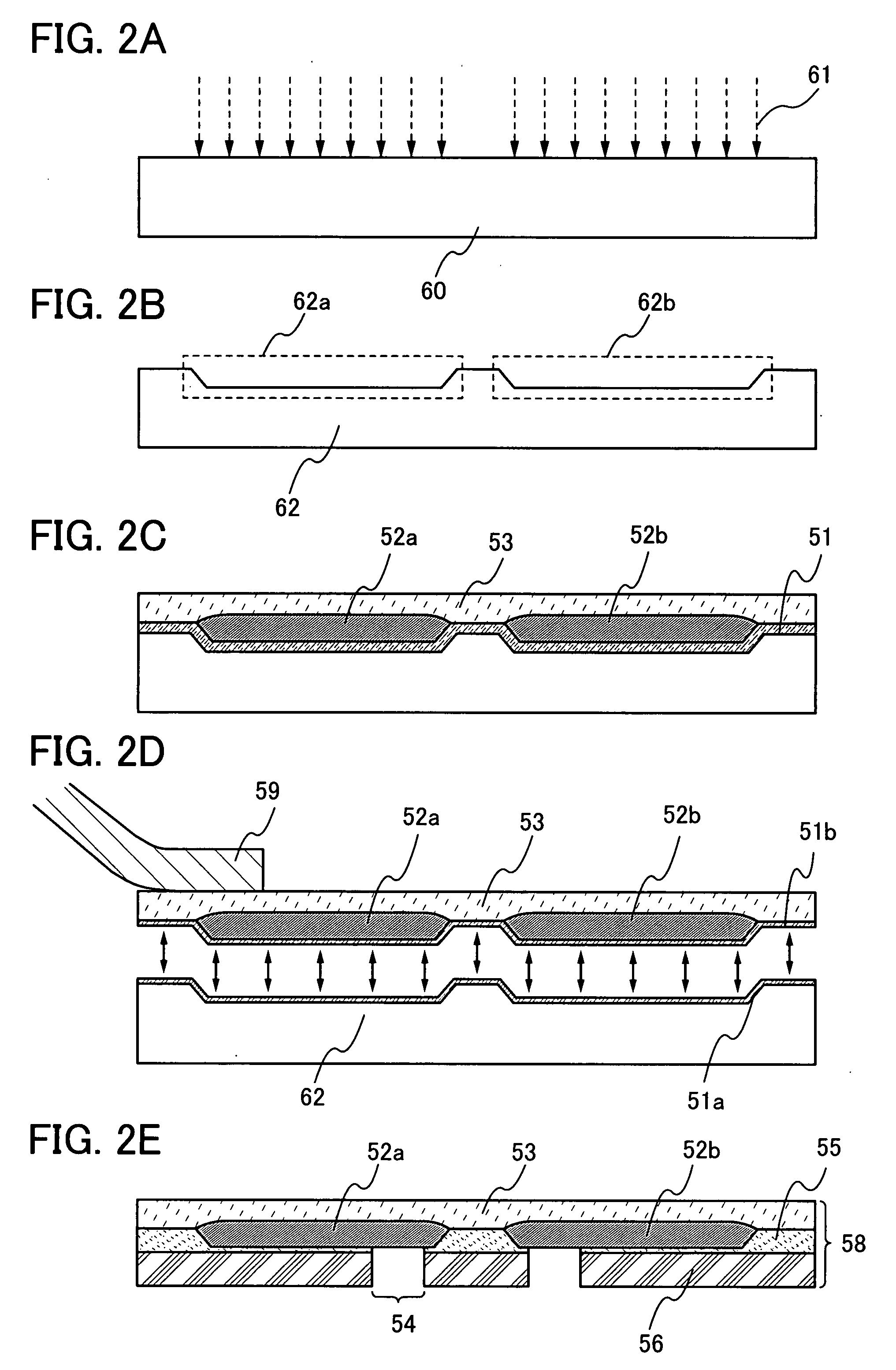

Method for forming conductive layer and substrate having the same, and method for manufacturing semiconductor device

InactiveUS20080096366A1Easy to splitWell formedDecalcomaniaSemiconductor/solid-state device detailsDevice materialSemiconductor

A separation layer is formed over a substrate having a depressed portion, using a silane coupling agent; a conductive layer and an insulating layer that covers the conductive layer are formed in the depressed portion over the separation layer; and a sticky member is attached to the insulating layer, then the conductive layer and the insulating layer are separated from the substrate. Alternatively, after these steps, a flexible substrate is attached to the conductive layer and the insulating layer.

Owner:SEMICON ENERGY LAB CO LTD

Method for forming conductive layer and substrate having the same, and method for manufacturing semiconductor device

InactiveUS7713836B2DecalcomaniaSemiconductor/solid-state device detailsSemiconductorSemiconductor device

Owner:SEMICON ENERGY LAB CO LTD

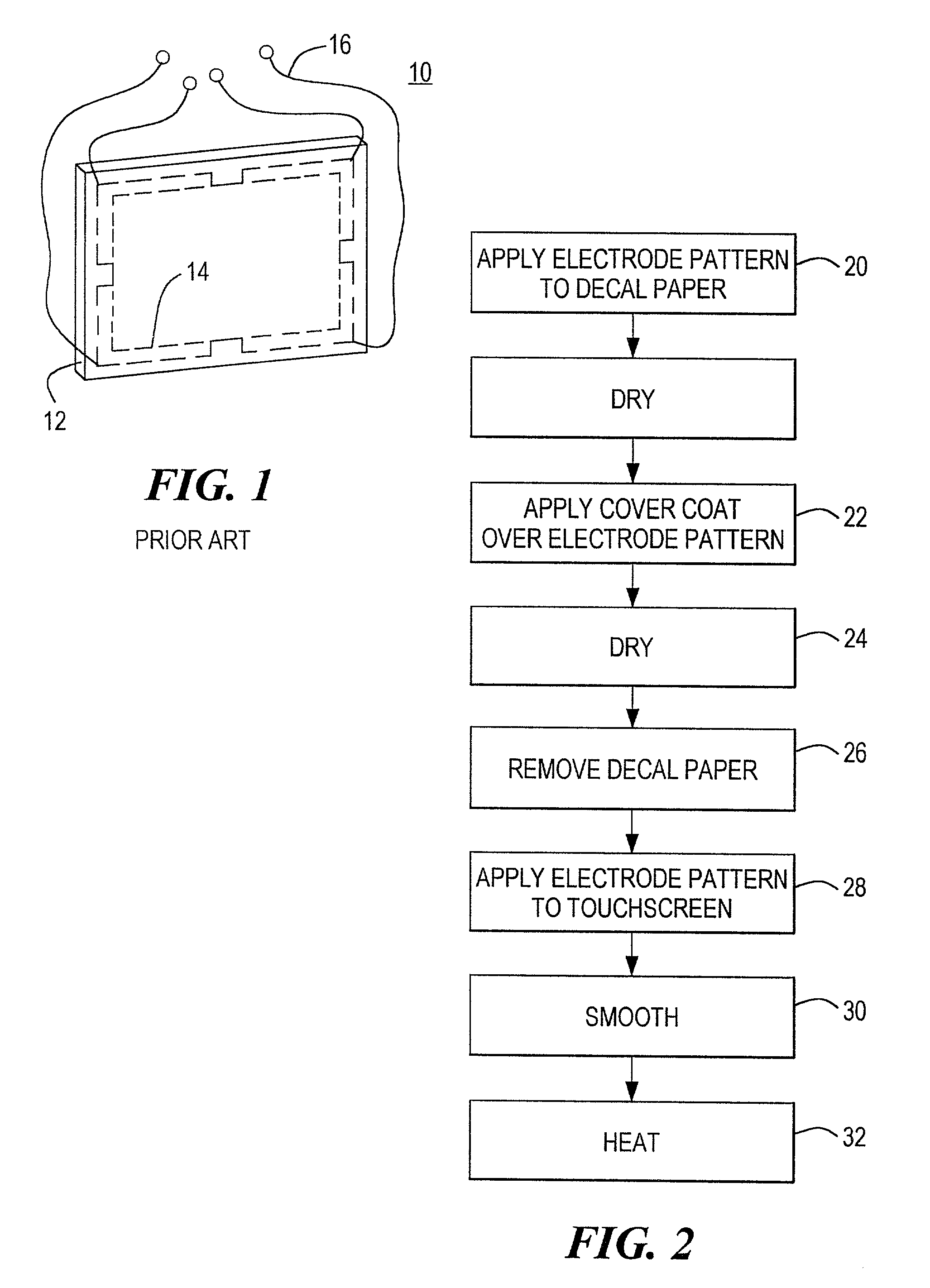

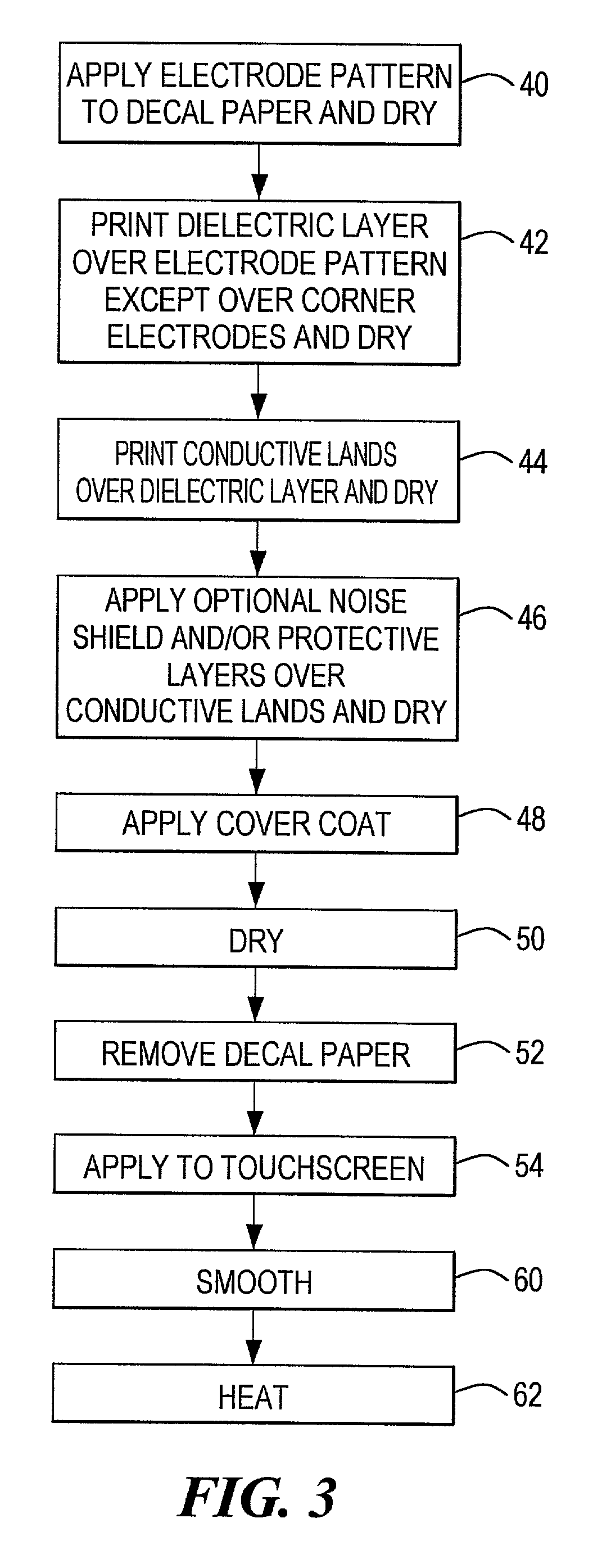

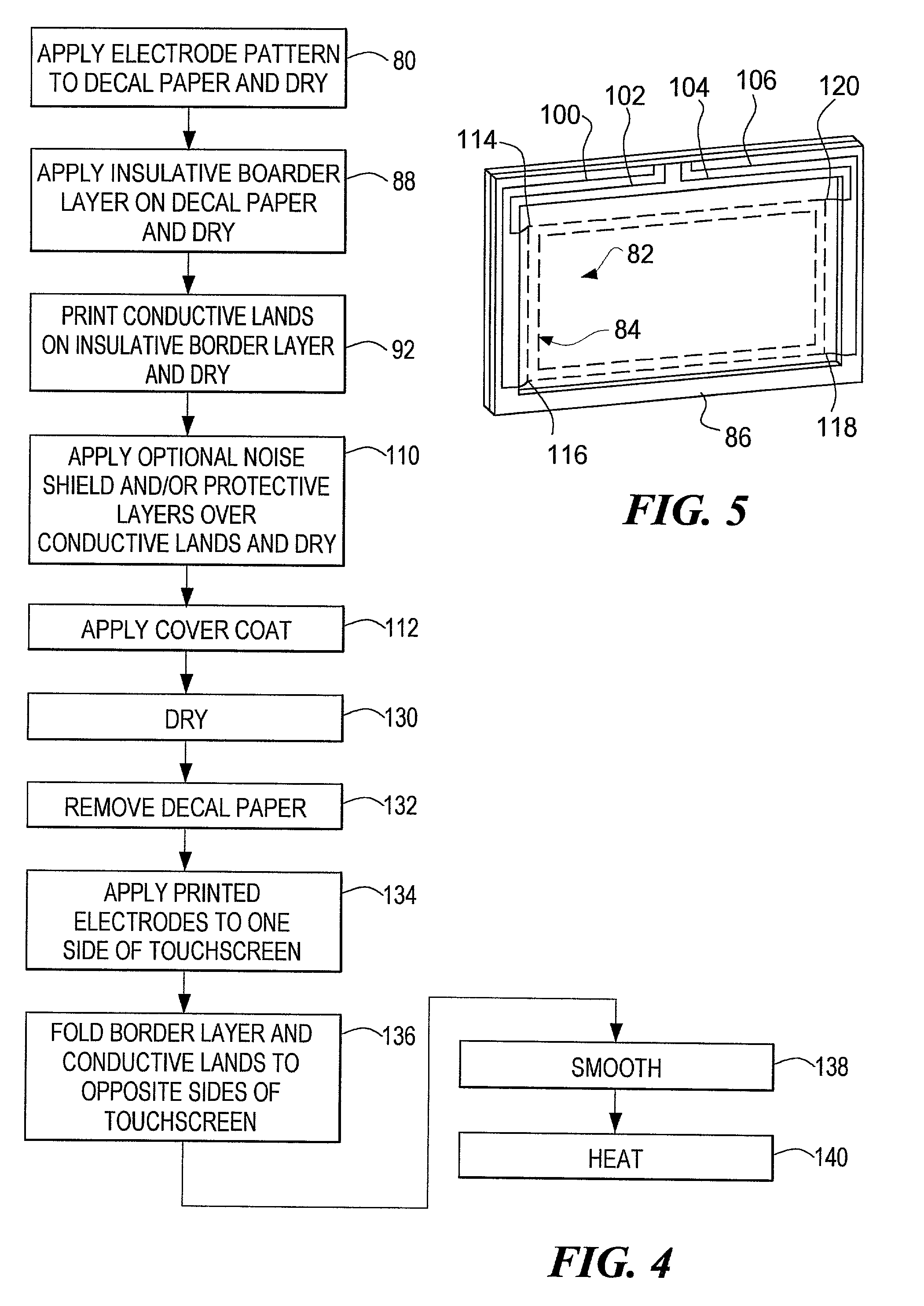

Touch screen with an applied edge electrode pattern

InactiveUS20010032698A1Precise applicationEliminate the problemDecalcomaniaDecorative surface effectsEngineeringTouchscreen

