Lithium-ion battery silicon carbon negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in the direction of battery electrodes, negative electrodes, active material electrodes, etc., can solve the safety problems of low specific capacity rate performance, high-performance power batteries, affecting the cycle performance of electrode materials, poor cycle performance, etc. problems, to achieve the effect of increasing cycle stability, avoiding adverse effects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a lithium-ion battery silicon / carbon negative electrode material and a preparation method thereof. The surface modification of nano-silicon is carried out by a simple and easy method, and the silicon-carbon negative electrode material with a core-shell structure is prepared. It not only has high specific capacity and initial efficiency, but also takes into account excellent cycle performance, simple process, low production cost, energy saving and consumption reduction, and is suitable for industrial production.

[0031] The invention provides a silicon-carbon negative electrode material for a lithium ion battery, which has a core-shell structure, the mass percentage of silicon element is 3-50%, the mass percentage of carbon element is 50-97%, and a small amount of oxygen element, silicon source The particle diameter of the graphite material is 5-250nm, and the particle diameter of the added graphite material is 0.1-40um. Among them, preferably, th...

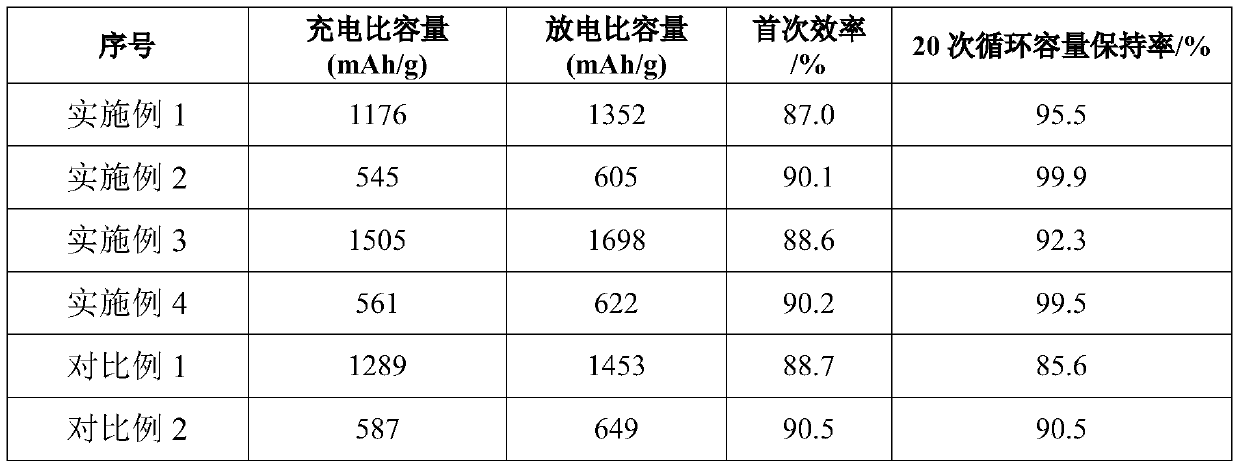

Embodiment 1

[0043] Preparation of High Performance Silicon / Carbon Anode Materials

[0044] (1) Add 1440g ethanol in the sand mill tank, add 160g polycrystalline micro silicon and stir for 15min, add 1.6g stearic acid, feed air in the mixing tank, start the grinder, grind for 4h, then add 16g graphene, 8g of carbon nanotubes, wet grinding for 2h; take part of the slurry to vacuum dry, oxygen and nitrogen analyzer to measure the oxygen content of nano-silicon, the test results are shown in Table 1;

[0045] (2) get the slurry that step 1 obtains and mix and stir 30min with 92g fine powder graphite;

[0046] (3) Spray drying the slurry in step 2 to obtain the silicon carbon core material;

[0047] (4) After merging the precursor in step 3 in a horizontal fusion machine, add asphalt for coating, and calcine and carbonize at high temperature under the protection of nitrogen; the calcination temperature is 1000°C, and the calcination time is 3h;

[0048] (5) Take the material in step 4 and crus...

Embodiment 2

[0053] (1) Add 1440g of ethanol to the tank of the sand mill, add 160g of single crystal micro-silicon and stir for 15 minutes, put air into the mixing tank, start the grinder, grind for 6 hours, take part of the slurry to vacuum dry, and measure the nanometer The oxygen content of silicon, the test results are shown in Table 1;

[0054] (2) get the slurry in step 1 and mix and stir 30min with 1400g graphite;

[0055] (3) Spray drying the slurry in step 2 to obtain the silicon carbon core material;

[0056] (4) After merging the precursor in step 3 in a horizontal fusion machine, add asphalt for coating, and calcine and carbonize at high temperature under the protection of nitrogen; the calcination temperature is 800°C, and the calcination time is 5h;

[0057] (5) Take the material in step 4 and crush and sieve to obtain a silicon-carbon negative electrode material with a core-shell structure, and its D50 particle size is 15.5 microns.

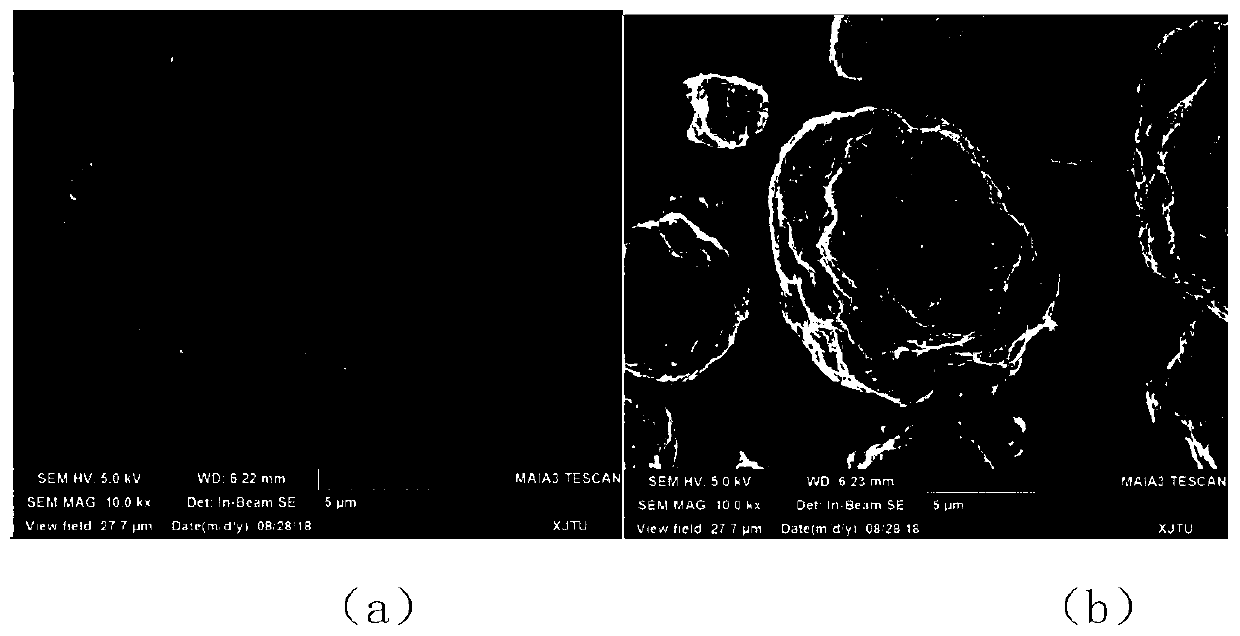

[0058] Characterization of physicoche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com