Patents

Literature

59results about How to "Fewer steps in the preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Edible detergent and preparation method thereof

ActiveCN102766538AEasy to commoditizeLow costCosmetic preparationsOrganic detergent compounding agentsColloidDipotassium Glycyrrhizinate

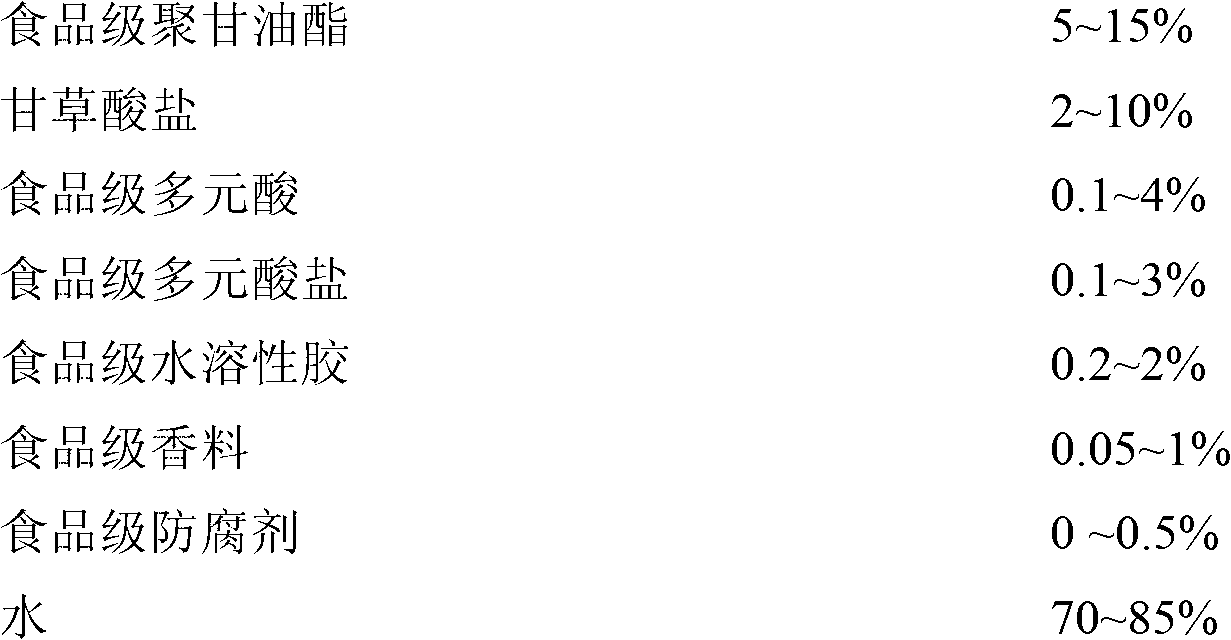

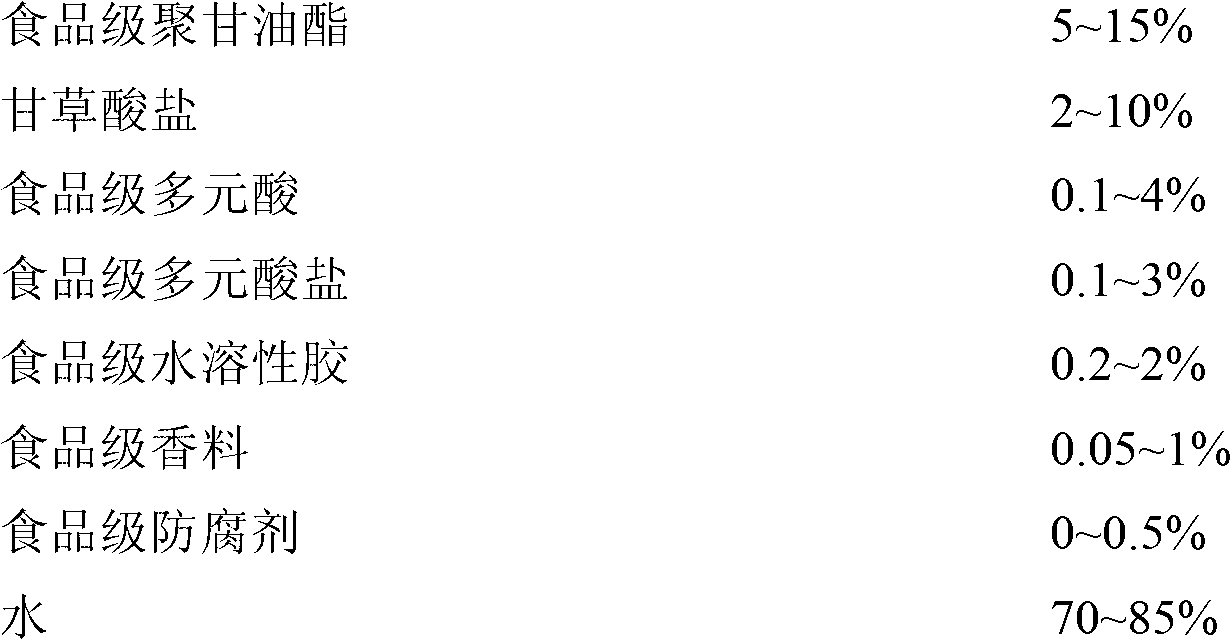

The invention relates to edible detergent and a preparation method thereof. The edible detergent is characterized by comprising, by weight, 5-15% of food-grade polyglycerin ester, 2-10% of dipotassium glycyrrhizinate, 0.1-4% of food-grade polybasic acid, 0.1-3% of food-grade polybasic acid salt, 0.2-2% of food-grade soluble colloid, 0.05-1% of food-grade spice, 0-0.5% of food-grade preservative, and 70-85% of water. Compared with the existing environment-friendly detergent produced by conventional preparation techniques, the edible detergent is better in stability, better in detergency, better in foaming performance and lower in cost.