Owner:MICROTOUCH SYST

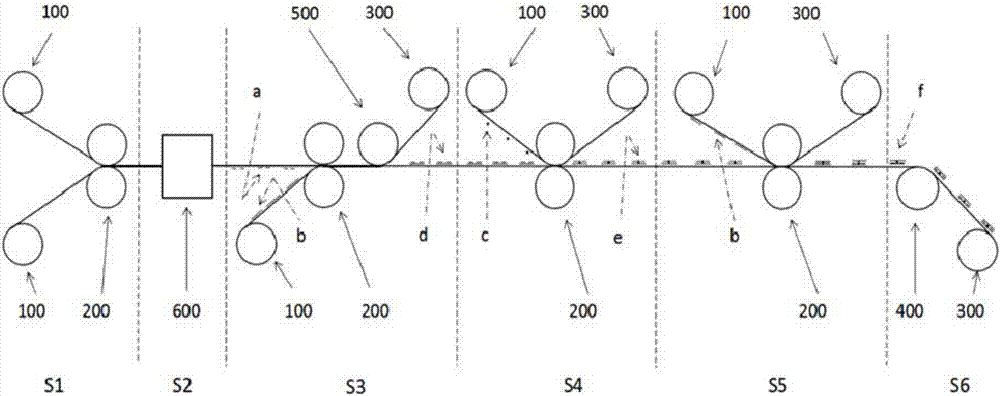

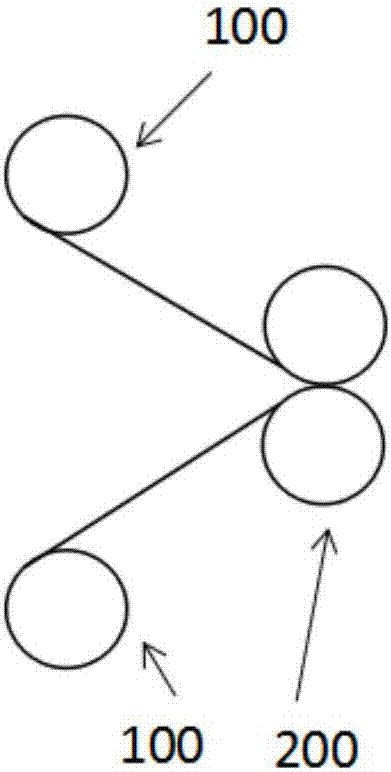

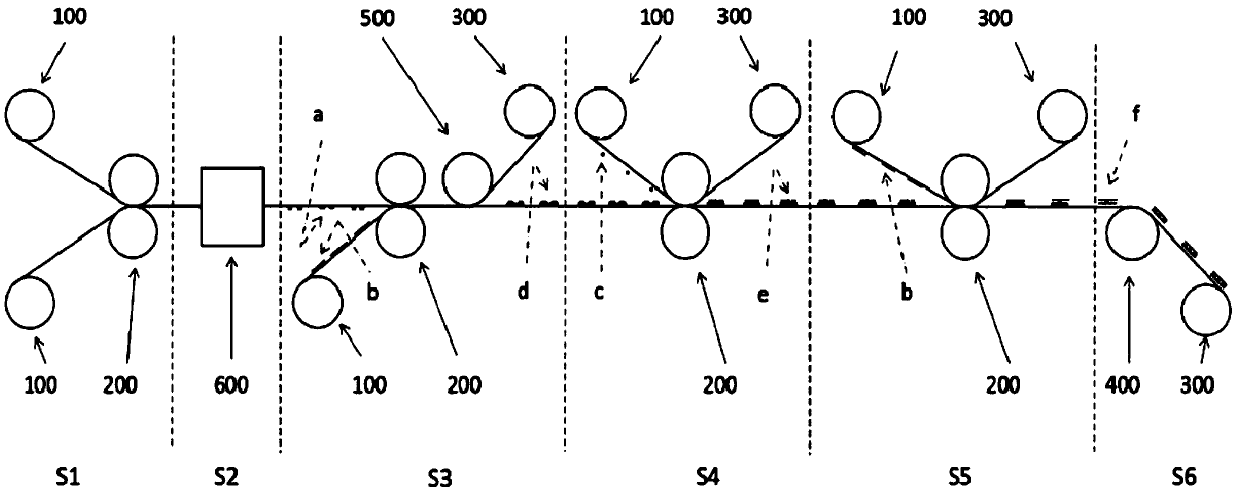

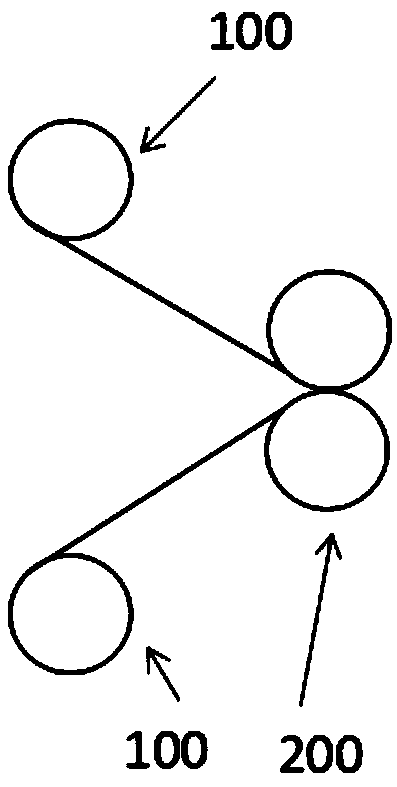

Method for manufacturing flexible circuit

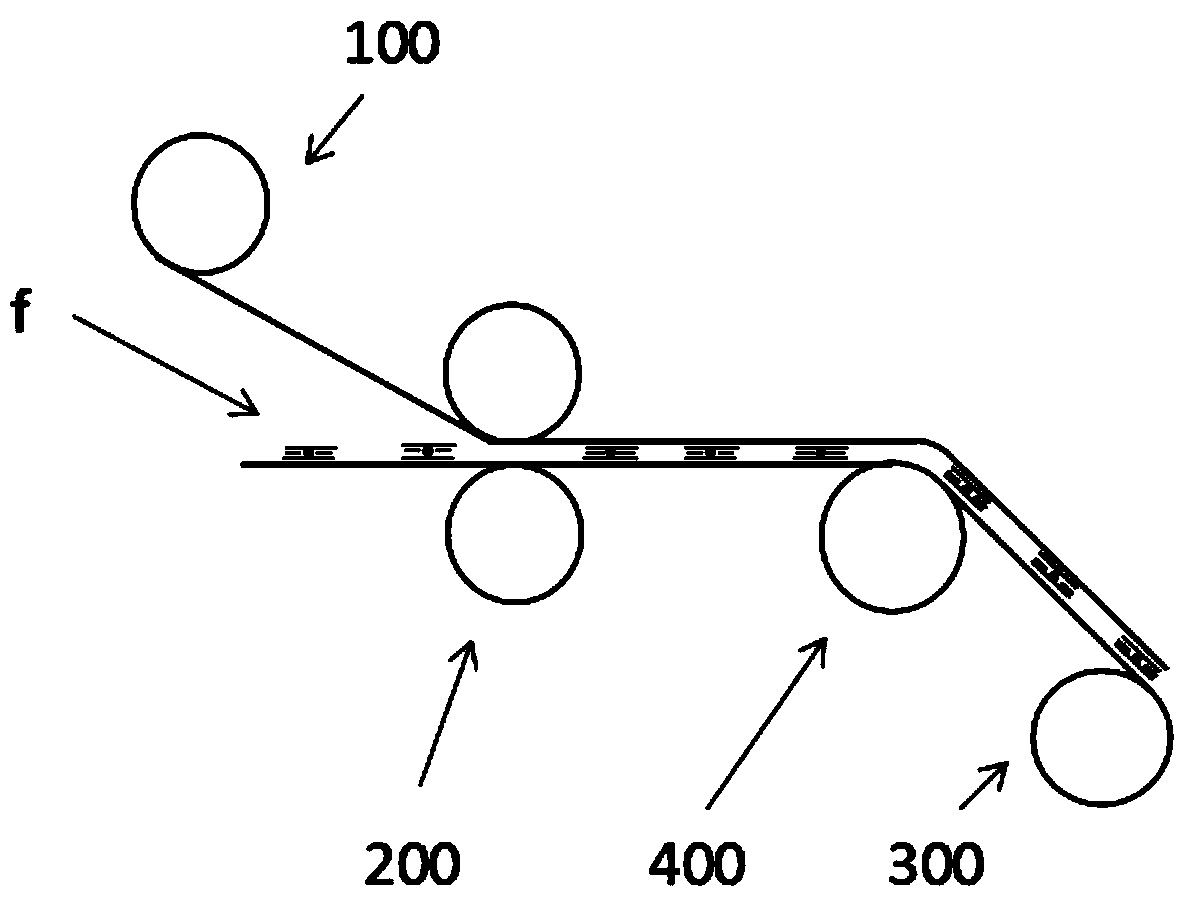

ActiveCN107222974AEfficient preparationFully automatedPrinted circuit assemblingDecalcomaniaElastomerFlexible circuits

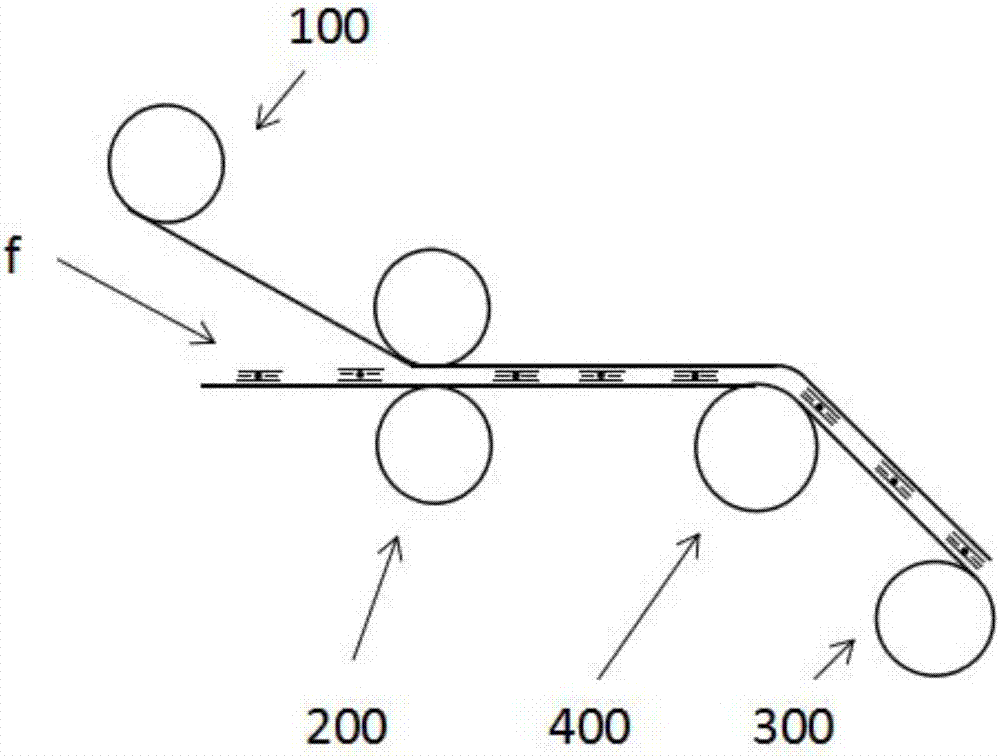

The invention discloses a method for manufacturing a flexible circuit. The method uses a roll-to-roll techniques and comprises the following steps of: S1, integrating a conductive layer and a first auxiliary substrate layer into one body and then making the same into a coiled material, using one end of the coiled material as an initial feeding unrolling end and unrolling the end to set length; S2, patterning the conductive layer of the coiled material unrolled to the set length to prepare a required circuit structure; S3, using a first elastomer layer provided with the substrate as a feeding end to be transferred to a pair of roller, transfer printing the circuit structure on the surface of the first elastomer layer, and removing the first auxiliary substrate layer; S4 assembling a chip and the circuit structure by using double-roll pressing and bonding difference so as to obtain a flexible circuit layer semi-finished product; and S5 transfer printing a second elastomer to the surface of the flexible circuit layer semi-finished product, wherein the second elastomer layer is used for the packaging layer of the flexible circuit layer semi-finished product. The method greatly improves the production efficiency of the flexible circuit by combining the process of making the flexible circuit with a roll-to-roll motion platform.

