Nanometer chitosan compound/fiber composite diaphragm for lithium battery and preparation method of diaphragm

A technology of nano-chitosan and lithium battery diaphragm, which is applied in the direction of battery pack components, circuits, electrical components, etc., can solve the problems of blocking feature loss, high heat and combustion, electrode short circuit, etc., to prevent the flow of electrons, equipment The effect of low investment and high electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

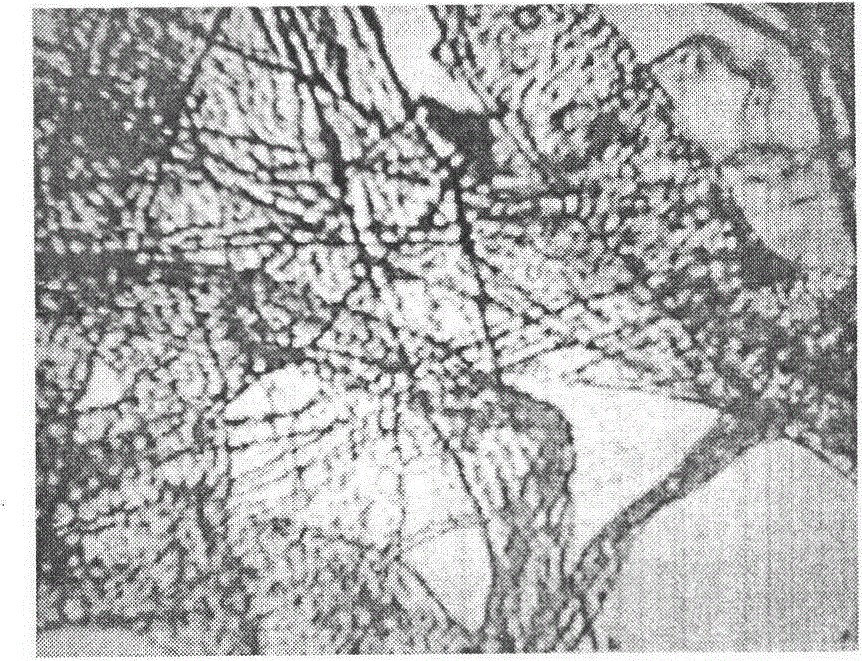

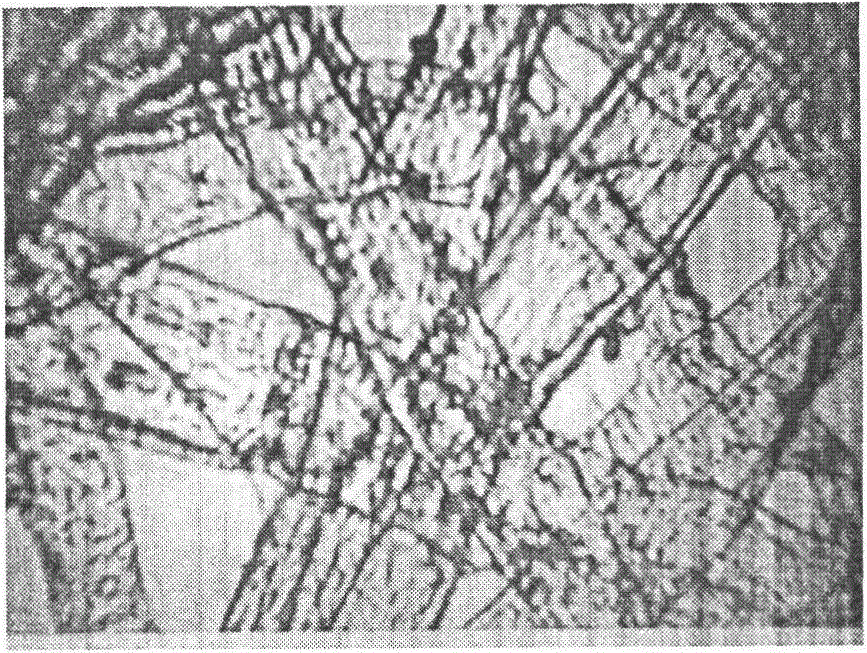

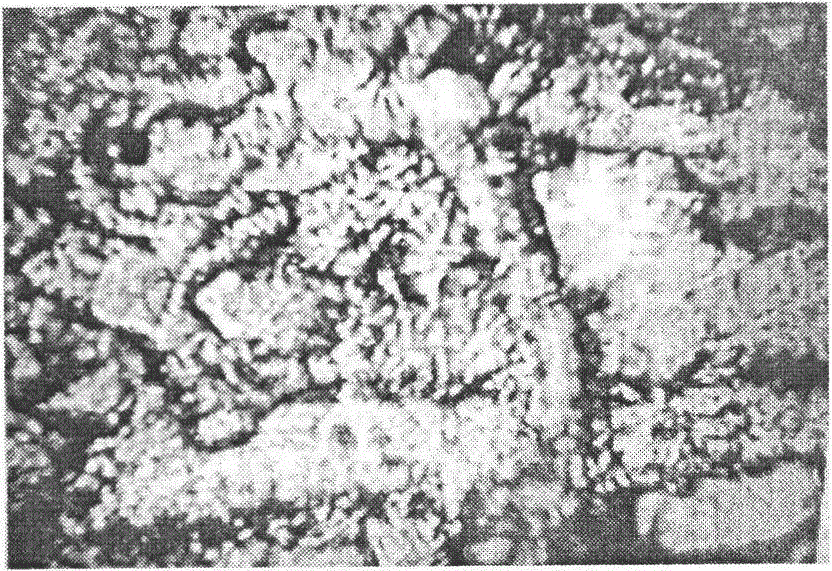

Image

Examples

preparation example Construction

[0026] The nano-chitosan composite / fiber combination lithium battery diaphragm provided by the invention is prepared by the following method:

[0027] 1. The calculated amount of natural fibrils and the calculated amount of deionized water are forced to disperse in a strong dispersion tank at room temperature for 30 minutes, and then placed in a container at 35-40°C for 1 hour, and placed as a water-dispersed fiber base material In a dedicated dispersion tank.

[0028] 2. Use the following Chinese invention patent (patent number: ZL02113792.6) claim 4 of the calculated amount, the B material (micron chitosan sol) synthesized in the second step and the Chinese invention patent (patent number: ZL200410081608.8 ) synthetic terminal product (nano-chitosan sol), directly / disposable into the water-dispersed natural non-woven fiber base material tank, after the natural non-woven fiber is dispersed evenly, open the lower end of the water-dispersed fiber base material tank The valve q...

Embodiment 1

[0033] 1. Disperse 1.52 grams of natural fibrils and 400 grams of deionized water in a strong dispersion tank at room temperature for 30 minutes, then place them in a container at 35-40°C for 1 hour, and place them as a water-dispersed fiber base In a dedicated dispersion tank.

