Method for preparing carbon-loaded metal sulfide nanocomposite through electrostatic spinning

A nanocomposite, electrospinning technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of many steps, the inability to combine metal sulfides and carbon materials, etc., to achieve increased conductivity and good electrochemical performance. performance, the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

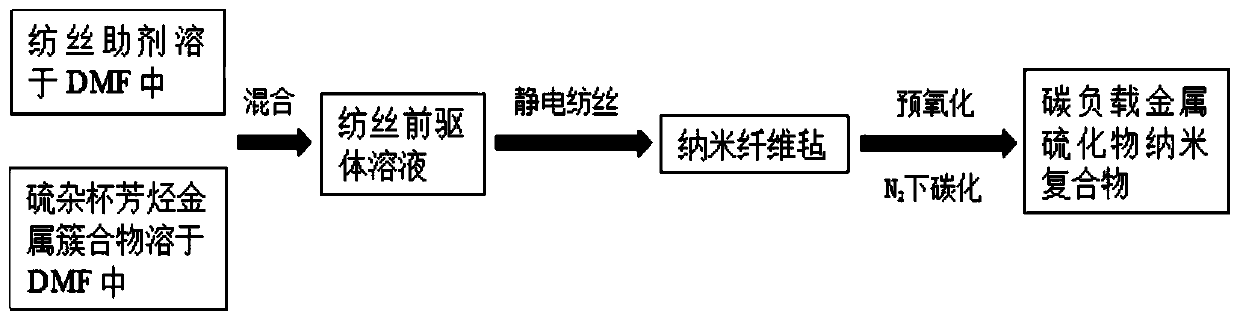

[0043] As shown in the figure, the method for preparing carbon-supported metal sulfide nanocomposites by electrospinning includes the following steps:

[0044] (1) Preparation of spinning precursor solution

[0045] Weigh 0.3g of load-thiacalixarene metal clusters (such as: Co 16 、Co 32 or Co 48) was dissolved in DMF (N,N-dimethylformamide), sealed with a parafilm, and stirred on a magnetic stirrer at room temperature until it was completely dissolved; at the same time, a certain proportion of spinning aid-PAN (poly Acrylonitrile) was dissolved in DMF, and stirred on a magnetic stirrer after sealing to form a uniform transparent solution; wherein the mass concentration of spinning aid was 6.8%, and the mass concentration of the load relative to spinning aid was 30%; finally The two parts of the solution are mixed together, sealed and stirred evenly, which is the spinning precursor solution;

[0046] (2) Preparation of nanofibers by electrospinning

[0047] Inhale the prep...

Embodiment 2

[0053] As shown in the figure, the method for preparing carbon-supported metal sulfide nanocomposites by electrospinning includes the following steps:

[0054] (1) Preparation of spinning precursor solution

[0055] Weigh 0.3g of load-thiacalixarene metal clusters (such as: Co 16 、Co 32 or Co 48 ) was dissolved in DMF (N,N-dimethylformamide), sealed with a parafilm, and stirred on a magnetic stirrer at room temperature until it was completely dissolved; at the same time, a certain proportion of spinning aid was weighed and dissolved in DMF ; The spinning aid is a mixture of PAN and PMMA; the mass ratio of PAN and PMMA is 7:3, and after sealing, it is stirred into a uniform transparent solution on a magnetic stirrer; wherein the mass concentration of the spinning aid is 10%, The concentration of the load relative to the spinning aid is 50%; finally, the two parts of the solution are mixed together, sealed and stirred evenly, which is the spinning precursor solution;

[0056...

Embodiment 3

[0063] (1) Preparation of spinning precursor solution

[0064] Weigh 0.3g of load-thiacalixarene metal clusters (such as: Co 16 、Co 32 or Co 48 ) was dissolved in DMF (N,N-dimethylformamide), sealed with a parafilm, and stirred on a magnetic stirrer at room temperature until it was completely dissolved; at the same time, a certain proportion of spinning aid was weighed and dissolved in DMF ; The spinning aid is a mixture of PAN and PMMA; the mass ratio of PAN and PMMA is 1:1; after sealing, it is stirred on a magnetic stirrer to form a uniform transparent solution. The concentration of the spinning aid is 12.4%, and the concentration of the load relative to the spinning aid is 40%; finally, the two parts of the solution are mixed together, sealed and stirred evenly, which is the spinning precursor solution;

[0065] (2) Preparation of nanofibers by electrospinning

[0066] Inhale the prepared spinning precursor solution into the syringe, remove air bubbles, adjust the syri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com