Owner:HUAZHONG UNIV OF SCI & TECH

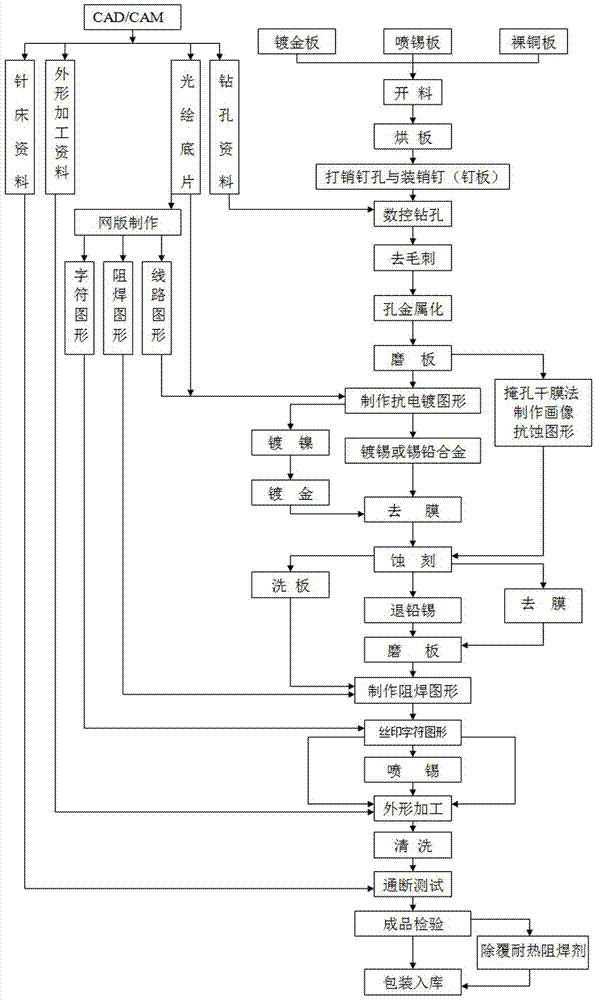

Method for manufacturing characters of printed circuit board

InactiveCN105208791AImprove alignment accuracyReduce bad problems such as easy blurDecalcomaniaPost-manufacturing circuit processesCooking & bakingScreen printing

The invention discloses a method for manufacturing characters of a printed circuit board. The method includes the following steps that S1, in the pre-process, a solder mask of the printed circuit board is manufactured; S2, solder resist ink with the same color as the needed characters is selected, and the viscosity of the solder resist ink is adjusted to an appropriate value; S3, a screen printing plate is prepared, and whole-plate screen printing is performed; S4, pre-baking is performed; S5, exposure and development are performed to obtain the characters of the printed circuit board; S6, after-baking is performed. The solder resist technological process is adopted for replacing a traditional character manufacturing process to manufacture the characters; the alignment accuracy of a solder resist exposure machine can reach the tolerance range of + / -20 micrometers which is far accurate than the tolerance range of + / -100 micrometers of human eye alignment, so that the alignment accuracy of the characters is greatly improved, and the undesirable phenomenon that the characters deviate or are printed on a bonding pad or become fuzzy easily is effectively reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method for manufacturing thickened silk printing plate and method for silk printing blue gel by using thickened silk printing plate

ActiveCN105050330AShort production processFull cuttingDecalcomaniaConductive pattern formationSlurry coatingEngineering

The invention relates to the technical field of PCB production, especially to a method for manufacturing a thickened silk printing plate and a method for silk printing blue gel by using the thickened silk printing plate. After slurry coating for second and third times, pressure-sensitive adhesive is pasted on the silk printing plate to increase the coating space. Relative thick photosensitive slurry can be coated on the silk printing plate. After coating for a third time, the thickness of the photosensitive film formed by dried photosensitive slurry reaches 0.35mm. An 18 silk printing plate is used to produce the thickened silk printing plate, of which the thickness reaches 0.51mm. When the thickened silk printing plate is used for silk printing blue gel, the thickness of the blue gel reaches 0.51mm, and the thickness of the blue gel after plate baking reaches 0.4mm. When the thickened silk printing plate is used for silk printing blue gel on PCB, the production requirement that the thickness of the blue gel reaches 0.25-0.55 mm can met through one-time silk printing. The production flow of silk printing blue gel is shortened, and the production efficiency is improved. When the thickened silk printing plate is used, silk printing pressure force of 5-6 kg / cm2 is adopted to make blue gel blanking complete, uniform and voidless and improve the quality of silk printed products.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Method for manufacturing solder mask layer on PCB

ActiveCN105208790APrevent removalProblems of preventing contamination of Immersion Nickel gold surfaceDecalcomaniaPrinted circuit aspectsSolder maskEngineering

The invention relates to the technical field of circuit board production, in particular to a method for manufacturing a solder mask layer on a PCB. According to the method, the solder mask layer is reinforced through secondary exposure, meanwhile a first shading area and a second shading area are arranged on a secondary film to prevent solder mask ink in a via hole from solidifying, a red adhesive tape is adhered to the position of a solder mask bridge and then secondary development is performed, the solder mask ink left in the via hole can be completely removed, and it can be ensured that the solder mask bridge does not swell and is not whity due to secondary development. The area of the first shading area and the area of the second shading area are set to be greater than those of the corresponding exposed positions and that of the orifice at the coating oil level position, and the problem that the solder mask ink left in the via hole solidifies during secondary development and is difficult to remove can be effectively prevented. By means of the method manufacturing the solder mask layer, the problem that the solder mask ink pollutes the nickel-gold immersion surface during nickel-gold immersion surface treatment can be prevented.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

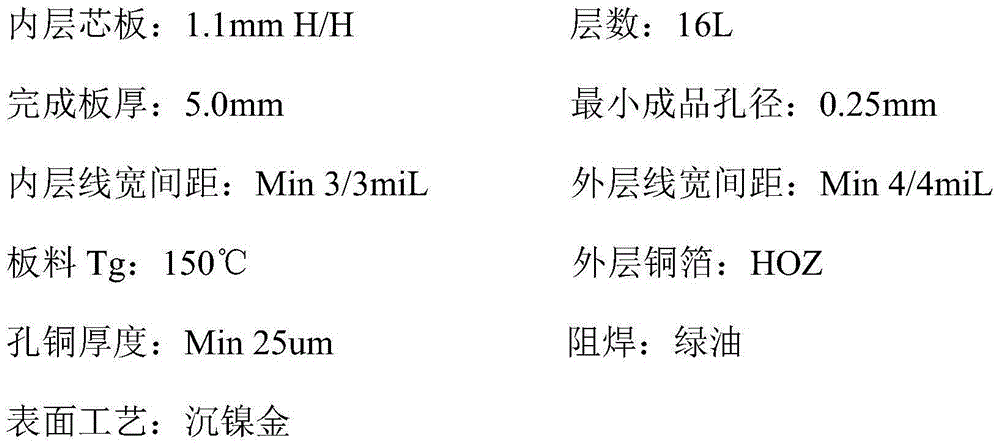

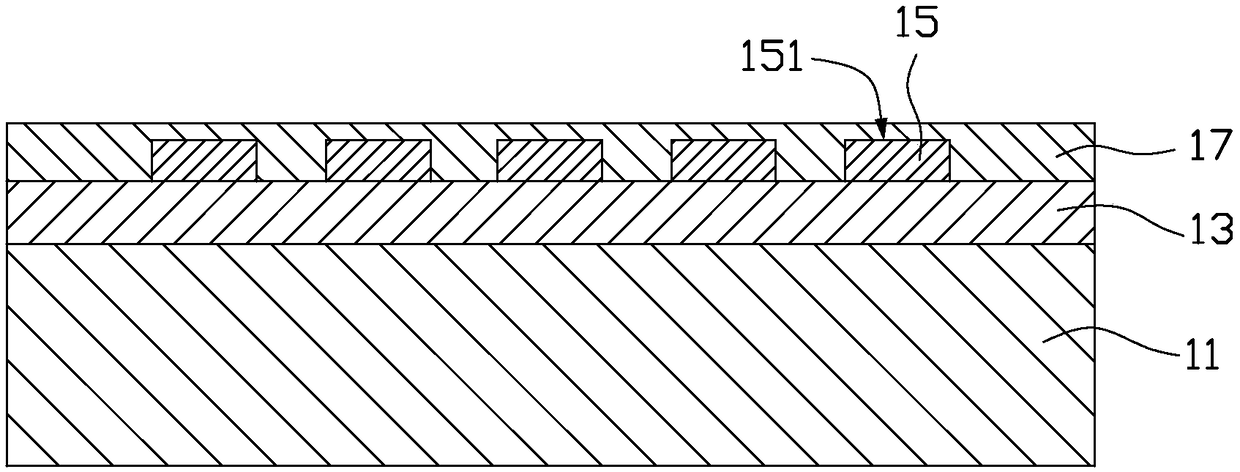

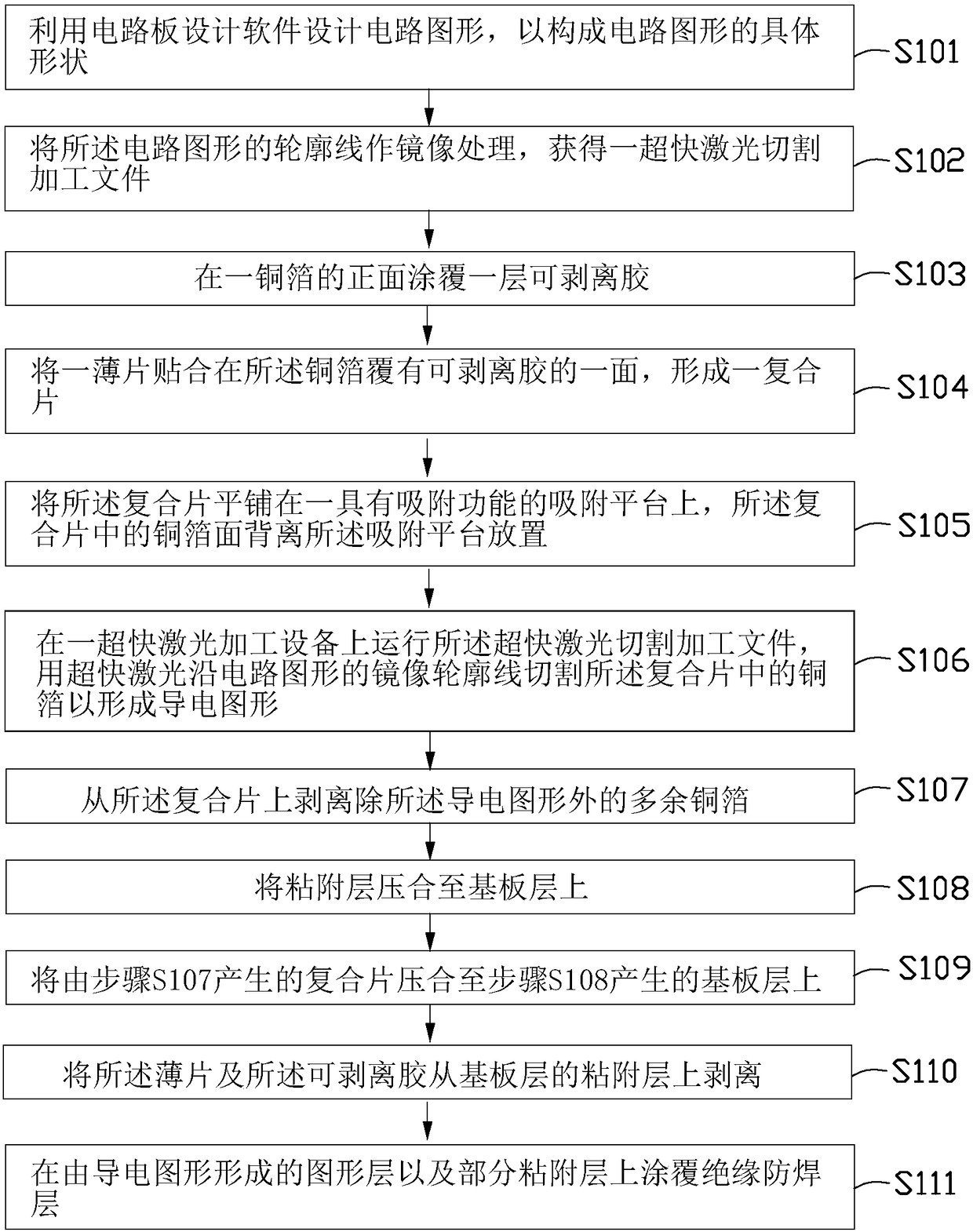

Circuit board and manufacturing method thereof

InactiveCN108235574ARealize green environmental protectionFree from contactDecalcomaniaConductive pattern formationEnvironmental resistanceEngineering

The invention provides a manufacturing method of a circuit board, which comprises the steps of designing a circuit pattern; performing mirror image processing on a contour line of the circuit patternto obtain a mirror image contour line of the circuit pattern; coating a copper foil with a layer of strippable glue; attaching a sheet to the side, which is coated with the strippable glue, of the copper foil so as to form a composite sheet; tiling the composite sheet on an adsorption platform with an adsorption function; cutting a copper foil surface in the composite sheet along the mirror imagecontour line of the circuit pattern by using super fast laser so as to form a conductive pattern; stripping the redundant copper foil except for the conductive pattern from the composite sheet; laminating the copper foil surface on which the conductive pattern is formed in the composite sheet to a circuit board substrate coated with an adhesive layer; and stripping the sheet and the strippable glue from the circuit board substrate. The invention further provides a circuit board manufactured according to the manufacturing method. The manufacturing method provided by the invention of the circuitboard has the characteristics of environment-friendly manufacturing process and simplified flow.

Owner:吴勇杰 +2

Method of applying an edge electrode pattern to a touch screen

InactiveUS7077927B2Eliminate the problemImprove reliabilityDecalcomaniaDecorative surface effectsEngineeringConductive materials

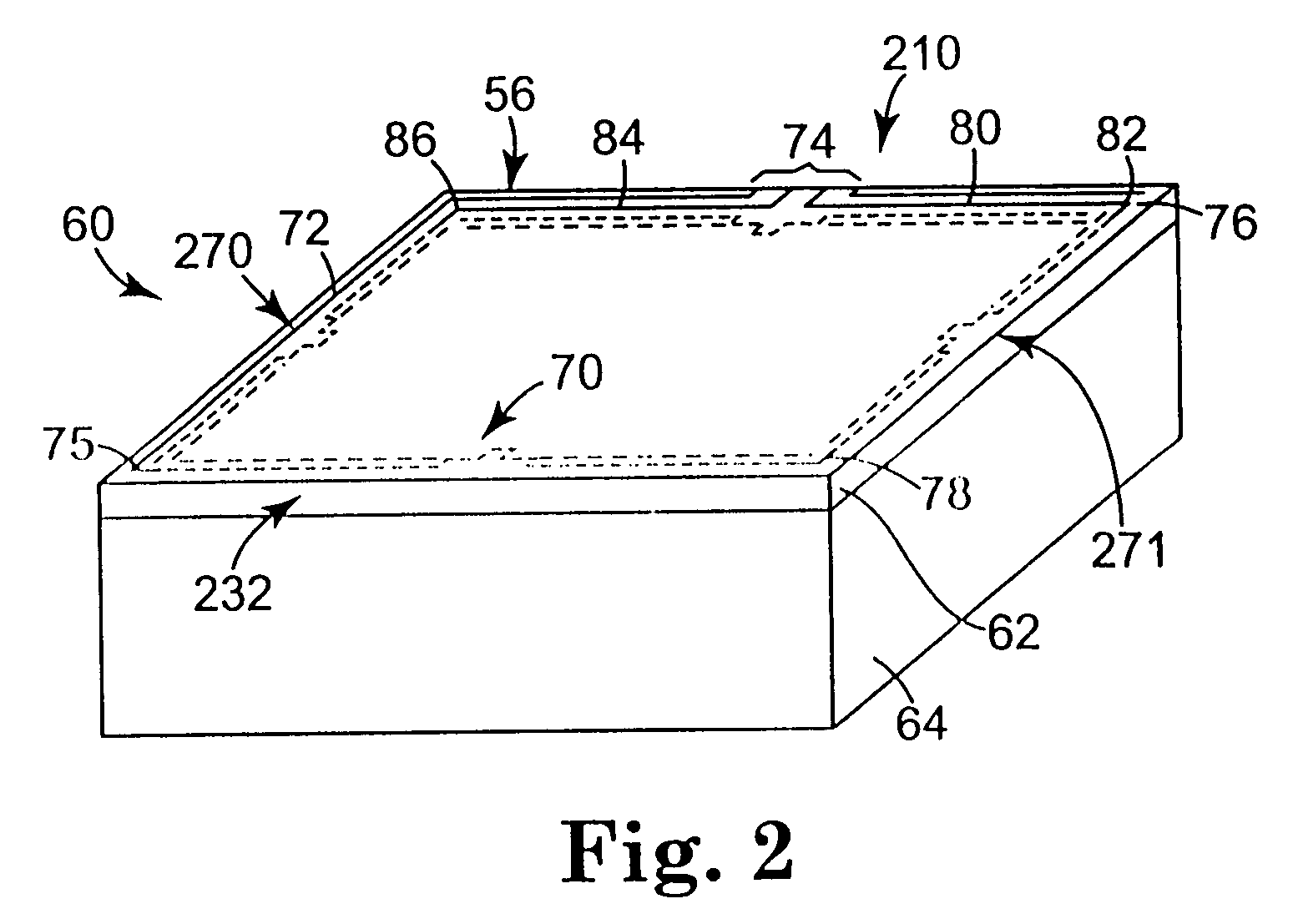

A method of applying an edge electrode pattern to a touch screen. The method includes depositing, on a first surface of a decal strip, conductive material in the form of an edge electrode pattern, placing the first surface of the decal strip on one edge of a touch screen, applying heat and pressure to an opposite surface of the decal strip until the edge electrode pattern is transferred from the first surface of the decal strip to the touch screen; and removing the decal strip.

