Method for preparing graphite phase carbon nitride doped titanium dioxide nanotube array photoelectrode by one-step method

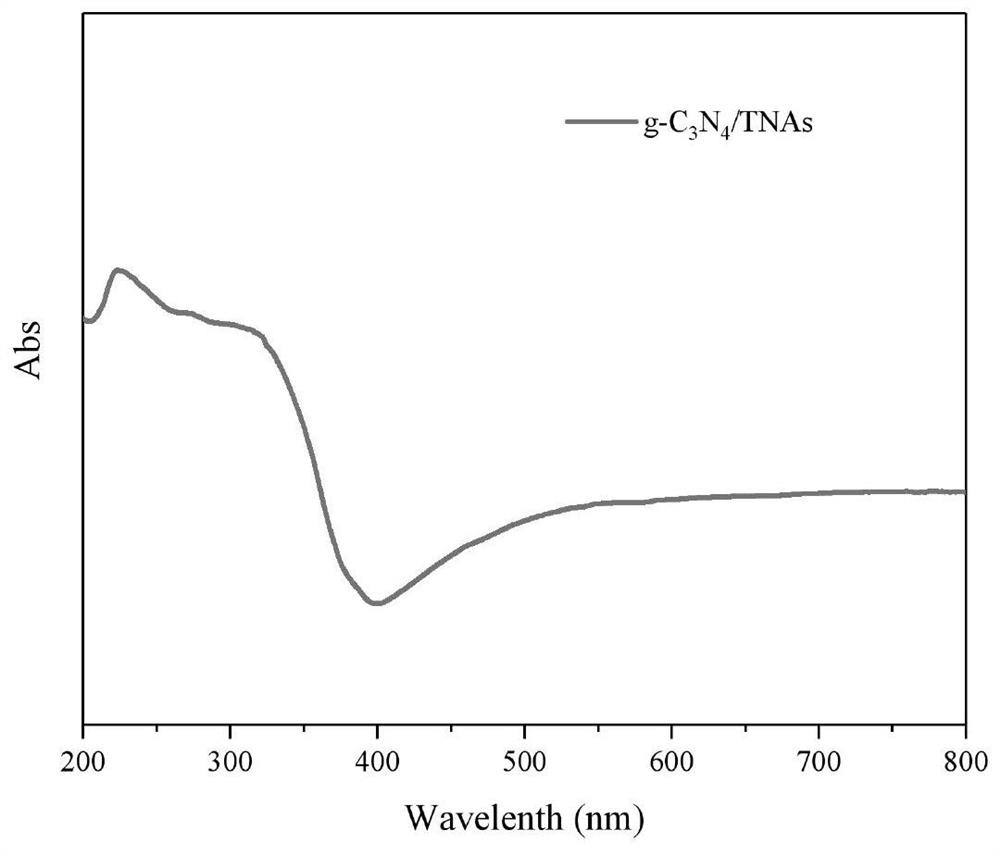

A technology of graphitic carbon nitride and nanotube arrays, which is applied in chemical instruments and methods, oxidized water/sewage treatment, electrolytic coatings, etc., can solve the problems of high preparation cost and shorten the preparation process, and achieve the promotion of charge separation and shorten Effect of preparation process, improvement of quantum efficiency and photoelectric conversion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

