Battery can and battery using the same

A battery can and battery technology, applied in dry batteries, secondary batteries, nickel storage batteries, etc., can solve the problems of lack of liquid leakage resistance, increased usage, and unnecessary increase of Ni.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

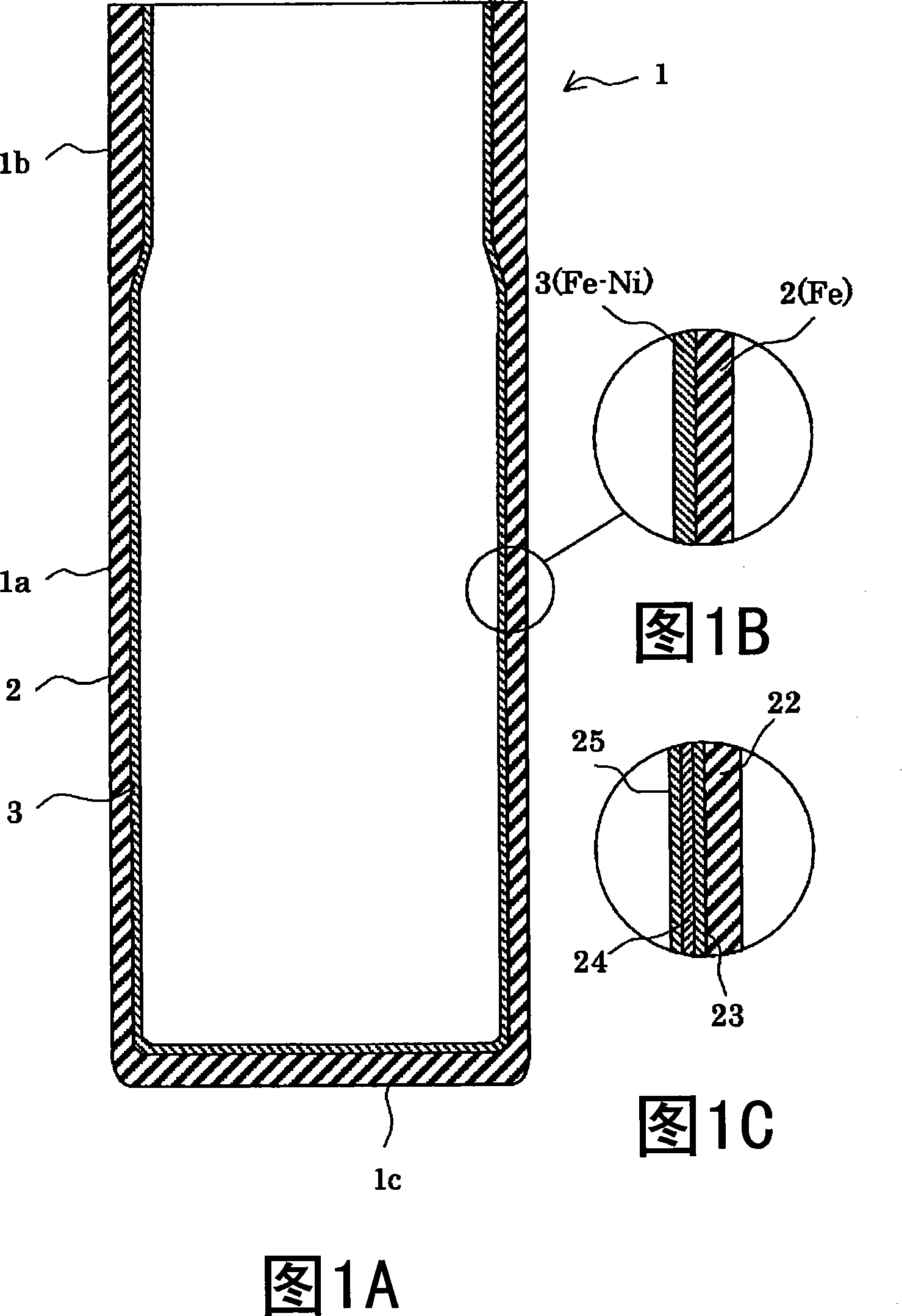

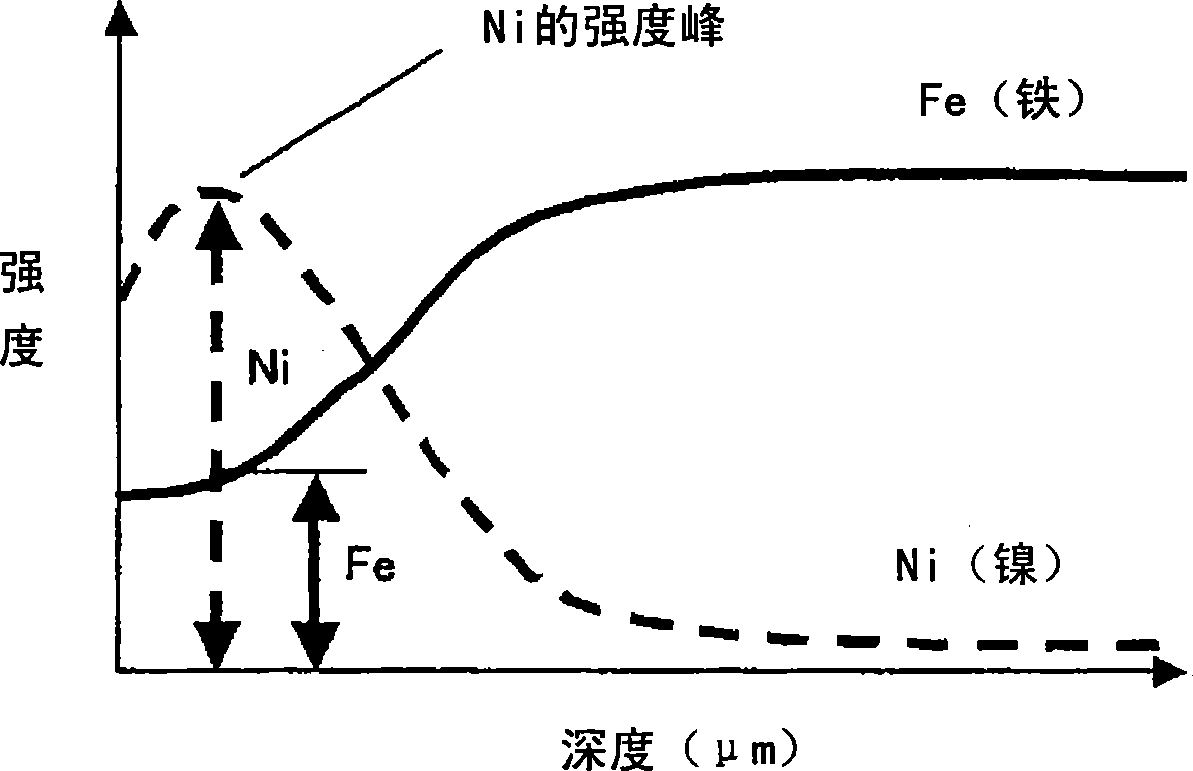

[0025] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. FIG. 1A is a longitudinal sectional view showing a battery can 1 according to an embodiment. The battery can 1 is formed in a bottomed cylindrical shape, and the thickness of the sealing part 1b and the bottom 1c located at the opening end side of the side peripheral part 1a are formed thicker than the thickness of the side peripheral part 1a. In addition, as shown in FIG. 1B , an Fe—Ni diffusion layer 3 is formed on the surface of the steel plate 2 on the inner surface of the battery can 1 .

[0026] The steel plate 2 used to make the battery can 1 is preferably a steel plate with an Fe content of 98% by weight or more. As components other than Fe, a small amount of C (carbon), Si (silicon), Mn (manganese), N (nitrogen), P (phosphorus), Al (aluminum), Ni (nickel), Cr (chromium), etc. In this embodiment, in order to perform the comparative test described below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com