Owner:3M INNOVATIVE PROPERTIES CO

High-temperature hot stamping film for manufacturing conductive wires, manufacturing method and application for high temperature hot stamping film

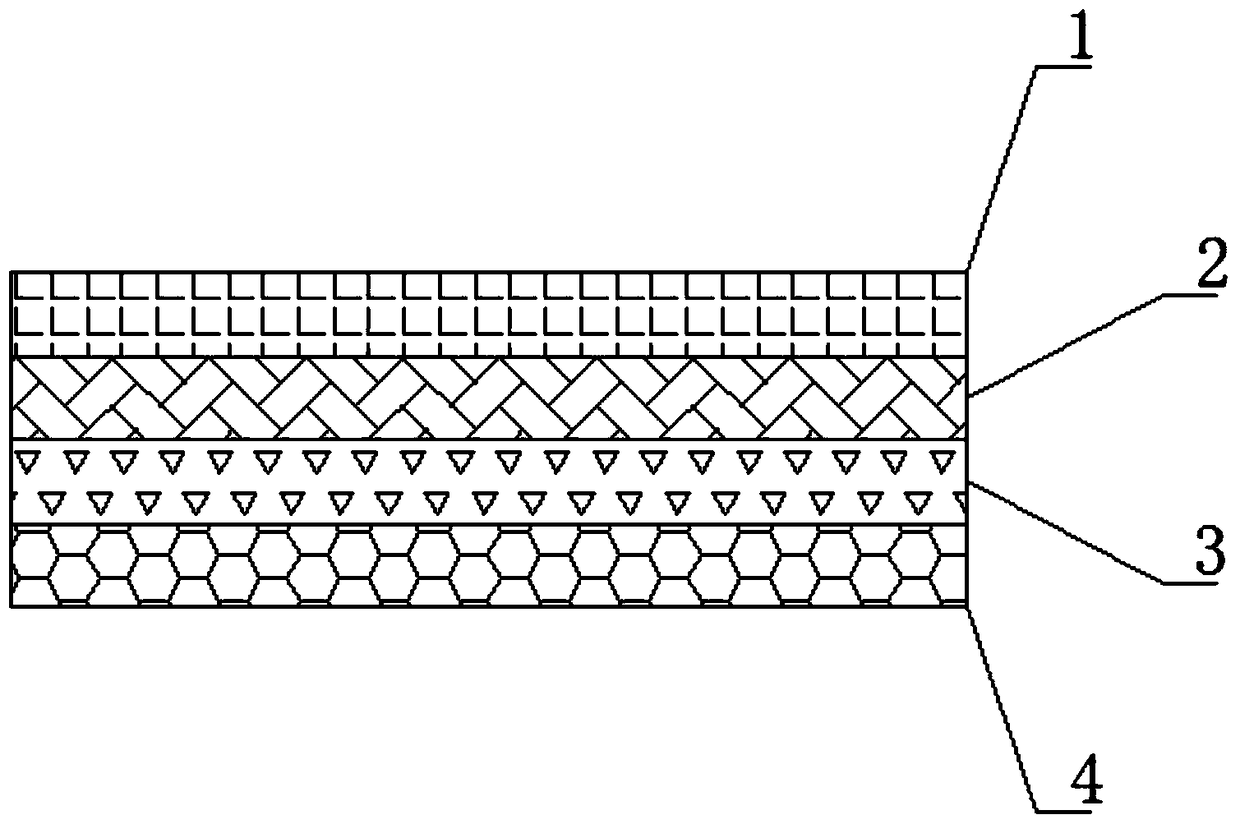

ActiveCN105323972ASimple structureLow costDecalcomaniaConductive pattern formationHot stampingEngineering

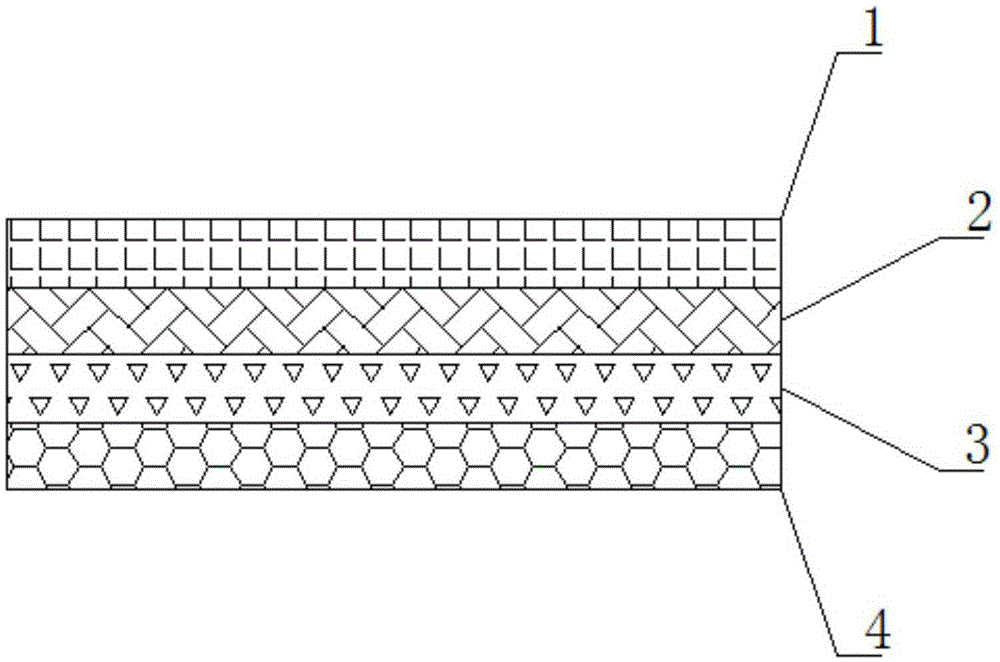

The invention relates to the technical field of hot stamping, and in particular to a high-temperature hot stamping film for manufacturing conductive wires, a manufacturing method and an application for the high temperature hot stamping film. The high-temperature hot stamping film comprises a base layer, a release layer, a conductive layer and a hot glue-melting layer in sequence; and required conductive wires can be manufactured by hot stamping heads of different shapes at the temperature of 160-180 DEG C. The special hot stamping film for the conductive wires is simple in structure, low in cost, and can be used for preparing various kinds of irregular conductive wires, such as rfid antenna, connection wires on pcb and the like.

Owner:WUHAN WEDO INFORMATION & TECH

Simple and convenient manufacturing method of circuit board

InactiveCN106211607AEasy to makeImprove performanceDecalcomaniaConductive pattern formationElectronic componentCopper

The invention discloses a simple and convenient manufacturing method of a circuit board. The method comprises the following steps of cutting a copper clad plate of which two surfaces are coated with copper films, and then polishing an oxide layer on the surface of the copper clad plate to obtain the processed copper clad plate; bonding and transferring the processed copper clad plate and printed circuit board paper and firmly transferring carbon powder on the paper to the copper clad plate to obtain the transferred copper clad plate; and corroding and drilling the transferred copper clad plate and welding electronic components to obtain the circuit board. In the manner, the simple and convenient manufacturing method of the circuit board does not comprise a complicated step; operating personnel are convenient to learn and grasp; meanwhile, good performance of the circuit board can be ensured; the quality of the circuit board is not reduced; and the using effect is good.

Owner:FOREWIN FPC SUZHOU

Lead-free electroplating method based on reserved larger finger connection position

ActiveCN108366492AGood lookingAvoid the stringent requirements for bit accuracyDecalcomaniaElectricityEtching

The invention discloses a lead-free electroplating method based on a reserved larger finger connection position. The method comprises the following steps that a production board is provided, the surface of the production board comprises an external line area and a finger area, and finger positions to be electroplated are made in the finger area; the external line area in the production board is silk-screened with anti-electricity gold printing ink or a coating adhesive tape, and copper surfaces of the finger positions are exposed; a copper surface, not formed by etching, of the external line area is used for conducting, and the finger positions are electroplated to form coatings; an external line is prepared in the external line area; and solar mask preparation, surface processing and molding are carried out on the production board successively to form a finished board. According to the method, the external line part is prepared after that the larger finger connection position is reserved, a final graph is formed via twice graph transfer, the problem of a residual electroplating lead of a traditional method is avoided, the signal completeness and anti-breakdown performance can be improved, and the problem that a signal line is too thin and etched of a traditional lead-removing chemical etching method is avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