Owner:NINGBO YUFANGTANG BIOTECH

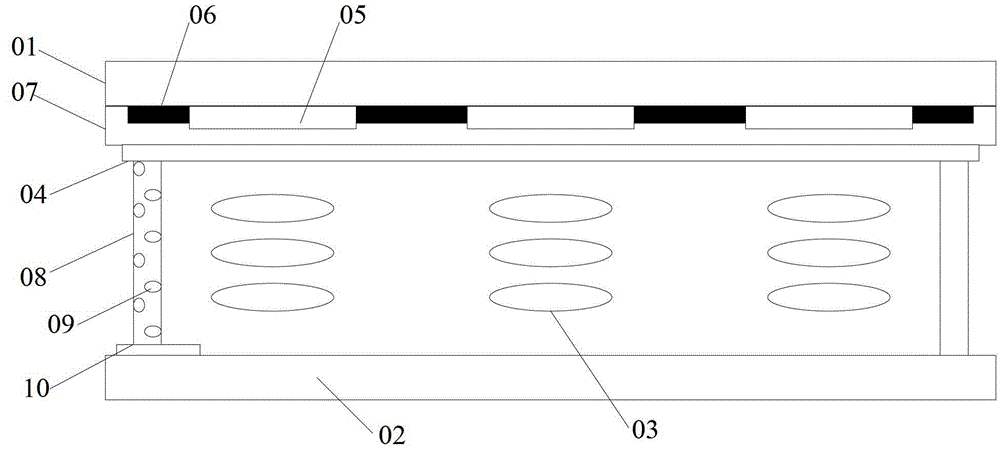

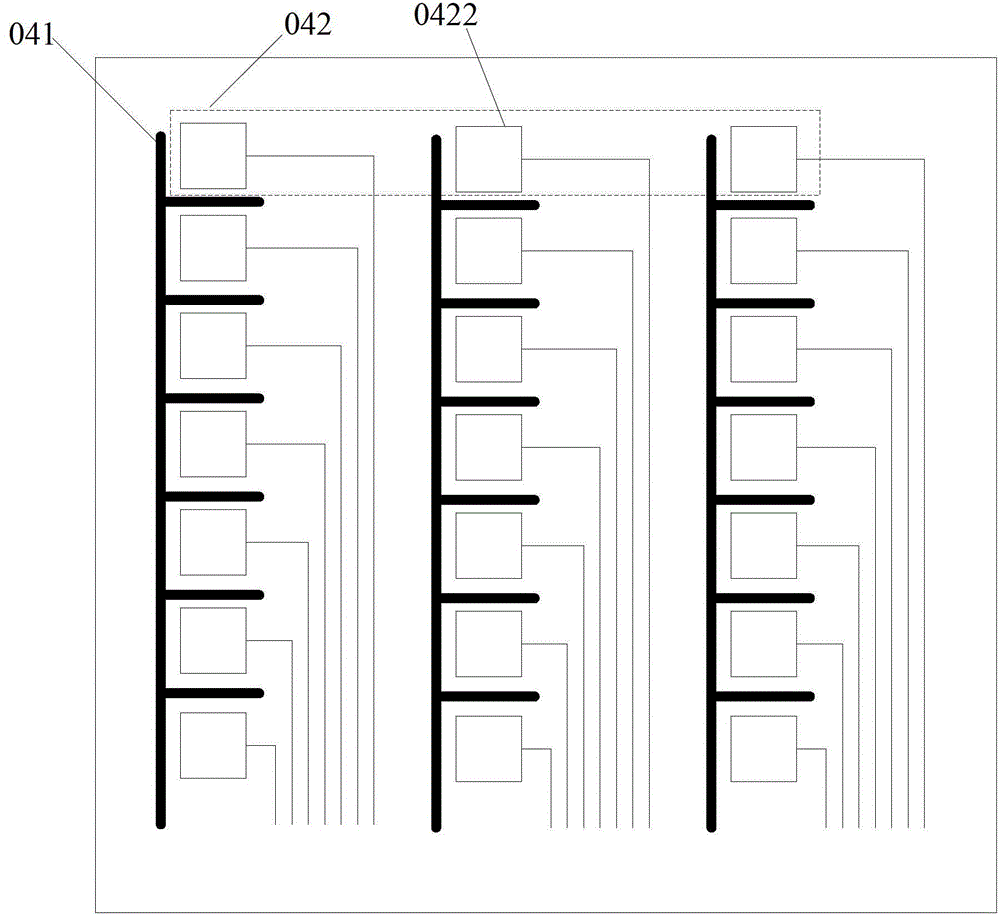

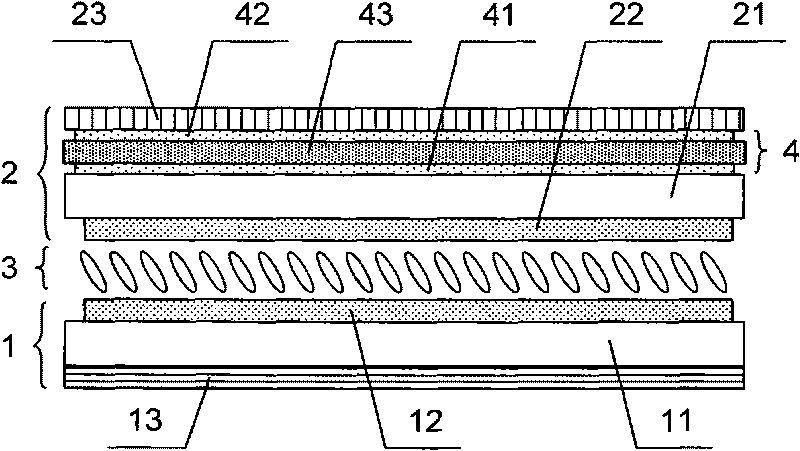

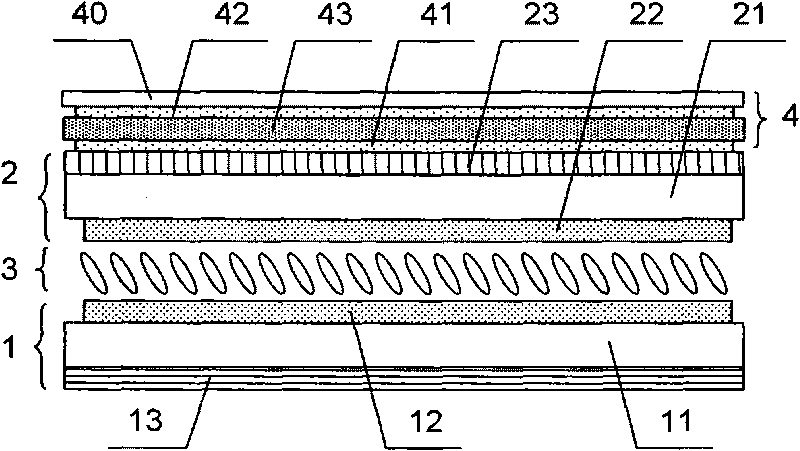

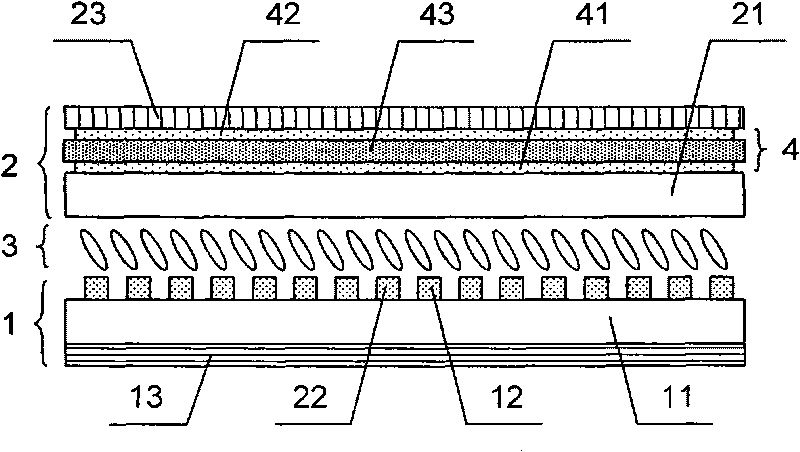

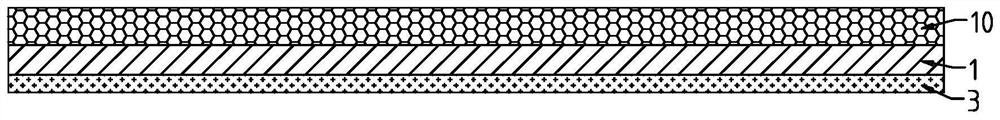

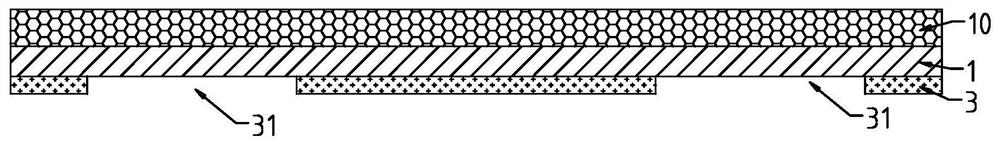

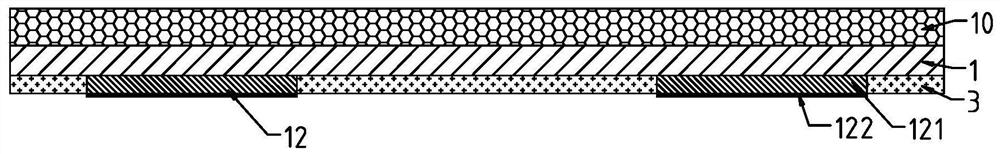

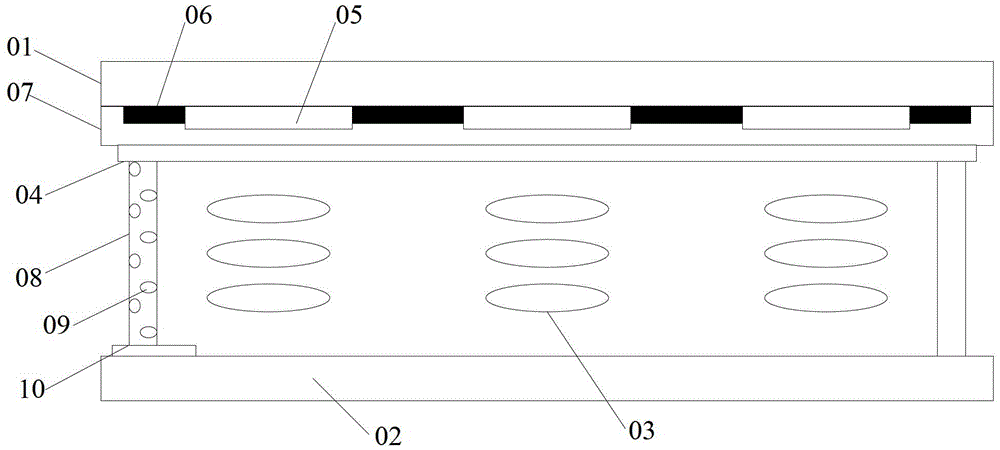

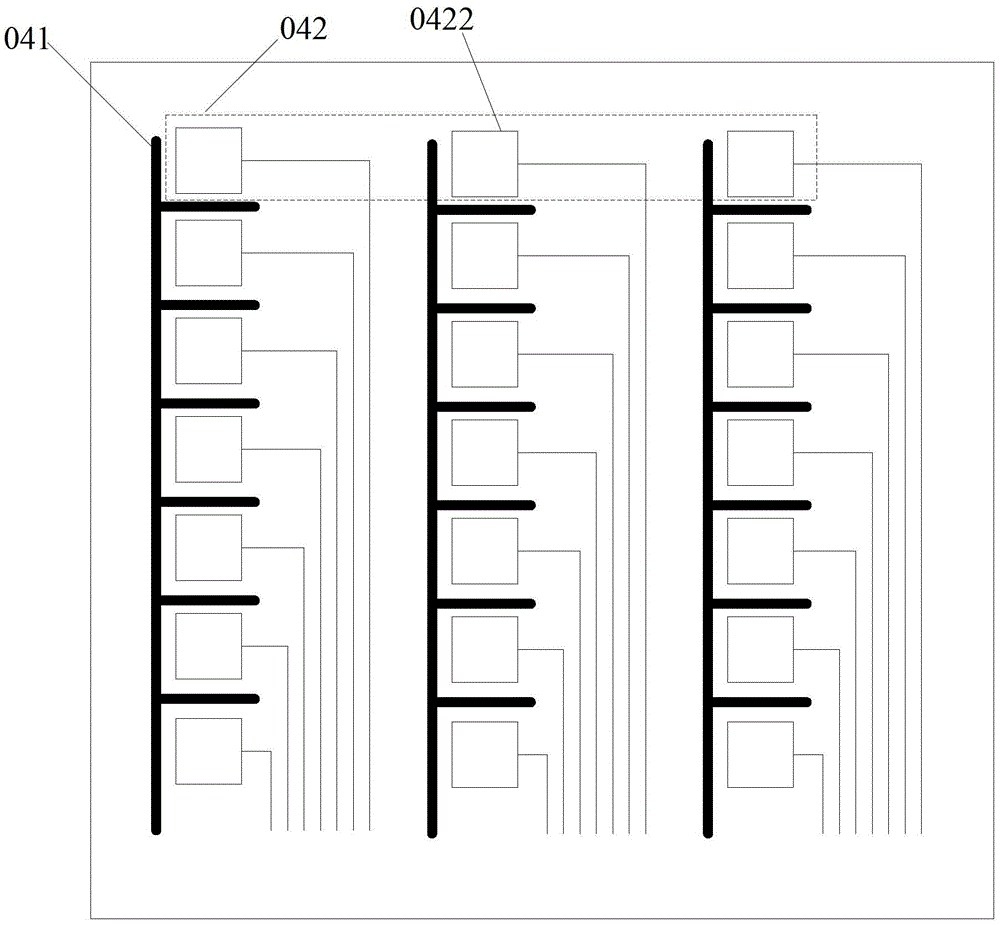

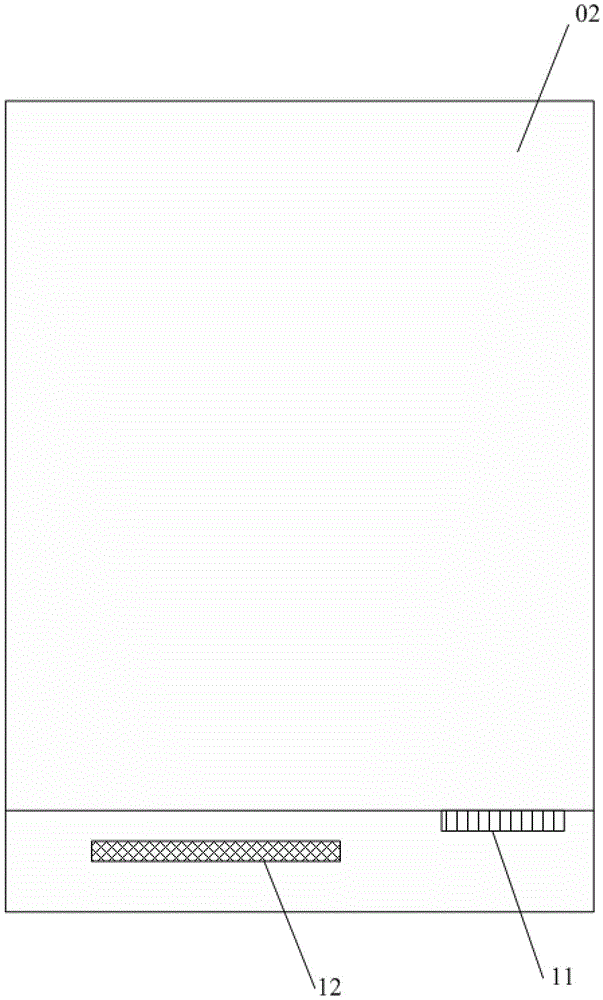

Capacitive in-cell touch panel and display device

ActiveCN103336635AAvoid mutual interferenceGuaranteed qualityInput/output processes for data processingLiquid-crystal displayDisplay device

The invention discloses a capacitive in-cell touch panel and a display device. A transparent touch sensing structure layer is arranged on one side, facing towards a liquid crystal layer, of an opposite substrate opposite to an array substrate, and comprises first touch sensing electrodes and second touch sensing electrodes, wherein the first touch sensing electrodes and the second touch sensing electrodes are arranged in the same layer and mutually isolated. Mutual interference between a touch signal and a display signal in the array substrate can be avoided due to the fact that the touch sensing structure layer realizing touch is arranged on the opposite substrate far away from the array substrate; the quality of liquid crystal display frames is ensured; and the reliability of touch operation is improved. In addition, since the first touch sensing electrodes and the second touch sensing electrodes are arranged in the same layer in the touch sensing structure layer arranged on the opposite substrate, compared with that two layers of strip electrodes mutually crossed in different surfaces are manufactured respectively to serve as the touch sensing structure layer, the structure is relatively simple; the preparation technology steps can be shortened; and the production cost can be lowered.

Owner:BOE TECH GRP CO LTD +1

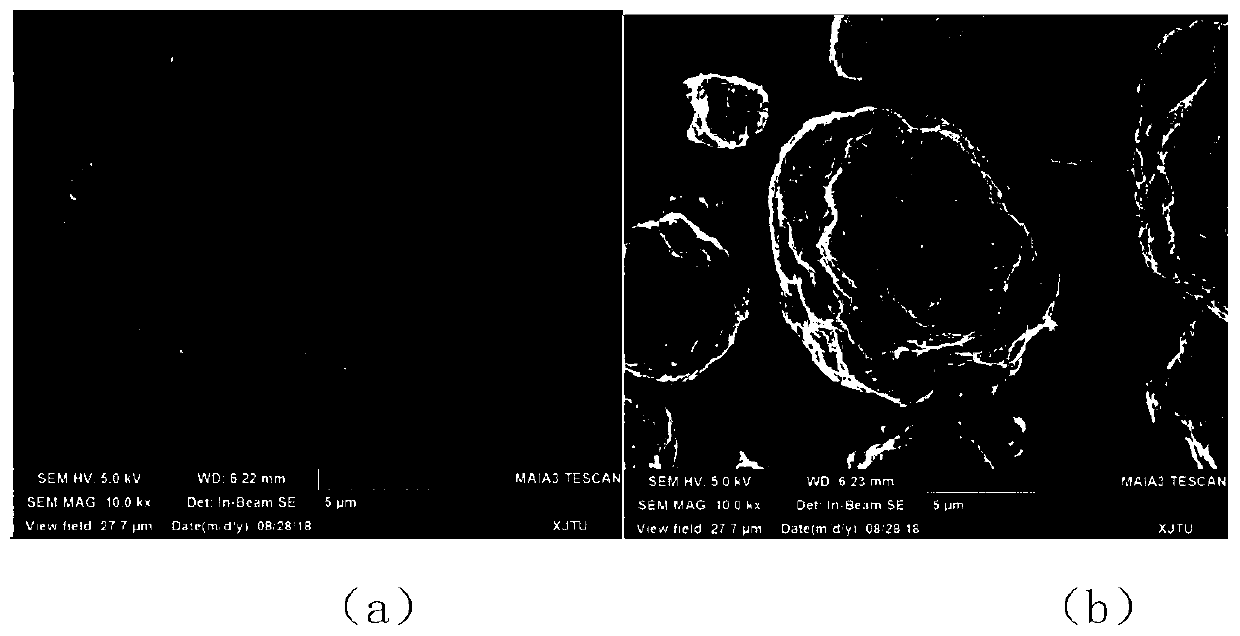

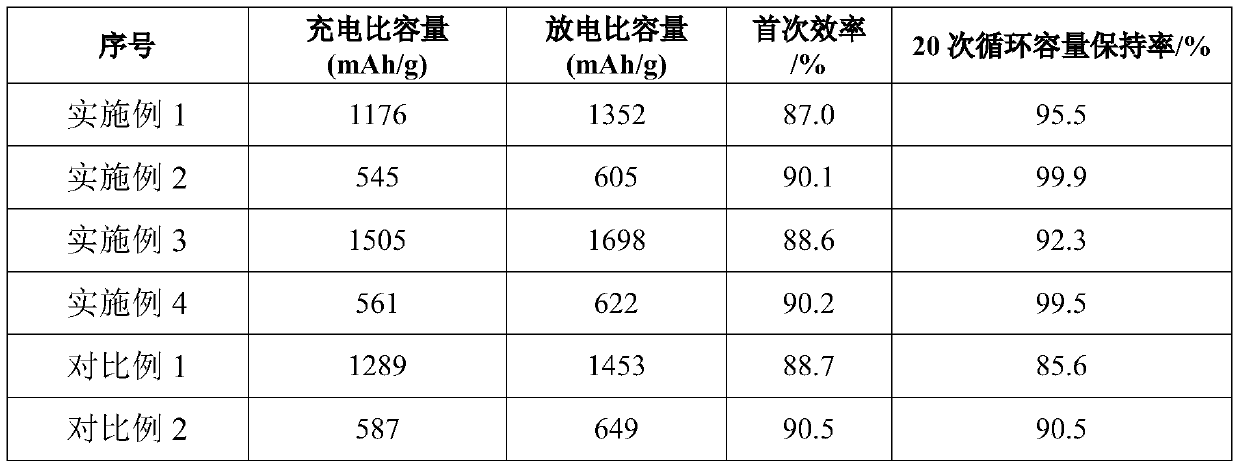

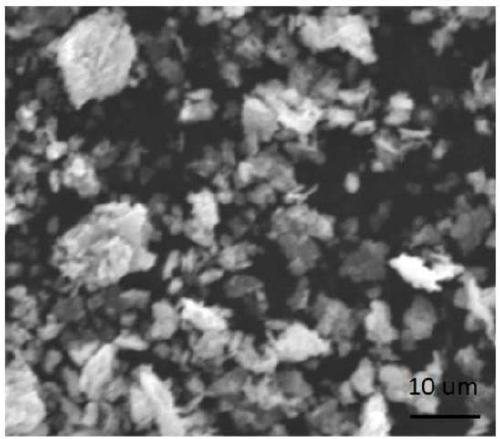

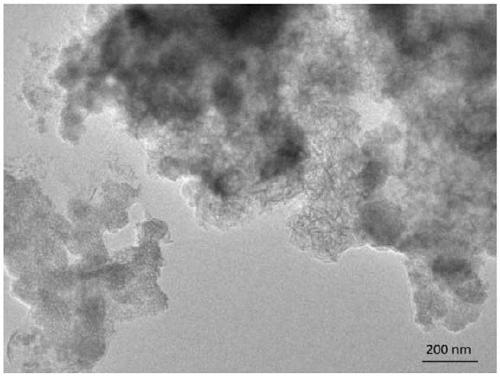

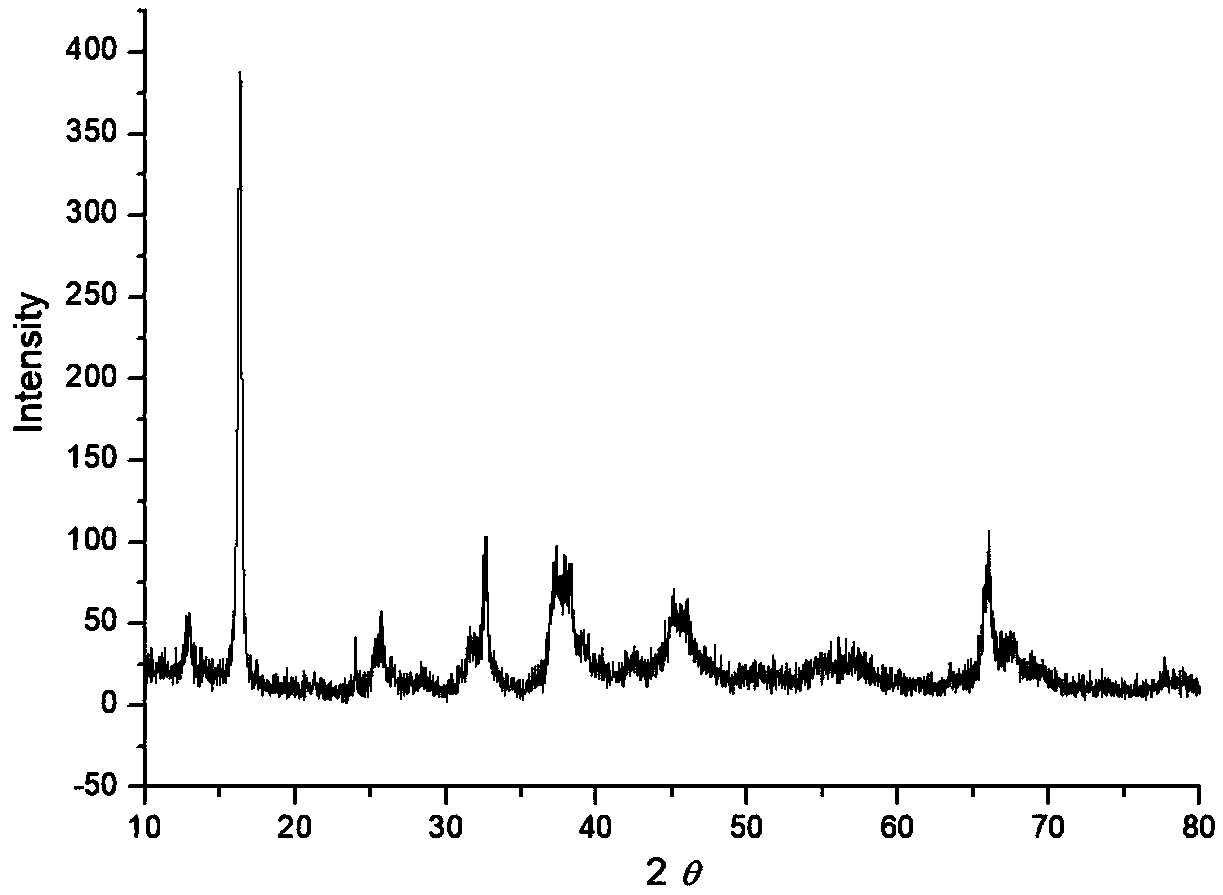

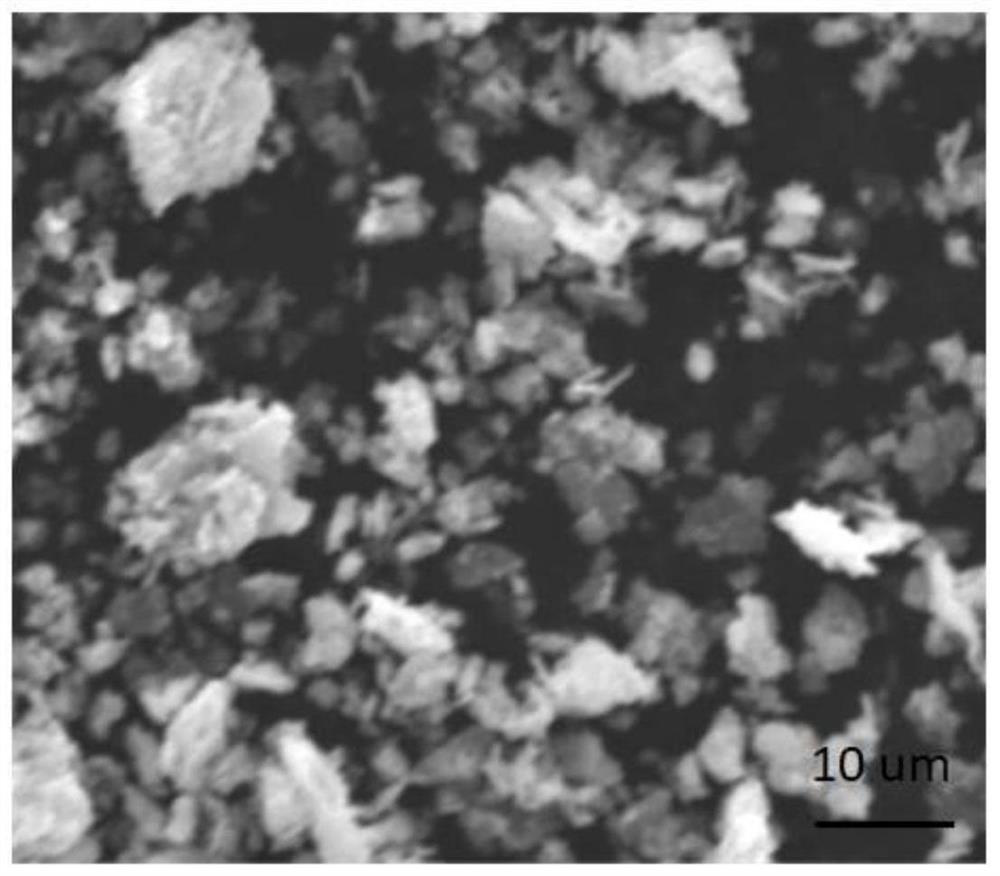

Lithium-ion battery silicon carbon negative electrode material and preparation method thereof

InactiveCN110504430AImprove cycle stabilityAchieving Controlled OxidationMaterial nanotechnologyNegative electrodesCyclic processCarbon coating

The invention provides a lithium-ion battery silicon carbon negative electrode material and a preparation method thereof. The preparation method of the lithium-ion battery silicon carbon negative electrode material comprises the following steps: S1, after mixing a silicon source and a solvent, wet grinding is performed under an oxidizing condition to form an oxide layer on the surface of the silicon source, wherein the mass of oxygen element accounts for 9.8% to 14% of the mass of the silicon source, and a slurry is obtained; S2, the slurry obtained in step S1 is compounded with a carbon material and dried to obtain a silicon carbon core material; S3, the silicon carbon core material obtained in step S2 is subjected to a fusion process treatment, and then mixed with a carbon coating material uniformly, and then calcined at a high temperature to be shaped; and S4, the material obtained in step S3 is crushed and sieved to obtain the silicon carbon negative electrode material. According to the invention, controlled oxidation of nano-silicon is realized during the wet grinding process, so that an oxide layer is formed on the surface of the silicon source; and the presence of the oxidelayer avoids side reactions between the silicon source and the electrolyte, and reduces the phenomenon of electrochemical agglomeration during the cyclic process at the same time; therefore, the cyclestability of the silicon carbon negative electrode material is significantly increased.

