Room-temperature solid sodium ion battery based on liquid alloy

A sodium-ion battery, liquid alloy technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problem of uneven charge deposition dendrite growth penetration, sodium metal fire or even explosion, poor wettability of metal sodium and other problems, to achieve the effect of being suitable for large-scale popularized production, low cost, and few preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

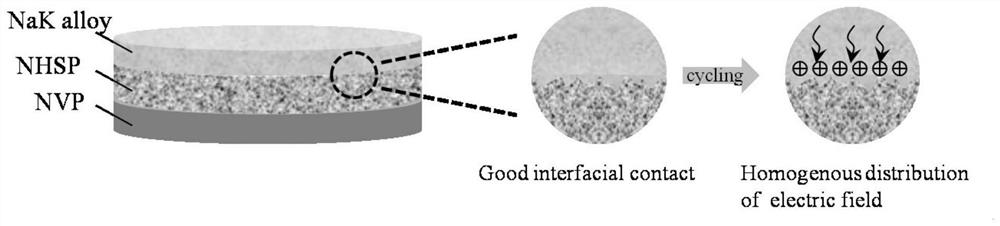

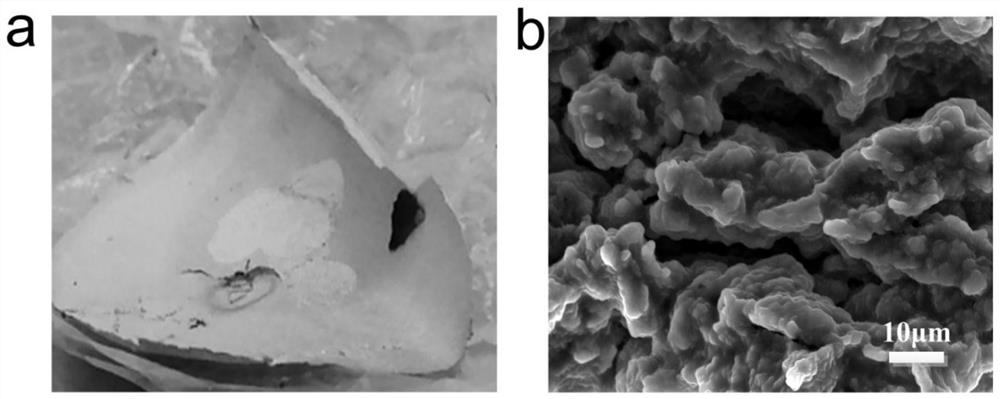

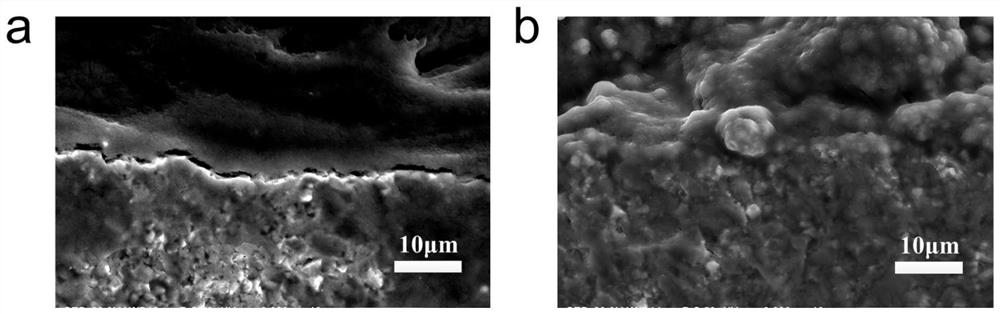

[0038] The present invention provides a room-temperature solid-state sodium-ion battery based on a liquid alloy. This embodiment includes the following operations: the negative pole of the solid-state sodium-ion battery is the sodium-potassium alloy negative pole prepared above, and the material of the negative plate is a liquid sodium-potassium alloy, sodium Potassium alloys exist in liquid form at room temperature, and can change the contact mode between the sodium metal negative electrode and the solid electrolyte into a liquid-solid contact. This method is conducive to improving the wettability of the negative electrode and solid electrolyte interface, making sodium ions more distributed, To better realize the uniform growth of metallic sodium, inhibit the generation of dendrites, and improve the performance of the battery, in order to explore the morphology characteristics of the prepared alloy negative electrode, the scanning electron microscope (SEM) was used to analyze t...

Embodiment 2

[0040] The difference from Example 1 is that redox graphene is used in this example. The three-dimensional porous structure of redox graphene can alleviate the volume change of metallic sodium during circulation. In order to explore the role of sodium potassium alloy in redox graphene film The existing form of the sodium-potassium alloy is placed in glycol dimethyl ether. Since it is known that the sodium-potassium alloy can be dissolved in ethylene glycol dimethyl ether, it can be observed that the sodium-potassium alloy pellets come out of the negative pole piece. It shows that its liquid state in the electrode is always maintained. The sodium-potassium alloy exists in a liquid state at room temperature, and the contact mode between the sodium metal negative electrode and the solid electrolyte can be changed into a liquid-solid contact. This method is conducive to improving the negative electrode and solid state. The wettability of the electrolyte interface makes the sodium i...

Embodiment 3

[0042] The present embodiment provides a room-temperature solid-state sodium-ion battery based on a liquid alloy, including the following operations: the following operations are carried out in a glove box filled with argon (water content3.2 f 1.9 Mg 0.1 Si 2 PO 4 Solid electrolyte, assembled button-type symmetrical battery, electroplating and stripping experiments with blue electric test system, the current density is 25mAcm -2 , the symmetrical battery assembled with sodium-potassium alloy as the negative electrode still has a small overpotential after 220 hours of cycling, when the current density increases to 40mAcm -2 , can still cycle stably, with an overpotential of only 10mV, while batteries assembled with ordinary sodium anodes can operate as low as 0.1mAcm -2 However, the solid-state sodium-ion battery still has a stable cycle performance at room temperature, and has strong practicability and is convenient for popularization and utilization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com