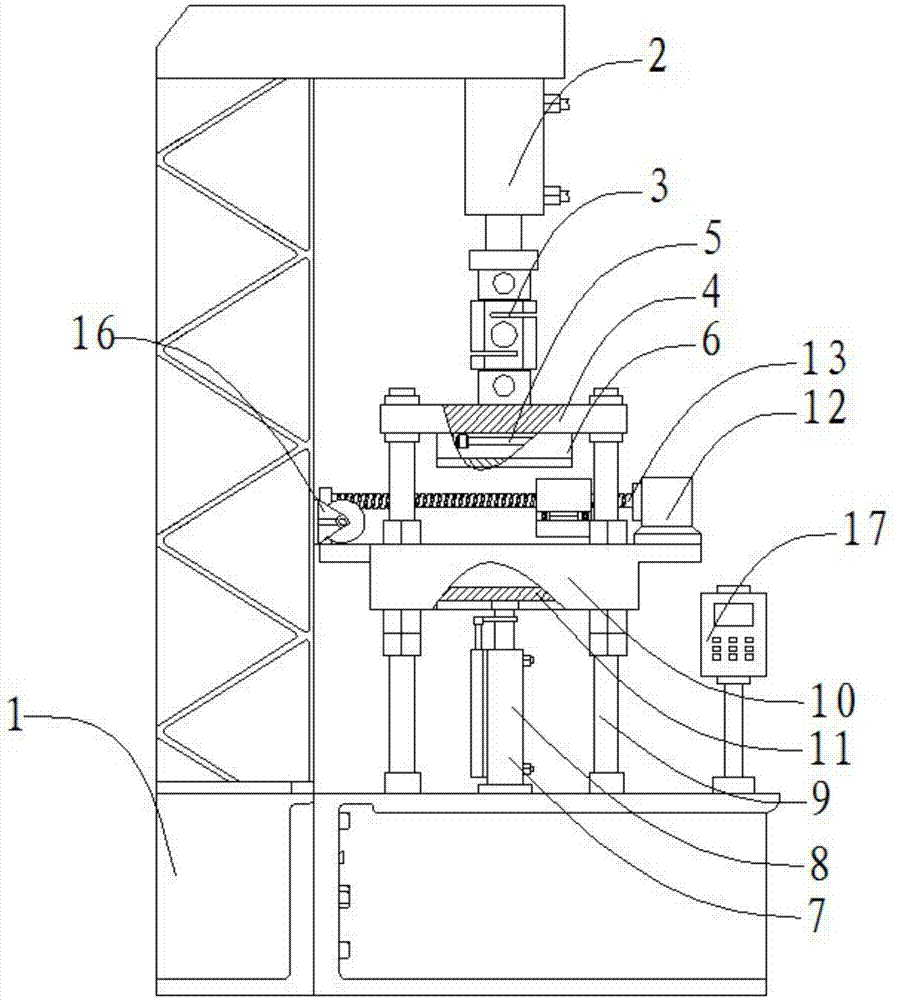

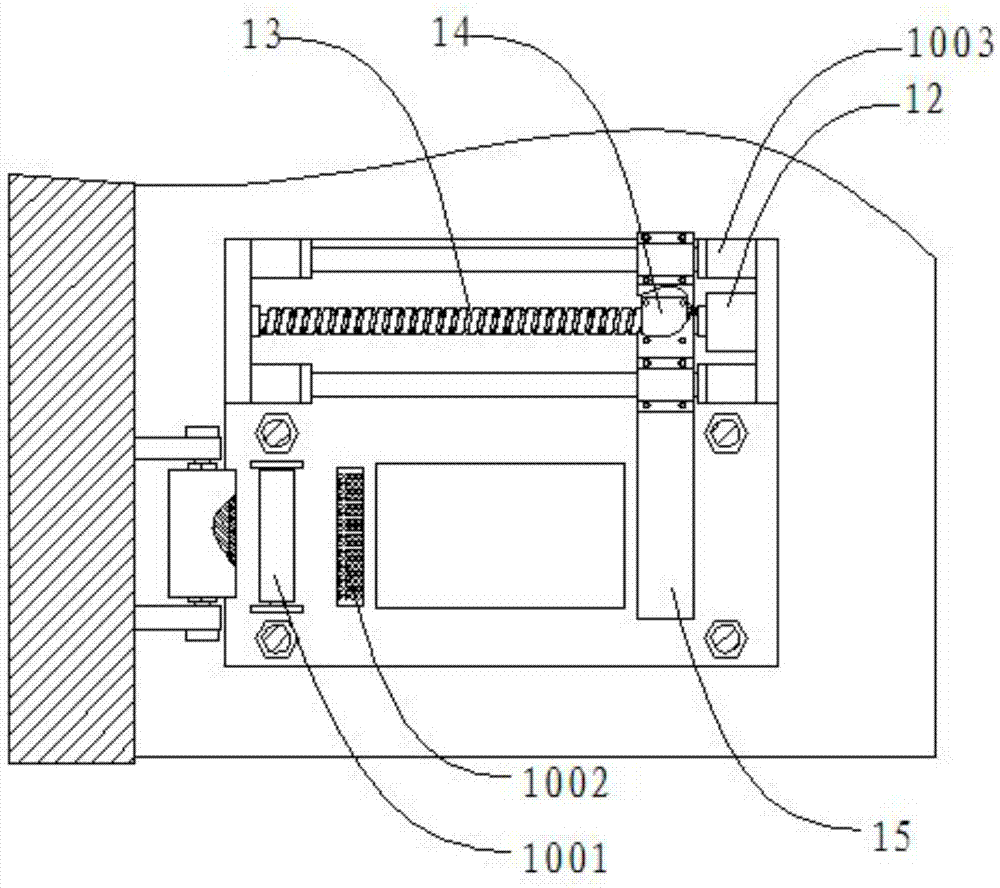

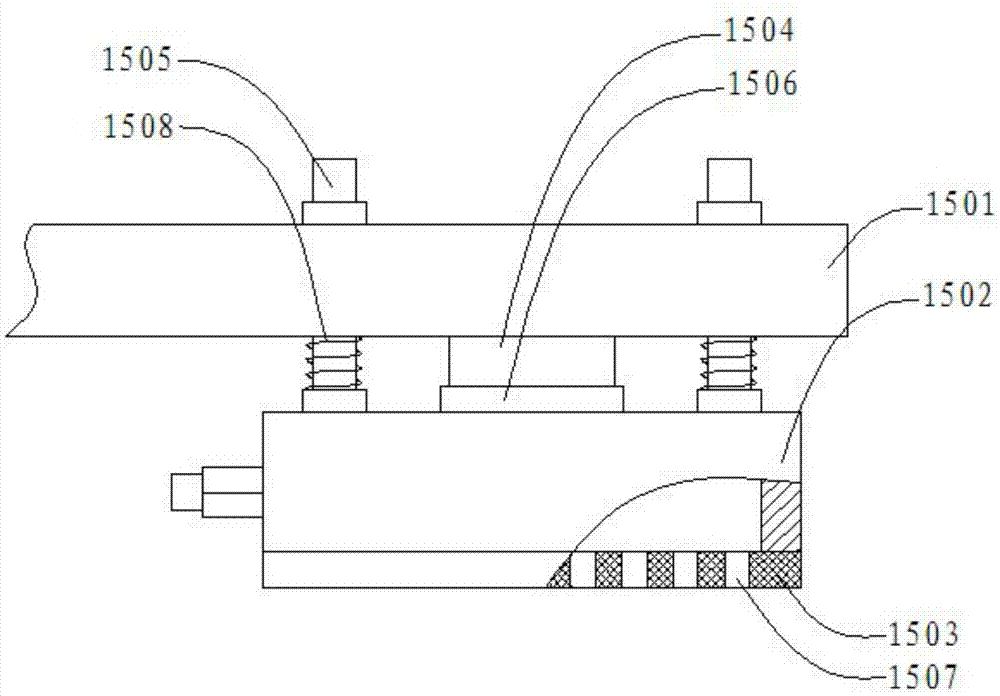

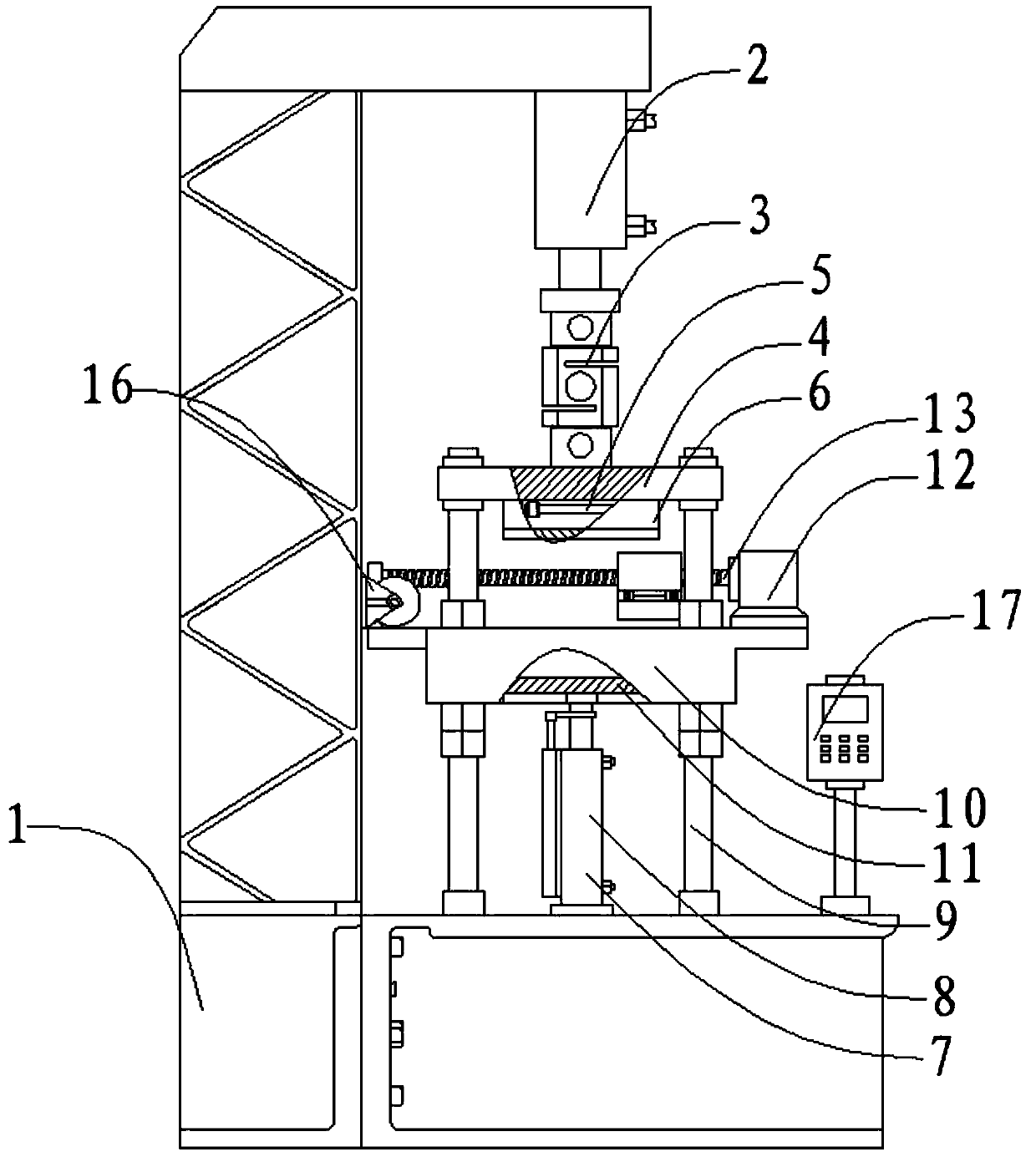

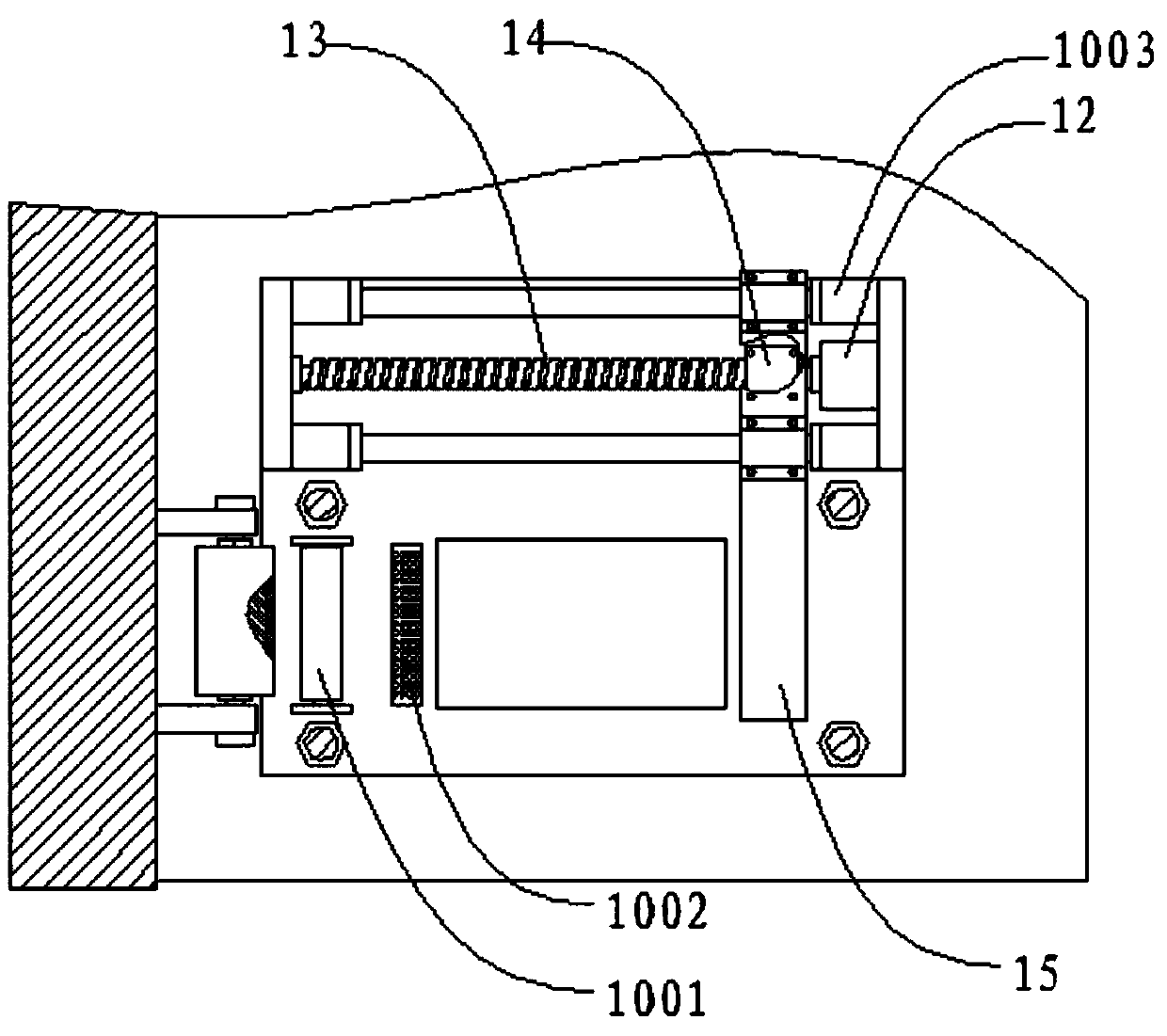

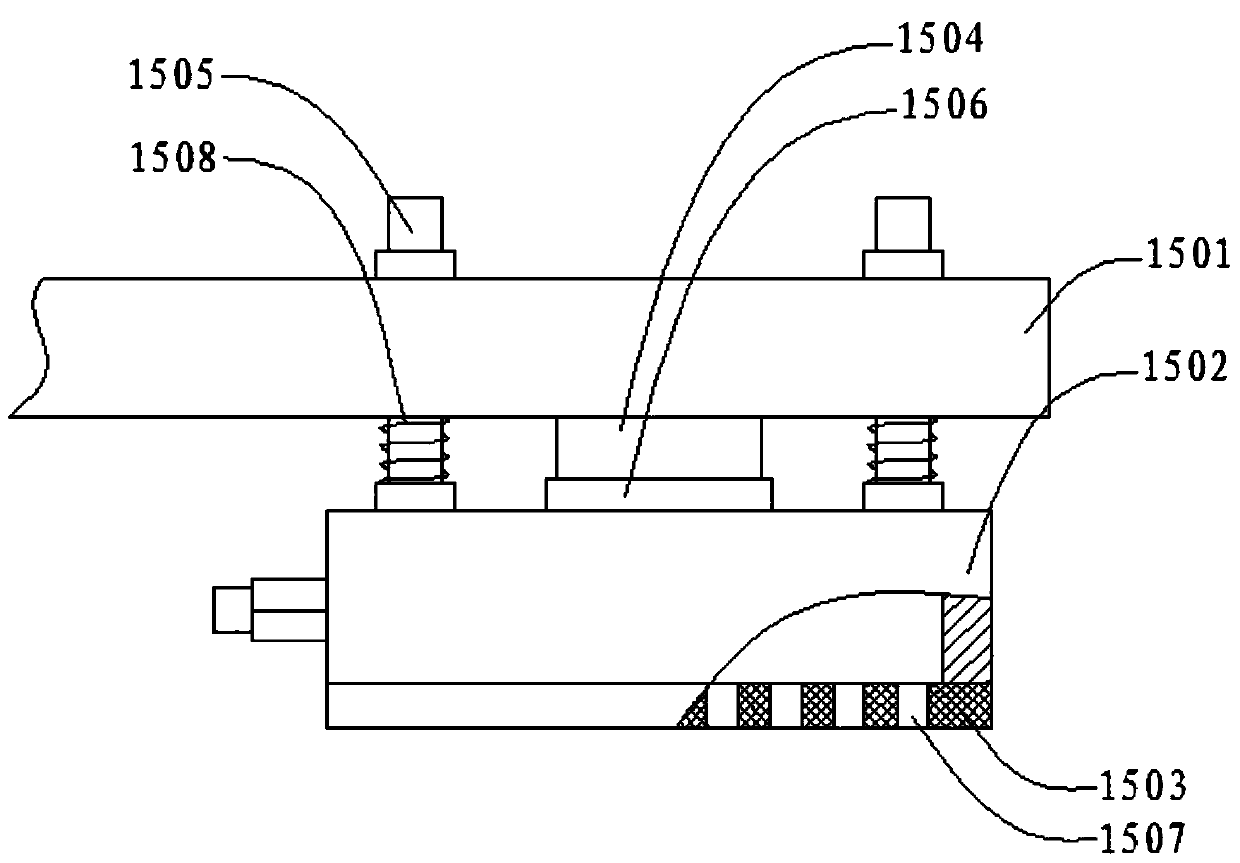

Automatic dry film pressing device for PCB

ActiveCN106937485AImprove securityAvoid it happening againDecalcomaniaConductive material chemical/electrolytical removalMotor driveHeat conducting

The invention discloses an automatic dry film pressing device for PCBs. The device comprises a frame, a first cylinder, a pull pressure sensor, an upper bracket, a heating pipe, a heat conducting pressure head, a second cylinder, a displacement sensor, columns, a lower bracket, a holding plate, a servo motor, a screw, a feed nut, a film absorbing component, a roller, and a controller. An air suction box absorbs a dry film. Then, the servo motor drives the feed nut to move leftwards through the screw, so as to drive the film absorbing component to move leftwards to right above the air suction box. After the film absorbing component absorbs the dry film under control of the controller, the film absorbing component is moved by the servo motor to a set position, and the second cylinder pushes the holding plate to move up to a set position. The first cylinder drives the upper bracket to move down, and the heat conducting pressure head presses the fry film on a PCB. The device changes the original line-contact filming mode into a surface-contact filming mode. The uniformity of filming is increased. Local bubble generation and wrinkling of a dry film on a PCB are avoided. The safety performance of PCB is improved. The labor intensity of operating personnel is reduced.