[0034] 2. Use 5 grams of the following Chinese invention patent (patent number: ZL02113792.6) claim 4, the B material (micron chitosan sol) synthesized in the second step and the Chinese invention patent (patent number: ZL200410081608.8) The compound (micron chitosan sol: nano chitosan sol / 3 grams: 2 grams) prepared by the synthesized end product (nano-chitosan sol) is directly / disposably put into the water-dispersed fiber base tank, and gently stirred . After the fibers are evenly dispersed, open the valve at the lower end of the water dispersion fiber base material tank, quickly drain the dispersed water in the fiber base material tank, load and combine the natural fibers of micron chitosan particl...

Embodiment 2

[0036] 1. Disperse 1.52 grams of natural fibrils and 400 grams of deionized water in a strong dispersion tank at room temperature for 30 minutes, then place them in a container at 35-40°C for 1 hour, and place them as a water-dispersed fiber base In a dedicated dispersion tank.

[0037] 2. Use 10 grams of the following Chinese invention patent (patent number: ZL02113792.6) claim 4, the B material (micron chitosan sol) synthesized in the second step and the Chinese invention patent (patent number: ZL200410081608.8) The compound (micron chitosan sol: nano chitosan sol / 5 gram: 5 gram) prepared by the synthesized terminal product (nano chitosan sol) is directly / disposably put into the water-dispersed fiber base tank, and gently stirred . After the fibers are evenly dispersed, open the valve at the lower end of the water dispersion fiber base material tank, quickly drain the dispersed water in the fiber base material tank, load and combine the natural fibers of micron chitosan par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com