High-light-transmitting composite material and preparation method thereof

A technology of composite materials and transparent plates, which is applied in the field of high light-transmitting composite materials and its preparation, can solve the problems of affecting the output power of solar modules, low light transmittance of solar photovoltaic glass, and unguaranteed film uniformity, etc., to achieve improved Anti-ultraviolet radiation ability, tight molecular arrangement, and the effect of improving light conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

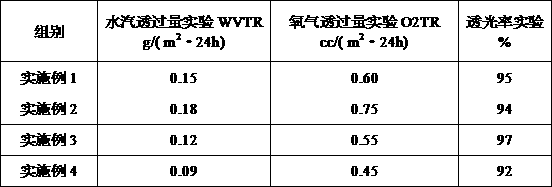

Examples

Embodiment 1

[0029] A high light-transmitting composite material, comprising a high-light-transmitting transparent plate, the high-light-transmitting transparent plate is a high-light-transmitting transparent PET plate with a thickness of 1mm, and the upper surface and the lower surface of the high-light-transmitting transparent plate are provided with oxidation Aluminum film layer, the thickness of the aluminum oxide film layer is 10nm, the modified UV fluorocarbon resin coating is arranged on the aluminum oxide film layer, the thickness of the modified UV fluorocarbon resin coating is 20 μm, the modified An embossed pattern is also printed on the permanent UV fluorocarbon resin coating.

[0030] The above-mentioned high light-transmitting composite material is prepared according to the following steps:

[0031] Step 1, in a vacuum up to 4×10 -4 In the vacuum chamber of mba, the temperature of the evaporation boat is raised to 1500°C, the aluminum wire is continuously sent to the evapora...

Embodiment 2

[0036] A high light-transmitting composite material, comprising a high-light-transmitting transparent plate, the high-light-transmitting transparent plate is a high-light-transmitting transparent PET plate with a thickness of 2mm, and the upper surface and the lower surface of the high-light-transmitting transparent plate are provided with oxidation Aluminum film layer, the thickness of the aluminum oxide film layer is 9nm, and the modified UV fluorocarbon resin coating is arranged on the aluminum oxide film layer, and the thickness of the modified UV fluorocarbon resin coating is 40 μm. An embossed pattern is also printed on the permanent UV fluorocarbon resin coating.

[0037] The above-mentioned high light-transmitting composite material is prepared according to the following steps:

[0038] Step 1, at a vacuum level of 3 x 10 -4 In the vacuum chamber of mba, the temperature of the evaporation boat is raised to 1550°C, the aluminum wire is continuously sent to the evaporat...

Embodiment 3

[0043] A high light transmission composite material, comprising a high light transmission transparent plate, the high light transmission transparent plate is a high light transmission transparent PET plate with a thickness of 4mm, the upper surface and the lower surface of the high light transmission transparent plate are provided with oxidation Aluminum film layer, the thickness of the aluminum oxide film layer is 11nm, and the modified UV fluorocarbon resin coating is arranged on the aluminum oxide film layer, and the thickness of the modified UV fluorocarbon resin coating is 5 μm. An embossed pattern is also printed on the permanent UV fluorocarbon resin coating.

[0044] The above-mentioned high light-transmitting composite material is prepared according to the following steps:

[0045] Step 1, when the vacuum reaches 3.5×10 -4 In the vacuum chamber of mba, the temperature of the evaporation boat is raised to 1600°C, the aluminum wire is continuously sent to the evaporati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com