Owner:SUZHOU DIFEITE ELECTRONICS CO LTD

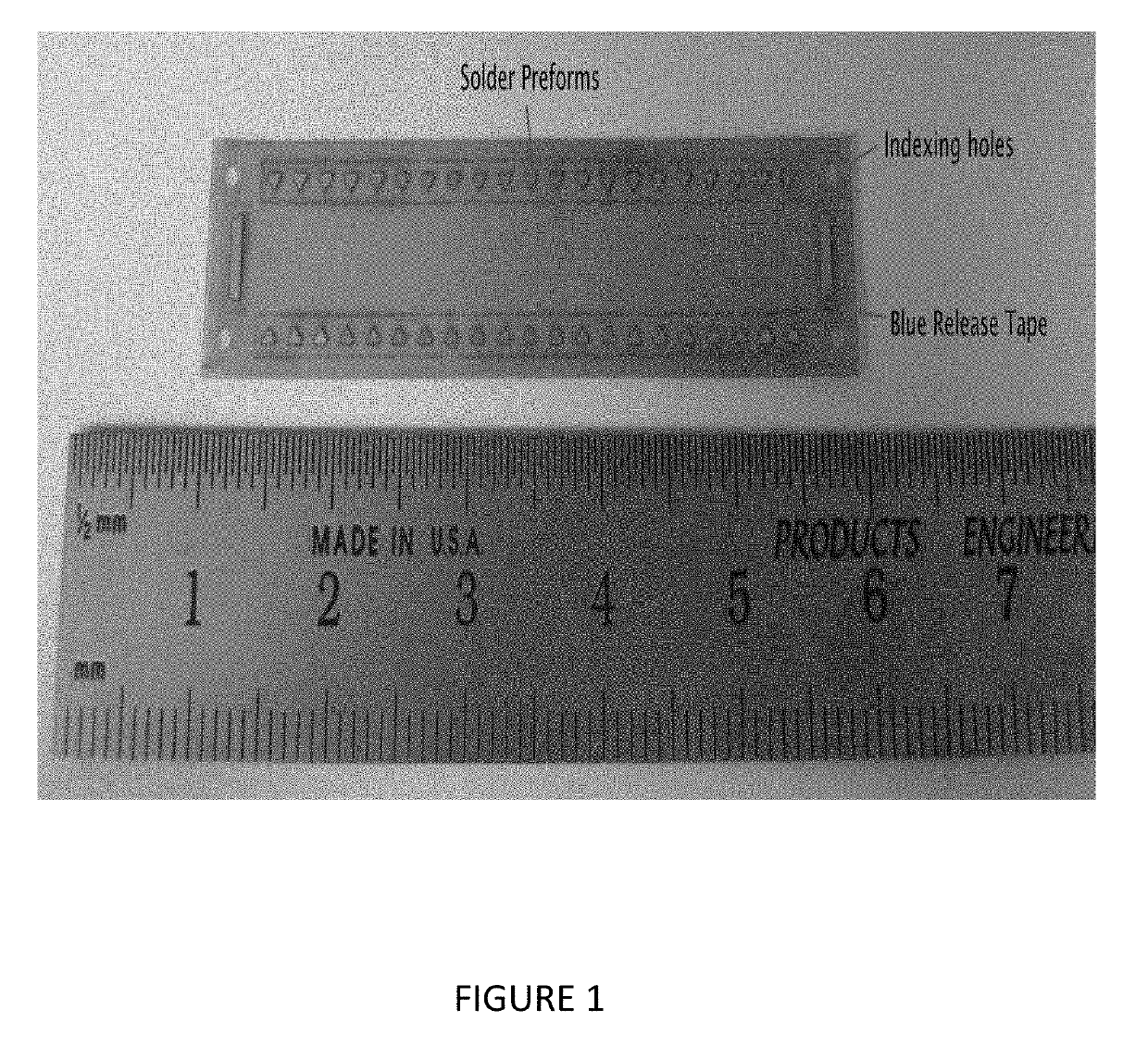

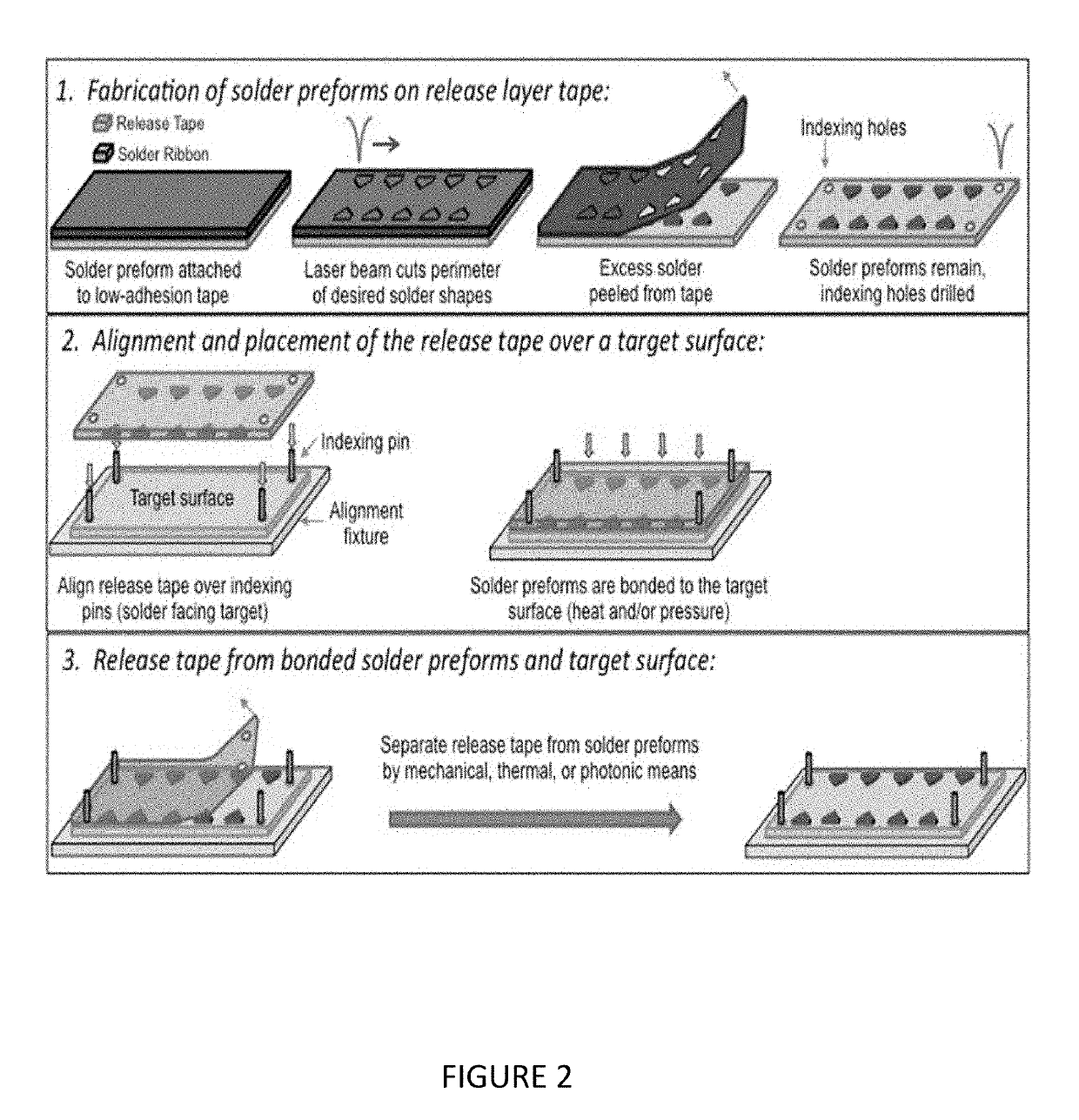

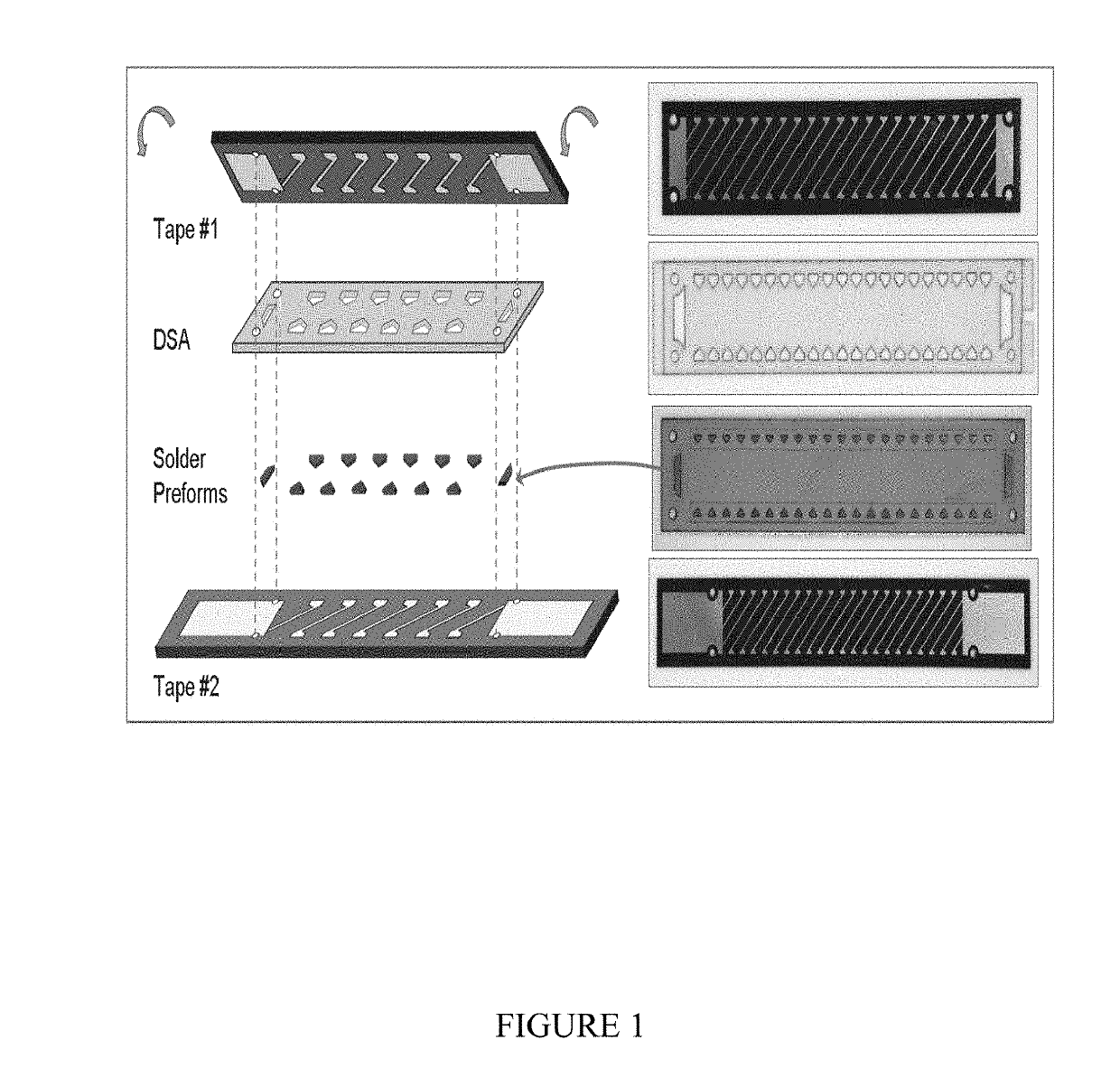

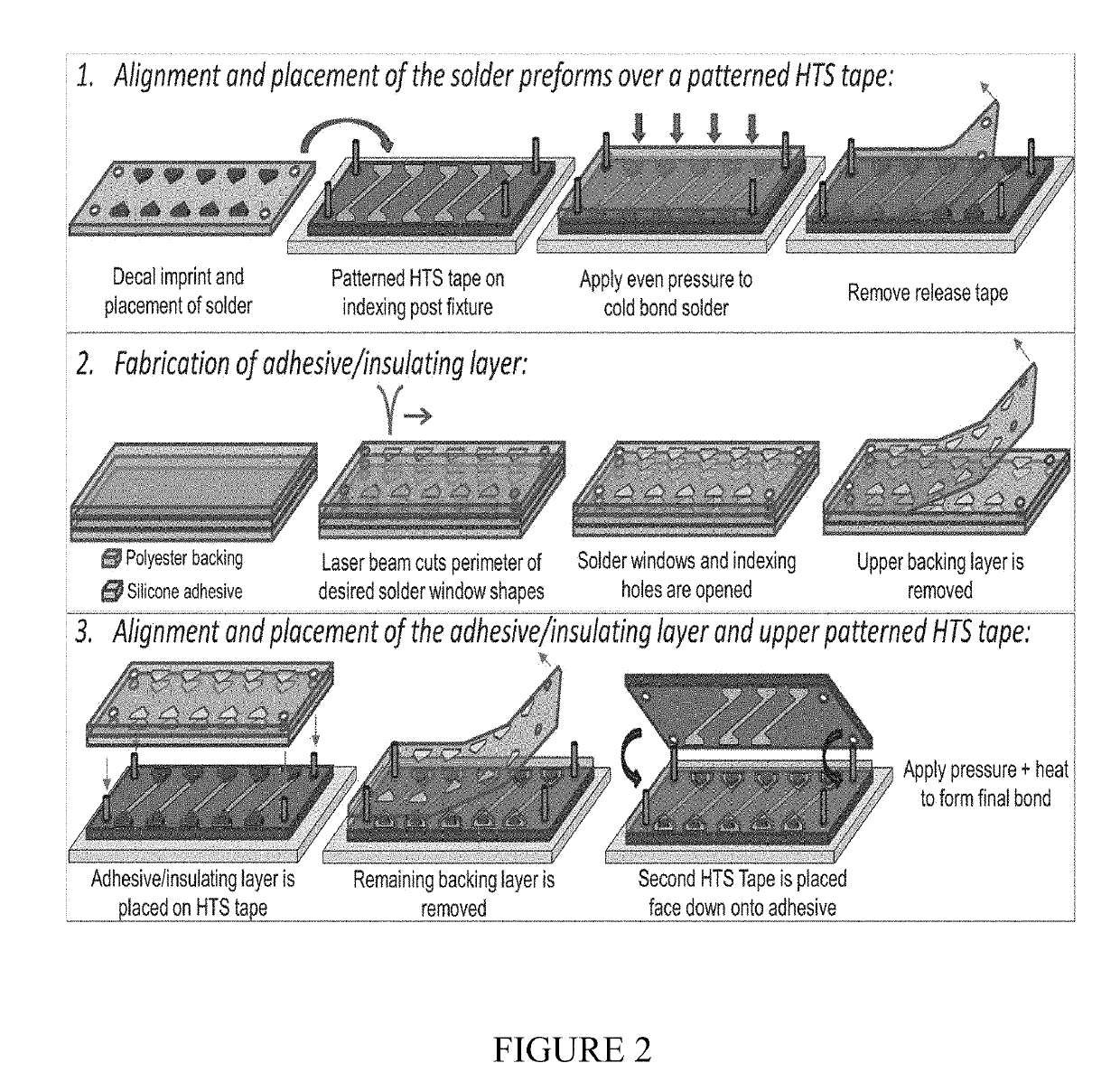

Precise Alignment and Decal Bonding of a Pattern of Solder Preforms to a Surface

InactiveUS20190184480A1Efficient and scalableEasy to integrateDecalcomaniaSemiconductor/solid-state device detailsTarget surfaceAdhesive belt

A method of making precise alignment and decal bonding of a pattern of solder preforms to a surface comprising cutting and placing a length of a solder ribbon onto a semiconductor release tape forming a solder ribbon and semiconductor release tape combination, placing the solder ribbon and semiconductor release tape combination on a vacuum chuck on X-Y stage pair in a laser micromachining system, adjusting the working distance, laser-cutting an outline, peeling off the solder ribbon, allowing the desired solder shape to remain, creating indexing holes, providing a target surface on an alignment fixture with indexing pins, aligning the indexing holes, placing the semiconductor release tape with the desired solder shape on the target surface, pressing the desired solder shape onto the target surface, removing the release tape, and making a pattern of the desired solder shape with precise alignment and decal bonding on the target surface.