Owner:SHAANXI COAL & CHEM TECH INST

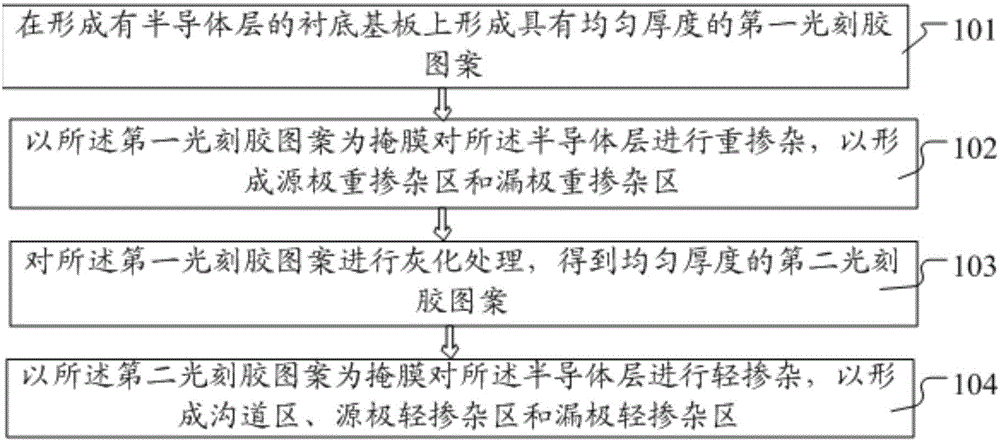

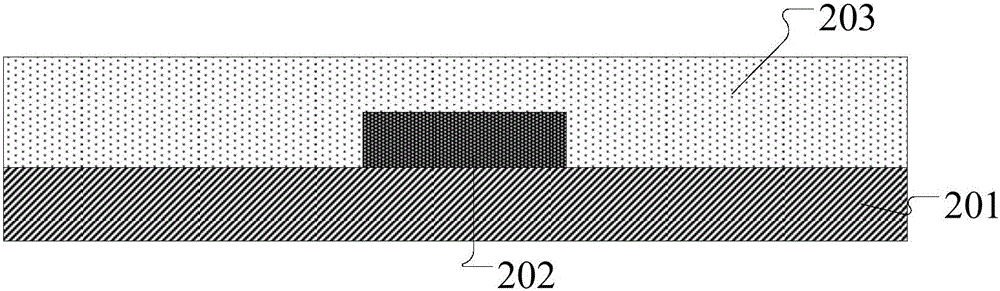

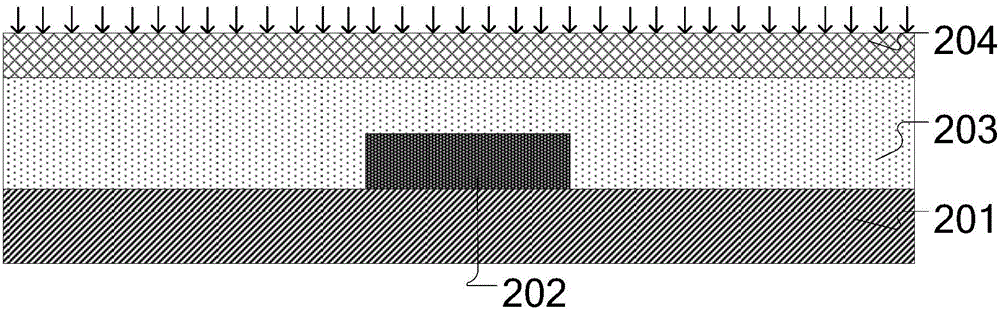

Preparation methods of thin film transistor and array substrate, array substrate and display device

InactiveCN106024633AFewer steps in the preparation processControl critical dimensionsTransistorSolid-state devicesDisplay devicePhotoresist

The invention provides preparation methods of a thin film transistor and an array substrate, the array substrate and a display device. The preparation method of the thin film transistor comprises the steps of: forming a first photoresist pattern with a uniform thickness on a substrate formed with a semiconductor layer; carrying out heavy doping on the semiconductor layer employing the first photoresist pattern as a mask to form a source heavily-doped region and a drain heavily-doped region; carrying out ashing treatment on the first photoresist pattern to obtain a second photoresist pattern with the uniform thickness; and carrying out light doping on the semiconductor layer employing the second photoresist pattern as the mask to form a channel region, a source lightly-doped region and a drain lightly-doped region. By the method, a photoresist can be fully utilized; the critical sizes of the source lightly-doped region and the drain lightly-doped region are accurately and efficiently controlled; and the product uniformity is ensured.

Owner:BOE TECH GRP CO LTD +1

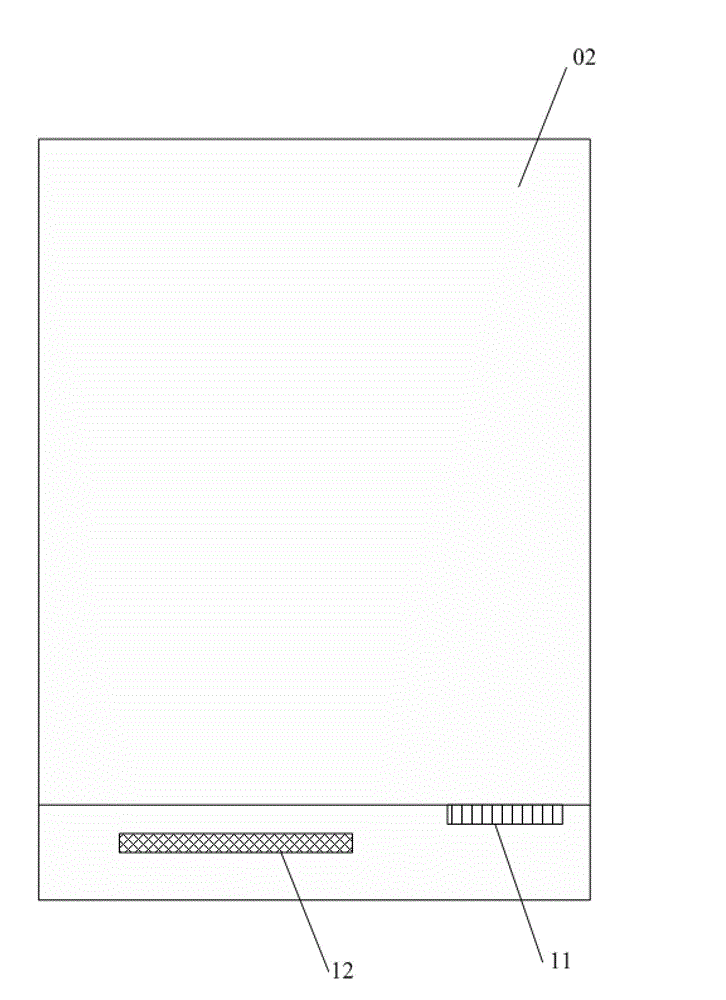

Liquid-crystal display with touch function and preparation method thereof

InactiveCN101762901AThe overall thickness is thinReduce weightStatic indicating devicesLiquid-crystal displayNewton's rings

The invention relates to a liquid-crystal display with a touch function and a preparation method thereof. The liquid-crystal display with the touch function comprises a first substrate and a second substrate, wherein the first substrate and the second substrate are oppositely packaged together and clamp a liquid crystal therebetween; the external surface of the first substrate is provided with a first polaroid, and the external surface of the second substrate is provided with a second polaroid with an integral structure and a touch structure layer for determining a position coordinate of a touch point. The invention not only causes the liquid crystal display to directly realize the touch function, but also realizes zero-distance combination of no gap between the touch structure and a liquid crystal panel through integrating the touch structure layer for determining the position coordinate of the touch point on the second substrate, thereby the technical defects of entering ashes and entering aqueous vapor of a conventional touch screen are completely overcome, and the technical defect of reducing display quality due to a Newton's ring generated by the conventional touch screen can be effectively avoided. Besides, the invention has the advantages of small thickness, light weight, material cost reduction, process step reduction, production time shortening and the like.

Owner:ZTE CORP

Non-acidizing method for producing high-efficiency phosphorus fertilizer

ActiveCN101429071APrevent compactionImprove fertilityBio-organic fraction processingOrganic fertiliser preparationPhosphateSoil fertility

The invention relates to a method for preparing high-efficiency phosphorus fertilizer without acidification. In the method, the material is ground by a vibration milling wet method to prepare super fine activated phosphate rock powder which has high specific surface area, the particle size is 90 percent and can passes through a 400-mesh sieve, the super fine activated phosphate rock powder is mixed with biological organic fertilizer according to the weight ratio of between 1 to 4 and 1 to 1, and pseudomonas fluorescens is added for mixing stockpile manure and fermenting so as to prepare the non-acidification high-efficiency phosphorus fertilizer. The method has the advantages of preparing the high-efficiency phosphorus fertilizer by physical and biological methods, reducing the environmental pollution, solving the problems of environmental pollution, high cost and the like existing in the prior phosphorus fertilizer preparation method and lowering cost of producing the phosphorus fertilizer, along with simple technique; moreover, in long-term usage, the phosphorus fertilizer can prevent the sealing of soil, improve the soil and enhance the soil fertility.

Owner:山东清大生态科技有限公司 +1

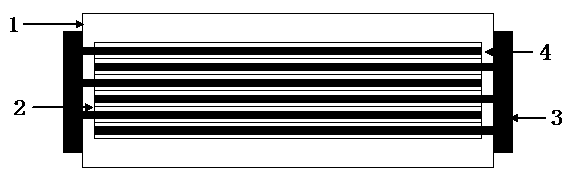

Graphite paper-barium titanate/polymide integrated composite thin-film capacitor

ActiveCN104036957ADirectly Test Dielectric PropertiesImprove thermal stabilityLiquid surface applicatorsThin/thick film capacitorBarium titanateGraphite

The invention relates to a graphite paper-barium titanate / polymide integrated composite thin-film capacitor. The graphite paper-barium titanate / polymide integrated composite thin-film capacitor comprises one or more layers of graphite-paper inner electrodes, dielectric layers among the inner electrodes and end electrodes at two ends. The graphite-paper-barium titanate / polymide integrated composite thin-film capacitor is characterized in that tatanate / polymide composite films are used as the dielectric layers, and the dielectric layers are integrally manufactured by graphite paper as carriers by means of the Czochralski method; the polymide is used as shell packing materials. The graphite-paper-barium titanate / polymide films are made by the Czochralski method, and solvent is removed and air microbubbles easy to cause breakdown are eliminated by reaction of vacuum heat imidization, so that dielectric constant is increased and the graphite paper-barium titanate / polymide integrated composite thin-film capacitor high in dielectric performance is manufactured. The manufactured thin-film capacitor has higher thermal stability, small thickness, high dielectric constant and low dielectric loss, energy loss caused by high-temperature sintering is avoided, and large-area manufacturing is realized.

Owner:OCEAN UNIV OF CHINA

Fireproof sound-proof heat-insulating aerogel composite material and preparation method thereof

The invention discloses a fireproof sound-proof heat-insulating aerogel composite material and a preparation method thereof. The preparation method comprises the following steps: Step 1, coating fibrofelt with fibre cloth; Step 2, immersing the fibrofelt coated with fibre cloth into a SiO2 sol solution; and Step 3, carrying out sol-gel and drying processes to obtain the fireproof sound-proof heat-insulating aerogel composite material. The product has excellent flame resistance, and the powdery problem of existing aerogel felt is solved; no obvious toxic flue gas is generated by decomposition under the condition of high temperature; and the preparation process is simple and meets the safe and environmental requirements.

Owner:应急管理部四川消防研究所

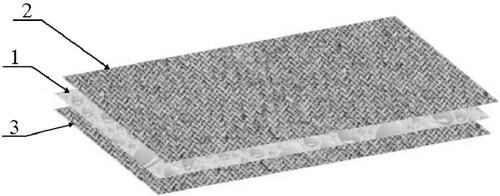

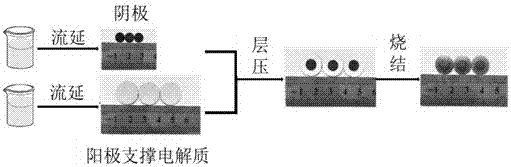

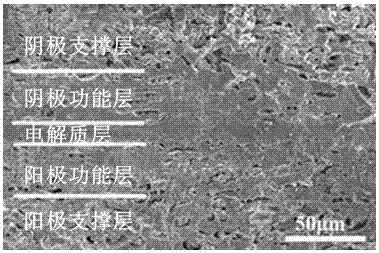

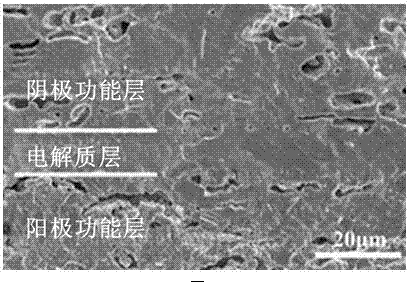

Single preparation method of solid oxide fuel cell

InactiveCN107195938AEven by forceReduce interface stressFinal product manufactureFuel cellsFuel cellsBattery cell

The invention relates to a single preparation method of a solid oxide fuel cell, and belongs to the field of a fuel cell. The method comprises the following steps of (1) casting an SSZ electrolyte layer; (2) casting a positive electrode functional layer and a positive electrode support layer on the SSZ electrolyte layer in the step (1) to form a biscuit A; (3) casting a negative electrode functional layer, and casting a negative electrode support layer on the negative electrode functional layer to form a biscuit B; (4) laminating the SSZ electrolyte layer surface of the biscuit A and a negative electrode functional layer surface of the biscuit B, and obtaining a complete all-battery biscuit by lamination; and (5) placing the all-battery biscuit obtained in the step (4) in a high-temperature furnace for sintering. The method has the advantages that uniform stress of the biscuit can be ensured by a lamination technology, so that the interface stress is reduced, and a crack and layering are eliminated; the biscuit A and the biscuit B are jointly laminated to form the all-battery biscuit by lamination, the all-battery is prepared by a one-step co-sintering technology, the step of a solid oxide full cell (SOFC) preparation process can be reduced, the production cost is reduced, and the time is saved.

