Solder-free high-thermal-conductivity semiconductor substrate and preparation method thereof

A high thermal conductivity, semiconductor technology, applied in semiconductor lasers, structural details of semiconductor lasers, laser components, etc., can solve problems such as high thermal resistance, chip breakage and damage, and reduced chip life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a solder-free high thermal conductivity semiconductor substrate, comprising the following steps:

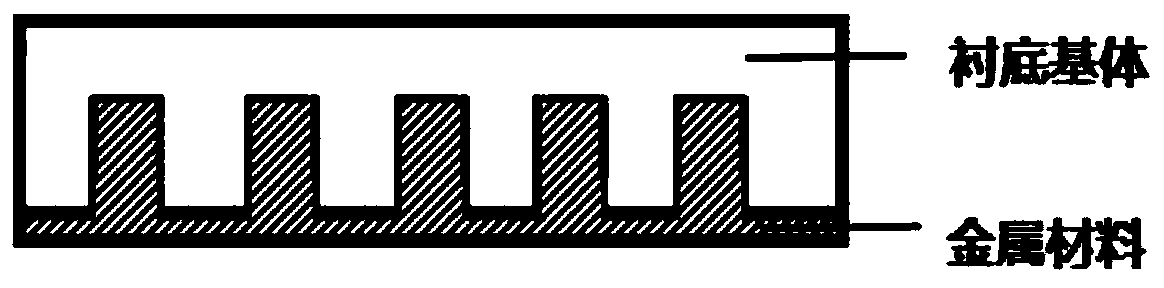

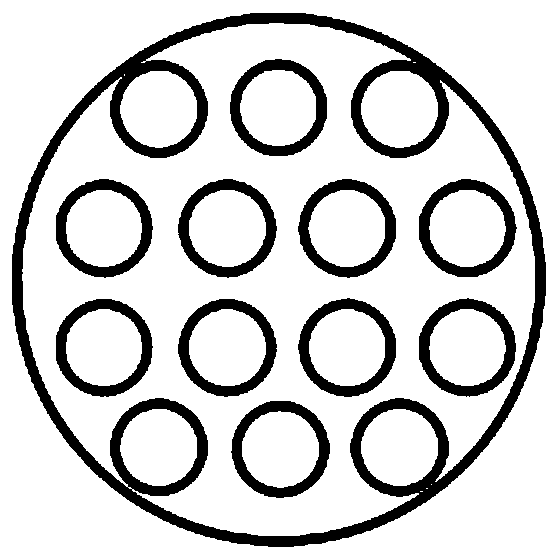

[0024] performing a photolithography process on the back of the substrate, forming a pattern of holes arranged in periodic distribution on the back of the substrate to obtain a photolithographic substrate;

[0025] performing an etching process on the photolithographic substrate sheet, forming periodically distributed holes on the back of the photolithographic substrate sheet to obtain an etched substrate;

[0026] Filling the holes of the etched substrate with a metal material by evaporation until the metal material is flush with the back of the etched substrate, and then continuing to form a metal material layer on the back of the etched substrate by evaporation to obtain Solder-free high thermal conductivity semiconductor substrate.

[0027] Since the size of the semiconductor laser is in the micron level, fine dust will al...

Embodiment 1

[0050] Using GaAs as a substrate and silver nanowires as an elastic filling material to prepare a solder-free high thermal conductivity semiconductor substrate includes the following steps:

[0051] (1) Photolithography: ultrasonically clean the GaAs substrate with acetone, ethanol and deionized water for 15 minutes respectively, then dry it with nitrogen, and finally heat it on a heating plate at 100°C for 5 minutes to completely remove water vapor; Use hexamethyldisilazane (HMDS) to pretreat the cleaned GaAs substrate, and then use AZ5214 photoresist as a mask to uniform the back of the GaAs substrate, and set the speed of the uniform equipment to 4000r / min, the hold time is 35s, so that the thickness of the photoresist on the GaAs substrate is 1.5μm; place the uniformed GaAs substrate on a heating platform with a temperature of 100°C, and soft bake for 90s; The soft-baked GaAs substrate was subjected to contact exposure, and the exposure time was 20s; the exposed GaSb subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com