A thermal interface material for chip detection and its preparation method

A thermal interface material and chip detection technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of thermal conductivity of contaminated chips, insufficient buffer of thermal interface materials, etc., achieve low pollution characteristics, reduce pollution phenomena, and withstand Good wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the above-mentioned thermal interface material, comprising the following steps:

[0031] (1) Mix the high thermal conductivity filler with the polymer carrier at a ratio of 1:1 to 8:1, and disperse evenly in an organic solvent (such as ethyl acetate, butyl acetate, acetone, toluene, xylene or ethanol, etc.) , to obtain a thermally conductive coating; in the preparation process, a pressure-sensitive adhesive with a mass of 0.5% to 10% of the total mass of the solid can also be added; the volume of the organic solvent is mainly limited by the solubility of the polymer carrier and the pressure-sensitive adhesive. Silicone oil is used as a polymer carrier. When silicone pressure-sensitive adhesive is used, the polymer carrier and pressure-sensitive adhesive can be dissolved by adding an organic solvent of about the same quality;

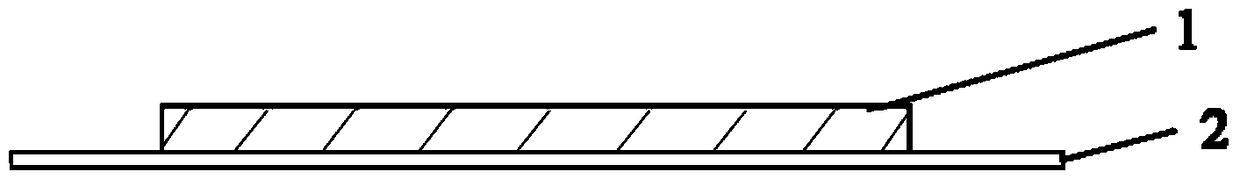

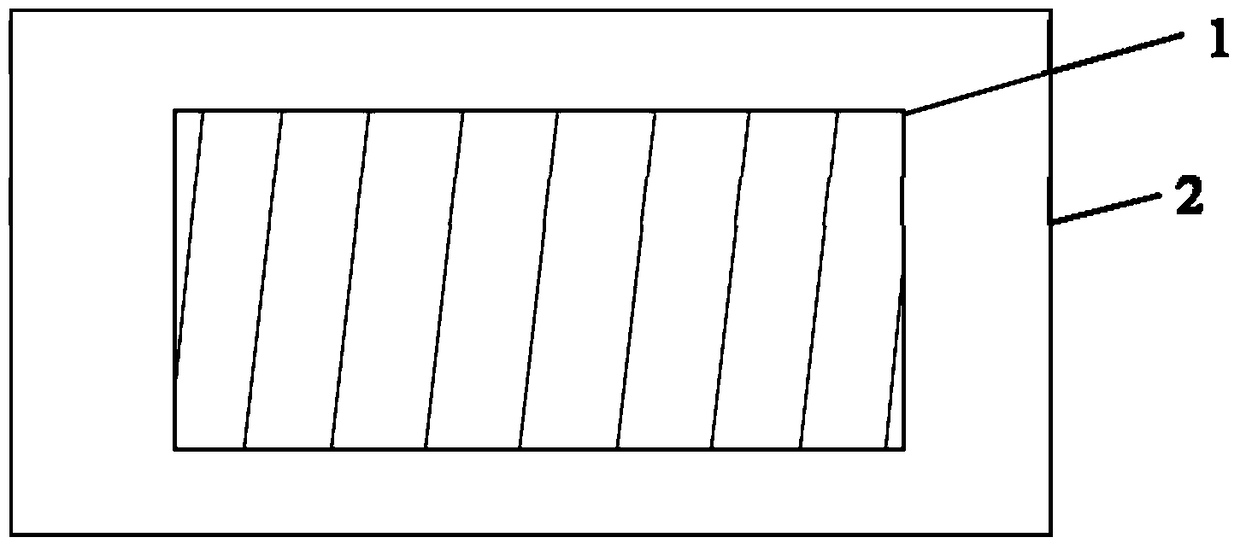

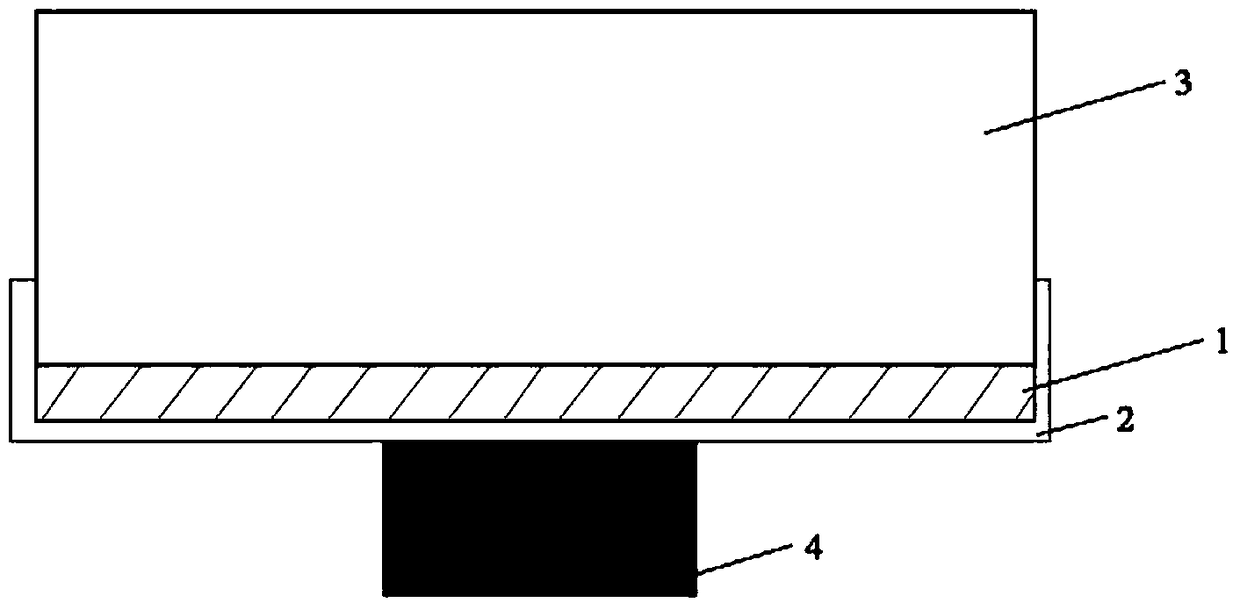

[0032] (2) Coating the thermally conductive paint obtained in the step (1) on all or ...

Embodiment 1

[0036] (1) First take 0.7g of hydroxyl silicone oil and 0.3g of silicone pressure-sensitive adhesive, dissolve them in 1g of toluene, add 4.0g of copper powder with a particle size of less than 50μm, and stir and mix them evenly;

[0037] (2) Apply the above mixture evenly on the surface of copper foil with a thickness of 35 μm;

[0038] (3) Heating at 80° C. for 30 minutes to completely volatilize the solvent, and prepare the thermal interface material. The surface coating thickness of the thermal interface material is about 300 μm.

[0039] Tested with a thermal conductivity testing device, the measured thermal conductivity of the material is 4.49W / (m·K).

Embodiment 2

[0041] Repeat Example 1 with the same steps as described, the difference is that the copper powder is replaced by a 4:1 mixture of copper powder with a particle size of less than 50 μm and silver powder with a particle size of less than 50 nm, and the thermal conductivity of the material measured at last is 6.24W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com