Spherical circuit transfer printing technology

A circuit, spherical technology, applied in the transfer method, printed circuit components, three-dimensional rigid printed circuit boards, etc., can solve the problem of unable to produce spherical circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below by means of specific embodiments:

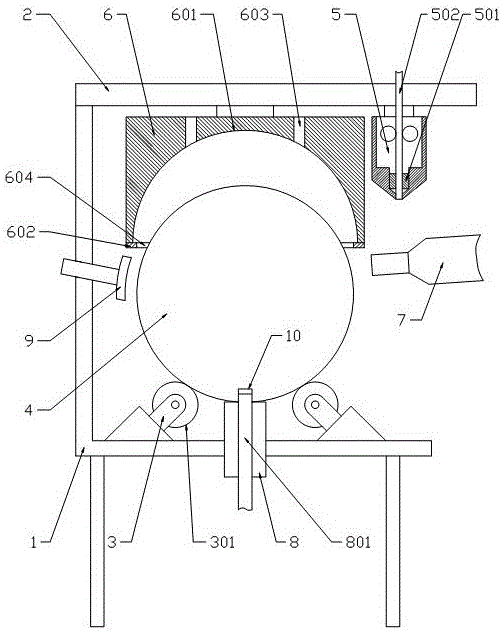

[0030] The reference signs in the drawings of the description include: lower frame 1, upper frame 2, support 3, friction wheel 301, base 4, printing mechanism 5, electric thermal sensor 501, pure copper wire 502, mold 6, concave Groove 601, cover plate 602, injection hole 603, circular hole 604, powder spraying mechanism 7, electromagnet 8, thimble 801, magnetic brush 9, blind hole 10.

[0031] The present invention will be described in further detail below by means of specific embodiments:

[0032] The present invention can be implemented with a spherical circuit transfer printing machine, which includes a frame, the frame includes a lower frame 1 and an upper frame 2, the upper frame 2 is located above the lower frame 1, and the lower frame 1 rotates Four supports 3 are connected, and each support 3 is connected with a first servo motor, and each support 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com