A pretreatment device for oil mist and dust and its applied purifier

A pretreatment device and pretreatment technology, applied in the field of purifiers, can solve the problems of large equipment footprint, economic losses, and increased pressure of dust collectors, and achieve the effects of small equipment footprint, extended service life, and guaranteed normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

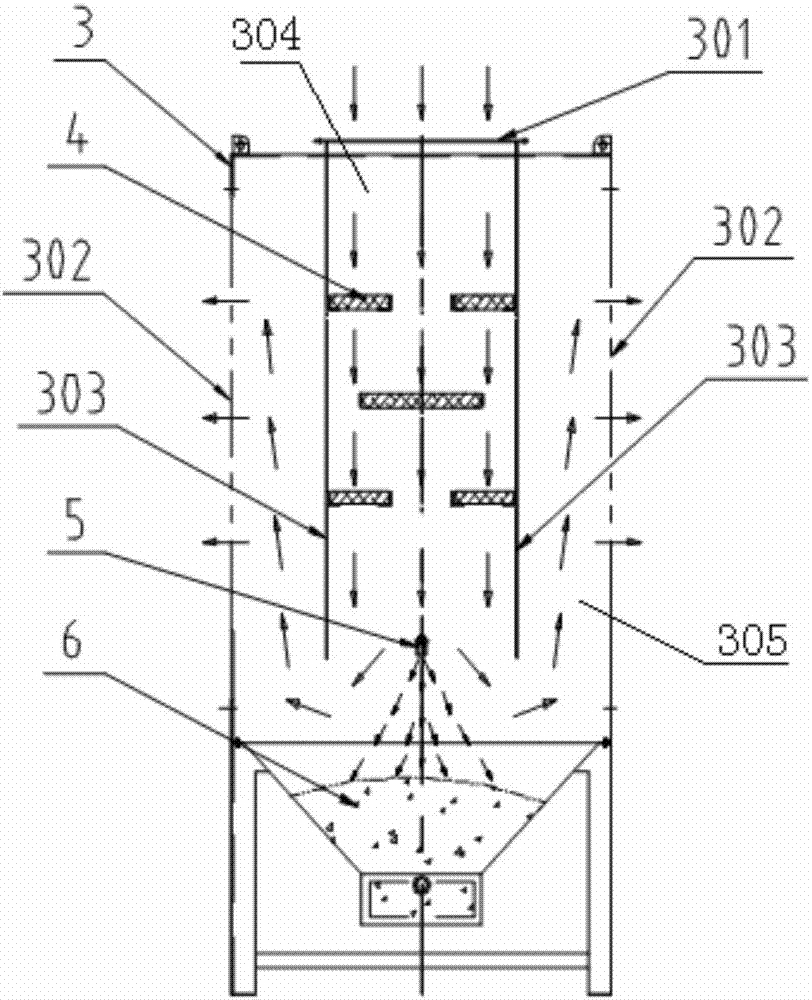

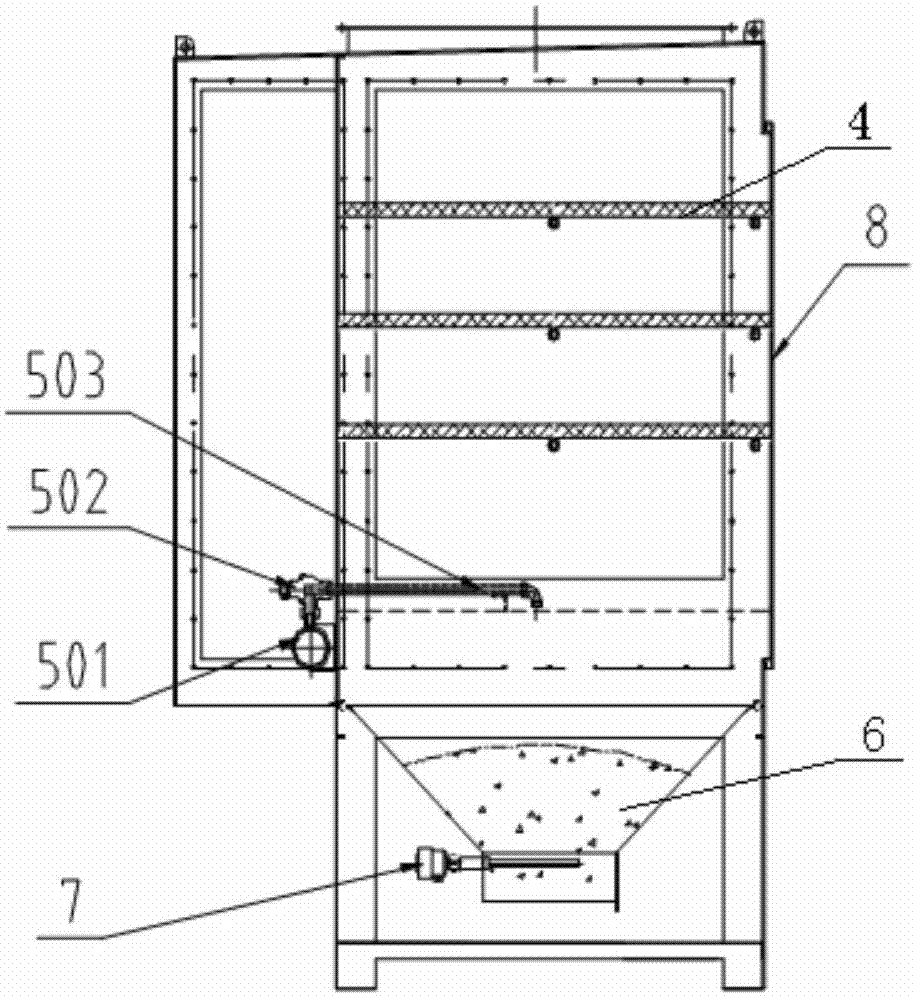

[0026] see figure 1 and figure 2 , the pretreatment device for oily mist and dust in the illustration is a preferred embodiment of the present invention, specifically including a pretreatment box 3, an air inlet 301 is provided on the top of the pretreatment box 3, and an air inlet 301 is provided on the side wall of the box. A plurality of air holes 302, the oil mist smoke enters from the air inlet, and is discharged from the air holes 302. The bottom of the pretreatment box is conical, which is filled with a certain amount of dry talc powder 6, and a powder spraying assembly 5 is arranged above the dry talc powder 6 pile, which is used to spray the dry talc powder to form The dust is mixed with the oily mist entering the tank.