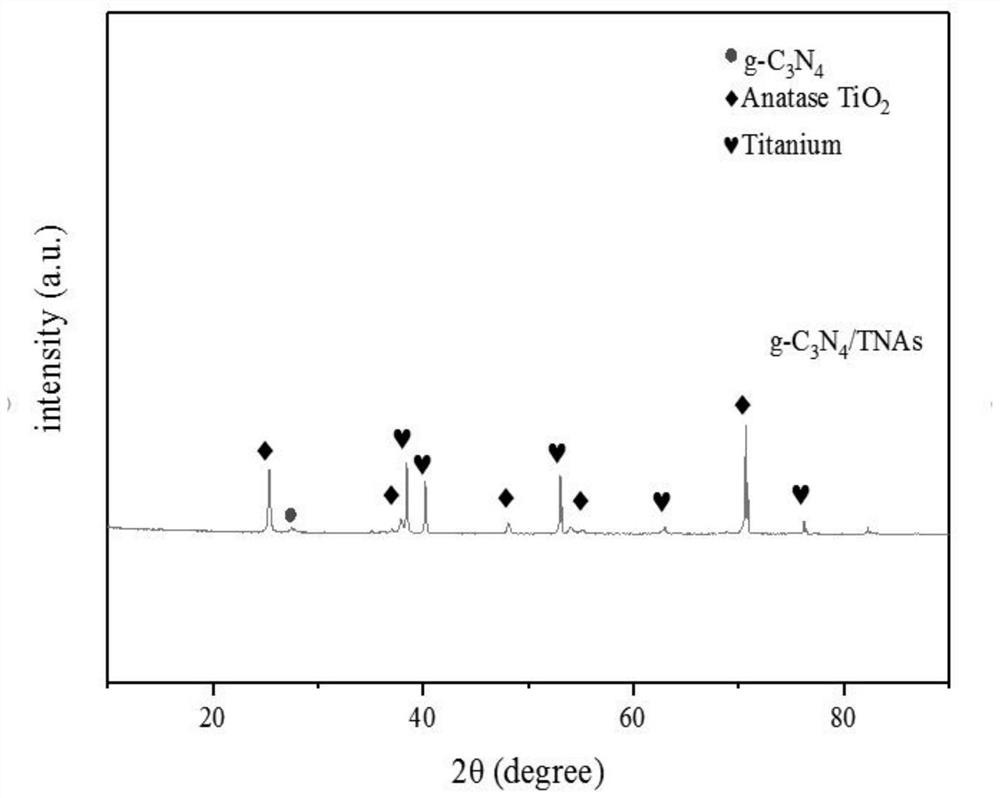

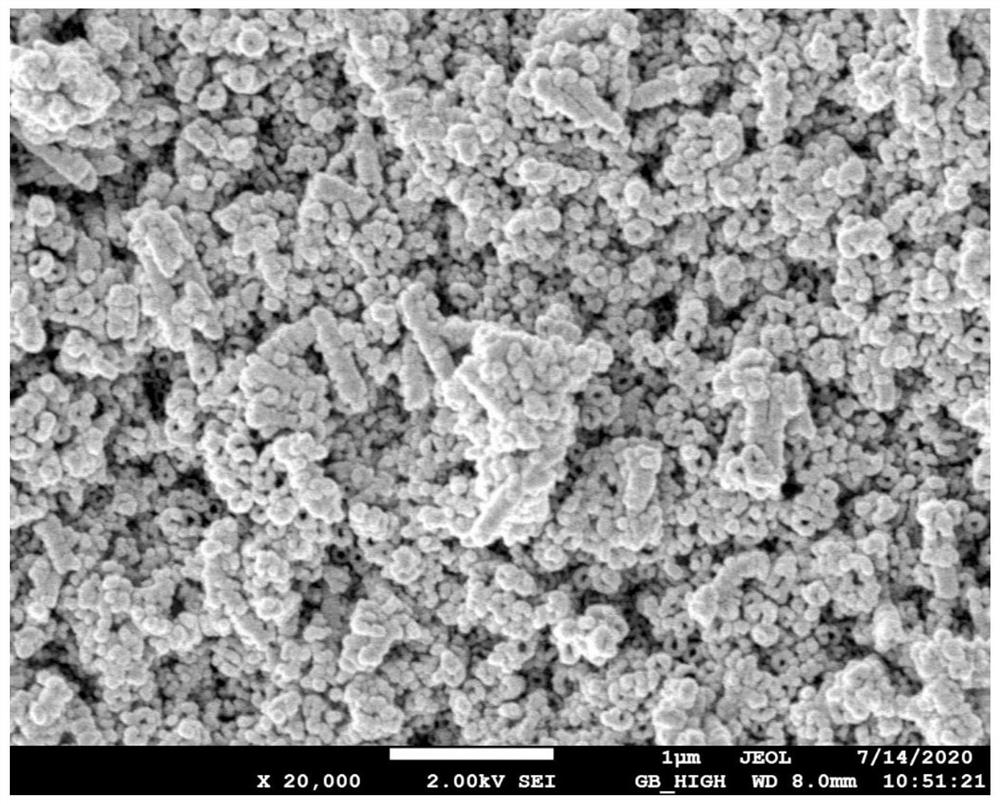

[0032] A method for preparing a titanium dioxide nanotube array photoelectrode doped with graphite phase carbon nitride in one step, specifically comprising the following steps:

[0033] S1: Pretreatment of titanium sheet

[0034] Wash the titanium sheet with hydrofluoric acid to remove the surface oxide layer, and then polish it with 500, 600, 800, 1000, 2000, 5000 mesh sandpaper after rinsing with clean water. Ultrasonic cleaning with water for 2 minutes;

[0035] S2: Preparation of graphitic carbon nitride

[0036] The precursor of graphite phase carbon nitride was calcined at 400°C for 2 hours, put into aqueous solution for ultrasonic dispersion for 2 hours, and freeze-dried;

[0037] S3: Preparation of mixed solution system for anodic oxidation simultaneous deposition process

[0038] Prepare a solution system with a graphite phase carbon nitride concentration of 1 g / L, anhydrous sodium sulfate concentration of 1 mol / L, and sodium fluoride concentration of 0.5 wt%, and...

example 2

[0043] A method for preparing a titanium dioxide nanotube array photoelectrode doped with graphite phase carbon nitride in one step, specifically comprising the following steps:

[0044] S1: Pretreatment of titanium sheet

[0045] Wash the titanium sheet with hydrofluoric acid to remove the surface oxide layer, and then polish it with 500, 600, 800, 1000, 2000, 5000 mesh sandpaper after rinsing with clean water. Ultrasonic cleaning with water for 2 minutes;

[0046] S2: Preparation of graphitic carbon nitride

[0047] The precursor of graphitic carbon nitride was calcined at 550°C for 2 hours, placed in an aqueous solution for ultrasonic dispersion for 2 hours, and freeze-dried;

[0048] S3: Preparation of mixed solution system for anodic oxidation simultaneous deposition process

[0049] Prepare a solution system with a graphite phase carbon nitride concentration of 1 g / L, anhydrous sodium sulfate concentration of 1 mol / L, and sodium fluoride concentration of 0.5 wt%, and st...

Embodiment 3

[0054] A method for preparing a titanium dioxide nanotube array photoelectrode doped with graphite phase carbon nitride in one step, specifically comprising the following steps:

[0055] S1: Pretreatment of titanium sheet

[0056] Wash the titanium sheet with hydrofluoric acid to remove the surface oxide layer, and then polish it with 500, 600, 800, 1000, 2000, 5000 mesh sandpaper after rinsing with clean water. Ultrasonic cleaning with water for 2 minutes;

[0057] S2: Preparation of graphitic carbon nitride

[0058] The precursor of graphite phase carbon nitride was calcined at 500°C for 2h, placed in aqueous solution for ultrasonic dispersion for 2h, and freeze-dried;

[0059] S3: Preparation of mixed solution system for anodic oxidation simultaneous deposition process

[0060] Prepare a solution system with a graphite phase carbon nitride concentration of 1 g / L, anhydrous sodium sulfate concentration of 1 mol / L, and sodium fluoride concentration of 0.5 wt%, and stir and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com