Owner:UNITED STATES OF AMERICA

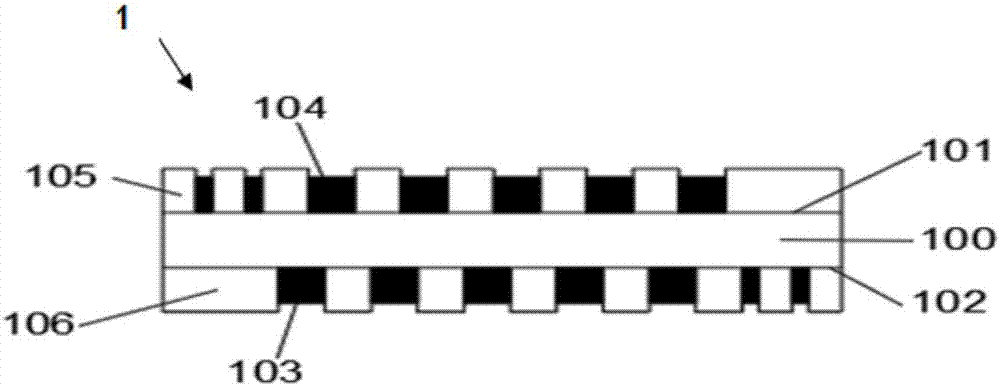

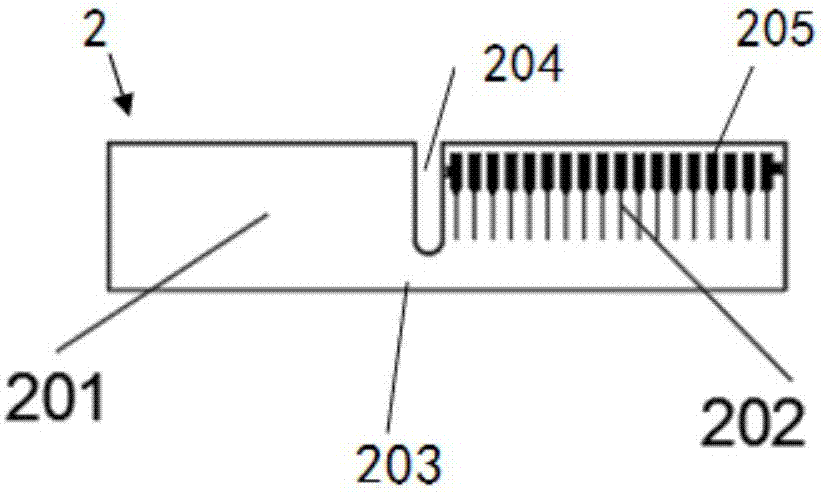

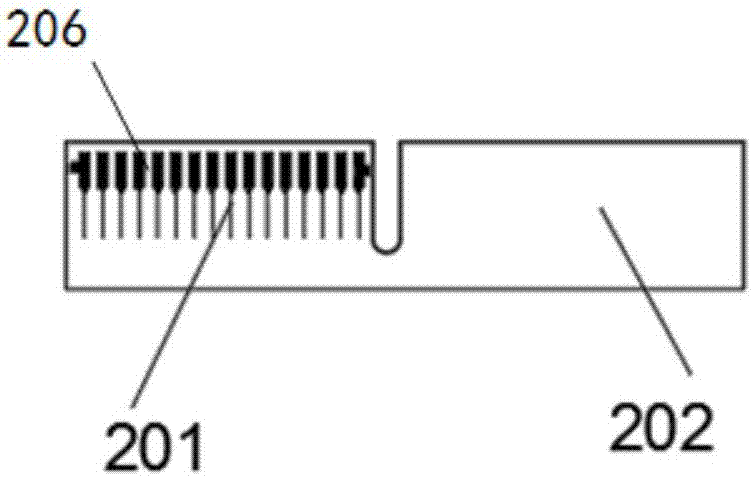

Double-side imprinted conductive film, manufacturing method thereof, circuit board and touch module

InactiveCN107396543AImprove transmittanceLow costDecalcomaniaConductive pattern formationConductive coatingEngineering

The invention relates to a double-side imprinted conductive film, a manufacturing method thereof, a circuit board and a touch module. The manufacturing method of the double-side imprinted conductive film comprises the steps of S1, providing a transparent substrate and a mould group, wherein the transparent substrate comprises a first surface and a second surface which are arranged oppositely, and the mould group comprises an input end mould and an output end mould both having corresponding para-position targets; S2, imprinting an input end circuit on the first surface of the transparent substrate through the input end mould by utilizing a nanometer imprinting way, and imprinting an output end circuit on the second surface of the transparent substrate through the output end mould by utilizing the nanometer imprinting way; and S3, carrying out conductive coating and solidification at the input end circuit and the output end circuit. The manufacturing method of the double-side imprinted conductive film is simpler; and higher yield is obtained.

Owner:SUZHOU WEIYEDA TOUCH TECH +1

Thinned electronic product and manufacturing method thereof

ActiveUS20190037698A1Simple manufacturing processReduce material costsDecalcomaniaPrinted resistor incorporationEngineeringElectronic component

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Method for simply and conveniently manufacturing circuit board

The invention discloses a method for simply and conveniently manufacturing a circuit board. The method comprises the following steps: enabling the smooth surface of paper to be printed to face a printing person, putting the paper to be printed into a printing instrument, printing drawn circuit boards, and obtaining a plurality of printed circuit boards; cutting the printed circuit boards, pasting the surface, which is printed with the circuit boards, of the paper on a copper cladding board to carry out heat transfer printing, and obtaining the circuit board subjected to the transfer printing; carrying out corrosion on the circuit board subjected to the transfer printing, inserting an electronic component, and processing to obtain circuit board. Through the way, the method for simply and conveniently manufacturing the circuit board is simple in operation and can be popularized and applied on a large scale, the manufacture method can be easily mastered, and a great quantity of manpower and material resources does not need to be input for learning.

Owner:FOREWIN FPC SUZHOU

Thinned electronic product and manufacturing method thereof

ActiveUS10123423B1Simple manufacturing processReduce material costsDecalcomaniaPrinted resistor incorporationEngineeringElectrical and Electronics engineering

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

A preparation method of a printed circuit board

InactiveCN109195346AQuality improvementGuaranteed service lifeDecalcomaniaScreen printingSilver paste

The invention provides a preparation method of a printed circuit board, comprising the following steps: a, selecting material and selecting circuit substrate; B, preparing composite silver paste; C, manufacture that circuit board drawing; D, manufacture of copper foil plate; (e) prin that circuit substrate drawing; F. Circuit board copying. The preparation method of the printed circuit board disclosed by the invention adopts the circuit of printing high-temperature silver paste on the substrate firstly, after four times of composite silver paste, screen printing and high-temperature and cooling treatment, the prepared circuit board and the silver paste circuit have good electrical conductivity, are insulated from the internal substrate, the silver paste is difficult to fall off and the quality of the circuit board is good. Then the copper foil circuit is compounded on the circuit board, and the double-layer circuit path is carried out, so that the circuit board has high quality and thedouble-layer path guarantees the service life of the circuit board.