Owner:HARBIN INST OF TECH

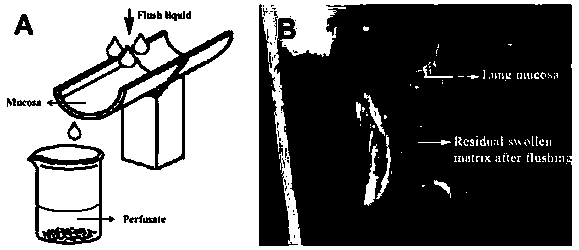

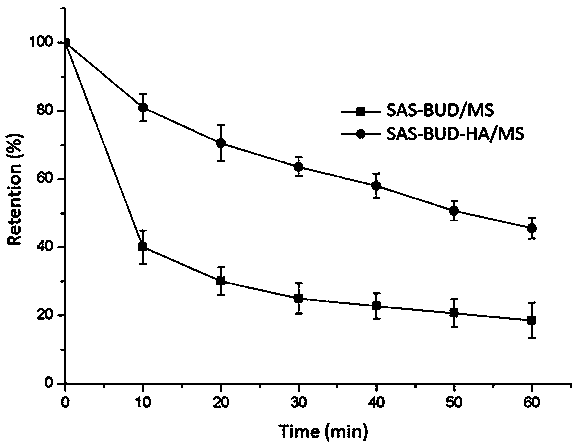

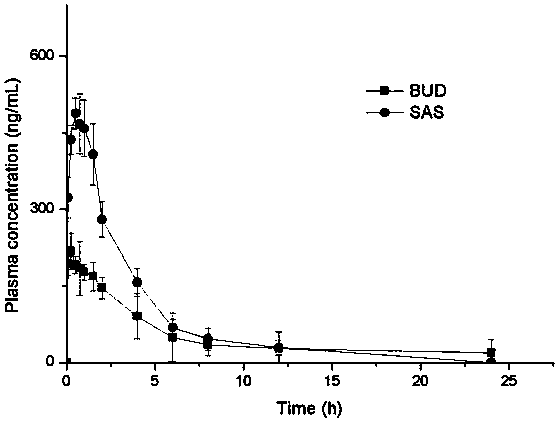

Biological adhesive lung aspiration nanometer composite microparticle and preparation method thereof

InactiveCN108721219AExtended stayImprove therapeutic indexPowder deliveryAerosol deliverySide effectWhole body

The invention belongs to the technical field of medicine, and relates to a biological adhesive compound lung aspiration nanometer composite microparticle and preparation thereof. The prepared nanometer composite microparticle is formed by simultaneously embedding nanometer crystals of one or two kinds of water-soluble anti-asthma and chronic pulmonary obstruction medicine and another kind of insoluble anti-asthma and chronic pulmonary obstruction medicine into a biological adhesive framework material. The composite microparticle uses a spray drying technology, and can realize the effects that1, the dissolution difficulty of the insoluble medicine is improved; the synchronous release of several kinds of medicine with different dissolution properties can be realized; the cooperated effectsare better achieved; 2, the uniform mixing of several kinds of medicine with different dose differences can be ensured; the technical process of the preparation is greatly simplified; the medicine quality is improved; the cost is reduced; the energy consumption is reduced; 3, through the application of the biological adhesive material, the lung mucous cilia clearing effect resistance can be effectively realized; the lung retention time is prolonged; the medicine concentration in the focus position is improved; the medicine absorption is delayed; the goals of improving the curative effect and reducing the whole body toxic and side effects can be achieved.

Owner:SHENYANG PHARMA UNIVERSITY

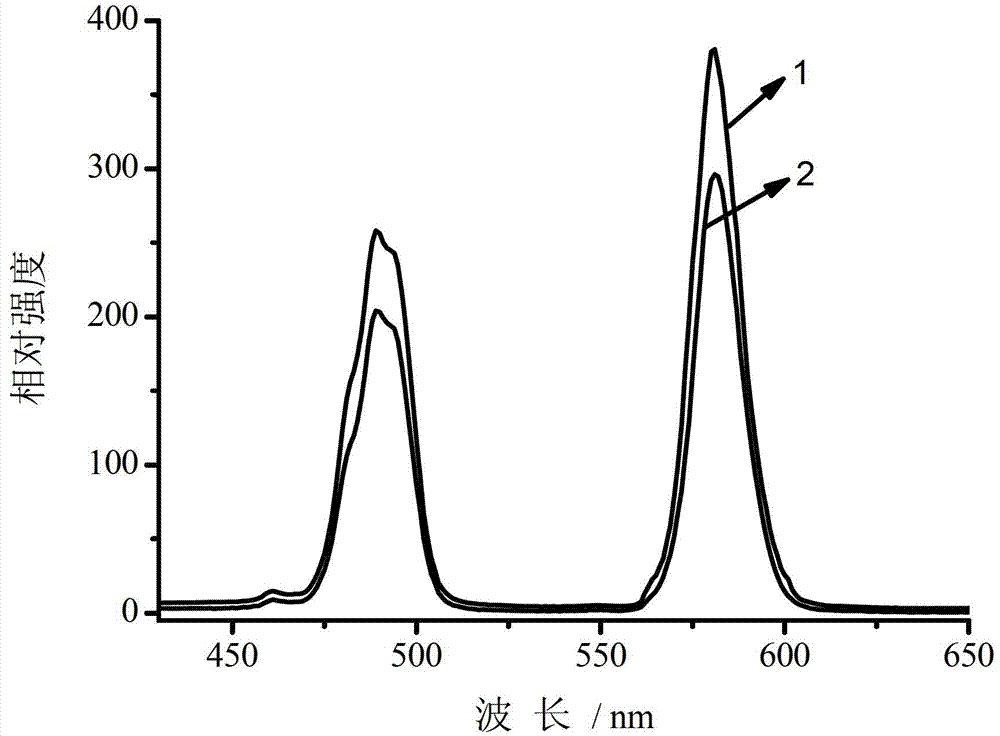

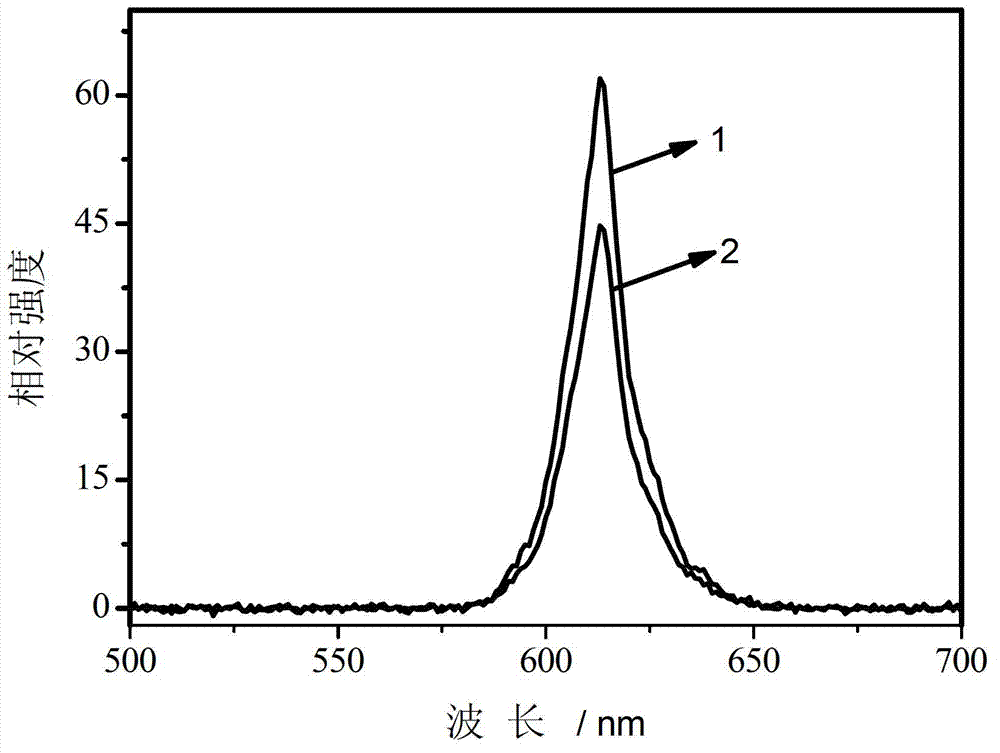

Metal particle-doped hollow structure orthophosphate luminescence material and preparation method thereof

InactiveCN103923658AImprove luminosityWavelength does not changeLuminescent compositionsMetal particleLength wave

The invention belongs to the field of luminescence materials, and discloses a metal particle-doped hollow structure orthophosphate luminescence material and a preparation method thereof, wherein the structure general formula of the luminescence material is Ba3-xGd(PO4)3:Dyx@My, M is doped metal nanoparticles and is at least one selected from Ag, Au, Pt, Pd and Cu, @ represents cladding, M is the inner core, and Ba3-xGd(PO4)3:Dyx is the outer shell. According to the metal particle-doped hollow structure orthophosphate luminescence material, the dispersed carbon spheres are adopted as the template, such that the obtained hollow structure having the spherical orthophosphate has the controlled morphology; and due to introduction of the M metal nanoparticles, the luminescence efficiency of the orthophosphate luminescence material can be substantially increased under the same excitation condition, and the wavelength of the emission light is not changed.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

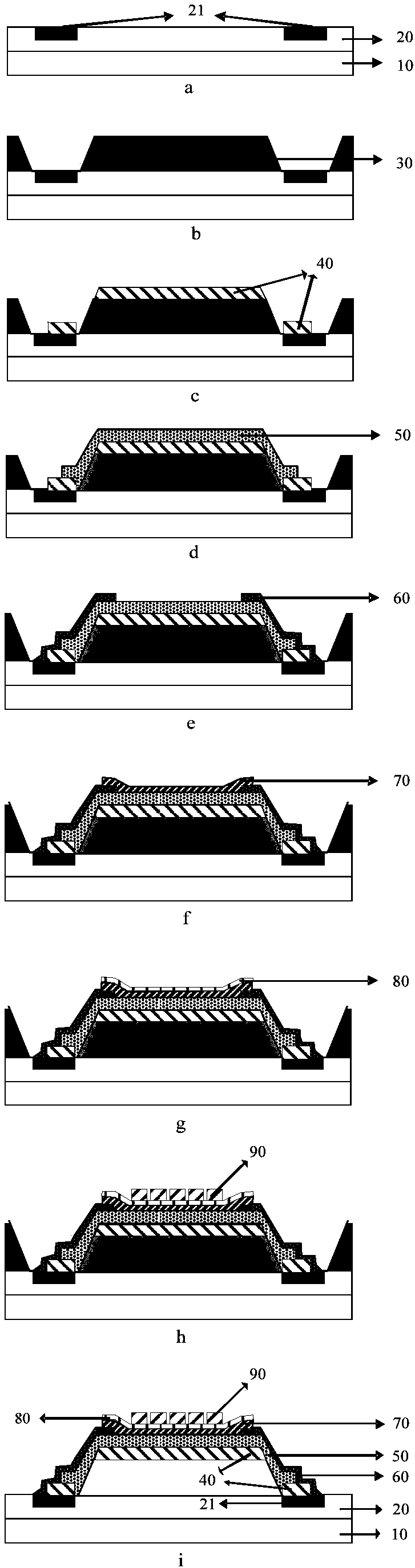

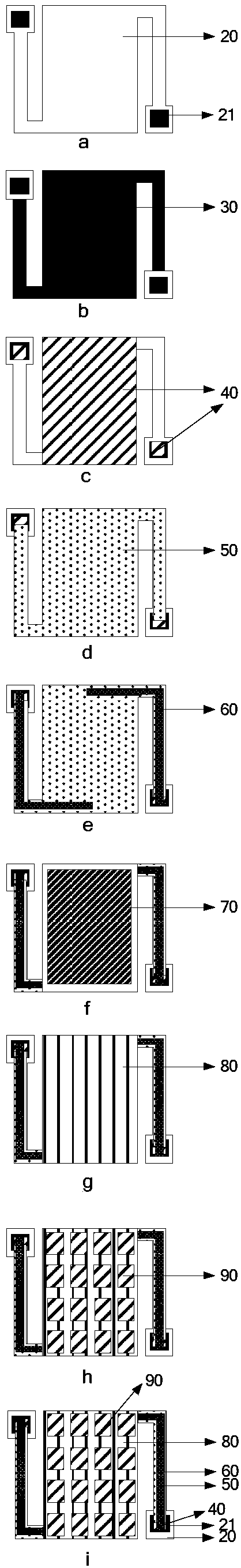

Metamaterial micro-bridge structure and preparation method thereof

ActiveCN108358157AWill not affect the working principleEnhanced terahertz radiation absorptionDecorative surface effectsChemical vapor deposition coatingRoom temperatureBridge deck

The invention provides a metamaterial micro-bridge structure, and relates to the technical field of terahertz detection array imaging at room temperature. The metamaterial micro-bridge structure comprises a substrate and a driving circuit layer, wherein a circuit interface is formed in the driving circuit layer; the metamaterial micro-bridge structure further comprises a bottom-layer metal thin film, a middle medium layer, an electrode layer, a thermosensitive thin film layer, a passivation layer and a top-layer metal thin film which are arranged from bottom to top in sequence; the middle medium layer comprises a deck, bridge legs and bridge masts; one part of the bottom-layer metal thin film is located below the deck, and the other part of the bottom-layer metal thin film is located belowthe bridge masts; a cavity is formed between the metal thin film located below the bridge deck and the driving circuit layer; the electrode layer is connected with the circuit interface; a sunken part is formed in the center of the electrode layer; and the bottom of the thermosensitive thin film layer is in contact with the middle medium layer through the sunken part. The metamaterial micro-bridge structure provided by the invention solves the problems that the existing metamaterial micro-bridge structure easily deforms and a preparation process is complicated; and meanwhile, the thermal response rate of a device is further increased.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

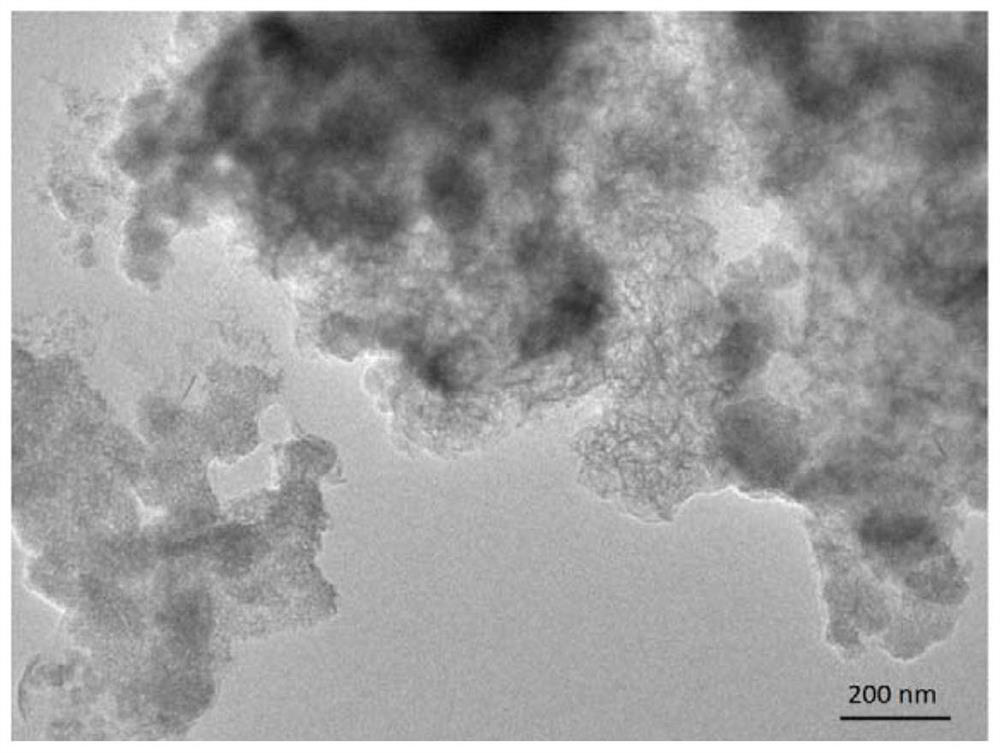

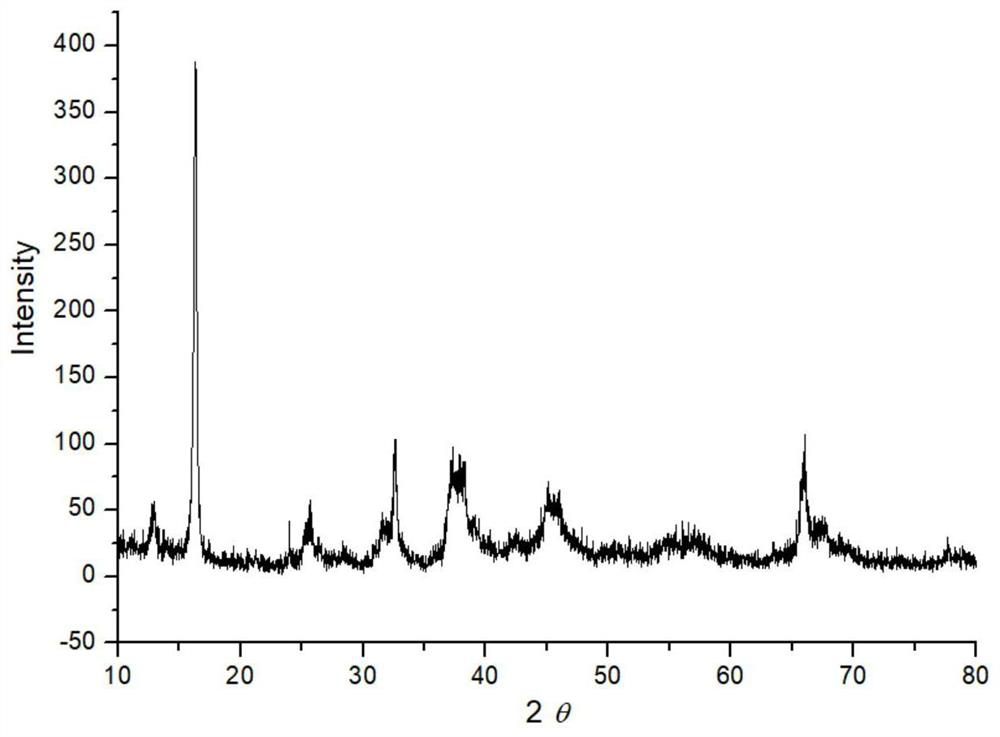

Sodium ion battery positive electrode material, preparation method thereof and sodium ion battery comprising same

ActiveCN109607624ASolve problems with capacity, etc.Fewer steps in the preparation processCell electrodesSecondary cellsChemical compositionPhysical chemistry

The invention provides a sodium ion battery positive electrode material, a preparation method thereof and a sodium ion battery comprising the same. The chemical composition of the sodium ion battery positive electrode material of the present invention is Na0.6Mn0.8Co0.2O2, and the sodium ion battery positive electrode material has a layer-tunnel composite structure. The sodium ion battery positiveelectrode material of the invention has a layer-tunnel composite structure, can combine the advantages of a layered structure and a tunnel structure, and can solve the problems existing in the capacity and other aspects of an existing single layered structural material. The preparation method of the sodium ion battery positive electrode material of the invention has fewer preparation steps and simple operation, and is suitable for large-scale popularization and production.