[0027] The interior of the pretreatment box 3 of the present embodiment is provided with a partition 303, and the partition 303 divides the inner chamber of the pretreatment box into an air inlet passage 304 and an air outlet passage 305 which com...

Embodiment 2

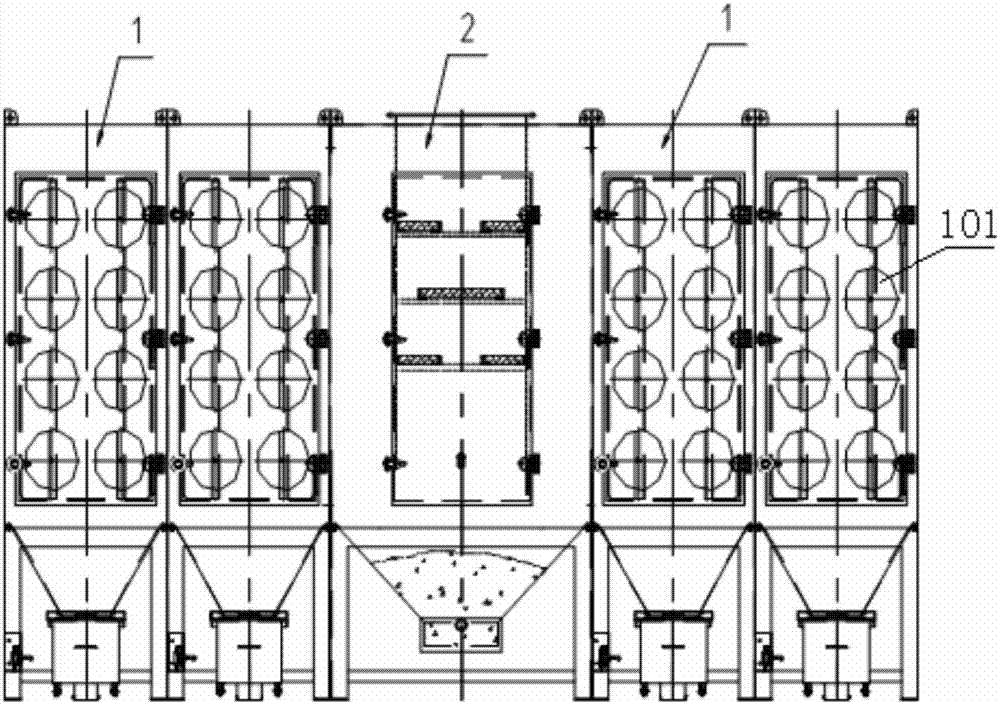

[0033] On the basis of embodiment 1, refer to image 3 and Figure 4 , a kind of oil mist fume purifier in the illustration is another preferred embodiment of the present invention, which includes two groups of dust removal devices 1 and the pretreatment device 2 in Example 1, wherein the pretreatment device 2 is arranged in the middle, The boxes of the two groups of dust removal devices 1 are fixed and connected side by side with the boxes of the pretreatment device, and the air holes on both sides of the pretreatment box are connected with the air inlet chamber of the dust removal device. Cartridge 102, the dust and oil mist coming from the air hole of the pretreatment box are filtered on the surface of the filter cartridge, and the filtered air is discharged through the air outlet connected inside the filter cartridge. The air inlet 301 of the pretreatment device 2 is The air inlet of the whole purifier, the air outlet 102 of the dust removal device 1 is the air outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com