Owner:安徽银点电子科技有限公司

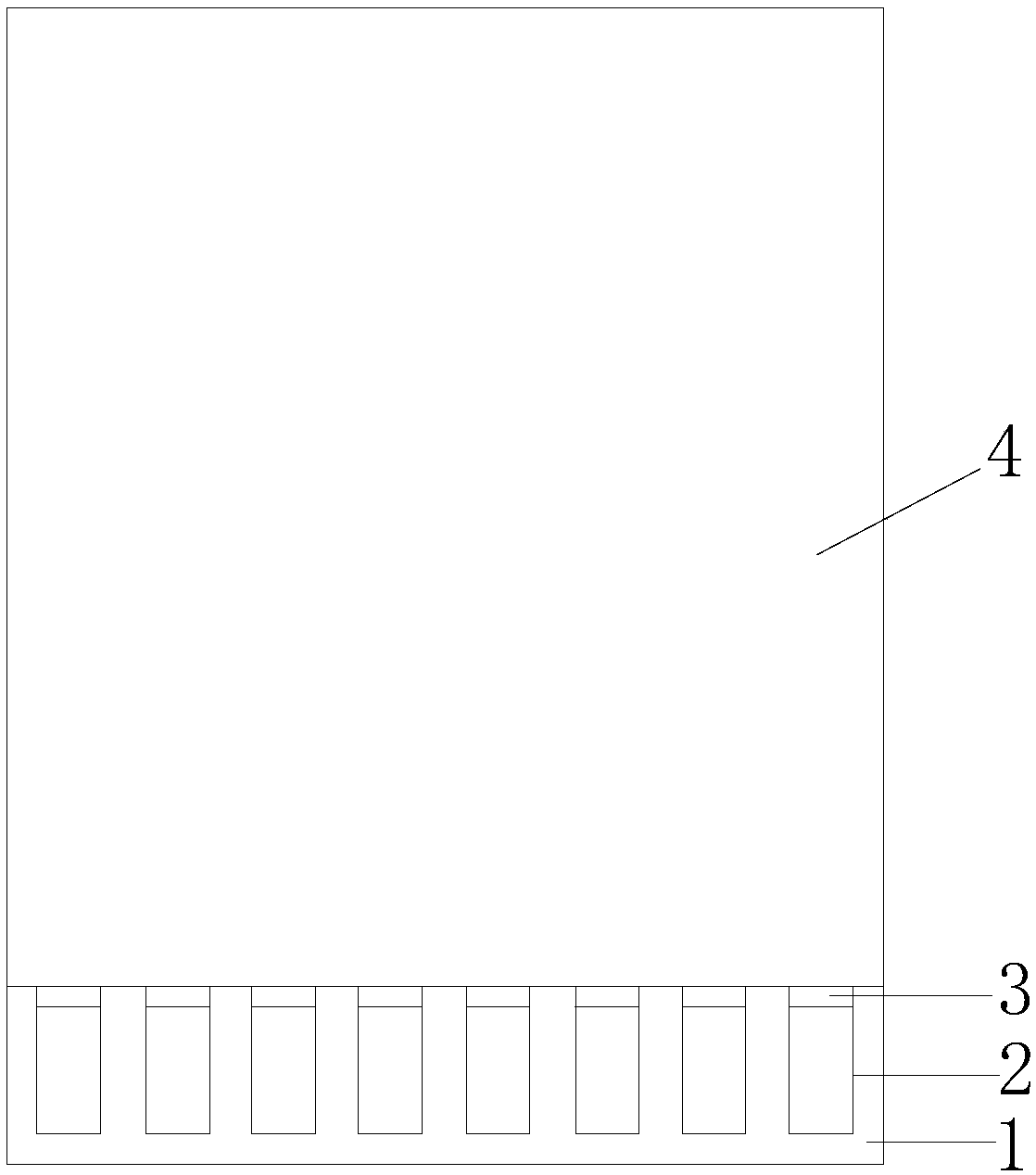

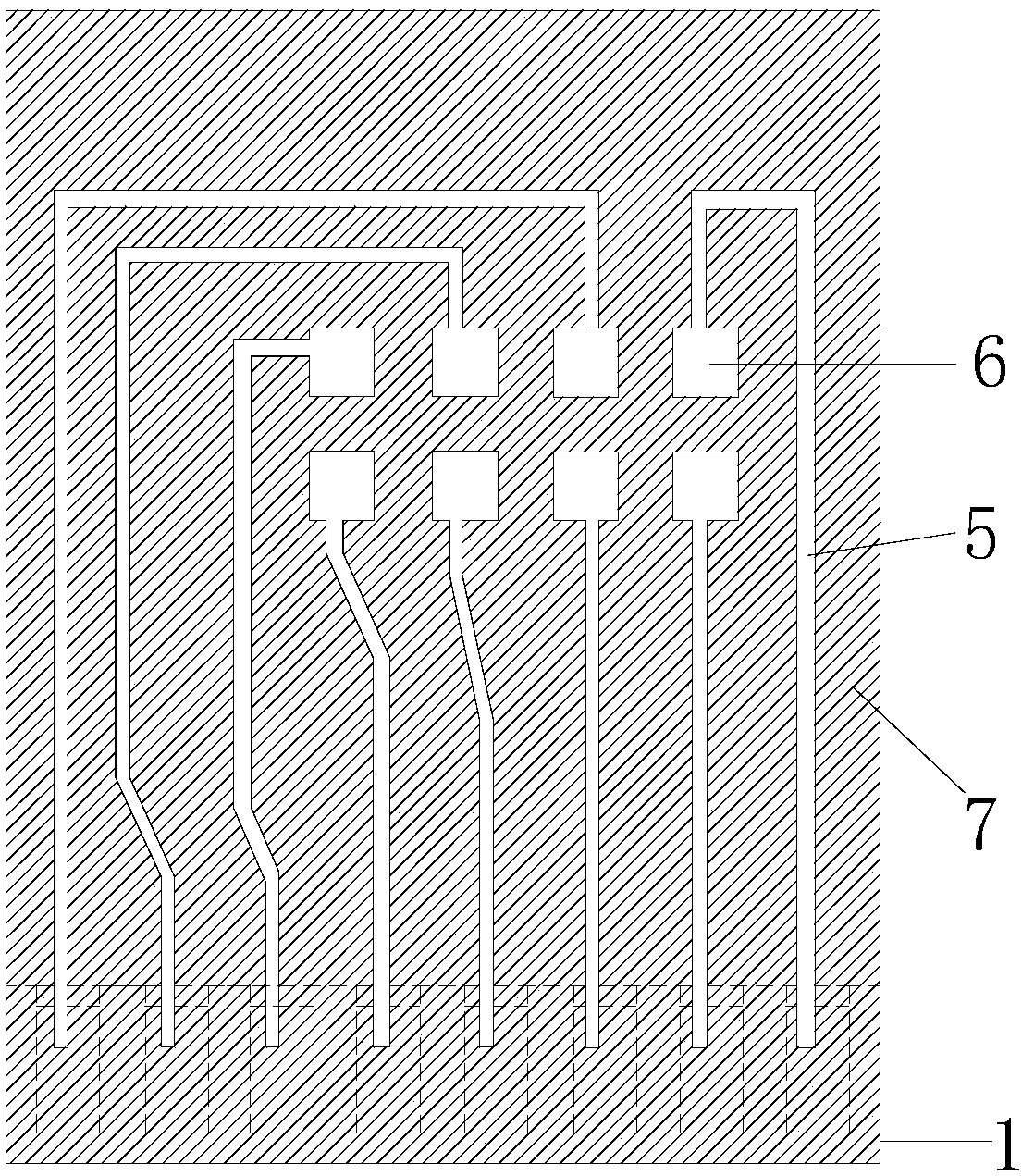

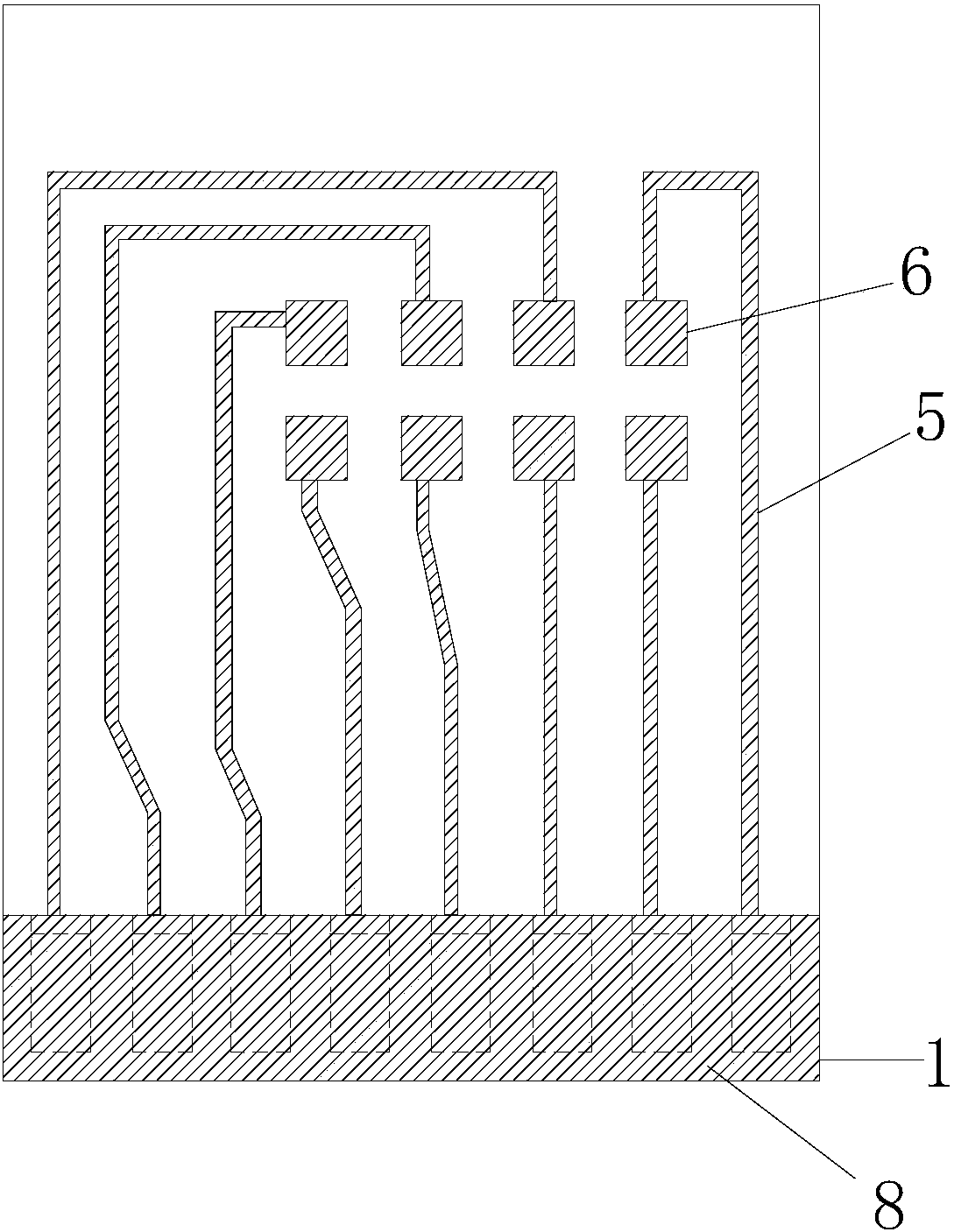

Small spacing P2.5 double-layer circuit board manufacturing process

PendingCN106912163AReduce productionThe production process is simpleDecalcomaniaAdhesive beltBi layer

The invention relates to a small spacing P2.5 double-layer circuit board manufacturing process. This method comprises the steps that 1, a PCB graph of a lamp face of a small spacing P2.5 double-layer circuit board to be manufactured and a PCB graph of a driving face of the small spacing P2.5 double-layer circuit board to be manufactured are printed on heat transfer paper through a laser printer or an ink-jet printer separately; 2, printed bottom-layer drawing paper is attached to a copper-clad plate by a paper self-adhesive tape, wherein the lamp face is attached to a bottom layer, the driving face is attached to a top layer, and positioning holes are drilled in the copper-clad plate; 3, ink powder is absorbed on the copper-clad plate through a heat transfer machine; 4, extra clad copper is washed off, and manufacturing of the small spacing P2.5 double-layer circuit board is finished. According to the small spacing P2.5 double-layer circuit board manufacturing process, a four-layer plate of an existing small spacing P2.5 double-layer circuit board is changed to a double-layer plate, the problems which exist in the prior art of small spacing P2.5 double-layer circuit boards are alleviated that the technology is cumbersome, high-frequency signals are attenuated and the production cost is high.

Owner:FUJIAN XIANGYUN PHOTOELECTRIC TECH

A method of fabricating a ductile circuit

ActiveCN107222974BEfficient preparationFully automatedPrinted circuit assemblingDecalcomaniaElastomerWork in process

Provided is a method for manufacturing a ductile circuit. The method uses a "roll-to-roll" type process, and involves: (S1) integrating a conductive layer and a first auxiliary substrate layer into one body and then making same into a coiled material, using one end of the coiled material as an initial feeding unrolling end, and extending same to a set length after unrolling; (S2) patterning the conductive layer of the coiled material unrolled to the set length to prepare a required circuit structure; (S3) using a first elastomer layer provided with a first auxiliary substrate as a feeding end, sending same to a pair of rollers, transfer printing the circuit structure to the surface of the first elastomer layer, and then removing the first auxiliary substrate layer; (S4) assembling a chip and the circuit structure together by using double-roll pressing and a bonding difference so as to obtain a ductile circuit layer semi-finished product; and (S5) transfer printing a second elastomer layer to the surface of the ductile circuit layer semi-finished product, wherein the second elastomer layer is used for a packaging layer of the ductile circuit layer semi-finished product. The method improves the production efficiency of the ductile circuit by combining the process of making the ductile circuit with a roll-to-roll motion platform.

Owner:HUAZHONG UNIV OF SCI & TECH

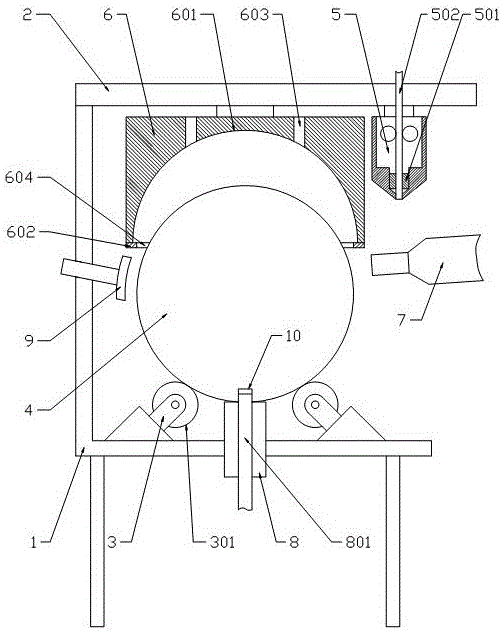

Spherical circuit transfer printing technology

ActiveCN106332463AAvoid direct adhesionEasy to unmold3D rigid printed circuitsDecalcomaniaIron powderCopper

The invention relates to the field of circuit board production technology, and discloses a spherical circuit transfer printing technology. The technology comprises the following steps: 1, installing a spherical substrate; 2, enabling the spherical substrate to be magnetized, and spraying iron powder to the surface of the substrate through a power spraying mechanism; 3, rotating the substrate to a zero position, and moving a printing mechanism to a part exactly above the substrate; 4, enabling the printing mechanism to draw the surface of the substrate through melt fine copper during the rotating of the substrate, and forming a spherical circuit; 5, rotating the substrate to the zero position, and limiting the rotation of the substrate; 6, moving the printing mechanism, moving the die with a hemispherical groove to a part exactly above the substrate, moving the die downwards, enabling a part, provided with the circuit, of the substrate to be placed in the groove, and sealing the mouth of the groove; 7, injecting a liquid substrate material into the groove of the die, and taking out a circuit board after the substrate material of the circuit board is solidified. The invention aims at providing the spherical circuit transfer printing technology, so as to product the spherical circuit board.

Owner:苏州昌利橡塑科技有限公司

Fabrication of High-Temperature Superconducting Striated Tape Combinations

ActiveUS20190189888A1Reduce mechanical stressImprove adhesionDecalcomaniaSolid-state devicesBand shapeHigh temperature superconducting

Owner:UNITED STATES OF AMERICA

A leadless electroplating method based on finger joint pre-size

ActiveCN108366492BGood lookingAvoid the stringent requirements for bit accuracyDecalcomaniaEtchingEngineering

Owner:SHENZHEN SUNTAK MULTILAYER PCB

A high-temperature hot stamping film for making conductive circuits, its manufacturing method and application

ActiveCN105323972BSimple structureLow costDecalcomaniaConductive pattern formationHot stampingEngineering

The invention relates to the technical field of hot stamping, in particular to a high-temperature hot stamping film for making conductive circuits, a manufacturing method and application thereof. The high-temperature hot stamping film includes a base layer, a release layer, a conductive layer and a hot-melt adhesive layer in sequence, and the required conductive lines can be hot-stamped at a temperature of 160-180°C by using ironing heads of different shapes. The conductive circuit hot stamping special film of the present invention has a simple structure and low cost, and can be used to prepare various irregular conductive circuits, such as RFID antennas, connecting wires on PCB boards, and the like.

Owner:WUHAN WEDO INFORMATION & TECH

A pcb board automatic dry film pressing device

ActiveCN106937485BImprove securityAvoid it happening againDecalcomaniaConductive material chemical/electrolytical removalMotor driveHeat conducting

The invention discloses an automatic dry film pressing device for PCBs. The device comprises a frame, a first cylinder, a pull pressure sensor, an upper bracket, a heating pipe, a heat conducting pressure head, a second cylinder, a displacement sensor, columns, a lower bracket, a holding plate, a servo motor, a screw, a feed nut, a film absorbing component, a roller, and a controller. An air suction box absorbs a dry film. Then, the servo motor drives the feed nut to move leftwards through the screw, so as to drive the film absorbing component to move leftwards to right above the air suction box. After the film absorbing component absorbs the dry film under control of the controller, the film absorbing component is moved by the servo motor to a set position, and the second cylinder pushes the holding plate to move up to a set position. The first cylinder drives the upper bracket to move down, and the heat conducting pressure head presses the fry film on a PCB. The device changes the original line-contact filming mode into a surface-contact filming mode. The uniformity of filming is increased. Local bubble generation and wrinkling of a dry film on a PCB are avoided. The safety performance of PCB is improved. The labor intensity of operating personnel is reduced.

Owner:SUZHOU DIFEITE ELECTRONICS CO LTD

Low cost antenna array fabrication technology

ActiveUS7510668B2Simple and cost-effective methodDecalcomaniaDecorative surface effectsEtchingManufacturing technology

Methods are provided for producing large volumes of small antenna arrays. In one embodiment, the method comprises the steps of creating an antenna array pattern as a computer file, printing the created pattern onto the surface of a suitable transfer paper, placing the printed image surface in contact with the surface of a material to be etched, and transferring the printed image to the surface of the material to be etched. The transfer can be effected by any combination of chemicals, heat, and / or pressure. After transfer of the printed image, the transfer paper is removed. The step of removing the transfer paper optionally includes wetting the transfer paper in a manner that dissolves the transfer paper leaving the printed antenna pattern on the surface of the material to be etched. The method further includes the step of etching the non-printed portions of the material, preferably by chemical etching, and removing the printed pattern from the surface of the material to yield an antenna array comprising a non-etched portion of the substrate surface. Arrays, and substrates having an etch-resistant mask for making the arrays, are also provided.

Owner:GENERAL ELECTRIC CO

A method for making a thickened screen plate and a method for using the thickened screen printing blue glue

ActiveCN105050330BShort production processFull cuttingDecalcomaniaConductive pattern formationScreen printingPolymer science

The invention relates to the technical field of PCB production and manufacturing, in particular to a method for making a thickened screen and a method for using a thickened screen printing blue glue. In the present invention, the pressure-sensitive adhesive is pasted on the screen during the second and third times of grouting, so as to increase the coating space, so that thicker photosensitive paste can be coated on the screen. After three times of coating, The thickness of the photosensitive film formed by drying the photosensitive paste can reach 0.35mm. Use the 18T screen plate to make the thickened screen plate, and the thickness of the thickened screen plate can reach 0.51mm. Therefore, use this thickened screen plate to print blue on the PCB. When gluing, the thickness of the blue glue can reach 0.51mm, and the thickness of the blue glue behind the baking plate can reach 0.4mm. Even if the thickened screen prepared by the present invention is used to screen-print the blue glue on the PCB, the production requirement of the blue glue thickness of 0.25-0.55 mm can be met by only one screen printing, thereby shortening the production process of the silk-screen blue glue and improving production efficiency. When using thicker screen printing blue glue, the screen printing pressure of 5-6kg / cm2 can make the blue glue blanking more fully, uniformly, without gaps, and improve the quality of silk screen printing.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com