Owner:深圳为方能源科技有限公司

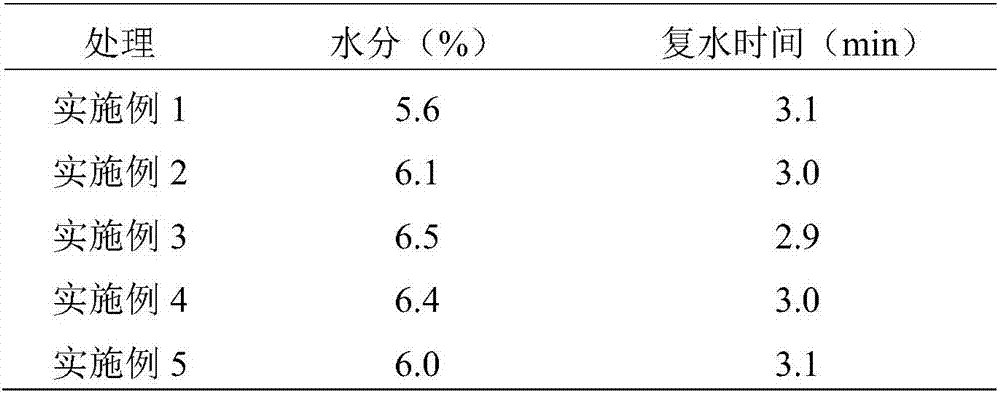

Instant noodle processing method

InactiveCN107006776AReduce lossesShorten the timeFood shapingFood ingredient as encapsulating agentDeep fryingParallel compression

The invention discloses an instant noodle processing method. The method includes steps: (1) seasoning adsorption, to be more specific, dissolving beta-cyclodextrin, soybean modified phosphatide, triglycerol monostearate and seasonings into water, well stirring, and adding salt, sodium pyrophosphate and guar gum to obtain mixed water solution; (2) dough kneading, to be more specific, mixing the mixed water solution with flour, and well stirring to obtain dough; (3) rolling and forming, to be more specific, putting the dough in an aging plate, performing low-temperature low-speed aging for 10-15min, pressing the aged dough into two pieces by two parallel compression rollers, and then passing through a compression roller to form a firm dough strip uniform in thickness; (4) shredding and cooking, to be more specific, slitting the dough strip, and performing steam cooking; (5) finished product formation, to be more specific, subjecting noodles to deep frying, air cooling and packaging to obtain finished products. By microencapsulation of the seasonings added into a dough cake, instant noodle preparation steps are reduced, and the production method is simple, easy in operation and available for industrial production.

Owner:江苏新顺福食品有限公司

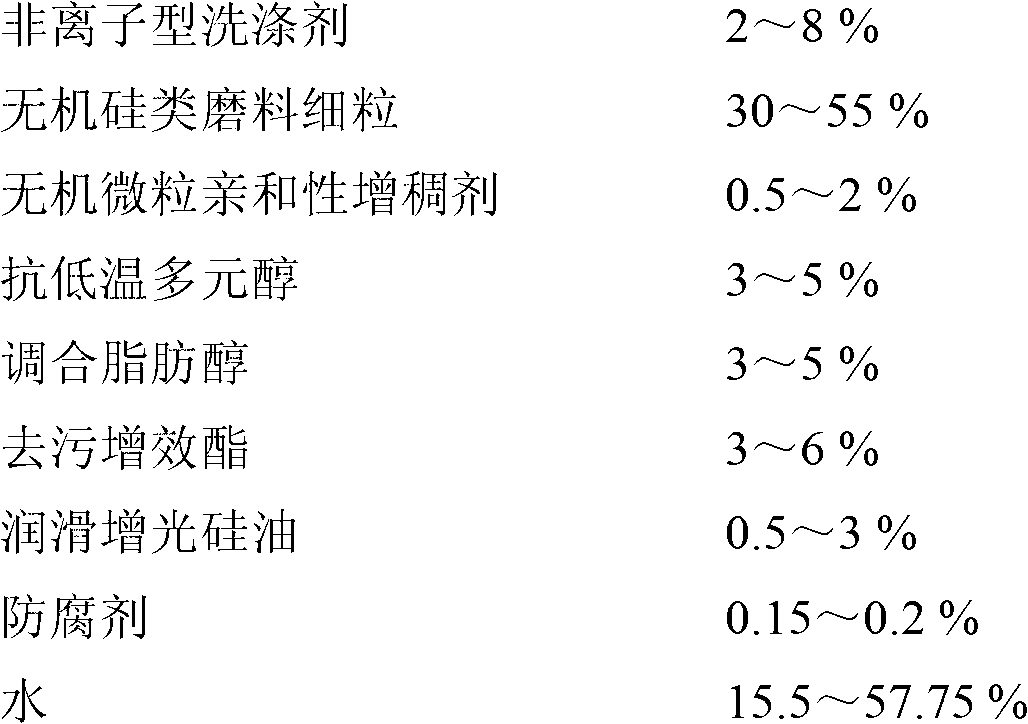

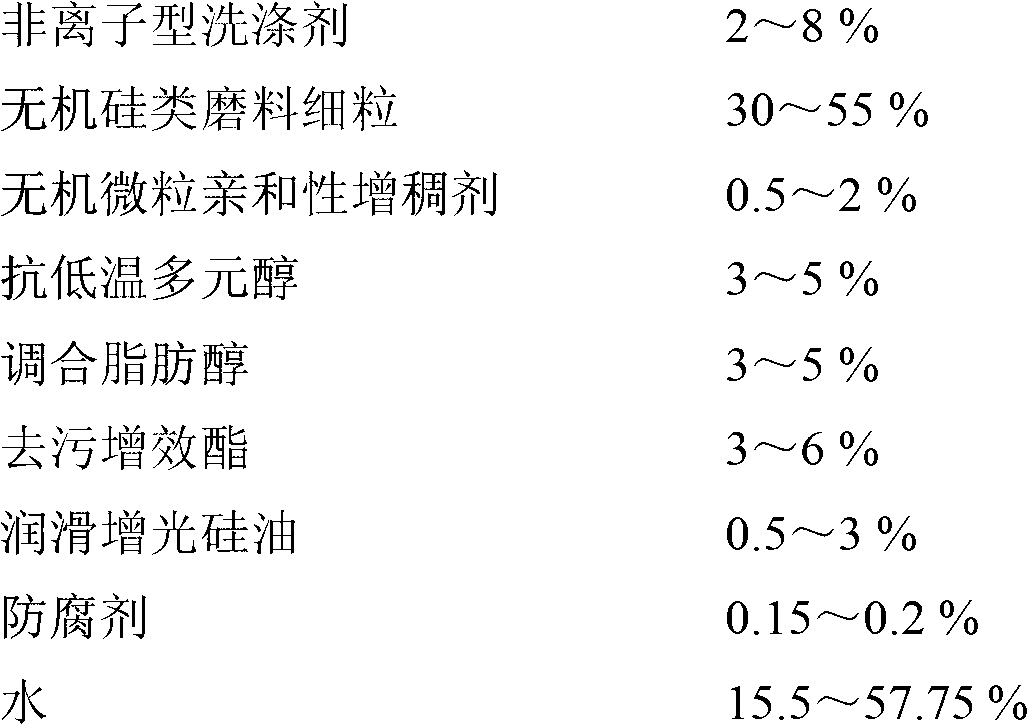

Powerful kitchenware detergent and preparation method thereof

ActiveCN102864031AAvoid scratchesEnvironmentally friendly ingredientsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleaning agentChemistry

The invention relates to a powerful kitchenware detergent and a preparation method thereof. Compared with the prior art, the detergent is high in scale and stain removing and brightening capacities, has no abrasion to kitchenware, is saving in water and materials and has no harm to skins; and the preparation method is simple and unique.

Owner:NINGBO YUFANGTANG BIOTECH

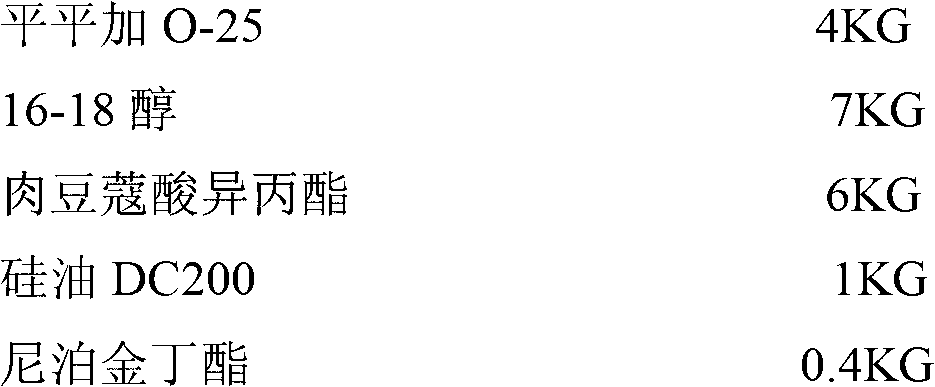

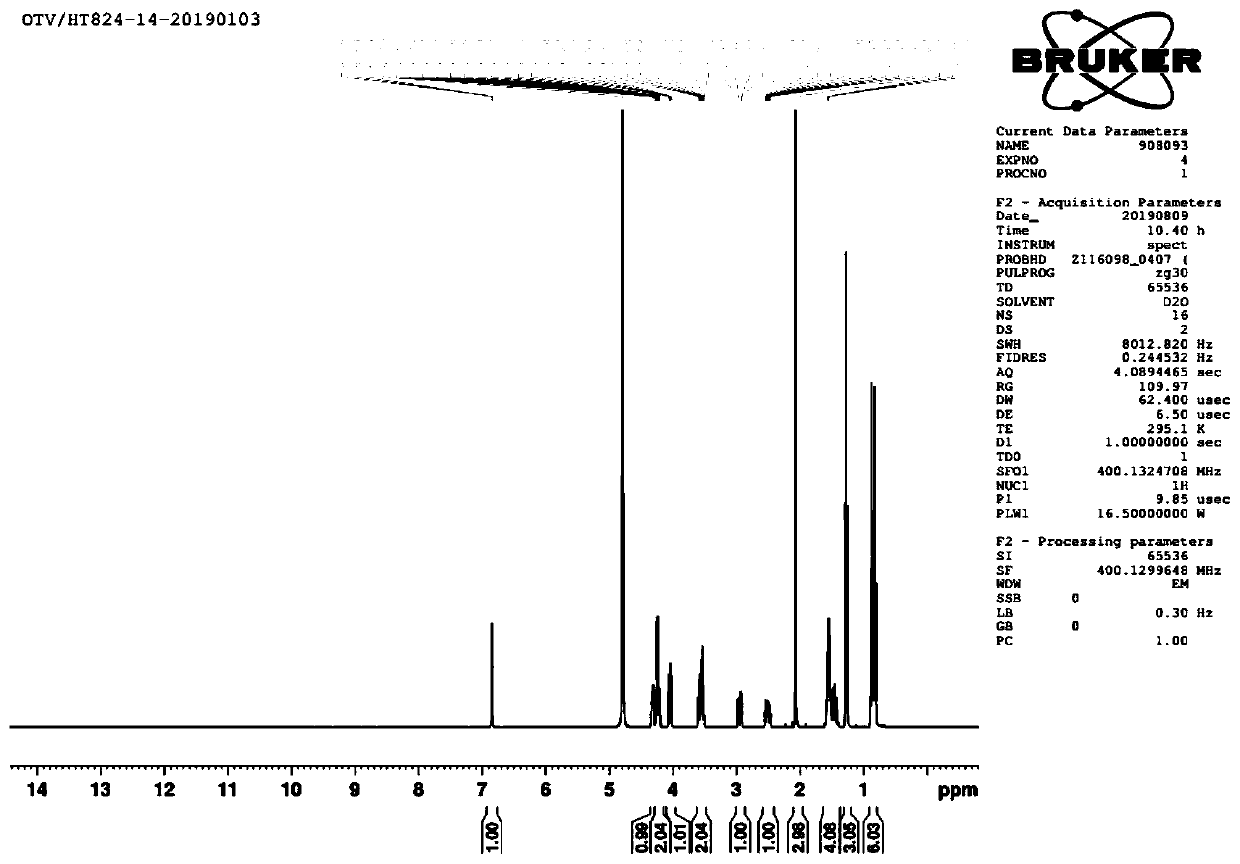

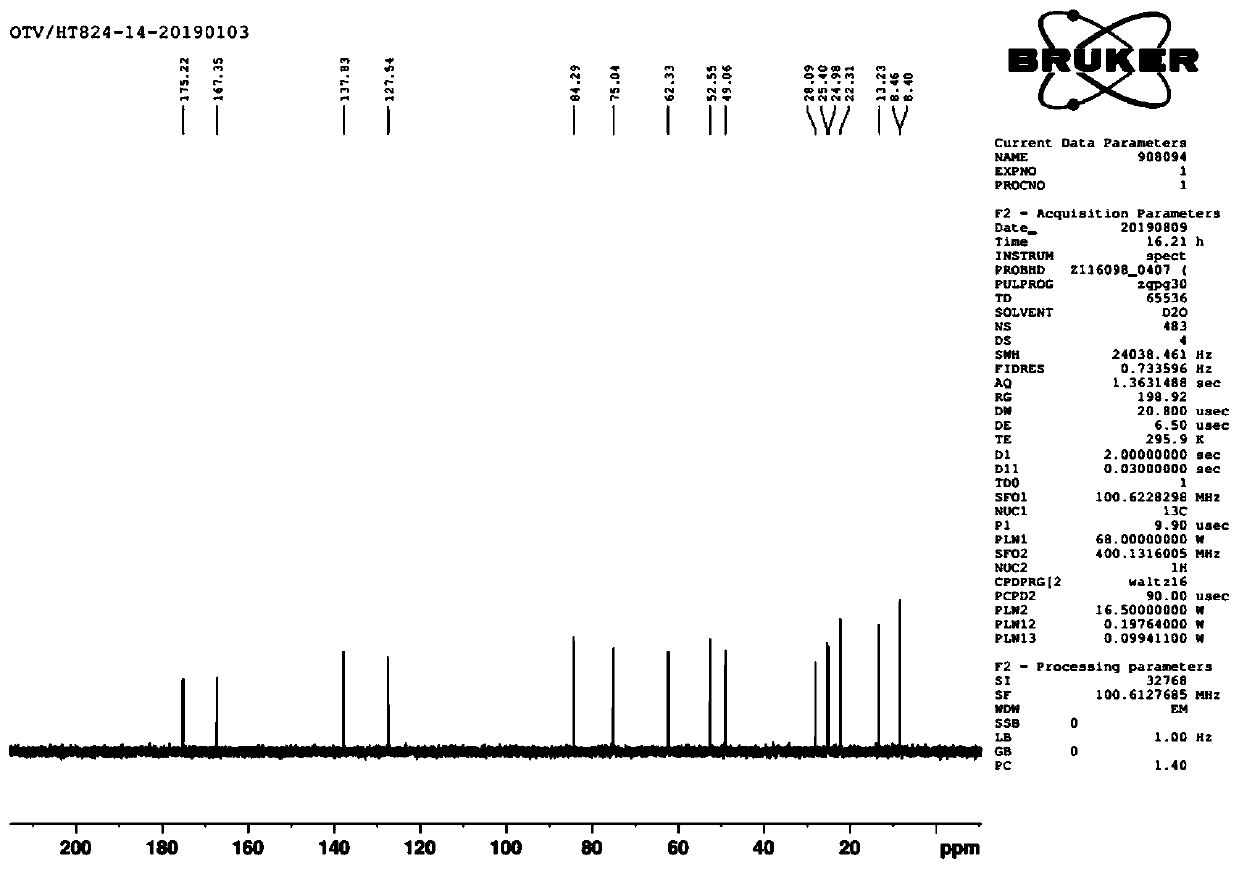

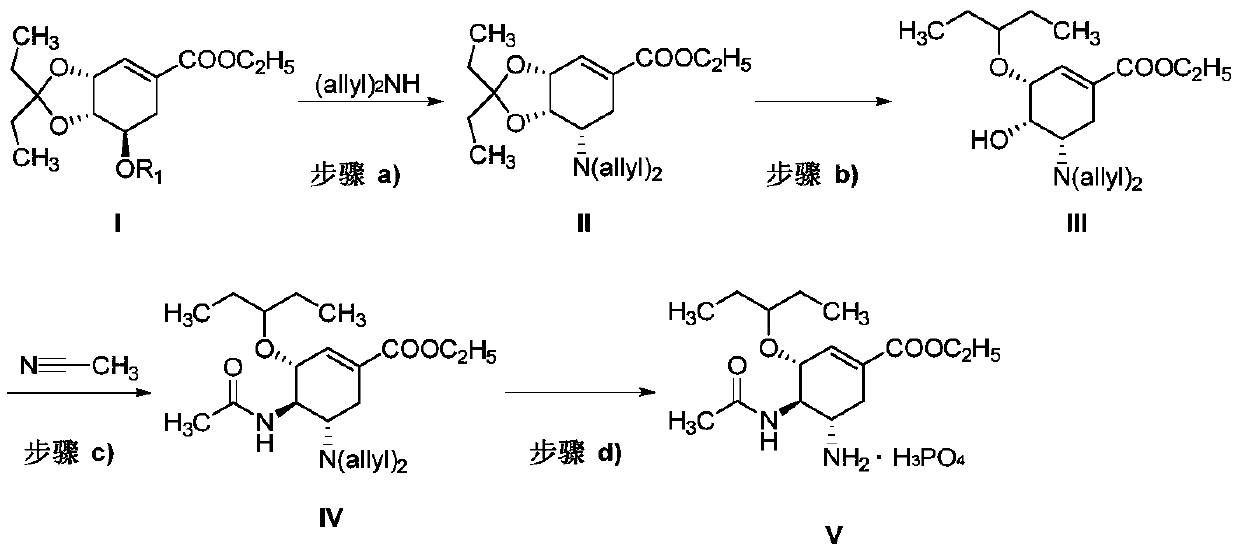

Preparation method of oseltamivir phosphate

ActiveCN110563600AFewer steps in the preparation processMild process conditionsOrganic compound preparationCarboxylic acid amides preparationOseltamivir PhosphateCarboxylate

The invention provides a novel preparation method of ethyl (3R,4R,5S)-4-acetylamino-5-amino-3-(1-ethylpropoxy)-1-cyclohexene-1-carboxylate phosphate, and belongs to the technical field of chemical drug synthesis. An acetamido group is introduced into the construction process of oseltamivir phosphate molecules by using a Ritter reaction. The preparation way of the initial raw material in the invention is close to the shikimic acid end of a natural product, so the novel preparation method has the advantages of mild conditions, simplicity in operation, high total yield, and suitableness for commercial production of oseltamivir phosphate bulk drugs. The method successfully avoids an original research route to overcome protection period limitation of an original research and preparation methodpatent, and can accelerate the solving of the problem of medication accessibility of the medicine in China.

Owner:BEIJING XINLINGXIAN MEDICAL TECH DEV CO LTD

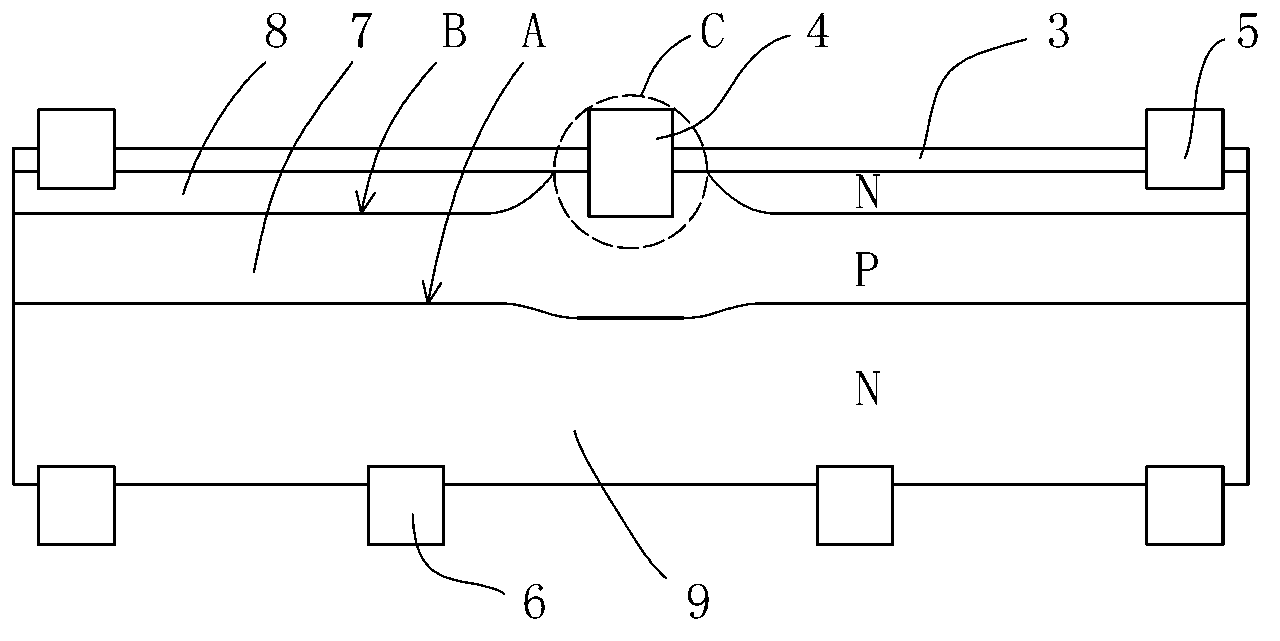

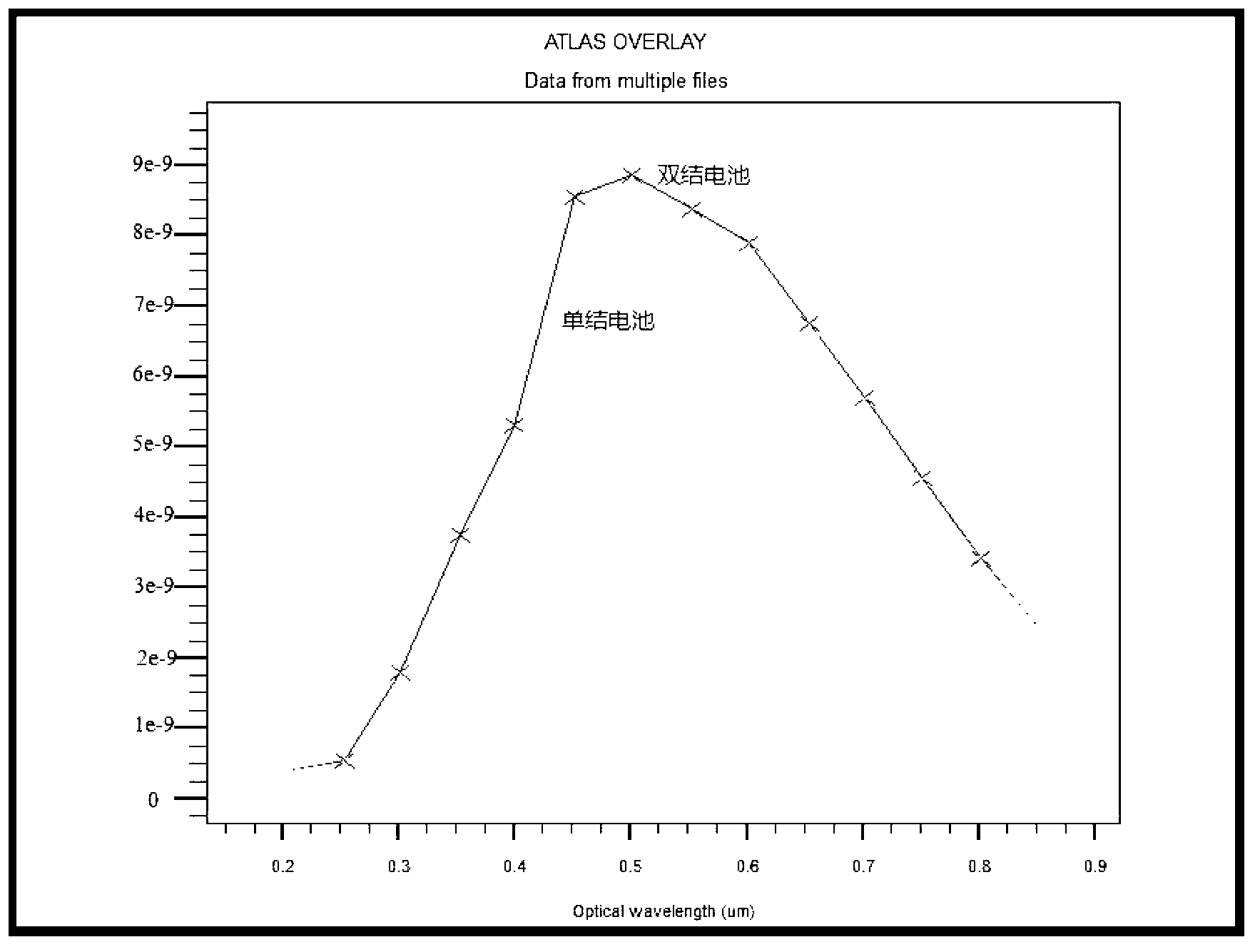

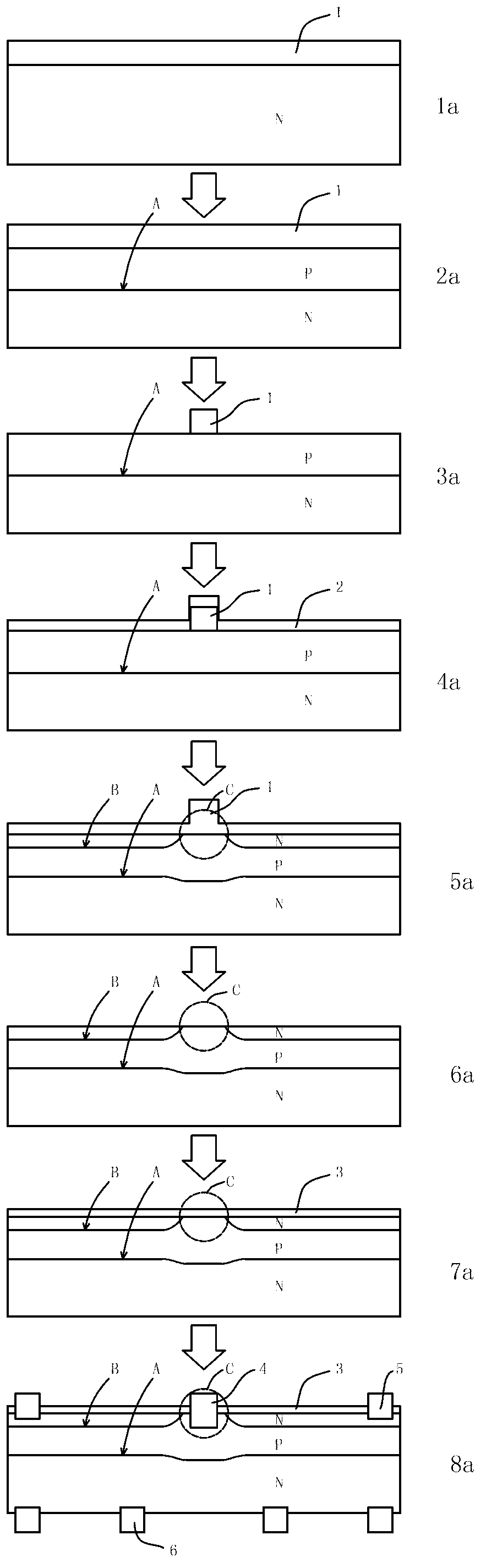

Parallel connection double-junction solar cell

InactiveCN103165721AWill not polluteGuaranteed heavy dopingFinal product manufacturePhotovoltaic energy generationMonocrystalline siliconOhmic contact

The invention relates to a parallel connection double-junction solar cell. The parallel connection double-junction solar cell comprises a silicon slice, a deep junction and a shallow junction are sequentially arranged on one side of the upper surface of the silicon slice from inside to outside to form a P-N-P type or N-P-N type double-junction cell, doping elements of the cell are diffused in a first crystal silicon layer between the deep junction and the shallow junction, the first crystal silicon layer extends to a top electrode area from inside to outside, the top electrode area is a heavy doping area, a second crystal silicon layer with electrical properties opposite to those of the doping elements is arranged above the shallow junction, the second crystal silicon layer is located outside the top electrode area on the upper surface of the silicon slice, a top electrode is in ohmic contact with the first crystal silicon layer, a transoid electrode which is in ohmic contact with the second crystal silicon layer is arranged on a non-top-electrode area, and the transoid electrode is connected with a back electrode. According to the parallel connection double-junction solar cell, two PN junctions are formed in the same monocrystalline silicon battery and share one p area, the difficulty of current carriers in a series connection laminated cell to penetrate through a tunnel junction is reduced, the absorption of short waves is facilitated by the aid of the shallow junction, the absorption of long waves is effectively guaranteed by the aid of the deep junction, and thereby performances of the cell are good.

Owner:NANTONG UNIVERSITY

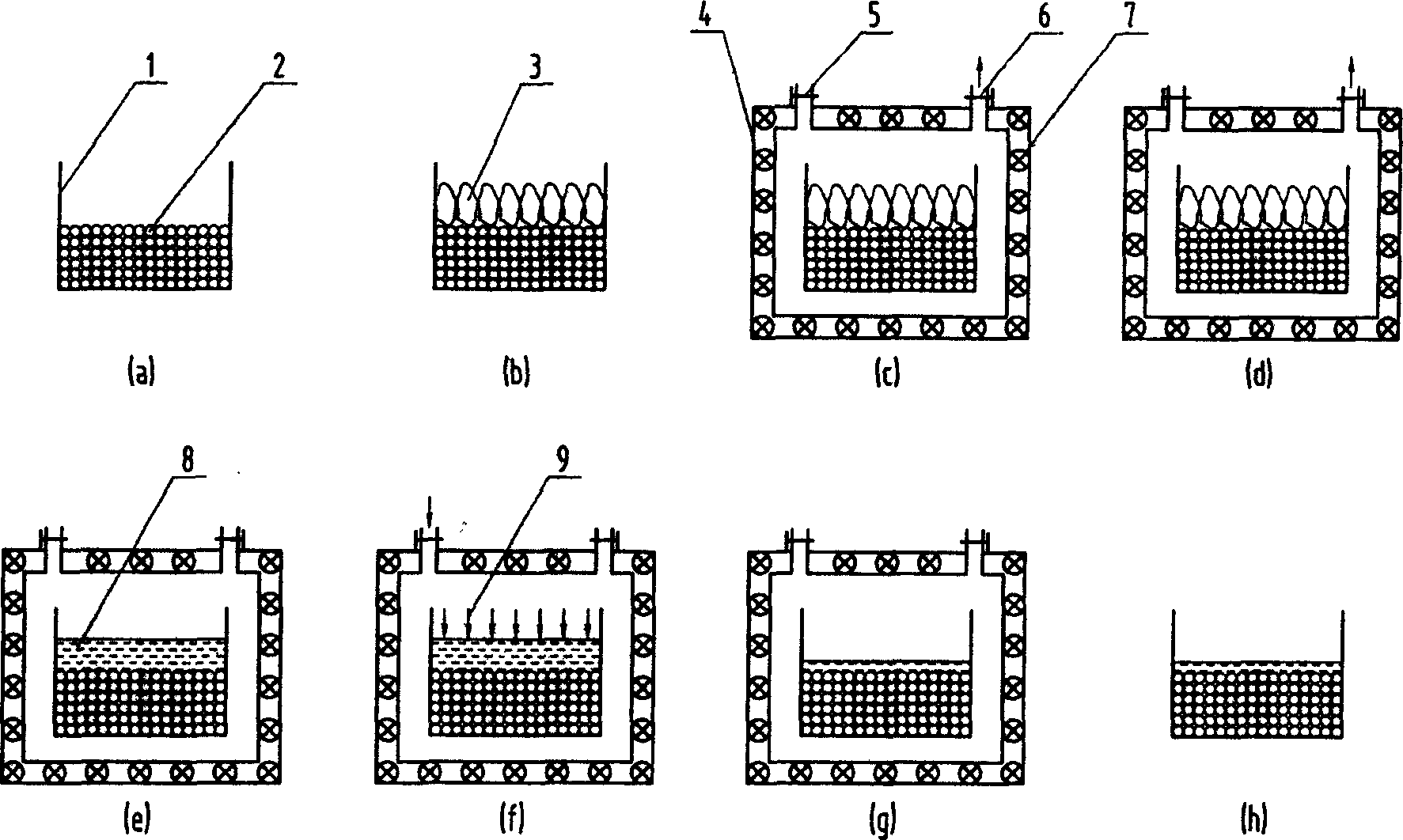

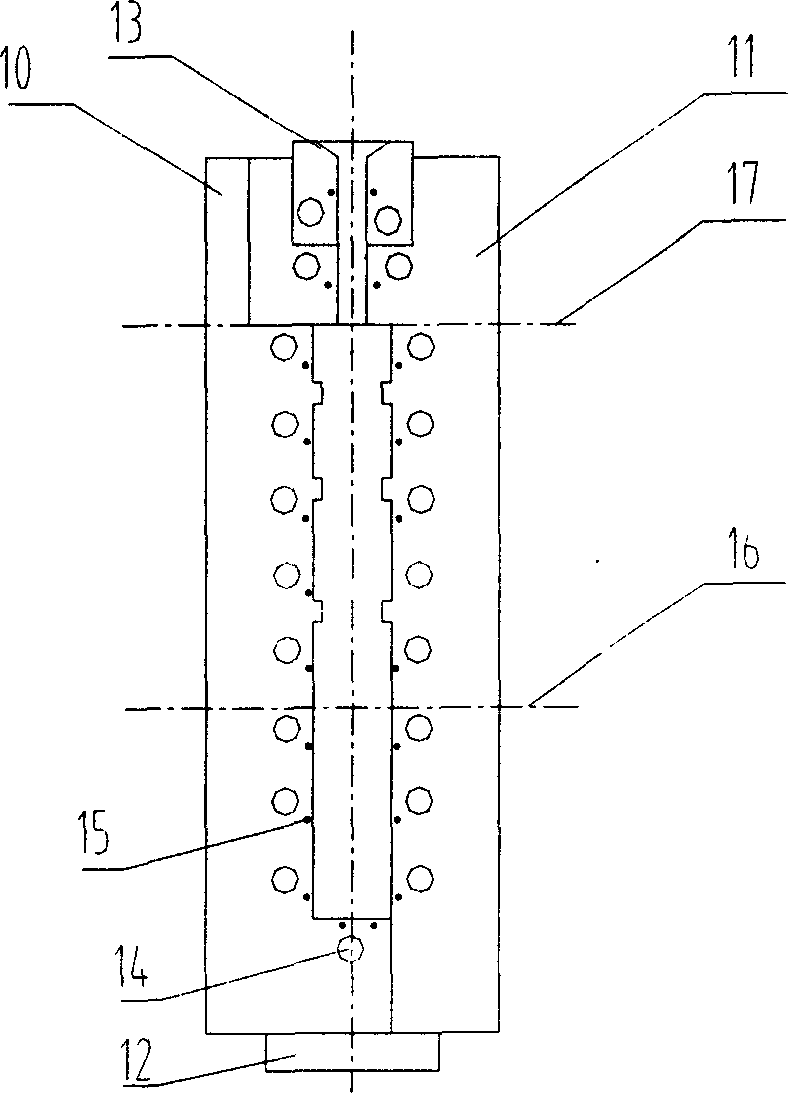

Metal composite, preparation, forming method and equipment

InactiveCN1562527AImprove performanceHigh proportion of ingredientsMetallic materialsDirectional solidification

A metallic composition is prepared from the metallic or non-metallic powder material A with high smelting point and the metallic material B iwth lower smelting point through mixing, vacuumizing while heating to a temp between the smelting points of A and B for smelting B, and holding the temp for penetrating the molten B into the powder material to obtain a solid-liquid composition. It can be shaped by casting, squeezing, rolling or directional solidifying.

Owner:周照耀

A kind of positive electrode material of sodium ion battery and its preparation method and sodium ion battery comprising it

ActiveCN109607624BSolve problems with capacity, etc.Fewer steps in the preparation processCell electrodesSecondary cellsPhysical chemistrySodium-ion battery

The invention provides a positive electrode material of a sodium ion battery, a preparation method thereof and a sodium ion battery containing the same. The chemical composition of sodium ion cathode battery material of the present invention is: Na 0.6 mn 0.8 co 0.2 o 2 ; The positive electrode material of the sodium ion battery has a layered-tunnel composite structure. The positive electrode material of the sodium ion battery of the present invention has a layered and tunnel composite structure, can combine the respective advantages of the layered structure and the tunnel structure, and can solve the problems existing in the existing single layered structure materials in terms of capacity and the like. The preparation process of the positive electrode material of the sodium ion battery of the present invention has few steps, simple operation, and is suitable for large-scale popularization and production.

Owner:深圳为方能源科技有限公司

Metal particle-doped hollow structure calcium titanate praseodymium luminescence material and preparation method thereof

InactiveCN103923651AImprove luminous efficiencyWavelength does not changeLuminescent compositionsPhysical chemistryMetal particle

The invention belongs to the field of luminescence materials, and discloses a metal particle-doped hollow structure calcium titanate praseodymium luminescence material and a preparation method thereof, wherein the structure general formula of the luminescence material is Ca1-xTi1-ySnyO3:Prx@Mz, M is doped metal nanoparticles and is at least one selected from Ag, Au, Pt, Pd and Cu, @ represents cladding, M is the inner core, and Ca1-xTi1-ySnyO3:Prx is the outer shell. According to the metal particle-doped hollow structure calcium titanate praseodymium luminescence material, the dispersed carbon spheres are adopted as the template, such that the obtained hollow structure having the spherical calcium titanate praseodymium has the controlled morphology; and due to introduction of the M metal nanoparticles, the luminescence efficiency of the calcium titanate praseodymium luminescence material can be substantially increased under the same excitation condition, and the wavelength of the emission light is not changed.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Lead frame for chip packaging, preparation method thereof, and chip packaging structure

PendingCN112366197AFewer steps in the preparation processSimple processSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsStructural engineering

The invention discloses a lead frame for chip packaging, a preparation method thereof, and a chip packaging structure. The lead frame comprises a bearing sheet, a first solder resist ink layer and a plurality of unit circuits arranged in a matrix, each unit circuit comprises a plurality of electrodes, and each electrode comprises a top electrode and a bottom electrode; the top electrodes are arranged on the top surface of the first solder resist ink layer; corresponding to each unit circuit, the first solder resist ink layer comprises a bottom electrode hole corresponding to the electrode, thebottom electrode is arranged in the bottom electrode hole, and the top of the bottom electrode is fixed on the bottom surface of the top electrode; and the bearing sheet is peelably adhered to the first solder resist ink layer and the bottom surface of the bottom electrode. The preparation method of the lead frame is few in steps, simple in process flow and low in cost.

Owner:深圳市鼎华芯泰科技有限公司

Hemocoagulase extracted from bothrops atrox and preparation method and application thereof

PendingCN108611341AReduce risk of exposureFewer steps in the preparation processHydrolasesPeptide/protein ingredientsBenzamidinePharmaceutical drug

The invention provides a hemocoagulase extracted from bothrops atrox and also provides a preparation method of the hemocoagulase. The method comprises the following steps of: pretreating the bothropsatrox; sequentially passing the diethylaminoethyl cross-linked dextran gel A-25 ion exchange chromatography, benzamidine agarose gel 4-FF (HS) affinity chromatography, and cross-linked dextran gel G-75 gel filtration chromatography; and obtaining hemocoagulase. The invention also provides the application of the bothrops atrox hemocoagulase. in the preparation of a medicament for treating bleedingdisorder. Compared with the prior art, the preparation process steps are less, the period is short, and the exposure risk of the process environment is reduced; the product yield is high, the processhas strong ability to remove impurities, the yield of the product can be obtained more than 35% and the purity is over 98%; the process stability is high and the product quality is good, and the process is beneficial to clinical medication safety.

Owner:GRAND LIFE SCI (LIAONING) CO LTD

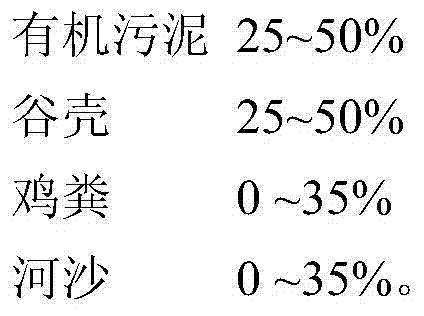

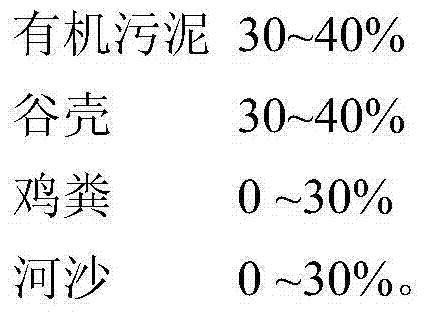

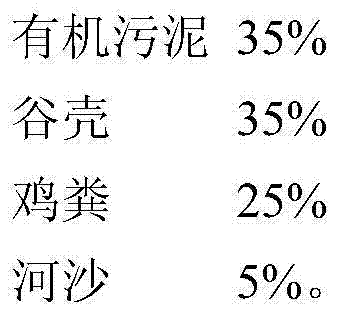

Solid substrate for raising seedlings by citrus container and preparation method of solid substrate

The invention belongs to the technical field of cultivation, in particular to a solid substrate for raising seedlings by a citrus container and a preparation method of the solid substrate. The solid substrate raising the seedlings by the citrus container comprises, in weight percent, 25-50% of organic sludge, 25-50% of rice husks, 0-35% of chicken manure and 0-35% of river sand or 30-50% of chicken manure residue, 30-50% of rice husks and 0-35% of river sand which are mixed. Peat is replaced by the aid of industrial and agricultural waste, the ideal solid substrate applicable to raising the seedlings by the citrus container is developed, the components of the substrate are optimized, and the novel solid substrate for raising the seedlings by the citrus container has the advantages that the solid substrate is green, environmentally friendly, low in cost and simple in preparation process, and growth and development of the citrus seedlings are facilitated.

Owner:CITRUS RES INST OF CHINESE ACAD OF AGRI SCI

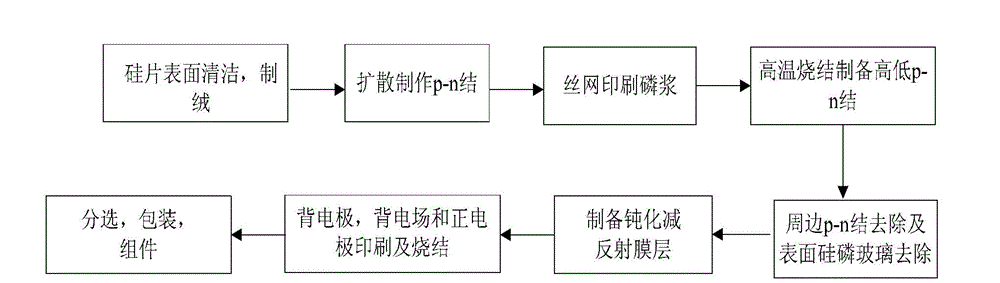

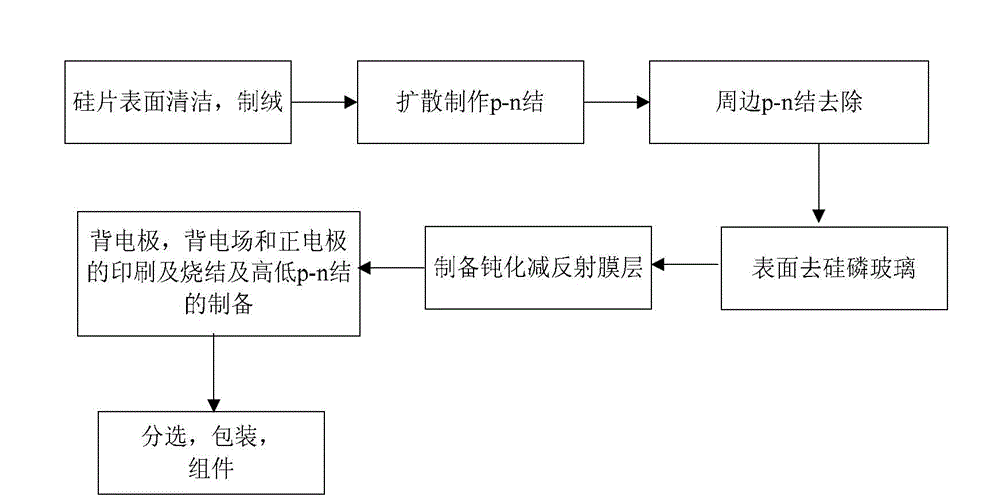

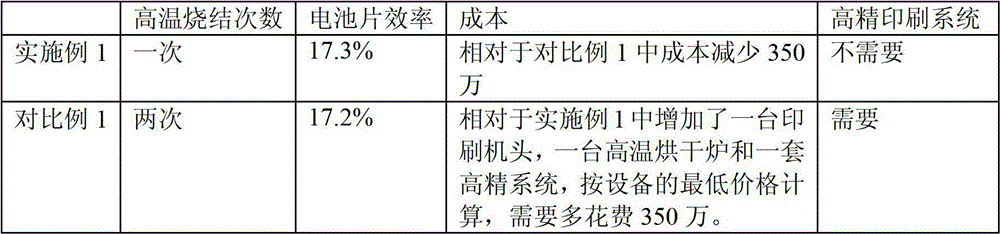

Manufacture method of selective emitter crystalline silicon solar cells

InactiveCN102983221AFewer steps in the preparation processLow costFinal product manufactureSemiconductor devicesPhosphateSilicon solar cell

The invention discloses a manufacture method of selective emitter crystalline silicon solar cells. The manufacture method comprises the following steps: cleaning the surface of a silicon wafer, making wool, diffusedly manufacturing shallow p-n knots, manufacturing antireflective film layers, printing a positive electrode and a back electrode, and performing sintering, wherein the step of printing the positive electrode adopts silver slurry containing phosphate to print. As the silver slurry containing phosphate is adopted to print the positive electrode, the silver slurry containing phosphate is subjected to oven-drying, sintering and annealing processes of a sintering furnace after the silver slurry containing phosphate is printed, and phosphorus atoms in the silver slurry are further subjected to phosphorus diffusion when the phosphorus atoms is sintered and annealed to form the positive electrode; a deep diffusion zone is formed in the area of the positive electrode contacted with the silicon wafer, namely deep p-n knobs are formed under the positive electrode; and a shallow diffusion zone is formed in the silicon wafer area not contacted with the positive electrode, so that the deep and the shallow p-n knobs are obtained while the positive electrode is formed. The manufacture method has fewer steps and low cost, and is suitable for industrial production; and as the printing process does not need to use a high-precision printing system, the equipment cost is greatly saved.

Owner:YINGLI ENERGY CHINA

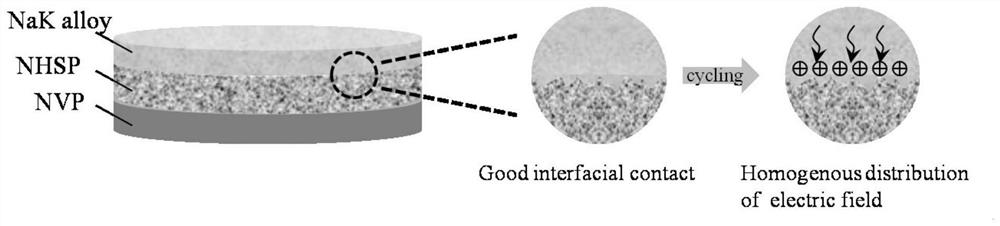

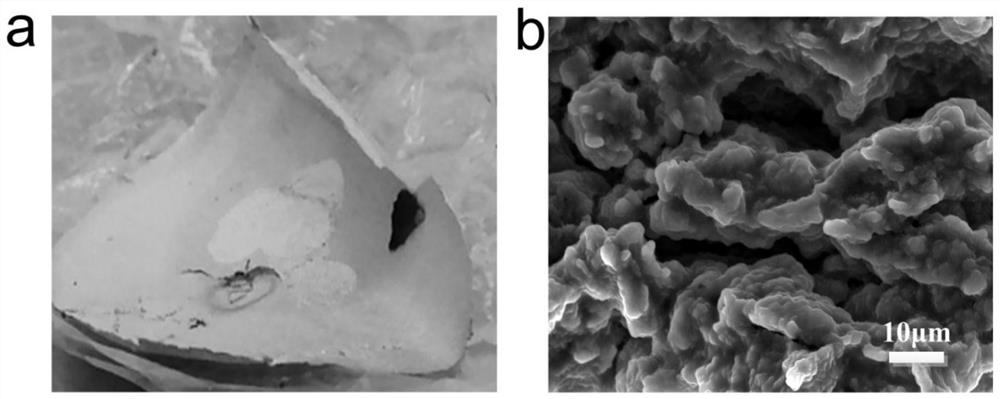

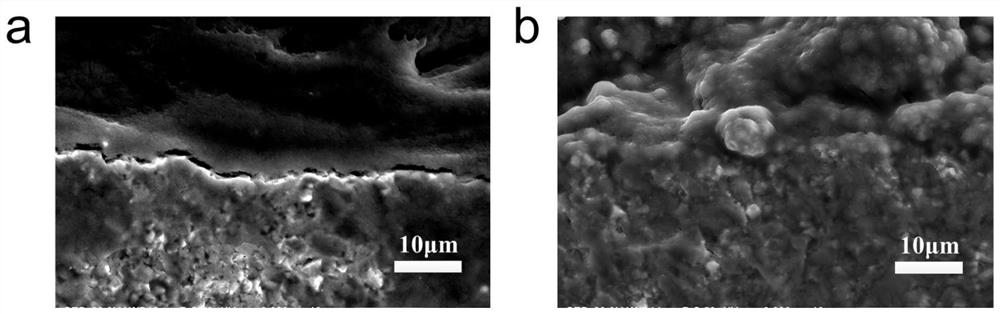

Room-temperature solid sodium ion battery based on liquid alloy

PendingCN113113593AImprove interfacial wettabilityUniform growthCell electrodesFinal product manufactureChemical physicsLiquid state

The invention discloses a room-temperature solid sodium ion battery based on a liquid alloy, and belongs to the technical field of batteries, a negative electrode material is a liquid sodium-potassium alloy (9.2 to 58.2 wt% Na), a supporting framework of the negative electrode material is redox graphene, a sodium-potassium alloy negative electrode is obtained by combining the liquid sodium-potassium alloy and the redox graphene, and compared with pure metal sodium as a solid-state sodium ion battery negative electrode, the sodium-potassium alloy negative electrode can effectively improve the wettability of the negative electrode and an electrolyte interface, and can provide more active sites for metal sodium deposition, so that metal ions are distributed more uniformly, meanwhile, the three-dimensional porous structure of the redox graphene can relieve the volume change of metal sodium in the circulation process, the sodium-potassium alloy negative electrode is applied to the solid-state sodium-ion battery, the performance of the sodium-potassium alloy negative electrode is obviously improved, and more importantly, the solid-state sodium-ion battery is tested at normal temperature, and the realization of the room-temperature solid-state sodium ion battery based on the liquid alloy becomes possible.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

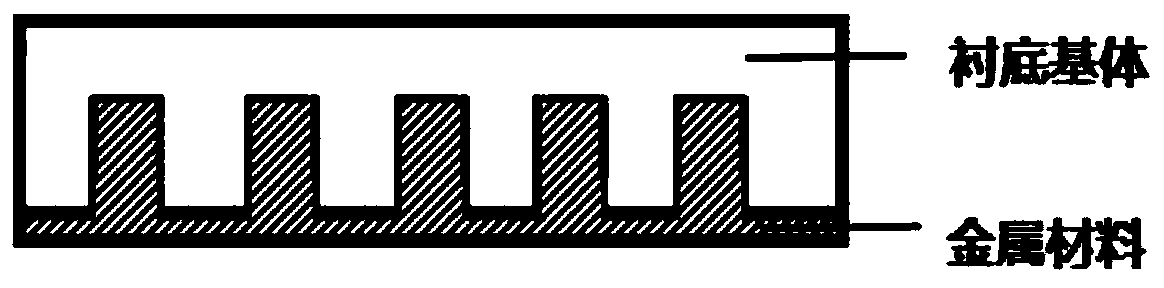

Solder-free high-thermal-conductivity semiconductor substrate and preparation method thereof

InactiveCN111082308AFewer steps in the preparation processExtend your lifeLaser detailsSemiconductor laser structural detailsMetallic materialsHeat sink

The invention provides a solder-free high-thermal-conductivity semiconductor substrate and a preparation method thereof, and belongs to the technical field of semiconductors. According to the semiconductor substrate is prepared by the method provided by the invention, holes are formed in the back surface, and filled with a metal material with relatively high ductility through an evaporation method; after the holes are filled, a metal material layer is then prepared on the back surface of the etched substrate by utilizing the evaporation method; when the semiconductor substrate is used, the metal material layer can be used as a solder layer, after the heat sink is heated, direct adhesion of the semiconductor substrate and the heat sink can be realized, an extra process of preparing the solder layer on the heat sink is omitted, and device preparation process steps are reduced. Besides, the holes are formed in the back surface of the substrate base body, and the holes are filled with themetal materials with good ductility and high heat conduction capability, so that the problems of chip damage and separation from the heat sink due to excessive stress when the chip is heated to expandare solved, the service life of the semiconductor laser chip is prolonged, and the performance of the semiconductor laser is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

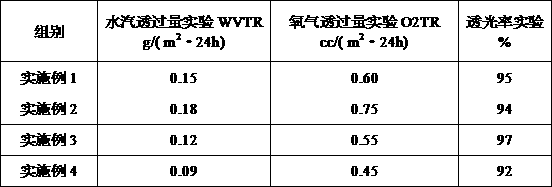

High-light-transmitting composite material and preparation method thereof

InactiveCN109449231ASimple structureSimple structure setupPhotovoltaic energy generationSemiconductor devicesResin coatingFluorocarbon

The invention discloses a high-light-transmitting composite material and a preparation method thereof. The high-light-transmitting composite material comprises a high-light-transmitting transparent plate, wherein an aluminum oxide film layer is arranged on the upper surface and the lower surface of the high-light-transmitting transparent plate separately; a modified UV fluorocarbon resin coating layer is arranged on the aluminum oxide film layer; and embossed lines are printed on the modified UV fluorocarbon resin coating layer. The preparation method comprises the following steps of: step 1,plating the aluminum oxide film layer on each of the upper surface and the lower surface of the high-light-transmitting transparent plate separately; step 2, coating the modified UV fluorocarbon resincoating layer on the aluminum oxide film layer; step 3, curing the modified UV fluorocarbon resin coating layer; and step 4, performing embossing on the coated cured modified UV fluorocarbon resin coating layer through an embossing roller to obtain a finished product. The high-light-transmitting composite material provided by the invention has the advantages of being simple in structure, high inbarrier property, high in light transmission and capable of improving the light conversion efficiency, lowering the production cost and the like; and in addition, the preparation method of the high-light-transmitting composite material provided by the invention has the advantages that the operation steps are simple, large-scale production can be realized easily and the like.

Owner:广东圣帕新材料股份有限公司

Preparation process of synthetic silicon electrode with foam conductive network as carrier

ActiveCN109546090AFewer steps in the preparation processSimple processCell electrodesCarbon nanotubeSacrificial metal

The invention relates to a preparation process of a synthetic silicon electrode with a foam conductive network as a carrier. With a foam conductive network as a carrier, organic silicon hydrolysis andsilicon dioxide deposition are carried out, the organic silicon and the silicon dioxide are mixed with aluminum chloride, thermal reduction is carried out, and an ethanol mixture of a carbon materialand polyvinylidene fluoride is sprayed, so as to obtain a foam conductive network / SiOx / C electrode. The foam conductive network is composed of framework metal and sacrificial metal. The framework metal includes one or more of nickel, iron, copper, tin and silver. The sacrificial metal includes one or more of magnesium, aluminum and lithium. The mole ratio of the framework metal to the sacrificialmetal is 0.1-5. The mole ratio of the sacrificial metal to the silicon is 1-4. The mole ratio of the sacrificial metal to aluminum chloride is 0.8-1.2. The ethanol mixture of a carbon material and polyvinylidene fluoride includes one or more of graphene oxide, multi-walled nanotubes, single-walled carbon nanotubes, carbon black, graphene, acetylene black, activated carbon, graphite, carbon microspheres, polyaniline and polypyrrole. The negative electrode material has good electrochemical properties, and has a good application prospect in the field of lithium ion batteries.

Owner:JIANGSU OLITER ENERGY TECH

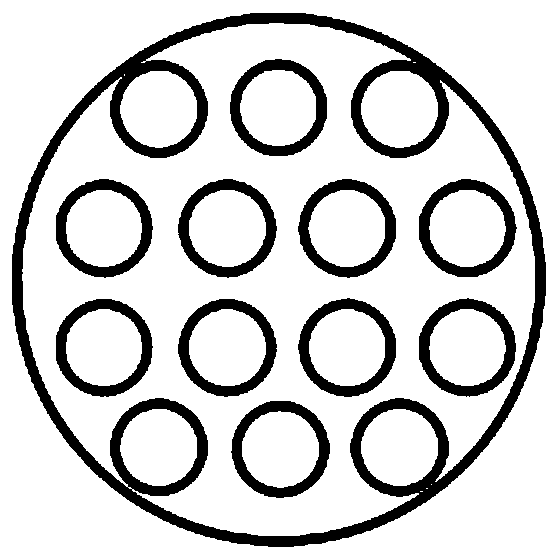

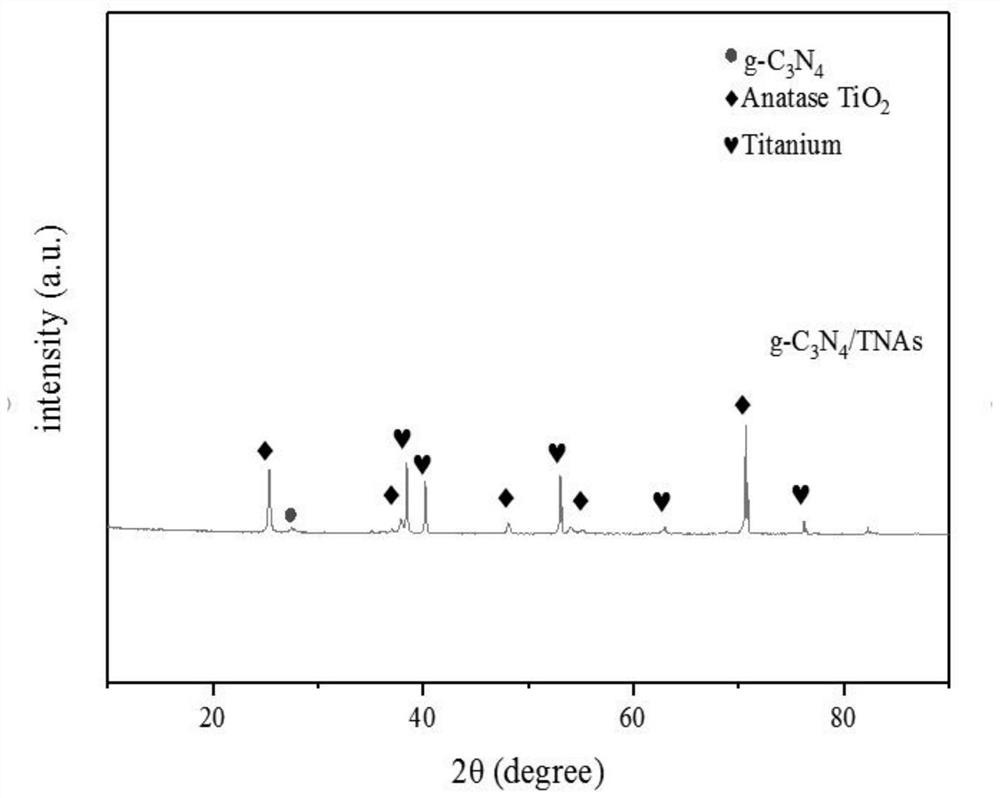

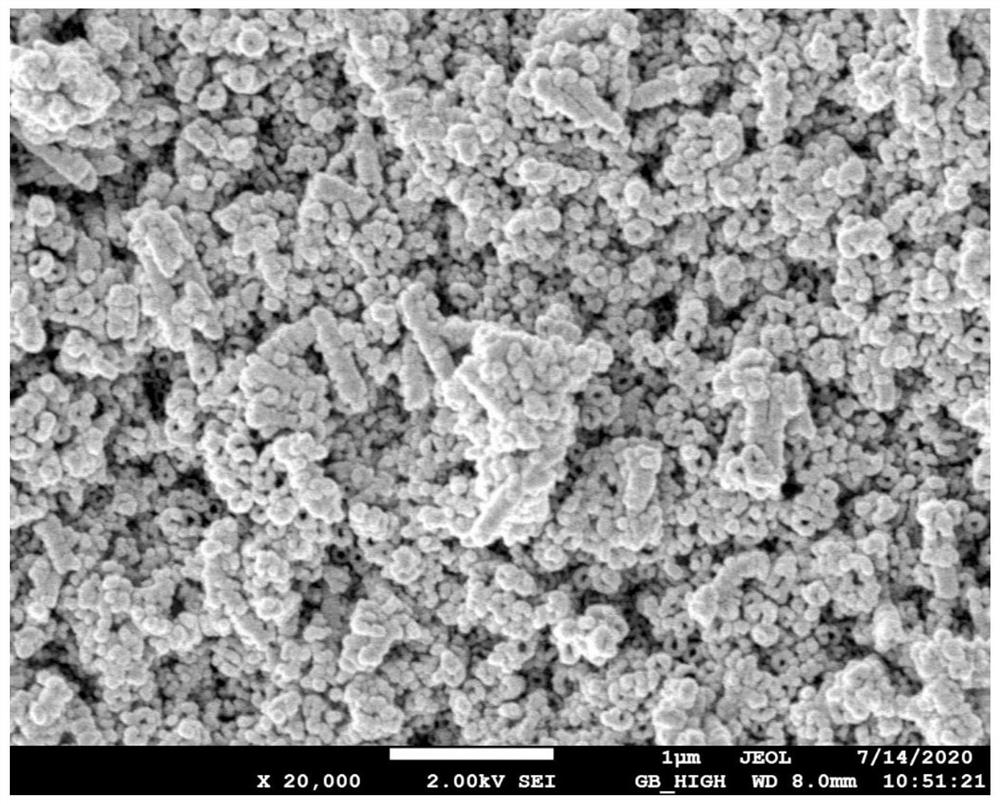

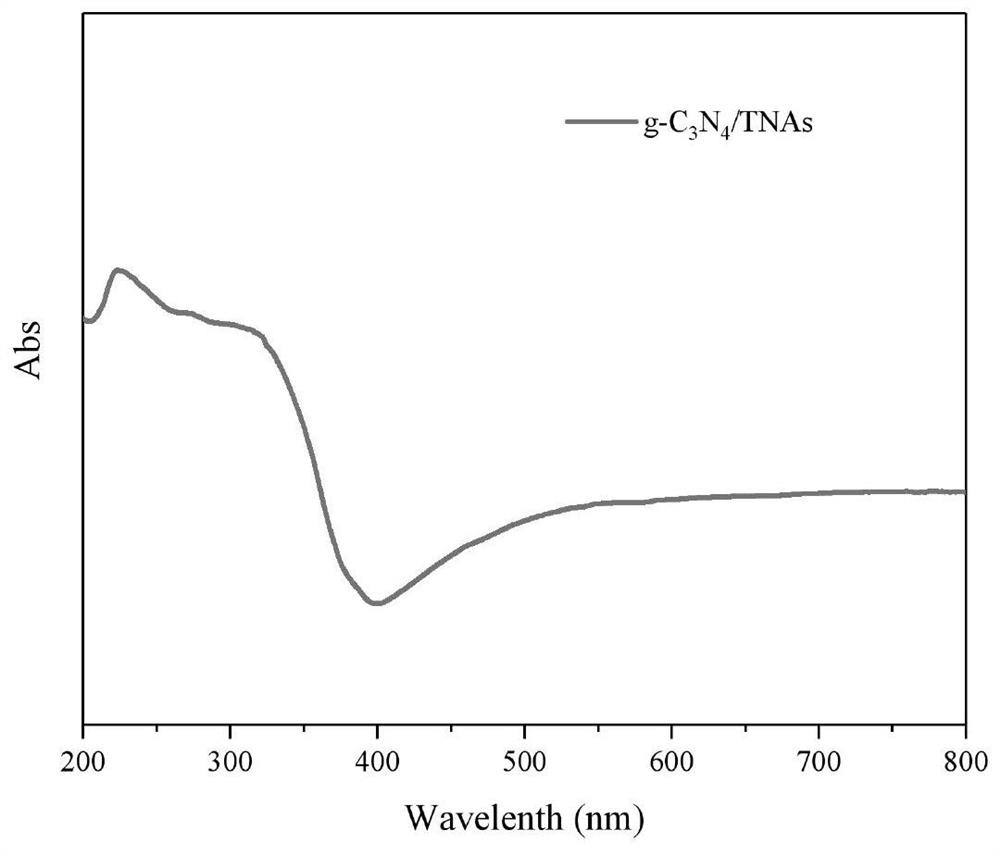

Method for preparing graphite phase carbon nitride doped titanium dioxide nanotube array photoelectrode by one-step method

PendingCN113562814AEasy to separateReduce production processWater/sewage treatment by irradiationElectrolytic inorganic material coatingTio2 nanotubeCarbon nitride

The invention discloses a method for preparing a graphite phase carbon nitride doped titanium dioxide nanotube array photoelectrode by a one-step method. The method comprises the following steps: 1, pretreating a titanium sheet; 2, pretreating a carbon nitride precursor; 3, preparing an anodic oxidation synchronous deposition process solution system; and 4, placing a titanium oxide nanotube array photoelectrode in the solution in the step 3, and performing anodic oxidation synchronous deposition by taking a platinum electrode as a counter electrode to obtain a graphite phase carbon nitride doped titanium dioxide nanotube array photoelectrode prepared by a one-step method. In this way, the preparation process steps are saved, and the electrode which is low in cost, good in stability, high in photocatalytic activity, green and free of pollution and has visible light photocatalytic activity can be prepared.

Owner:QINGDAO AGRI UNIV

A capacitive embedded touch screen and display device

ActiveCN103336635BAvoid mutual interferenceGuaranteed qualityInput/output processes for data processingTouch SensesControl signal

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com